PPPI Full Catalog - The Vanjen Group

advertisement

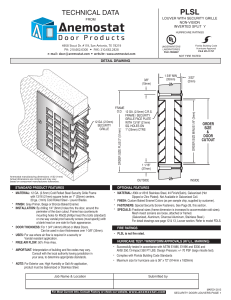

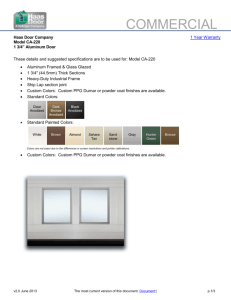

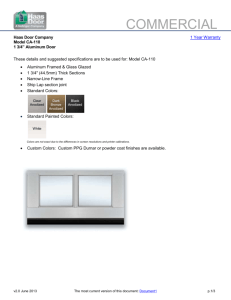

Professional Power Products Inc. Products And Services Introduction Professional Power Products Inc. (PPPI) Is a full service, vertically integrated supplier of power generation equipment. We offer a complete line of products including base tank, enclosures, switchgear and loadbanks. ? PPPI offers complete solutions for the POWER power generation industry such as: ? Engineering FOR THE FUTURE ? Design ? Production ? Testing OFFERING UNMATCHED CAPABILITIES ? Support Whereas most companies may only PPPI is a world leader by being one of the largest and most highly respected provider of custom built products that support the power generation industry. provide a partial solution. Our heavy investment in the facility and staff allows us to offer capabilities that no one else can match. PPPI offers a complete solution for the engineering, design, production, testing and support of power generation packages All of the components other than the genset itself are engineered, fabricated, assembled and fully tested at our facility. We ensure satisfaction with a fully staffed quality control department. We offer UL certification on many items we build. We offer all of the components to make a complete package, and test it as a unit. PPPI also provides conception to implementation full aspect support. 3 SERVICE -ENGINEERING Our engineering department can offer support long before the project is committed to paper or specifications are even written. We have the resources and expertise to create custom engineered solutions that meet customer specifications and respond to unique requirements. The broad scope of our product offerings means we can integrate multiple components into one perfect turnkey solution tailored specifically to our customers’ requirements. ENGINEERING PPPI has a complete engineering department of over twenty engineers utilizing the latest software. Mechanical, electrical and field engineers we have them all. 4 SERVICE -ENGINEERING Features Capabilities ? Twenty plus engineers ? Mechanical Engineers ? Engineers focused on acoustics ? Electrical Engineers State of the art software ? Finite Element Analysis software ? Structural integrity analysis ? Failure analysis ? Loads analysis ? Auto CAD ? 3-D design software ? Acoustic analysis ? Acoustic modeling ? Documentation control ? Manufacturing process design ? Quality assurance ? Material selection ? Since 1992 PPPI has proven itself as a specialized provider of integrated engineering solutions for the international power generation industry. Whether you need simple modifications made to a OEM housing or a custom-engineered CHP turnkey project, we will help in planning all aspects from order to delivery. After an order or contract is executed, we will provide detailed CAD drawings for your review and approval prior to manufacture We will also include a detailed set of installation drawings and instructions with the shipment of components. Whether your project requires one genset in a single enclosure or multiple units in a multi story enclosure broken down into 16 modules to ship, we engineer it to be delivered correctly. It doesn’t matter if it is a simple skid-base unit to a complex multi-genset, multi-story modular unit, by utilizing our engineering department to lay out the design there is no speculation or experimentation as the unit is built. Couple that with our complete vertical integration and you have some of the shortest lead times in the industry. 5 SERVICE - FABRICATION ON SITE FABRICATION From raw metal to finished product, PPPI provides in-house fabrication and metal stamping for total project quality and delivery control. 6 SERVICE - CAPABILITIES Features Capabilities We custom build: ? Welding ? Punching ? Sawing ? Shearing ? Drilling ? Forming ? Burning ? Plasma Cutting ? Laser Cutting ? Sand Blasting ? Panels ? Louvers ? Screens ? Trays ? Walls ? Floors ? Grating ? Doors And others Specifications Some of our tools: • Two Nishimbo Turret punches • Laser cutting table • Plasma cutting table • Shears • Brake presses ? Metal folders From simple skid-base to complex multi-unit, multi-story designs, PPPI can create almost any custom metal fabrication or add-on to meet your unique job. Couple these hands-on skills with our engineering department that designs and oversees the fabrication, add our complete vertical integration, and this ensures you have flawless quality with short lead times. 