section 23 09 00 instrumentation and control for hvac

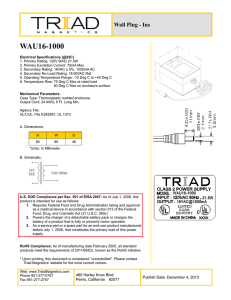

advertisement