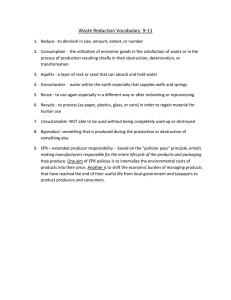

Bakelite® EPR 04572-EPH-EPC-EPC 865

advertisement

Technical Information EP Epoxy Resins Bakelite EPR 04572 Three component epoxy resin system Characteristics Properties Unit EPR 04572 EPH 04572 Viscosity at 25 °C mPa·s 15000 ± 1000 240 ± 40 Epoxy equivalent Anhydride equivalent g/equiv. g/equiv. 160 ± 3 Properties Viscosity at 25 °C Unit mPa·s EPC 04572 250 ± 20 178 EPC 865 260 ± 50 EPM 05288 1000 ± 250 Applications Bakelite ® EPR 04572 with the anhydride hardener Bakelite ® EPH 04572 and the accelerator Bakelite ® EPC 04572 is a low viscosity hot curing epoxy resin system suited to the production of composite fibre components using the Filament Winding technique and Pultrusion. The moulding materials made with the EPR 04572 matrix possess good electrical and mechanical characteristics with good thermoforming stability and thermal to ageing stability. For Pultrusion we recommend to use between 2.0 and 3.0 % of an internal release agent, for example Bakelite ® EPM 05288. Instead of Bakelite ® EPC 04572 can be used as accelerator Bakelite ® EPC 865. As a result the processing time will be longer by comparable reactivity. The fracture mechanical properties of this standard epoxy resin system can be significantly improved by adding the toughened epoxy resin EPR 05399. Shelf Life In sealed containers at 20 - 25 °C - 12 months. page 1/ 5 ... area: ATE-E1 ... created: 04/97... edit date: 02/05 All information, recommendations and suggestions provided by Bakelite AG in the form of verbal or writ ten communication, or in pertinent data bases, represent our best knowledge and experience. Such data are non-binding in character, and do not represent, either explicitly or implicitly, assurances or a gua rantee of specific properties. The specified parameters merely represent typical data; they do not form a basis for either a guarantee or a specification. The information, recommendations and suggestions we provide describe our products and possible applications in general or exemplary terms; they do not rela te to specific cases. The process of constant continued development and improvement of our products can lead to changes in pertinent parameters, texts and illustrations; no s pecial mention is made of pos sible alterations. Our technical advice does not free the customer of its responsibility to verify our current information, in particular our technical data sheets, safety data sheets and technical information leaflets. The customer will conduct its own tests of our products to determine their suitability for the intended pro cesses and uses, as well as to establish that their processing properties are appropriate in the pertinent situation, since our products may be used in a wide range of technical applications that involve very dif ferent requirements according to the specific situation. Therefore, such specific cases are outside our control, and are the excIusive responsibility of the customer. A pertinent agreement is necessary in case a binding assurance of specific parameters is required. Customers and users of our products must them selves observe possible patent rights, existing legislation and regulations. This publication does not represent a license, nor does it authorize infringement of any type of patent. Note: This version superse des and replaces all previous publications on this subject. Bakelite® is a registered trademark of Bakelite AG in Europe. Rütaphen ® is a registered trademark of Bakelite AG in the United States and Canada. Technical Information EP Epoxy Resins Bakelite EPR 04572 Impregnation Depending on precise requirements the amount of EPC 04572 accelerator used can vary between a minimum of 0.2 and maximum of 3.0 parts by weight in relation to the amount of the resin. Resin, hardener and accelerator can be easily mixed at temperatures between room temperature and 40 °C. Mixing ratio: 100.0 parts 110.0 parts 1.5 parts by weight by weight by weight EPR (resin) EPH (hardener) EPC (accelerator) Potlife: at 40°C app. 7h, at 60°C app. 4h Temperature [°C] / [° F] 25 / 77 1) Initial Time up to double viscosity1) [h] viscosity on addition of accelerator EPC 04572 [mPa·s] 1200 0% 20 h 2.0 % 5.0 h = 10 gram sample at 20 °C / 68 °F, viscosity at 25 °C / 77 °F Viscosity behaviour of EPR 04572 against temperature 1600 1400 viscosity [mPas] 1200 1000 800 600 400 200 0 25 27,5 30 32,5 35 37,5 40 temperature [°C] page 2/ 5 ... area: ATE-E1 ... created: 04/97... edit date: 02/05 All information, recommendations and suggestions provided by Bakelite AG in the form of verbal or writ ten communication, or in pertinent data bases, represent our best knowledge and experience. Such data are non-binding in character, and do not represent, either explicitly or implicitly, assurances or a gua rantee of specific properties. The specified parameters merely represent typical data; they do not form a basis for either a guarantee or a specification. The information, recommendations and suggestions we provide describe our products and possible applications in general or exemplary terms; they do not rela