7 SERVICE - CAPABILITIES CAPABILITIES PPPI has invested heavily in custom designed buildings, plant infrastructure, equipment and trained employees that specifically meet the demands of the power generation industry. This results in capabilities that no one else has. • Multiple buildings with specific work areas for efficient work flow ? Six radio-controlled trolley cranes cover all work areas ? Complete parts department ? Fifty-foot work bays •175,000 square feet • 200,000 lb. single lift capacity trolley cranes in new building 8 SERVICE - CAPABILITIES Features Capabilities Building constructed specifically for our ? unique needs Six bridge cranes ? Drive-through bays ? Three separate build areas ? Eight acres of storage ? 200,000 lb. single pick capable ? Separate panel shop ? Acoustic test pad ? Indoor storage ? Parts department ? Quality control inspections ? We can lift entire assemblies internally Specifications We have specialized build areas for each component such as wall prefabrication, welding, fuel tanks, load banks, painting, sandblasting, testing and assembly. 9 PRODUCT - PANELS PANELS & CONTROLS Our panel shop can build UL listed controls, cabinets, and logic as simple as an analog engine control or as complex as a complete digitally interfaced oil platform. We have PLC logic and code programmers on staff. 10 PRODUCT - PANELS Features Capabilities UL 508 ? PLC based controls including: ? Allen Bradley ? Siemens ? Modicon ? GE/Fanuc ? Omron ? Cutler Hammer ? Square D ? Many others ? Remote controls ? Building integration ? Existing systems ? Design ? Engineering ? Fabrication ? Detailed panel and wiring ? drawings Arrangement drawings ? Electrical design ? PLC programming ? Integration ? UL listed ? Complete start-up capabilities ? Engraving ? Panel Types Start/stop panels ? Paralleling panels ? Distribution panels ? Breaker cabinets and panels ? Monitoring panels ? Remote panels ? Control lineups ? Remote controls ? Wall mount controls ? Metering panels ? Building integration ? PLC control panel ? AC drive cabinets ? Custom Breakers ? Operator interface consoles ? Existing systems ? 11 PRODUCT - LOAD BANK Loadbank Types ? Resistive ? Resistive reactive • Radiator mounted ? Permanent ? Trailer mounted • Free standing • Portable • Any voltage, any size • DC • UL listed LOAD BANK PPPI produces a wide variety of load banks designed to meet your specific requirements, along with the supplemental controls, readouts and other equipment to manage them and other load generating equipment 12 PRODUCT - LOAD BANK Features Options Construction ? Formed galvanized steel/aluminum ? Thermostatically controlled contactors Formed Galvanized Steel ? Stainless steel construction with ? encapsulated resistors High Voltage DC-up to 1000 Vdc ? Integral component box ? Variable Voltage ? Single phase AC ? Left side-mounted component box ? Remote-mounted component box ? Integral control panel ? Airflow switch ? Intake Temperature switch ? Sound attenuation up to 40 dBa ? reduction 90º discharge turning hood ? 45º discharge turning hood ? Aluminum wall construction ? Resistive ? Resistive, reactive ? Certification ? UL 508 ? UL file number - E302404 Cooling ? Integrally mounted fans Resistive elements ? Corrosion resistant chromium alloy, continuous coil ? Short circuit protection Our loadbanks are produced entirely in house Please see the following pages for exact models and specifications 13 MODELS OF LOAD BANKS PPPI has five distinct models. One for every application PowerMaster Stand alone permanent load bank ? Load Rating from 100KW - 3000KW at 480V ? Load Rating from 50KW - 1500KW at 208V ? Load Rating up to 1000KW at 380V ? Vertical airflow ? Enclosure Dimensions of 44"W x 48"D x 70"H, 108"H with hood for up to 400KW at 480V or 200KW at 208V ? Enclosure Dimensions of 44"W x 58"D x 108"H, 154"H w/hood for up to 1000KW at 480V or 500KW at 208V ? Enclosure Dimensions of 88"W x 58"D x 108"H, 154"H with hood for up to 2000KW at 480V or 1000KW at 208V ? Enclosure Dimensions of 138"W x 58"D x 108"H, 154"H w/hood for up to 3000KW at 480V or 1500KW at 208V PowerStorms Stand alone movable load bank ? Load Rating from 100KW - 1000KW at 480V ? Load Rating from 50KW - 600KW at 208V ? Horizontal airflow ? Enclosure Dimensions of 62"W x 60"D x 52"H for up to 400KW at 480V or 200KW at 208V ? Enclosure Dimensions of 62"W x 84"D x 84"H for up to 600KW at 480V or 300KW at 208V ? Enclosure Dimensions of 72"W