CONX MODULAR

®

PIPE RACK

2

Modular Pipe Rack

ConX Modular Pipe Rack System

®

FASTER

BETTER

Covered by the following: U.S. P.N. 6,837,016; 7,051,917; 7,021,020; 7,621,099; Australia Pat. No. 2001288615; Canada

Pat. No. 2,458,706; China Pat. No. ZL 01 8 23730.4; Japan Pat. No’s. 4164548; 4427080; Mexico Pat. No. 262,499; EPat.

No 1668197 (DE, ES, FR, GB, IE, IT, NL, SE, TR); India Pat. No. 219,425. Other U.S. and Foreign Patent Protection Pending.

Copyright © 2010 ConXtech, Inc. All rights reserved.

www.ConXtech.com

SAFER

Covered by the following: U.S. P.N. 6,837,016; 7,051,917; 7,021,020; 7,621,099; Australia Pat. No. 2001288615; Canada

Pat. No. 2,458,706; China Pat. No. ZL 01 8 23730.4; Japan Pat. No’s. 4164548; 4427080; Mexico Pat. No. 262,499; EPat.

No 1668197 (DE, ES, FR, GB, IE, IT, NL, SE, TR); India Pat. No. 219,425. Other U.S. and Foreign Patent Protection Pending.

Copyright © 2010 ConXtech, Inc. All rights reserved.

www.ConXtech.com

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack

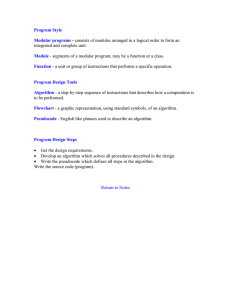

A System Comprised of Standard Connections and Details

The ConX Chassis Based Modular Pipe Rack System is an ideal solution for the efficient design, fabrication and construction of pipe rack and processing

structures. ConXtech and its growing network of certified fabricators leverage ConXtech’s standardized connectors and employ automated manufacturing

technologies to deliver modular and typically brace-free structures. This technology assisted approach accelerates design through construction allowing

industrial facilities to come on-line months or years earlier vs. more conventional structural options.

®

™

®

Standardization around a simple common connection in a structure enables unprecedented efficiencies while significantly reducing risk, complexity

and cost. The design of a ConX structure is dramatically simplified by using a small set of ConX details instead of the hundreds or thousands of unique,

custom designed and hand crafted details used in conventionally designed structures. This system is what ConXtech calls Chassis Based Modular™.

Robust ConX connections are at the heart of the system. They are unique in the fact that no field welding is required. They are comprised of a set of four

mating steel connectors that are factory welded onto wide flange beam ends and square columns (HSS or box). Beams are lowered and locked around

the four sides of a square column resulting in a robust bi-axial moment “collar”. This modular rack comprised of ConX columns and beams is easily

transported and safely and rapidly assembled in the mod-yard (modules) or field (stick-built).

The ConX connections provide an inherently seismic, blast and progressive collapse resistant structural chassis. Standardization streamlines structural design and analysis and enables material optimization. ConX is intuitive to assemble and ideal especially where there is a shortage of qualified and skilled labor.

Since it is based around a bolted connection, the system allows for future expansion and reconfiguration. Structural members and optional accessories

can safely and easily be attached or removed as required. ConXtech has also developed foundation systems, layout tools and templates which ensure

unprecedented accuracy and predictability in the field.

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

3

4

Modular Pipe Rack

ConX Systems Sized Right for Different Structural Applications

®

ConXL System

TM

Field Assembly Rate: Typically 5 MH/Ton

ConX

Moment Connection (Fixed)

ConX

Moment Connection (Fixed)

ConXLTM 300

ConXLTM 400

HSS or BOX Column Size: Nominal 300mm (12” square)

Variable Beam Depth*: 14” to 24”

Variable Beam Spans**: 12’ to 30’

HSS or BOX Column Size: Nominal 400mm (16” square)

Variable Beam Depth*: 18” to 44”

Variable Beam Spans**: 18’ to 65’

* Allowable beam depth can be greater than or less than this range, dependent upon structural performance criteria.

