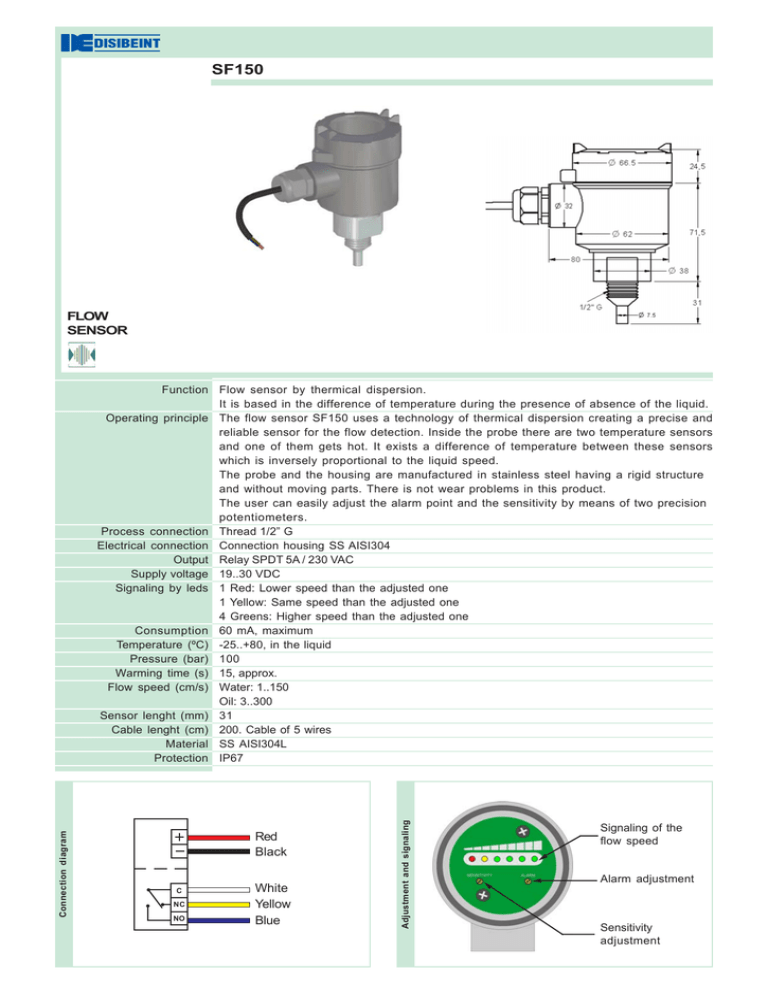

FLOW SENSOR Red Black White Yellow Blue

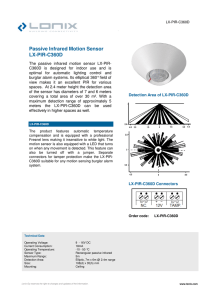

advertisement

SF150 FLOW SENSOR Red Black C NC NO White Yellow Blue Adjustment and signaling Connection diagram Function Flow sensor by thermical dispersion. It is based in the difference of temperature during the presence of absence of the liquid. Operating principle The flow sensor SF150 uses a technology of thermical dispersion creating a precise and reliable sensor for the flow detection. Inside the probe there are two temperature sensors and one of them gets hot. It exists a difference of temperature between these sensors which is inversely proportional to the liquid speed. The probe and the housing are manufactured in stainless steel having a rigid structure and without moving parts. There is not wear problems in this product. The user can easily adjust the alarm point and the sensitivity by means of two precision potentiometers. Process connection Thread 1/2” G Electrical connection Connection housing SS AISI304 Output Relay SPDT 5A / 230 VAC Supply voltage 19..30 VDC Signaling by leds 1 Red: Lower speed than the adjusted one 1 Yellow: Same speed than the adjusted one 4 Greens: Higher speed than the adjusted one Consumption 60 mA, maximum Temperature (ºC) -25..+80, in the liquid Pressure (bar) 100 Warming time (s) 15, approx. Flow speed (cm/s) Water: 1..150 Oil: 3..300 Sensor lenght (mm) 31 Cable lenght (cm) 200. Cable of 5 wires Material SS AISI304L Protection IP67 Signaling of the flow speed Alarm adjustment Sensitivity adjustment Assembly instructions When the sensor SF150 is installed, the sealing joint must be used (supplied). · Be sure that the distance (a) between a curve of the pipe and the sensor is, at least, four times the pipe diameter (see figure 1). · Confirma that there are not air bubbles inside the pipe to allow a reliable action alarm (see figure 2). · For non-fully filled pipes, the sensor must be installed underneath and the level of the liquid must be higher than the probe height (see figure 3). · Be sure that the sensor is tightly screwed to avoid any leakage. It can be mounted in any angle position. For a best sensitivity and fast response, look at the mounting position in figure 4. · If some particle or impurities can exist in the liquid, place a filter around the probe or before it and according the flow direction. (figure 1) (figure 2) (figure 4) (figure 3) Alarm adjustment (1) Assembly the sensor in the pipe. (2) Apply the supply voltage and wait 15 seconds for the initial warming. (3) Unscrew the top cover. (4) Adjust the sensitivity turning the potentiometer clockwise. (5) Select the flow speed at the minimum acceptable. (6) Turn the alarm potentiometer until the yellow led and the three green leds get lighting. (7) Adjust slowly the alarm potentiometer clockwise until the yellow led and one green led get lighting. (8) Reduce slowly the flow speed until the red led gets lighting, verifying that the alarm operates properly. (9) If the deviation between the yellow led and the red led is too big, decrease the sensitivity turning the potentiometer clockwise. Repeat the steps (5), (6) and (7). (10) Put the cover. Maintenance In normal operation conditions any special maintenance is required. The pollution in the probe could alter its thermal properties. If required, use an appropiate solvent for cleaning the probe surface regularly. After the cleaning process, it is recommended to confirm the alarm setting as well as the state of the sealing joint. Rev. 00 · 04/06/08 · DISIBEINT se reserva el derecho de alterar las especificaciones de este documento sin previo aviso ) Segle XX, 91 E08032-Barcelona ℡ T: +34 934 330 370 F: +34 934 354 532 www.disibeint.com Þ disibeint@disibeint.com