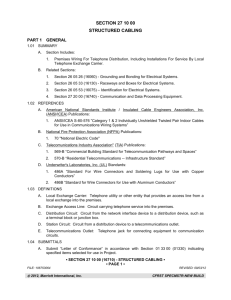

Addendum #3 - City of Westland

advertisement