** Allowable spans may vary from those shown above, dependent on beam tributary area and floor loading.

ConXR System

TM

Field Assembly Rate: Typically 5 MH/Ton

ConX

Moment Connection (Fixed)

ConX

Moment Connection (Fixed)

ConXRTM 100

ConXRTM 200

HSS Column Size: Nominal 100mm (4” square)

Fixed Beam Depth: 6” (W 6X9)

Variable Beam Spans**: 4’ to 10’

HSS Column Size: Nominal 200mm (8” square)

Fixed Beam Depth: 12”(variable weight)

Variable Beam Spans**: 8’ to 24’

** Allowable spans may vary from those shown above, dependent on beam tributary area and floor loading.

®

ConX Gravity Connection (Pinned)

Used in in conjunction with all ConX Moment Connection Systems

ConX® Gravity Connection (Beam to Beam)

ConX® Gravity Connection (Beam to Column)

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack

How the Collar Connectors Work

The Connection Technology

ConX® is the only connection in the world where all six degrees of

restraint (X, Y, Z, Mz, My & T) are achieved when the gravity seated

tapered interface is Lowered & Locked™ into place.

The connection capacity is then “Fixed” by installation of collar bolts

which provide the full capacity of the attached members on all axes in a

fully rigid connection.

ConX Columns

®

Square columns serve as the vertical structural members of ConX

structures. These columns are manufactured in a controlled factory

environment by welding four tapered mating collars to the column

at the specified elevation. Columns are later filled with concrete to

mitigate corrosion and potential trapped gases as well as optimize

column steel thickness.

With ConXR, the mating collars are welded to the face of an 8”x8”

HSS column.

ConXL uses a slightly different connection design with connectors

welded to the corners of 16”x16” HSS or box columns.

ConX Beams

®

ConX beam assemblies have moment connector plates factory welded

to both ends of wide flange beams (moment/moment ConX beams), or

two plasma cut gravity connectors on both ends of the beam (gravity/

gravity ConX beams). ConX beams can also have a gravity connector on

one end, and a moment connector factory welded to the other (gravity/

moment ConX beams).

ConXR uses a 12”deep machined connector plate with a tapered dovetail

design.

ConXL uses a tapered upper and lower flange plate configuration which

is adaptable to different beam depths.

ConX Collars

®

During the field assembly process, ConX beams are Lowered & LockedTM

into place between ConX columns from the top down. The connectors

immediately and easily lock into place resulting in an instantly stable

connection. Mitered vertical edges of the connectors allow four identical

plates to surround a column and form a ConX collar.

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

5

6

Modular Pipe Rack

Safety - Built into Every Connection

Gravity stabilied Lower & Locking connections bring immediate stability to structure without adding bolts.

™

No field welding mitigates risk:

- Eliminates “heat” on structure

- Mitigates need for walking steel

Fewer man hours = lower risk

Assembly typically performed from man lifts

Integrated modular components enhance safety:

- Self Aligning Stacking/Lifting Lug (SLLUGTM) for rigging, hoisting and stacking modules

- Reusable Modular Access Platforms

- ConX Module Assembly Stand

Lower & Locking™ connections provide opportunity for safe disassembly and reassembly

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack

Getting Started with ConX

®

ConXtech begins working with owners and their design teams early in the process. Most often this is during the site evaluation and feasibility study period.

®

Conceptual Design

Once the program goals are defined, ConXtech’s integration experts collaborate with the team to understand application, loading and other project specific

requirements and then quickly identify the optimal ConX System for the particular project and propose an appropriate framing plan to generate a 3D model.

At this stage ConXtech and/or our certified fabricators can provide budgetary numbers and an estimated fabrication and field assembly schedule.

Design Development

ConXtech has developed ConXCAD digital toolkits to combine the design, fabrication and field assembly processes into an integrated software solution. A

virtual ConX Modular Pipe Rack (Digital Chassis) is quickly configured during the earliest design phase of the project. This automated and systemic approach,

with a finite number of structural elements, enables a revised structural budget to be quickly generated as plans evolve.

Construction Documentation

Creating the documentation required to design, structurally evaluate, and fabricate a steel superstructure conventionally is a time-consuming and fragmented

process. The ConX Digital Chassis provides the basis for the final structural analysis, detailing, as well as all of the data that drives the automated manufacture

of ConX assemblies.

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

7

8

Modular Pipe Rack

Digital Design Workflow in a 3D modeling environment

A predictable ConX Modular Pipe Rack steel frame (Digital Chassis) is

quickly configured at the earliest design phases of the project. The ConX

steel frame can be initially modeled in plant design software like PDMS

and SmartPlant 3D or ConXtech can rapidly define the ConX frame in the

steel design and detailing software Tekla Structures. In either workflow,

the 3D model can be electronically exchanged using industry standard file

formats such as SDNF (Steel Detailing Neutral File) and CIS2 (CIM Steel).

