CONTENTS 1.0 Introduction 3 1.1 Scope of Document 3 1.2 Brief

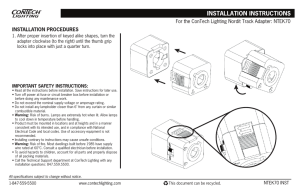

advertisement