Water and Wastewater Corrosion Resistant Products

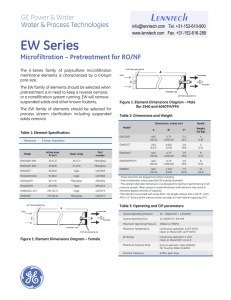

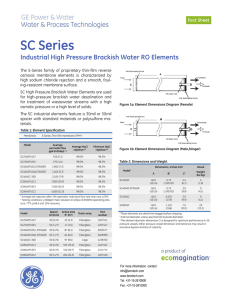

advertisement