®

As the piping design progresses, there may be a change in the number of pipe support and anchor load support beams required on the structure. Using Navisworks, ConXtech and the piping designers store saved locations and redline changes directly in the 3D model. Clashes can also be automatically found and then

resolved between the piping and structural steel.

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack

The digital ConX Modular Pipe Rack in Tekla Structures includes an “as built” level of detail all the way down to every nut and bolt that will be used in the field.

By having this high level of detail, ConXtech electronically extracts all of the Bill of Materials, shop, and erection drawings directly from the 3D model. This rapid

extraction of data from a single database helps compress the project schedule and increase the volume of manufacturing production that can be processed.

ConXtech also automatically extracts CNC information that drives cut and drill machines in the shop to help insure fabrication quality and field fit-up.

®

The 3D model contains all of the profile, weight, piece mark, as well as grid and top of steel information. This allows ConXtech’s field superintendents and project

managers to easily plan shipping truck loads and the erection sequence of steel by simply picking the pieces in the 3D model. Isometric erection drawings and

sorted erection order reports are then automatically generated from the 3D model.

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

9

10 Modular Pipe Rack

ConX Modular Chassis Components

®

Su

ipe

1. P

m

Bea

ort

ipe

2. P

mM

Bea

rt

ppo

p

Sup

ort

3.

M)

BM

nt (

e

om

hor

Anc

p

Sup

vity

Gra

G)

(BG

m

Bea

4.

SS)

-H

(CM - Box)

n

um (CB

Col

7

6

5

9

1

3

8

2

4

Stick Built Footing shown

For Module Assembly Components

See Page 11

1. Pipe Support Beam Moment (BMM)

2. Pipe Support Beam Gravity (BGG)

3. Anchor Support Beam

4. Column (CM)

5. Added Upper Level with Moment Connection

6. Added Upper Level with Gravity Connection

7. T-Support Assembly

8. Trapeze Assembly

9. Cantilever Outrigger

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 11

Optional ConX Accessories

®

5. Column Extension with Moment Connection

6. Column Extension with Gravity Connection

7. T-Support Assembly

8. Trapeze Assembly

9. Cantilever Outrigger - Moment Connection (BMC)

Large Diameter Pipe Shoe

with Universal Anchors

Large Diameter Pipe Shoe

with Universal Guides

9. Cantilever Outrigger - Gravity Connection (BGC)

Small Diameter Pipe Shoe

with Universal Anchors

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Small Diameter Pipe Shoe

with Universal Guides

12 Modular Pipe Rack

ConX Module Assembly System Components

®

Quick Lift Module (QLM )

TM

TM

Ground Assembly Stand

Stacking Lifting LugTM(SLLUGTM)

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 13

ConX Modular Access System - Interer Module Make up Platform

®

Inter Module Make up Platform Truss

Modular Access Platform

Modular Walk Surface

Modular Railing

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Cantilever Outrigger

- Gravity Connection (BGC)

Modular Toe Kick

Modular Ladder

14 Modular Pipe Rack

ConX Modular Access System - Modular Access Platform / Cable Tray Catwalk

®

Cable Tray Catwalk

Modular Access Platform

Cable Tray Support Outrigger

Modular Railing

Cantilever Outrigger

- Gravity Connection (BGC)

Modular Toe Kick

Modular Ladder

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 15

Field Assembly Overview

ConX structures are designed and detailed considering construction sequence. The use of 3D modeling provides exact grid locations, weights, center of

gravity, and dimensional information which are all critical to the field in planning the erection phase of the project. Each piece is then manufactured, marked

and shipped with respect to the erection sequence enabling maximum productivity.

®

6. Add Variab

for Sloped Li le Height “T” Post

nes if requir

ed

5. Deliver

&

Pipes & Ca Install Upper Level

ble Tray

4. Install U

Transverse pper Level

Beams

3. Deliv

Lower L er & Install

evel Pip

es

2. Ass

Upper emble Rack

Level T

w

ransve ithout

rse Be

ams

1. Fo

in adv otings com

ance

p

of Ere leted

ction

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

16 Modular Pipe Rack

Assembly Sequence – Stick Built

1

2

3

4

5

6

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 17

Assembly Sequence – Mod Yard Assembly

1

2

3

4

5

6

7

8

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

18 Modular Pipe Rack

Assembly Sequence – Module on a Stick Base

1

2

3

4

5

6

7

8

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 19

Example ConXR Modular Pipe Rack 2 Level-Fixed Base (20’ X 20’ Grid)

TM

*NOTE: For projects with loads that

exceed the standard capacities defined below, please contact ConXtech

directly at info@conxtech.com for

additional ConX solutions.

