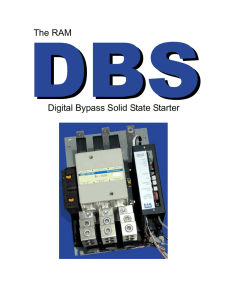

Digital Bypass Starter (DBS IIISM)

Digital Bypass Starter

(DBS III

SM

)

Quick-Start Guide

2

DBS III with Integrated Altistart 22/48 Compact Soft Starter

An economical solution for new and retrofit industrial refrigeration applications.

The new Schneider Electric DBS III with integrated Altistart 22/48 soft start/stop unit allows you to improve performance and provide stable operation for your refrigeration equipment.

Features:

> Color touch screen (HMI), graphic alphanumeric display featuring a quick setup menu, advanced dual profile setup, fault history menu, and data monitoring menu

> True three-phase control and other protection functions including:

• shunt trip

• phase loss and phase reversal protection

• soft stop

> Direct upgrade from legacy DBS or Wye-Delta starters

> Simple power and control wiring

> Simple integration into OEM machines

> Oversized control transformer

> Fused oil pump starter

> Isolated control voltage section (NFPA 70E ® / CSA Z462)

> High SCCR (65 kA @ 460 V & 42 kA @ 600 V)

> Shorting contactor eliminates SCR losses

3

4

Digital Bypass Starter

(DBS III

SM

)

Quick-Start Guide

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION,

OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and

follow safe electrical work practices. See NFPA 70E or

CSA Z462.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this equipment before working on or outside

equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

1

2

3

Step 1: Lock-out and tag-out all electrical power feeding the old starter p Prepare for replacement of old starter by making sure all power sources are removed, and proper lock-out and tag-out procedures are followed.

Step 2: Remove old starter p Mechanically and electrically remove the old starter.

p Make notation of the following:

– old starter incoming phase orientation

– motor lead phase orientation

– all control wiring terminations and how they correspond schematically to the new DBS III control terminals p NOTE: For 6-lead wye delta motor starters, make a notation and follow motor lead phasing and pairing. The new DBS III is a three lead output connection to the motor.

Step 3: Unpack and mount the new DBS III p Mechanically mount the new DBS III by bolting it to a concrete pad, or bolting it to an equipment room wall

( allowing adequate clearance for door opening).

p Prepare incoming power and control cables inside cabinet.

– Power cable entrance can be top/top, bottom/bottom or top/bottom.

– Terminate control wire in the isolated door-in-door cabinet located on the front of the DBS III.

5

4

5

6

6

Step 4: Terminate control wiring p Control terminals are marked according to schematic.

p Compare functions from old starter to the DBS III by schematic.

p Remove any jumpers for OEM controller indicated on schematic for the current feedback loops.

7

Step 5: Prepare power wiring p Verify input A-B-C phasing is the same from the old starter to the new DBS III starter.

p Incoming power feed is wired to L1-L2-L3.

p Verify A-B-C sequence motor lead output phasing is in the same sequence from the old starter to the new DBS III starter.

p Wire the Output motor leads T1-T2-T3.

p Verify all wiring is properly terminated, phasing sequenced properly, and torqued down to lugs per specifications.

8

9

Step 6: Clean all mounting and wiring debris from enclosure p Verify the enclosure is free from any debris.

p Vacuum out the enclosure.

p Verify all metal filings have been removed.

Step 7: Verify that DBS III is safe to energize p Remove lock-out and tag-out.

p Verify the DBS III is safe to energize.

p Apply power to the panel by closing the disconnect switch.

p Confirm the DBS III settings are correct for your application via the HMI Quick Start Menu.

p Prepare system for the “Motor rotation check” (Step 8).

Step 8: Motor rotation check p Confirm proper rotation of the compressor by…

– “Bumping” motor load in accordance with compressor

OEM instructions. Incorrect rotation will damage equipment.

– NOTE: If motor rotation is incorrect, change two output motor leads at the DBS III motor lugs (T1, T2, T3).

Step 9: Proper operation

The DBS III is now ready for full operation on your compressor. Trained compressor operators can now run the machine with the DBS III starter. Operating conditions can be monitored on the DBS III user interface screen.

7

Schneider Electric USA, Inc.

8001 Knightdale Blvd.

Knightdale, NC 27545

USA Customer Care Center

Tel: 888-778-2733 www.schneider-electric.us

© 2014–2015 Schneider Electric. All rights reserved. Schneider Electric, and “Make the most of your energy” are trademarks owned by Schneider Electric Industries SAS or its affiliated companies. All other trademarks are property of their respective owners.

Design: Schneider Electric

Photos: Schneider Electric

2200IB1402-ENG

03/2015