x 54"D x 106"H for up to 1000KW at 480V or 500KW at 208V 14 LOAD BANKS CONTINUED PowerTrans Load bank with a medium voltage step down transformer ? Load Rating from 750KW - 3000KW ? Voltage Range: 4160V - 13,800V ? Vertical or Horizontal airflow ? Enclosure Dimensions of 156"W x 96"D x 116"H, 164"H w/ hood for up to 1000KW at 480V or 500KW at 208V with 4160V step down transformer ? Enclosure Dimensions of 252"W x 156"D x 121"H, 198"H w/ hood for up to 3000KW at 480V or 1500KW at 208V with 13,800V step down transformer PowerDuo Series Permanent resistive / reactive load bank ? Resistive/ Reactive ? Load Rating from 100KW/ 75KVAR - 500KW/ 375KVAR ? Vertical airflow ? Enclosure Dimensions of 88"W x 58"D x 108"H, 154"H w/hood for up to 200KW ? Enclosure Dimensions of 92"W x 82"D x 94"H, 138"H w/hood for up to 500KW/375KVAR 15 LOAD BANKS CONTINUED PowerFlow series Radiator mounted resistive load bank ? Ratings: 1.From 25KW - 1500KW at 480V 2.From 25KW - 500KW at 208V 3.Maximum kilowatt rating 60% of genset output capacity ? Maximum Size: 136"W x 118"H x 27"D, 50"D w/ component box ? Module addition to factory units Below are models we configure with radiator mounted loadbanks regularly Enclosed Gensets Caterpillar Cummins DQDAA DQFAD DQFFA DSHAD DQKAB DQHAB DFEJ DSFAE GTA-28 C4.4 C9 C15 Open Gensets: Caterpillar 3512B 3512C 3516B 3516C C6.6 C9 C15 C18 C27 C32 Kohler REOZMB REOZZD REOZJD REOZD REOZDD REOZDC 125RZG 16 LOAD BANKS CONTINUED PowerGlide Series Portable resistive load banks ? Single or Dual Voltage (480V/240V) ? Load rating from 100KW - 600KW ? Horizontal airflow ? Easily transportable on locking casters ? Enclosure Dimensions of 66"W x 42"D x 60"H for up to 600KW at 480V or 300KW at 208V Powerline Series Portable resistive load banks ù DC resistive ù Load Rating from 15KW - 50KW ù Voltage range from 24Vdc - 300Vdc ù Horizontal airflow ù Easily transportable with handles or locking casters ù Enclosure Dimensions of 20"W x 27"D x 32"H for up to 30KW at 300Vdc PowerRide Trailer mounted load banks Ratings: ? Single or Dual Voltage(480V/240V) ? Load Rating from 100KW - 2000KW Features: ? Horizontal or Vertical airflow ? Single or Dual axle trailer We are a custom build load bank supplier. Call us for any other type or size. 17 PRODUCT - SWITCHGEAR Need hundreds of breakers with complete tie in controls for multiple gensets? We can do that. SWITCHGEAR Custom built switchgear from a simple start stop panel to a complete multi unit, paralleling grid tie-in; PPPI has the in house expertise and electrical engineers to design, engineer, fabricate and test any type of control, PLC or switchgear. 18 PRODUCT - SWITCHGEAR Features Applications UL 508 ? ? UL 891 ? UL 1558 ? UL 1670 ? UL 1671 ? Single generator ? Multiple generator ? Standby ? Prime ? Peak shaving ? Utility paralleling ? Distributed generation ? Manual ? Automatic ? PLC and other logic ? SCADA ? Containerized Typical switchgear applications include: ? Gensets ? Remote locations ? Municipalities ? Airports ? Manufacturing facilities ? Hospitals ? Telecommunications ? Data centers ? Universities ? Hotels ? Mining ? Oil platforms ? Isolated facilities ? Airports ? Government facilities Options • Scada ? PLC’s ? Low voltage ? Medium voltage ? High voltage ? Control systems ? Paralleling ? Multiple units ? Remote control Need just a breaker in a housing? and more We can do that. 19 PRODUCT - ENCLOSURE ENCLOSURE We build custom enclosures for: ? Any application ? Any size ? Any specification PPPI can build them any size. Our largest to date is 47,000 sq. ft. two stories high, 16 individual modules Power generation ? Oil field ? Oil platforms ? Standby or prime ? Co-generation ? Industrial ? Turbines ? Large units ? Skid base ? Fuel tank base ? Drop over ? Multiple units ? Skin tights ? Walk ins ? Sound attenuated ? 20 PRODUCT - ENCLOSURE Features Options ? Stainless steel ? Aluminum ? Gravity dampers ? Fixed louvers ? Motorized dampers ? Exhaust Outlet opening through ? Modular panel pre-fab wall design ? Modular panel roof design to support 100 pounds per square foot ? No extra support needed for silencer needed ? Any size door ? Full stainless steel supported door hinges ? Rated for 156 mph wind load ? Lift-off design for rigging constraints ? Riveted construction (No tek screws) ? Any size package imaginable internal ceiling, roof collar welded to roof skin ? Radiator Cap Access opening/s through internal ceiling, Roof Collar welded to roof skin ? Mounting provisions for Neutral Grounding Resistors, external silencers, SCR systems, silencer concealment carriers, roof mounted intakes, ventilation vans ? Wet Paint or powder coated panels utilize Neoprene Gasketing. Wet paint utilizes caulking between seams ? Exterior joining trims for joining wall panels using exterior connections only. Used on sections splitting for shipment. ? Openings for Intake/Discharge air, air conditioners, Louvers ? Hoods- Intake and discharge ? Wind rating up to 156mph And more... Specifications IBC Certification UL UL listing UL QRNZ BOCA NEC NFPA and more And others... 