PIPE RACK CABLE TRAYS

ESTIMATED LATERAL LOAD RANGE

FOR THIS STANDARD RACK CONFIGURATION*

6’

15’

FIXED

20’

MOMENT CONNECTION

MOMENT CONNECTION

HSS 8X8X5/8

20’

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

20 Modular Pipe Rack

Example ConXR Modular Pipe Rack 3 Level-Fixed Base (20’ X 20’ Grid)

TM

*NOTE: For projects with loads that

exceed the standard capacities defined below, please contact ConXtech

directly at info@conxtech.com for

additional ConX solutions.

PIPE RACK CABLE TRAYS

ESTIMATED LATERAL LOAD RANGE

FOR THIS STANDARD RACK CONFIGURATION*

6’

6’

15’

FIXED

20’

MOMENT CONNECTION

GRAVITY CONNECTION

MOMENT CONNECTION

HSS 8X8X5/8

20’

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 21

Example ConXR Modular Pipe Rack 4 Level-Fixed Base (20’ X 20’ Grid)

TM

*NOTE: For projects with loads that

exceed the standard capacities defined below, please contact ConXtech

directly at info@conxtech.com for

additional ConX solutions.

PIPE RACK CABLE TRAYS

ESTIMATED LATERAL LOAD RANGE

FOR THIS STANDARD RACK CONFIGURATION*

6’

6’

6’

15’

FIXED

20’

GRAVITY CONNECTION

MOMENT CONNECTION

GRAVITY CONNECTION

MOMENT CONNECTION

HSS 8X8X5/8

20’

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

22 Modular Pipe Rack

42

20'-0

34

30

29

28

27

26

AREA 10

25

791'-5

B.5

A

B

C

F

E

D

I

H

G

J

L

K

M

N

20

21

V

U

22

AREA 04

23

24

AREA 06

X

W

Y

DD

CC

BB

GG

EE

HH

FF

II

JJ

MM

KK

LL

OO

NN

QQ

RR

PP

SS

TT

WW

UU

VV

YY

XX

ZZ

T

7@20'-0=140'-0

16

17

20'-0

18

19

30'-0 20'-0 20'-0

AREA 01

14@20'-0=280'-0

21@20'-0=420'-0

471'-5

31

32

33

AREA 03

AA

Z

AREA 08

35

36

37

38

39

40

28'-0 23'-5

9'-7

41

40.7

S

R

43

AREA 02

Sample Plans

25@20'-0=500'-0

15

11

12

13

14

8@20'-0=160'-0

8

9

10

15@20'-0=300'-0

10@20'-0=200'-0

O.8

P

O

Q

11@20'-0=220'-0

6

7

20'-0

5

4

1

2

3

AREA 05

AREA 07

20'-0

20'-0

990'-0

B-6 W12X30

CFA1028

B-3

W12

X30

W12

X30

CFA1012

LEAVOUT

B-6 W12X30

W12

X30

W12

X30

CFA1017

CFA1018

PROFILE

ROD1"

ROD1"

W12X40

W12X30

W12X30

W12X30

W12X30

W12X30

HSS8X8X5/8

HSS8X8X5/8

HSS8X8X5/8

HSS8X8X5/8

CONXR

FL3/16"X7 3/4"