te to specific cases. The process of constant continued development and improvement of our products can lead to changes in pertinent parameters, texts and illustrations; no s pecial mention is made of pos sible alterations. Our technical advice does not free the customer of its responsibility to verify our current information, in particular our technical data sheets, safety data sheets and technical information leaflets. The customer will conduct its own tests of our products to determine their suitability for the intended pro cesses and uses, as well as to establish that their processing properties are appropriate in the pertinent situation, since our products may be used in a wide range of technical applications that involve very dif ferent requirements according to the specific situation. Therefore, such specific cases are outside our control, and are the excIusive responsibility of the customer. A pertinent agreement is necessary in case a binding assurance of specific parameters is required. Customers and users of our products must them selves observe possible patent rights, existing legislation and regulations. This publication does not represent a license, nor does it authorize infringement of any type of patent. Note: This version superse des and replaces all previous publications on this subject. Bakelite® is a registered trademark of Bakelite AG in Europe. Rütaphen ® is a registered trademark of Bakelite AG in the United States and Canada. 4.0 % 1.5 h Technical Information EP Epoxy Resins Bakelite EPR 04572 Properties of the cured, non reinforced resin system: Mixing ratio: 100.0 pbw EPR 04572 : 110.0 pbw EPH 04572 : 1.5 pbw EPC 04572 Curing: 6h at 110°C/175 °F, heating up to 230°C (20K/m), 10h at 230°C Properties Flexural strength, DIN 53452 Impact strength Compressive strength Heat deflection temperature Tg Units MPa mJ/mm² MPa °C EPR 04572 60 - 65 9 - 11 180 - 190 220 Bakelite® EPC 865 as comp. C: For a long processing time we would recommend to add our accelerator EPC 865 as component C. Gel-time [seconds] 150 °C / 302 °F Mixing ratio hot plate 100,0 pbw EPR 04572 110,0 pbw EPH 04572 3,0 pbw EPC 865 180 ± 20 Gel-time [seconds] 180 °C / 356 °F hot plate TG [°C] 3) TMA 60 ± 10 194 3) Curing conditions, 1 h 80 °C / 176 °F + 1 h 180 °C / 356 °F viscosity increase at 25°C and 40°C 100 ppw EPR 04572 + 110 ppw EPH 04572 + 3 ppw EPC 865 viscosity [mPas] 2500 2000 25°C 1500 1000 40°C 500 0 0 100 200 300 time [min] 400 500 page 3/ 5 ... area: ATE-E1 ... created: 04/97... edit date: 02/05 All information, recommendations and suggestions provided by Bakelite AG in the form of verbal or writ ten communication, or in pertinent data bases, represent our best knowledge and experience. Such data are non-binding in character, and do not represent, either explicitly or implicitly, assurances or a gua rantee of specific properties. The specified parameters merely represent typical data; they do not form a basis for either a guarantee or a specification. The information, recommendations and suggestions we provide describe our products and possible applications in general or exemplary terms; they do not rela te to specific cases. The process of constant continued development and improvement of our products can lead to changes in pertinent parameters, texts and illustrations; no s pecial mention is made of pos sible alterations. Our technical advice does not free the customer of its responsibility to verify our current information, in particular our technical data sheets, safety data sheets and technical information leaflets. The customer will conduct its own tests of our products to determine their suitability for the intended pro cesses and uses, as well as to establish that their processing properties are appropriate in the pertinent situation, since our products may be used in a wide range of technical applications that involve very dif ferent requirements according to the specific situation. Therefore, such specific cases are outside our control, and are the excIusive responsibility of the customer. A pertinent agreement is necessary in case a binding assurance of specific parameters is required. Customers and users of our products must them selves observe possible patent rights, existing legislation and regulations. This publication does not represent a license, nor does it authorize infringement of any type of patent. Note: This version superse des and replaces all previous publications on this subject. Bakelite® is a registered trademark of Bakelite AG in Europe. Rütaphen ® is a registered trademark of Bakelite AG in the United States and Canada. Technical Information EP Epoxy Resins Bakelite EPR 04572 Properties of the cured, non reinforced resin system Mixing ratio: 100.0 pbw EPR 04572 : 110.0 pbw EPH 04572 : 3 pbw EPC 865 Curing: 2 h 80 °C / 176 °F + 3 h 180 °C / 356 °F Properties Flexural strength, DIN 53452 / ISO 178 Deflection, DIN 53452 / ISO 178 Modulus in flexure, DIN 53452 / ISO 178 TG (DMTA); Peak max TG (DMTA); Peak max Spec. Volume Resistivity, DIN VDE 0303 T3 Surface Resistance, DIN VDE 0303 T3 Dielectric breakdown voltage, DIN