21 TYPES OF ENCLOSURES PPPI has many types and styles available “Walk-In” Type Enclosure Wall Panels A. Ratings: 1. Acoustical Average dBA reduction (Calculated using Laboratory Transmission Loss Data and Factory provided Raw Acoustical Mechanical Data.) a. 4.5”D Aluminum 37.3 dBA reduction b. 4.5”D Galvanized Steel 40.2 dBA reduction c. 6”D Aluminum 40.3 dBA reduction d. 6”D Galvanized 45.9 dBA reduction 2. Thermal “R-Value”- 4.5”D Panels: R19, 6”D Panels: R30 3. Wind Loading 120mph B.Maximum Sizes: 1.136”H x 36”W x 6”D C.Construction 1. 4.5”D Aluminum 0.10” Marine grade Aluminum outer skin formed at 4.5”D. Contains 6” thick iberglass insulation compressed using interior perforated/punched metal. 2. 4.5”D Galvanized Steel 12ga. Galvanized Steel outer skin formed at 4.5”D. Contains 6” thick fiberglass insulation compressed using interior perforated/punched metal. 3. 6”D Aluminum w/ (2) Layer Drywall- 0.10” Marine grade Aluminum outer skin formed at 6”D. (1) layer of 3.5” thick fiber glass insulation & (1) layer of 6” thick fiberglass insulation compressed using perforated/punched metal. 5. 6”D Galvanized Steel 12ga. Galvanized Steel outer skin formed at 6”D. (1) layer of 3.5” thick fiber glass insulation & (1) layer of 6” thick fiberglass insulation compressed using perforated/punched metal. 6. 6”D Galvanized Steel w/ floating Steel Sheet outer skin formed at 6”D. (1) layer of 6” thick fiberglass insulation, (1) 16ga. Galvanized Steel Sheet, (1) layer of 4.25” thick fiber glass insulation compressed using formed interior perforated/punched metal. 22 ENCLOSURES CONTINUED “Skin Tight” Type Enclosure Wall Panels A. Ratings: 1. Acoustical Average dBA reduction (Calculated using Laboratory Transmission Loss Data and Factory provided Raw Acoustical Mechanical Data.) a. 3”D Aluminum: 32.2 dBA reduction b. 3”D Galvanized Steel: 34.2 dBA reduction 2. Thermal “R-Value”- R13 3. Wind Loading 120mph B.Maximum Sizes: 1.118”H x 36”W x 3”D C.Construction: 1. 3”D Aluminum 0.10” Marine grade aluminum outer skin formed at 3”D. Contains 4.25” thick fiberglass insulation compressed using interior punched closing plates. 2. 3”D Galvanized Steel 14ga. Galvanized Steel outer skin formed at 3”D. Contains 4.25” thick fiberglass insulation compressed using interior punched closing plates. Special build wall panels Common to both “walk-in” and “skin-tight” Special Build List (Major features listed below) 1. Stainless Steel Wall Panels Stainless Steel is used as a Substitute for Aluminum or Galvanized for superior corrosion resistance. 2. Fire Resistant Wall Panels Manufactured utilizing Fire Rated Insulation and Interior Seam covers to provide a 1 or 2 hour fire resistance. 3. “Switch Gear” Type Wall Panels Painted Interior surfaces with Seam covers. 4. “Welded Seam” Type Wall Panels Panel seams are welded instead of Bolted. 23 ENCLOSURES CONTINUED “Walk-in” Enclosure Type Doors A. Ratings: 1. Thermal “R-Value” 2”D Door: R13, 4.25”D Door: R19 B. Maximum Sizes: 1. 2”D & 4.25” Doors: Height 118”H 2. 2”D & 4.25”D Doors: Width- Single Door: 48”W, Double Doors: 120”W C. Construction: 1. 2”D Aluminum Single Door 0.10” Marine grade Aluminum outer skin formed at 2”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. Left Hinge, Right Handle. Single Door Leaf. 2. 2”D Galvanized Steel Single Door 12ga. Galvanized Steel outer skin formed at 2”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. Left Hinge, Right Handle. Single Door Leaf. 3. 2”D Aluminum Double Door 0.10” Marine grade Aluminum outer skin formed at 2”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. Active Door: Left Hinge, Right Handle. Dummy Door: Right Hinge w/ left spring latches. 4. 2”D Galvanized Steel Double Door 12ga. Galvanized Steel outer skin formed at 2”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. Active Door: Left Hinge, Right Handle. Dummy Door: Right Hinge w/ left spring latches. 5. 