W12

X30

BFA

100

4

BFA

100

1

B-7

B-7

W12

X30

W12

X30

B-6 W12X30

W12

X30

W12

X30

1

B-

0

X4

12

W

CFA1015

CFA1013

CFA1012

CFA1012

CFA1011

0

X3

12

3 W

B-

0

X3

12

0

3 W

X3

B12

4 W

B

18

17

16

15

14

CFA1010

CFA1010

0

X3

12

W

0

X3

12

4 W

B30

X

12

4 W

B-

0

X3

12

4 W

B-

13

CFA1008

CFA1009

3

B-

0

X3

12

4 W

B-

B-4

B-3

CFA1011

0

X3

30

12

2X

4 W W1

B3

B-

CFA1012

0

X3

12

4 W 30

BX

12

0

3 W

3

X

B

12

0

4 W X3

B12

3 W

B

0

X3

12

0

4 W 2X3

1

B3 W

B0

X3

12

3 W

B-

0

X3

12

W

B-4

CFA1011

4

B-

CFA1011

CFA1014

CFA1013

NORTH

W12

X30

W12

X30

B-4

W12

X30

B-3

W12

X30

W12

X30

B-4

W12

X30

NAME

ANCHOR ROD

ANCHOR ROD

BEAM-BMM

BEAM-BGG

BEAM-BMM

BEAM-BMG

BEAM-BME

BEAM-BMM

COLUMN-CG-20

COLUMN-CM-20

COLUMN-CM-24

COLUMN-CMI-24

OUTER COLLAR

BW-B

B-6 W12X30

B-4

B-4

B-5

CFA1019

CFA1016

B-6 W12X30

B-4

QTY.

192

48

15

19

37

1

6

4

12

4

10

2

87

6

CFA1027

B-4

W12

X30

W12

X30

B-3

W12

X30

B-4

W12

X30

0

X3

12

4 W

B0

0

X3

X3

12

12

0

4 W

4 W

X3

BI

B12

30

W

30

X

4

2

X

1

B12

H

0

3 W

4 W

X3

BB12

30

4 W 30

X

0

B

3

X

12

12

2X

4 W W1

3 W

BCFA1014

0

3

BX3

B0

12

X3

W

12

-4

30

30

W

B

X

X

4

12

12

B30

0

3 W

4 W 12X

X3

BB12

0

3 W

X3

4 W

B12

B30

4 W

X

B

12

3 W

BB-4

CFA1016

W12

X30

CFA1028

B-4

W12

X30

CFA1027

B-4

CFA1027 HSS8X8X5/8

CFA1026

W12

X30

B-3

W12

X30

SEE E4002 FOR MATCH LINE

AREA 4 STEEL

Area: 10

MARK

AB2

AB3

B-1

B-3

B-4

B-5

B-6

B-7

C-1

C-2

C-3

C-4

CX01

CX02

B-6 W12X30

B-4

G

10

12

D

C

F

B.5

9

11

0

REV

For Field Use

01/16/2012

DESCRIPTION

DATE

ConXtech

E

24493 Clawiter Rd.

Hayward, CA

AREA 10 FILTRATION

DESCRIPTION

PROJECT NAME

DRAWN BY

DATE DRAWN

AREA 10 FILTRATION ISOMETRIC

BELRIDGE WATER SOFTENING PLANT

CMK

JOB No.

1049

01/15/2012

DRG No.

