Sensata M2

advertisement

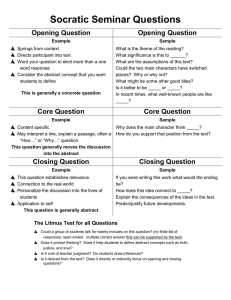

M2 Series

Narrow Differential Welded,Hermetic Seal

. Snap-action

switching

. Single

pole,

single

throw

. Preset,

non-adjustable

calibration

. Welded,

withnitrogen

hermetic

sealandbackfilled

. Normally

closed

openornormally

. Qualified

/ 20(orderbyMSnumber)

to MIL-$24236

. GAM.T1

Actual

size

TypicalCrossSectionView

M2 thermostats are recommended

temperature sensor and actuates

for use as controls and warning

devices in guided missiles, aircralt

a switch capable of handling high

power. Welded closed after

controls, heating blankets,

accurate calibration, the M2 is

electronic circuit components,

tamperproof.

servomechanisms, gyroscopes,

aerial cameras, crystal ovens,

surface heaters, computers and

similar electronic devices where

reliable performance is vital.

The M2 is available with a variety

of terminals and can be mounted

in any position: through openings

in metal closures, in casting

wells, in ducts for control of air

Precision temperature accuracy

temperature. A surface mounting

and long life reliability are

bracket or stud can be provided.

achieved through the use ofthe

well known Klixon snap-acting

disc. This unique mechanism

multiplies the motion of the

TI's years of engineering experience have yielded a wide variety

Base

of easy to use mounting means.

SpecialM2 Thermostats

Many configurations are available beyond the standard units shown above. Several varieties are shown below.

The device can easily be custom designed into packages such as probe thermostats or strap mounted units.

M2S.39STYLE

Stud

#6-32x .187Threaded

M2S.35STYLE

#6-32x.375

Threaded

Stud

with PottedTerminals

and12"Leads

Surface

Sensing

(

\.

21532

STYLE

AirFlowSensor

M2S.31STYLE

IntegralMountingBrackets

with

.115Dia.Holeson 13/16"Centers

PartNumberingSystemfor SpecialM2 Thermostats

To facilitate the ordering of M2 thermostats to your specifrcations use the part number code below. The code

permits you to call out a complete production parb number at the time of component selection.

M2S L 163 03 05

_I-T T

T{PE

M2S

Basic

number

OPERAIION

L=Openontemp.rise

rise

ontemp.

F=Close

,*ra*t*E' --l

temperatureoF

Closing

q/

39

TOLERANCE

temperature

Closing

(fF)

tolerance

DIFFERENTIAL

05=2'5F

SWLESELECT

e.g.:-39

PerformanceCharacteristics

Action

Switch

SPSI normally openor normally

closed

ContactRatings(Besistive)

Voltage 30vDc120VACCycles

2.0 250,000

Amperes 2.0

Basedonstandarddifferential

ShockResistance

100G,6 milliseconds,

Method213

per MIL-STD-2O2,

(monitored)10 microseconds

chatter, max.

Hermeticity

1 X 104atm cclsec.max,

per MIL-STD-202,

Method112,

ConditionC

SaltSpray

per MIL-STD-202,

Method101,

ConditionB, 57osolution

ContactResistance

0.050ohmsmaximum,

per MIL-STD-202,Method307

DielectricStrength

1250VAC,rms,

60 cyclesfor 1 minute,

per MIL-STD-202,Method301

Opening Closing

Temperature

Temperalure

Ditlerential Tol.fF)

('F)

std. spec

u

2-5

0 to250

aJ

(-17to121"C) (1.1to2.8'C) '\9.2tr 11.7{

r4

3-7

251to300

i4

(122to 149"C) (1.7to3.9"C)(12,8"C

!2.2'C

The M2 thermostat is ordered by

specifying the closing temperature with tolerance and the

opening temperature in terms of

Weight(Average)

5.4 grams

a differential range, either above

or below the actual closing

Range

AmbientTemperature

-65"Fto 400"F(dependingon calibratedtemperature).Exposureis

limited to 100'F aboveoperating

temperaturefor closeon rise

devicesor 100"Fbelowoperating

temperaturefor op,enon rise

devices.

VibrationResistance

10-2000Hz, 10G,

per MIL-STD-202,Method204,

ConditionD, (monitored)

chatter,max.

10 microseconds

50G (unmonitored)

20-2000Hz (opencontacts)

Settings

Temperature

temperature.

Example: Closeat 100"F+4,open2-5"F

above.In anyonelot, the thermostats

Each

will closebetween96 and 104"F.

thermostatwill open2-5"Fabovethe

actualclosingtemperatureofthat

thermostat.

Part NumberingSystemfor StandardM2Thermostat

To facilitate the ordering of M2 thermostats to your specifications use the part number code below. The code

permits you to call out a complete production part number at the time of component selection.

-]TT I

M 21 1 L

TYPE

Basic

number

BRACKET

1=Nobrachet

2 =Loose

brackel

TERMINAL.

1=Straight

2=450

3=Right

angle

1 6 3 0 3 0 5 2 1

***l

TOLEBANCE

Closing

rise

L=Open

ontemp.

temperature

F=Close

rise

ontemp.

(fR

lolerance

TEIiIPERATURE

3=i3

(oF)

Closing

temperature

4=+4

= 163'F,090

=90'F)

(e.9.163

5=15

DIFFERENTIAL

(M=2to4oF

05=2to5oF

07=3to7"F

CONTACTS

1=Silver

contacts

2 =Goldplated

contacts

PLATING

2 =Copper-nickel

4 =Tinplate

6 =Copper

7 =Gold

8 =Zinc/olive

drab

chromate

48 AngleTerminals

StraightTerminals

.G3 DIA HOLE ---\

I I

, r,u

f . . ^

T- ------f--->->!

( Hl l

,oo'"o,1

l

l

l

r

-l

. / l

f-

375MAx

II

.T

660 MAX

250

I

Mounting

Bracket

ft3 DtA HOLE -\

T-

350 MAX

J

l. 45.

! ,

|

t

r

RightAngleTerminals

f

r---T_--=11

^

-l

T

( lHi.*o"ot

3 q q * o ,|

]

l - r -J l .-------T-------

positon.

intheclosed

of 1OOF

inexcess

overrides

l0lemperature

notbesubiected

should

ThermoStats

in

tncnes.

snown

Dimensions

T- -t-_V/T

I

I

+ I-

a---u(

\

-

E

l

.o75MAx