4.25”D Aluminum Single Door 0.10” Marine grade Aluminum outer skin formed at 4.25”D. Contains (1) layer of 6” thick fiber glass insulation compressed using interior perforated/punched metal. Left Hinge, Right Handle. Single Door Leaf. 6. 4.25”D Galvanized Steel Single Door- 12ga. Galvanized Steel outer skin formed at 4.25”D. Contains (1) layer of 6” thick fiber glass insulation compressed using interior perforated/punched metal. Left Hinge, Right Handle. Single Door Leaf. 7. 4.25”D Aluminum Double Door 0.10” Marine grade Aluminum outer skin formed at 4.25”D. Contains (1) layer of 6” thick fiber glass insulation compressed using interior perforated/punched metal. Active Door: Left Hinge, Right Handle. Dummy Door: Right Hinge w/ left spring latches. 8. 4.25”D Galvanized Steel Double Door 12ga. Galvanized Steel outer skin formed at 4.25”D. Contains (1) layer of 6” thick fiber glass insulation compressed using interior perforated/punched metal. Active Door: Left Hinge, Right Handle. Dummy Door: Right Hinge w/ left spring latches. Continued 24 ENCLOSURES CONTINUED Doors continued D.Standard Hardware: 1. Hinge “Roton” style, full height, gear hinge. Aluminum construction 2. Door handle three point latching with emergency egress lever. Pad lockable, stainless steel construction 3. Door restraint door hold back device where possible. Door restraint chain where needed. E. Door Options: 1. 2. 3. 4. Single door right hinge, left handle Door opener/closer device Single point latch w/ emergency push bar egress Drip rails over the door type 25 ENCLOSURES CONTINUED “Skin Tight” Enclosure Type Doors A. Ratings: 1. Thermal “R-Value” 2.5”D Door: R13 B. Maximum Sizes: 1. 2.5”D “Skintight” Doors: Height 84”H 2. 2.5”D “Skintight” Doors: Width Single Door: 54”W, Double Doors: 72”W C. Construction: 1. 2.5”D Aluminum Single Door 0.10” Marine grade Aluminum outer skin formed at 2. 5”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. 2. 2.5”D Galvanized Steel Single Door 14ga. Galvanized Steel outer skin formed at 2. 5”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. 3. 2.5”D Aluminum Double Door 0.10” Marine grade Aluminum outer skin formed at 2. 5”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. 4. 2.5”D Galvanized Steel Double Door- 12ga. Galvanized Steel outer skin formed at 2. 5”D. Contains 4.25” thick fiberglass insulation compressed using interior perforated/punched metal. D. Standard Hardware: 1. Hinges Lift off style 2. Door Handl- Single point latching. Pad lockable, Stainless Steel construction 3. Door Restraint Door holdback device where possible. Door restraint chain where needed. E. Door Options: 1. Single Door right/left hinge, left/right handle 2. Roll up style door 3. Emergency egress 4. Caterpillar enclosure latch hardware 5. Drip rails over the door type 26 ENCLOSURES CONTINUED Roof/Ceiling Designs A. Ratings: 1. Thermal “R-Value”: a. “Drop In” Light Rail Style Ceiling- R19 b. “Skin Tight” Type Roof Panel- R13 2. Roof Loading- 65 PSF B. Maximum Sizes: 1 “Bolt Together” Type Roof 180”W x Unlimited Length (Utilizing 42”W Maximum width roof panels) 2. “Skin Tight” Type Roof 108”W x Unlimited Length (Utilizing 42”W Maximum Width roof panels) 3. “Welded” Type Roof 180”W x Unlimited Length (Maintaining 24” Rafter Spacing) C. Construction: 1. “Drop In” Light Rail Style Ceiling (2) 12ga. Galvanized Steel channels containing 6” thick Fiberglass insulation supported by formed cross channels and Perforated Steel 2. “Bolt Together” Type Roof Formed 12ga. Roof Channels bolted to enclosure 12ga. Galvanized Steel or 0.10” Aluminum bolt on Roof Sheets overhanging roof channels 3. “Skin Tight” Type Roof 3”D formed 14ga. Galvanized Steel or 0.10” Aluminum Roof panels with 4.25” thick Fiberglass information compressed by punched Closing Plates. 4. “Welded” Type Roof Formed 12ga. Galvanized Steel or 0.10” Aluminum Roof frame with welded roof Rafters. Roof rafters formed to provide Slope for weather runoff. 12ga. Galvanized Steel or 0.10” Aluminum Roof Sheets Seam welded to Roof Rafters. D. Special Build Roofs: 1. “Welded” Type Insulated Roof Same as “Welded” Type Roof above except the entire assembly is stuffed with Fiberglass insulation, after welding, and is compressed by Perforated Steel sheets 2. “Low Profile” Type Insulated Roof- Same as “Welded” Type Insulated Roof above that mounts directly on top of PPPI standard Light Rail instead of on top of the exterior wall panels. 