E10000

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Modular Pipe Rack 23

ConX Benefits at Every Stage of a Project

®

Safety

1.Robust Structure

Design

1.Robust & Brace Free Structure

▪▪ Premium

▪▪ Pre-fabricated off site

▪▪ No field welding

▪▪ Allows ultimate pipe routing options

▪▪ Simplifies equipment placement

▪▪ Design flexibility - same frame for various loads

▪▪ Reduces dependency on information flow between trades

2.Reduced Risk

▪▪ Fewer personnel required

▪▪ Lower & LockingTM connection

▪▪ Gravity stabilized without bolts

▪▪ No “spud” required to align

2.Components Accelerate Design

▪▪ Pre-designed, standardized connections

▪▪ Fewer variations in beam sizes

▪▪ More standardization of beams with same erection marks

▪▪ Modular, adjustable “pipe guides” and supports

▪▪ Modular equipment

▪▪ Modular platforms

▪▪ Modular scaffolding

3.Standardized Construction Site Advantages

▪▪ Efficient, consistent work planning & flow

▪▪ Clean / uncluttered site

4.Easy to “top load” pipe

5.Standard repeatable work

3.Standardized

▪▪ Simplified safety training

Modularization

1.No added braces for transport loads

2.Built in stability without base connection

3.No diagonals to interfere with pipe or

equipment

Operational

1.No diagonals to interfere with maintenance

access

2.No diagonals to interfere with equipment

removal or replacement

4.Precise dimensions

3.No diagonals to interfere with piping

modifications

5.Top load pipe in partially complete structure

4.Expandable horizontally

6.Expandable horizontally

5.Expandable vertically

7.Expandable vertically

6.Safer work environment

8.Innovative ConX SLLUGTM

▪▪ A multi-function Stacking Lifting Lug

▪▪ The ConX Way for safe lifting, aligning, stacking and

transporting industrial modules

Life Cycle and Sustainability

1.Interchangeability of “standard” modular

components extends life cycle

2.Easily expandable

Fabrication

1.Shorter lead times

2.Robotics and specialized fixturing in ConX

Factory easily scale to meet demanding

schedules for multiple projects with minimal

labor

3.Standardized work

3.Relocatable

4.Potential for disassembly, reconfiguration

and re-use

▪▪ Lower & LockingTM bolted assemblies can be easily

unbolted and disassembled for future use

5.Safe to disassemble

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

▪▪ Higher throughput with existing facility

▪▪ Higher throughput with existing workforce

▪▪ Reduced layout and fit up

▪▪ Process oriented workflow

▪▪ Specialized jigs and fixturing delivers precision

▪▪ Reduces RFI’s

▪▪ Reduces errors and re-work

▪▪ Simplifies entire fabrication process

▪▪ Scalable process

24 Modular Pipe Rack

Qualifications

Procurement

1.Fewer variables in member sizes and SKU’s

▪▪ Volume purchasing power & cost control

▪▪ Availability

▪▪ Predictability in quality and sourcing

▪▪ Simplified inventory

2.Proven with 7+M sf deployed to date

3.Only connection tested 100% on both

axes

2.Common components

▪▪ Mass-customization

▪▪ Production off-site ensures quality

▪▪ Interchangeability of parts

▪▪ Opportunity to stock common items

4.Meets all special high seismic detailing

requirements

3.Early release

4.Shorter lead times

5.Robotics and specialized fixturing in ConX

Factory easily scale to meet demanding

schedules for multiple projects with minimal

labor

▪▪ Significantly simplifies logistics

▪▪ Reduces manpower required

▪▪ Reduces cost of onsite support for workforce

▪▪ Ensures quality and accurate fit up

▪▪ Lowers total freight cost

▪▪ Reduces risk

2.Safer

4.Factory welded components

▪▪ Robotically welded standardized connections

3.Minimize or eliminate lay down

-- Ensures quality

-- Eliminates field weld inspection

▪▪ Just in time delivery

▪▪ Minimal sorting required

▪▪ Erect directly from truck

5.Simplified Bolting

▪▪ Reduced quantity of standardized bolts - prepackaged

with DTI washers

Detailing

-----

1.Simple digital model creation

▪▪ Limited variables

▪▪ Standard detail libraries

▪▪ No braces simplifies integration of non-structural elements

2.Digital concept model rapidly evolves into

final model

▪▪ Early dimensionally accurate BIM is a clash prevention tool

Piping Process & Design

▪▪ Anatomically correct at concept

▪▪ Expandable horizontally

▪▪ Expandable vertically

▪▪ 2x to 5x faster

▪▪ Interchangeable parts

▪▪ Factory fabricated full-length columns & beams

▪▪ No “cut and fit” on site

▪▪ Reduces plumbing and squaring

▪▪ No scoring or galvanizing for slip critical joints (U.S.)

2.Easier logistics and workflow

2.Modular chassis

1.Faster

3.Factory built kit-of-parts

1.Factory manufactured “kit of parts”

▪▪ Increases pipe rack capacity

▪▪ Greatly reduces pipe coordination

▪▪ Greatly reduces equipment coordination

Assembly

▪▪ Lower and LockingTM connection

▪▪ Simplified process driven erection

▪▪ Smaller workforce in field

Logistics

1.No diagonal braces

1.Extensively tested in full scale

Ensures bolting materials are there and ready

Accelerates bolt-up process

Reduces handling and make-up of bolts

Simplifies and accelerates QC by enabling visual field

inspection

-- Eliminates possibility of using wrong bolts

6.Intuitive Lower & LockingTM connections

speeds assembly and ROI

▪▪ Allow for safer erection

▪▪ Fewer number of pieces to erect

▪▪ Reduces risk in schedule

▪▪ Eliminates errors and re-work

7.Standardized process-driven construction

▪▪ Simplified layout with omni-directional columns

▪▪ Efficient and consistent work planning

▪▪ Consistencies among multiple projects

▪▪ Faster site prep: simplified foundations

▪▪ Fewer manpower-related logistics

▪▪ System reduces learning curve

8.Install work platforms and catwalks as

primary structure is erected

Copyright © 2000-2015 ConXtech, Inc. All rights reserved.

