Installation Manual Atra Adirondack GZ 650 DV Fireplaces

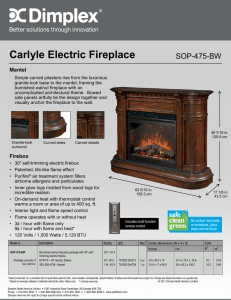

advertisement