3. Single Slope Roof- Same as “Welded” Type Roof above but comprised of roof rafters with a single slope in lieu of the standard dual slope with middle peak. 27 PRODUCT - SOUND ATTENUATION SOUND ATTENUATION Acoustic enclosures will be as varied as the site requirements. Here at PPPI we have developed our acoustic expertise to a fine art. We don’t put some rockwool insulation in and call it good. Our engineers design “quiet” into the enclosure and we deliver it using our own proprietary modular panel construction. We back this up with independent thirdparty testing. Bench built modular panels for predictable acoustical control We can quantitatively prove our panels and entire enclosure meet a given specification. Can other packagers do this? 28 PRODUCT - SOUND ATTENUATION Features ? Various levels of attenuation available ? Modular wall panels with integrated sound attenuation ? Acoustic test on site as a complete package ? Access to various third party acoustic testing labs ? 45.9 dBA reduction has been obtained Consider this It is not just about making the enclosure quiet, but the airflow, temperature and functionality of the unit as a whole. This takes engineers whose focus is acoustics together with mechanical engineers and electrical engineers with years of experience using high quality materials. All the engineering is backed up with third-party testing verification. Does your current provider have these resources? This ability doesn’t come easily. It takes a conscious willingness to invest in the building, the people, testing and the R&D to make this happen. 29 PRODUCT - FUEL TANK Sub-Base tanks •Day tanks •Transfer tanks •Double wall •UL listed ? Any capacity FUEL TANK • No limit on size ? PPPI has built 15,000 gallons ? Listed UL • UL 2085 • UL 142 • Custom builds • Custom sizes • Baffled • Diked, open or closed • Spill containment 30 PRODUCT - FUEL TANK Tank Options Special Builds (Local ordinances, codes, etc) 1. Fuel Level switches/sendersCustom lengths depending on tank depth and required level Special Build Examples: 1. Mobile (trailers) - Maximum Dimensions: 284”L (not including tongue) x 76”W x 15.5”H. Maximum weight: 24,000 lbs (3 axles) 2. Overfill prevention- Positive Shut off valves, Spill boxes (interior & exterior) 3. Manual Fill Ports- Pad lockable, Positive Fill type “Scully” 2. California- Spill Protection, Overfill Protection, Flame arresters, Field Pressure Test 4. Fuel Heater Systems- Heater, RTD, cut-off switch 3. Chicago- 125% Secondary Containment, Specific Material thickness requirements 5. Fuel Polishing System- Filter, Microbe Eliminator, pump 4. CUL- Inner Tank: 5 PSI, Rupture: -12 PSI Vacuum (5 hr), -8 PSI Vacuum (5 days) 6. Vents- Standard and Emergency Relief, Interior and Exterior 7. 5. Florida, Michigan, Nassau County, NYC To name a few Tank Drains Tank Types 8. Fuel Transfer Systems- Single, Duplex, and Triplex pump setups. Fuel Supply and Return. 9. Spare Fittings 10. Conduit access areas- “stub ups” • Generator base tanks ? Double wall tanks ? Open diked base tank ? Closed to diked tank ? Secondary containment tanks ? Protected secondary containment tanks ? Day tanks 11. Stand Pipes- or “dip” tubes for engine fuel supply/return, pump supply/return and more 12. Lift off Enclosure Frame attachment 13. Recessed Floor- For Engine Spill containment 14. Sloped Drainage Sheets- Used in Air Discharge areas that are open to the elements. Contain drains with threaded NPT, screened, openings. 15. Diamond Plate Top Skin- For slip resistance. 31 UL 142 Fuel Tanks Certifications: 1. UL 142- Steel aboveground tanks for Flammable and Combustible Liquids. Sub-base and Day tank (free standing) style tanks. 2. MH26043- File Number Ratings: 3. Main/Rupture Tank Pressure- 3 to 5 PSI for 1 hour, Prototype Testing: 15 PSI Hydrostatic test for Two minutes 4. Fuel Capacity- Based upon L x W x H of Main tank. Since UL gives us certifications for unlimited length the capacity is also unlimited. 5. Maximum weight for lifting- I-beam, Formed Sides: 120,000 lbs (6 point pick), Skin Tight: 48,000 lbs (6 point pick) 4. Floor Loading- 225 PSF Maximum Sizes: 6. I-Beam Sides- Unlimited Length x 156” Wide x 23.57” High 7. Formed Sides - Unlimited Length x 156” Wide x 60” High 8. “Skin Tight” Style- Unlimited Length x 102” Wide x 42” High 9. “Type 2” Style (Used on Factory Enclosures)- Unlimited Length x 45”Wide x 45”High 10. “Day Tank” Style- Unlimited Length x 62” Wide x 94” High UL 2085 Fuel Tanks Certifications: 1. UL 2085- Safety Protected Aboveground Tanks for Flammable and Combustible Liquids. Sub-base and Day tank (free standing) style tanks. 