next generation silicon solar cell technology

advertisement

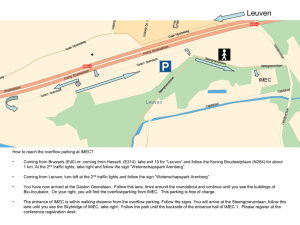

next generation SILICON solar cell technology Cu-plated large-area silicon solar cell with 20,8% efficiency. ENERGY, THE CHALLENGE OF THE 21ST CENTURY Generation of clean energy is one of the main challenges of the 21st century. Solar energy is the most abundantly available renewable energy source which could be supplying more than 50% of the global electricity demand in 2100. Imec uses its expertise in the domains of nanotechnology, device physics, process technology and advanced analysis and modeling to provide industry-relevant solutions for photovoltaic (PV) energy generation. As crystalline Si solar cells are expected to remain the most widely used PV technology for quite some time, imec has an important focus on silicon solar cells. Imec’s silicon solar cells research concentrates on the development of high-efficiency cost-effective and industry relevant solar cells. As part of the Solliance alliance, imec is also working on organic photovoltaics and alternative materials for CIGS solar cells. These thin film PV technologies can include new features such as flexibility and transparency which will fuel a wide range of new PV applications. Together with the industry, imec develops short-term solutions which can be implemented in production lines in short term, and does mid- and long-term R&D involving the development of new device concepts, characterization and deposition techniques, laser technologies and various other processing steps (such as e.g. copper metallization). Imec is also exploring PV system innovations broadening its PV activities beyond pure cell R&D. This includes e.g. the possibility of integrating electronics, energy storage, energy yield optimisation, etc. into the PV system. In this way the added value of solar energy in the global renewable energy arena will be further increased. Small area interdigitated back contact solar cells (IBC) with 23,3% efficiency. PERC & PERT: IBC: I-module: Large-area p-type PERC and n- Interdigitated back contacts Towards future smart modules type PERT solar cells Imec has developed a high-efficiency baseline process for interdigitated back contact (IBC) solar cells within its multi-partner silicon solar cells industrial affiliation program resulting in efficiencies of over 23,3% on Fz and Cz n-type silicon wafers. The cells are 2cm x 2cm processed in a 5 by 5 array on large area 156mm x 156mm wafers. Currently the focus of research is on process simplification and module integration. Regarding cell and module integration a first challenge is to design the IBC cell such that the performance is not limited by series resistance while thick metal stacks are avoided. The second challenge is to develop a cost effective process flow for module integration. Although the silicon feedstock price has come down significantly, the cost of the silicon wafer is still a considerable part of the solar cell cost. Hence, reducing the silicon content by reducing the silicon wafer thickness remains important for future low cost solar cell manufacturing. When cells become too thin to handle and process efficiently, a solution is to make thin silicon foils and place these foils onto the module glass plate in an early stage of manufacturing (the i-module concept). These foils are then further processed into solar cells on module level. Next to silicon wafer cost reduction, this concept also allows module level processing of e.g. the cell interconnections and the integration of additional electronics in the module for e.g. power conversion and load optimization. Imec’s proprietary PERC and PERT processes maximize the conversion efficiency of cells through structure and material optimizations while maintaining cost effective device concepts and processing.Today’s baseline p-type Si PERC process flow on 156mm x 156mm wafers is industrially applicable and contains advanced homogeneous emitter and front-side metallization, rear-side dielectric passivation with a local Al (aluminum) back surface field. N-type PERT cells with a rear side emitter will allow us to push conventional twoside contacted solar cells conversion efficiencies to its maximum. Recent developments: New Ni/Cu/Ag metallization processed in one plating sequence, resulting in higher efficiencies and reduced cost. P-type PERC and n-type PERT solar cells with Cu front contacts, with efficiencies upto 20,8%, have been realized in imec’s pre-pilot line. Solar cell reliability and standard tab adhesion tests on imec’s plated Cu/Ni/Ag front contacts show no correlated influence of these materials on the life time of the cell and module. This validates the industrial viability of this technology. Process development of spatial atomic layer deposition (ALD) Al2O3 for rear side and emitter passivation. Large area i-PERCtype silicon solar cells with ALD passivation and industrial screen printed contacts with a cell efficiency of 20.2% have been achieved. Integration of ultra-thin (100 μm), largearea (156mm x 156mm) PERC based solar cells into a class A PERC module, demonstrating the robustness and industrial relevance of the technology. Recent developments: Optimisation and simplification of cleaning processes enables a more cost effective IBC process without conversion efficiency loss. Exploration of alternative patterning techniques such as laser patterning or screen printing instead of lithography show the possibility of achieving good patterning performance without significant conversion loss. Selective epitaxial processing for the formation of p+-type emitters in IBC cells show excellent results, enabling a route for future simplified cost effective IBC cell processing. Excellent predictive device simulation knowledge allows rapid exploration of processing innovations which are then validated by actual cell processing. Recent developments: Improved porous silicon etching process enabling a good yielding detachment layer for 40um thin silicon foils. Excellent carrier life times achieved in thin epifoils bonded on glass. Integration of function cells in the i-module process flow indicating the potential of the technology. Why imec? Imec is an independent research center, carrying out R&D programs in which companies, universities and other research institutes can participate. We have dedicated cooperation schemes that are tuned to the needs of the industry. Imec is bridging the gap between proofof-concept in the lab and industrial manufacturing. Benefit from imec’s offer formed by its unique combination of energy-relevant competences: 30 years of experience in photovoltaics and microand nanoelectronics, new materials, characterization and reliability ... are explored in a R&D cost, risk and IP sharing environment. In this way this research complements and enhances our partners’ existing proprietary technologies. Researchers from the partners (industrial residents) can join imec’s research team allowing hands-on contribution to the research while capturing the results and experience. Silicon Solar cells affiliation program industrial Research program focusing on the development of cost effective and industrially applicable crystalline silicon solar cells with an efficiency of well above 20% based on imec’s 30 years track record. What we offer? Solliance program Imec offers a variety of business solutions ranging from research collaborations at various levels of scope and depth to license agreements and transfer of IP. Research program in co-operation with the Solliance partners focusing on the development of thin-film solar cells: (a) organic solar cells with increased efficiency and life time, (b) CIGS and alternative materials for CIGS (CZTS). 01 Multi-partner R&D programs Pre-competitive research on the development of innovative solar cell devices, new processing technologies, equipment & material screening and PV system improvement. In this way new technologies towards improved cell effiencies and lower manufacturing cost Organic Photovoltaics 02 Bilateral collaborations Companies can also partner with imec under a bilateral agreement, developing specific advanced and disruptive photovoltaic technology. Such R&D programs are jointly defined and may be tailored towards the needs and applications of the industrial partner. State-of-the-art research facilities A pre-pilot line for silicon solar cells (S-line, almost 1000m²) running a base line +20% efficiency PERC cell process tailored to develop and refine solar cell processes until they are ready to be further integrated into production lines. The equipment is similar to that of a state-of-the-art, industrial solar cell production environment, and the batch size is large enough to allow valid predictions of averages, standard variations and yield. Techniques used in the prepilot line include isotropic acidic texturing, plasma texturing, reduced pressure POCl3 diffusion, large area PECVD deposition of Si nitride, belt furnace rapid thermal anneal, in-line ALD, in-line Cu-plating, a flexible laser platform, a wide range of measurement and characterization equipment, and many more. A pre-pilot line for organic solar cells, (O-line, almost 200m²), an integrated processing facility for organic solar cells with all processing steps needed for the fabrication and characterization of state-of-the-art bulk hetero-junction and small molecules single junction and multijunction organic solar cells Contact us imec Belgium E-mail: Philip.Pieters@imec.be Phone: +32 16 28 12 59 imec India E-mail: Tony.Vandenzegel@imec-in.in Phone: +91 80 40 300 442 imec office Japan E-mail: Mitsugu.Yoneyama@imec.be Phone: +81 80 5180 1081 imec office US E-mail: Eric.Dy@imec.be Phone: +1 415 480 4519 imec Taiwan E-mail: Peter.Lemmens@imec.be Phone: +886 3 5781 115 304 imec The Netherlands E-mail: Ruben.DeFranciscoMartin@imec-nl.nl Phone: +31 404 02 0444 imec China E-mail: Gao.Teng@imec.be Phone: +86 21 5017 2918 www.imec.be Imec is a registered trademark for the activities of IMEC International (a legal entity set up under Belgian law as a “stichting van openbaar nut”), imec Belgium (IMEC vzw supported by the Flemish Government), imec the Netherlands (Stichting IMEC Nederland, part of Holst Centre which is supported by the Dutch government), imec Taiwan (IMEC Taiwan Co.) and imec China (IMEC Microelectronics (Shangai) Co. Ltd.) and imec India (imec India Private Limited).