Regarding information presented on this page, please refer to the patent notice which appears on the back cover of this document.

Covered by the following: U.S. P.N. 6,837,016; 7,051,917; 7,021,020; 7,621,099; Australia Pat. No. 2001288615; Canada

Pat. No. 2,458,706; China Pat. No. ZL 01 8 23730.4; Japan Pat. No’s. 4164548; 4427080; Mexico Pat. No. 262,499; EPat.

No 1668197 (DE, ES, FR, GB, IE, IT, NL, SE, TR); India Pat. No. 219,425. Other U.S. and Foreign Patent Protection Pending.

Copyright © 2010 ConXtech, Inc. All rights reserved.

www.ConXtech.com

Phone: 510-264-9111 x 115

Fax: 510-264-1181

Covered by the following: U.S. P.N. 6,837,016; 7,051,917; 7,021,020; 7,621,099; Australia Pat. No. 2001288615; Canada

No. 2,458,706;

China Pat.Suite

No. ZL 01

8 23730.4;

Japan Pat. No’s.CA

4164548;

4427080; Mexico Pat. No. 262,499; EPat.

Corporate Headquarters: 6701 KollPat.

Center

Parkway,

150

l Pleasanton,

94566

No 1668197 (DE, ES, FR, GB, IE, IT, NL, SE, TR); India Pat. No. 219,425. Other U.S. and Foreign Patent Protection Pending.

Copyright

2010 ConXtech,

All rights reserved.

www.ConXtech.com

Manufacturing Operations:

24493© Clawiter

Rd Inc.

| Hayward,

CA 94545

Additional information is available on our website at www.ConXtech.com

Copyright © 2000-2014 ConXtech, Inc. All rights reserved.

Structures, methodologies, concepts, descriptions thereof, trademarks, logos of ConXtech® shown, illustrated and described in this document are covered by various

forms of intellectual property protections considered by ConXtech to be of great value. These protections include, but are not limited to, copyrights, and the following

U.S. and Foreign Patents which variously cover ConXtech’s ConX® structures and methodologies:

US and Foreign Patents: U.S. P.N. 6,837,016; U.S. P.N. 7,021,020; U.S. P.N. 7,837,084; Australia P.N. 2001288615; Canada P.N. 2,458,706; China P.N. ZL 01 8 23730.4; Japan P.N. 4165648; Mexico P.N. 262,499;

U.S. P.N. 6,802,169 B2; U.S. P.N. 8,161,707; Australia P.N. 2002244318; Brazil P.N. PIO209851-20; Canada P.N. 2479217; China P.N. ZL 2008 1 0110625.8; Mexico P.N. 282571; U.S. P.N. 7,051,917; Australia P.N.

2004319371; Canada P.N. 2,564,195; China P.N. ZL 2004 8 0042862.5; Hong Kong P.N. 1102268 Japan; P.N. 4427080; Mexico P.N. 275284; U.S. P.N. 7,127,863; U.S. P.N. 7,530,205; U.S. P.N. 7,146,770; U.S.

P.N. 7,131,240; U.S. P.N. 7,503,151; U.S. P.N. 7,621,099; U.S. P.N. 7,716,820; U.S. P.N. 8,205,312; China P.N. ZL2004 8 0026485.6; EPO P.N. 1668197 (FR); EPO P.N. 1668197 (DE); EPO P.N. 1668197 (IE); EPO P.N.

1668197 (IT); EPO P.N. 1668197 (NL); EPO P.N. 1668197 (ES); EPO P.N. 1668197 (SE); EPO P.N. 1668197 (GB); Turkey P.N. TR 2009 0820 T4; India P.N. 219,425; U.S. P.N. 7,527,466; U.S. P.N. 7,040,069; U.S. P.N.

7,621,088; U.S. P.N. 7,441,692; Australia P.N. 2005283131; Canada P.N. 2,578,959; China P.N. ZL 2005 8 0030159.7; Japan P.N. 4,482,586; Mexico P.N. 270,862; U.S. P.N. 7,051,918; U.S. P.N. 7,802,406; Canada

P.N. 2,153,038; US P.N. 8,011,150; U.S. P.N. 7,837,084; U.S. P.N. 7,941,985; Australia P.N. 2008260527; Canada P.N. 2,685,181. Other U.S. and Foreign Patent Protection Pending.

Printed on Recycled Paper