2. MH26043- File Number Ratings: 3. Main/Rupture Tank Pressure- 3 to 5 PSI for 20 minutes, 4. Fire Rating- 2 Hour 5. Fuel Capacity- Based upon L x W x H of Main tank. Since UL gives us certifications for unlimited length the capacity is also unlimited. 6. Maximum weight for lifting- I-beam, Formed Sides: 120,000 lbs (6 point pick) 5. Floor Loading- 225 PSF Maximum Sizes: 7. I-Beam Sides- Unlimited Length x 144” Wide x 23.57” High 8. Formed Sides, Day Tank- Unlimited Length x 144” Wide x 46” High PRODUCT - CONTAINERS Trailer & Containers share most of the same options. However the trailer can be more heavily customized with larger components. For example a radiator can be much larger. CONTAINER Features We build contained units sometimes called : 20-45’ ISO container ? Intake and exhaust louvers ? Easy access doors ? Service doors ? Control space ? Cable tie in (many options) ? Gauges ? 12/24v interior lighting ? Shore power connections ? Stairs ? • ISO container • Trailer mounted • Power modules • Turnkey power package • Rental grade unit and more 32 PRODUCT - TRAILER Options Options Fuel tank ? Fuel monitoring and controls ? ATS ? Switchgear ? Transformers ? Space heaters ? Grid capable ? Remote monitoring ? Over spill containment boxes ? Controls of any type ? Sensors and automation ? Monitoring ? Vertical discharge plenum ? Sound attenuation ? Pumps ? Filter systems ? Any type of plumbing or routing ? Oil monitoring and replenishment ? External fuel connections ? Extra access doors ? Stand alone control rooms ? Isolated control rooms ? Recirculating dampers ? Wrapped exhaust ? Motorized dampers ? Voltage change boards ? Extra landing gear ? Redundant systems ? TRAILER We build rental type units of any size any kW including the trailer or modifying an existing OEM package unit and more The drop deck trailer unit has many advantages over a container unit 33 SERVICE - PAINTING To effectively coat steel, it is necessary to prepare it by sandblasting. Most companies cut corners by scraping, brushing or chemically treating. PPPI utilizes a dedicated sandblast booth. PAINT & METAL PREP We dedicate special indoor areas to metal preparation. Not in the dirt, not outside and not in the middle of other work areas where debris can ruin a good paint job. Name the kind of paint Name the color We can do it, including powder coating These steps result in superior quality. Ask other companies if they take these steps Our drive through paint booth is large enough to paint a full size container. 34 Powder Coating Professional Power Products utilizes Powder Coating for the Finish Top Coat on Many of its units. The choice of powder coating is largely for its increased durability versus conventional liquid coatings. First each part of a PPPI unit is washed at temperatures exceeding 120F in a five stage, Iron Phosphate system. This ensures the parts are clean and free from oils or grease from the manufacturing process. During the wash the surfaces of the parts are chemically etched to increase adhesion of the finish coat to the substrate. The parts are then air dried in at convection oven at 250F. Parts then proceed via conveyor to the spray booth where the powder is applied through electrostatic means. This helps ensure thorough and uniform coverage. PPPI typically applies Polyester or Hybrid Powders to its units. These Powders are formulated to have exceptional physical properties such as: Ultraviolet Light (UV) Resistance: this refers to the finishes ability to resist fading or bleaching from sun light over time. Salt Spray Resistance: this refers to the finishes ability to resist the effects of high humidity and/or extreme weathering conditions. The powders used by PPPI typically can withstand over 250 hours of Salt Spray Testing. This is equivalent to nearly 8 years of outside exposure. Chemical Resistance: this refers to the finishes ability to resist the effects of contact with chemicals/solvents. The powders used by PPPI typically can withstand contact with Diesel Fuels, Gasoline and solvents such as Methyl Ethyl Keytone (MEK). After coating the parts proceed to the cure oven where the powders are baked at temperatures ranging from 390F to 410F. During the curing process the polymers within the powder cross link to from a tough uniform surface. This process is what produces the fine, attractive, durable finish found on PPPI's products. Finished Powder coating weights (thickness) are typically 2 - 4 mils, which exceeds liquid coatings that typically finish in the 1-1.5 mil range. Wet Paints A heavy industrial grade, 2 component, hi-build