Final report, October 2007

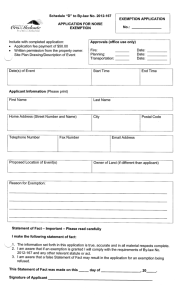

advertisement