epoxy primer formulated to have excellent chemical and abrasion resistance. Exhibits excellent corrosion resistance and adhesion over properly prepared steel, galvanized metal and various other metal substrates. Surface tolerant over tightly adhered rust and most tightly adhered existing coatings. VOC compliant. Designed to be used as an interior/exterior primer for structural steel, steel storage tanks and equipment in heavy duty, industrial maintenance environments. V-tech 500 may be used as an intermediate coat over organic zinc, inorganic zinc and catalyzed epoxy primers. Suitable for fresh water immersion. A two-component, aliphatic/acrylic polyurethane coating that has superior performance in a heavy duty industrial environment. Pinnacle 330HS has excellent color and gloss retention, good flexibility and abrasion resistance, and is resistant to a wide range of solvents and chemicals under splash and spill conditions. V.O.C. compliant. Pinnacle 330HS is formulated as a high performance finish coat on properly primed exterior steel tanks, structural steel and equipment, galvanized steel, concrete and masonry surfaces in highly corrosive environments or prolonged exterior exposure. SERVICE - TEST CELLS Testing is crucial to ensure the completed product functions properly. At PPPI all products go through a testing process as basic or all inclusive as the customer may demand. Our design engineers oversee this to ensure the complete systems function to specifications. PPPI has the most comprehensive testing available. Our grid Electrical and gas tie-in capability alone sets us far apart from the rest of the industry. From diesel to natural connections we have the fuel available to test most units. Couple that with our huge load bank inventory, remote radiators, multi-tap transformers and the qualified trained personnel to oversee it, and we can test and record just about anything. . If you need witness testing, we can do that. This will ensure to us, you the customer, owners, and consulting engineers that the complete unit performs as designed prior to it being shipped to site. All this can be verified with various means of recording. TEST CELLS Consider this, we have permanent surveillance and video tape at every testing. This can suffice for witness testing and spare the expense of travel to the plant. Permanent inhouse testing facility 36 SERVICE - TEST CELLS Features ? Any voltage Low - Medium - High ? Two test bays ? Sound attenuated ? Safe, controlled test environment • 15 MW loadbank capability ? Resistive ? Resistive/reactive ? Parallel testing ? Switchgear • 208 - 15kv transformers • Grid connectivity • Natural gas supply for 3MW High and low pressure • Remote radiators • Qualified test personnel • Acoustic testing • Strip charts • Witness testing Our ability to test the complete unit before it delivers ensures there are no issues on site. 37 SERVICE - FIELD SERVICE FIELD SERVICE PPPI has field service personnel that travel the world to support our product. From simple repairs to unforeseen issues, they can do it all, even re-write programs on the spot if needed 38 SERVICE - FIELD SERVICE Features Capabilities PPPI’s field service group of highly qualified and factory trained engineers and technicians are dedicated to providing professional service to our customers, old and new. Professional Power Products offers complete technical support for all of our product offerings. Our fabrication technicians and mechanical technicians are available to meet the needs in the field from start-up support to installation services. Our field service group has earned a reputation for excellence and support levels. It is not uncommon for them to re-program or rewrite code for complex PLC’s, SCADA or switchgear applications right there at the jobsite. Most packagers don’t have a field support team or the ability to implement one. The depth of resources at Professional Power Products allows us to support the customer before, during and even after the sale. 39 OTHER SERVICES & PRODUCTS Light Towers Fire control systems Filtered air flow Parts or job trailers Modular design - such as this 16 module two story modular unit Special Enclosures Modification of OEM package Arctic built packages 35 OTHER SPECIAL PROJECTS 40 41 PROFESSIONAL POWER PRODUCTS, INC 448 West Madison Street Darien, WI. 53114 Phone: 262-882-9000 Fax: 262-882-9010 Contact: Ken Trent 262-882-9000 ktrent@mypppi.com Kevin Kempton 702-308-5222 kkempton@mypppi.com www.professionalpowerproducts.com 42