VDE 0303 T2 Dielectric Strength, DIN VDE 0303 T2 Dielectric dissipation factor at 23 °C (73 °F) / 1 MHz, DIN VDE 0303 T4 Dielectric constant at 23 °C (73 °F) / 1 MHz, DIN VDE 0303 T4 Tracking Resistance, DIN 53480 Unit MPa mm MPa °C / °F °C / °F Ohm cm Ohm KV Volts /mils Value 104 5.5 3480 204 / 399 188 / 370 1.7 ·1015 2.0 ·1015 40 965 0.023 3.34 CTI 250 M Note: To improve the fracture mechanical properties we recommend to add the toughened epoxy resin Bakelite® EPR 05399 !! Properties of the reinforced resin Curing: 2 h 80 °C / 176 °F + 3 h 180 °C / 356 °F + 2 h 200 °C / 392 °F C-fibre reinforced material: Properties TG (DMTA); Peak max TG (DMTA); Peak max Flexural strength DIN 53452 / ISO 178 ILSS (short beam) 2 mm (6 layer C-fibre / Kramer 445 T), resin content: 29.6 % Temperature Room temperature Unit °C / °F °C / °F MPa Value 192 / 378 178 / 352 1058 Room temperature MPa 47.1 page 4/ 5 ... area: ATE-E1 ... created: 04/97... edit date: 02/05 All information, recommendations and suggestions provided by Bakelite AG in the form of verbal or writ ten communication, or in pertinent data bases, represent our best knowledge and experience. Such data are non-binding in character, and do not represent, either explicitly or implicitly, assurances or a gua rantee of specific properties. The specified parameters merely represent typical data; they do not form a basis for either a guarantee or a specification. The information, recommendations and suggestions we provide describe our products and possible applications in general or exemplary terms; they do not rela te to specific cases. The process of constant continued development and improvement of our products can lead to changes in pertinent parameters, texts and illustrations; no s pecial mention is made of pos sible alterations. Our technical advice does not free the customer of its responsibility to verify our current information, in particular our technical data sheets, safety data sheets and technical information leaflets. The customer will conduct its own tests of our products to determine their suitability for the intended pro cesses and uses, as well as to establish that their processing properties are appropriate in the pertinent situation, since our products may be used in a wide range of technical applications that involve very dif ferent requirements according to the specific situation. Therefore, such specific cases are outside our control, and are the excIusive responsibility of the customer. A pertinent agreement is necessary in case a binding assurance of specific parameters is required. Customers and users of our products must them selves observe possible patent rights, existing legislation and regulations. This publication does not represent a license, nor does it authorize infringement of any type of patent. Note: This version superse des and replaces all previous publications on this subject. Bakelite® is a registered trademark of Bakelite AG in Europe. Rütaphen ® is a registered trademark of Bakelite AG in the United States and Canada. Technical Information EP Epoxy Resins Bakelite EPR 04572 Processing guide for Pultrusion: Resin bath: room temperature Tool temperature: 180 °C – 200 °C / 356 – 392 °F Speed: approx. die length per minute (die length = 36 inches; 36 inches / min. speed) Note: We recommend to use between 2.0 and 3.0 % of an an internal release agent, for example Bakelite ® EPM 05288. To improve the surface quality of the profile we suggest to use typical fillers 10 – 20%, like ASP 400 P. Precautions When handling Bakelite epoxy resins and Bakelite hardeners, will you please observe the APME documentation “epoxy resins and curing agents”. page 5/ 5 ... area: ATE-E1 ... created: 04/97... edit date: 02/05 All information, recommendations and suggestions provided by Bakelite AG in the form of verbal or writ ten communication, or in pertinent data bases, represent our best knowledge and experience. Such data are non-binding in character, and do not represent, either explicitly or implicitly, assurances or a gua rantee of specific properties. The specified parameters merely represent typical data; they do not form a basis for either a guarantee or a specification. The information, recommendations and suggestions we provide describe our products and possible applications in general or exemplary terms; they do not rela te to specific cases. The process of constant continued development and improvement of our products can lead to changes in pertinent parameters, texts and illustrations; no s pecial mention is made of pos sible alterations. Our technical advice does not free the customer of its responsibility to verify our current information, in particular our technical data sheets, safety data sheets and technical information leaflets. The customer will conduct its own tests of our products to determine their suitability for the intended pro cesses and uses, as well as to establish that their processing properties are appropriate in the pertinent situation, since our products may be used in a wide range of technical applications that involve very dif ferent requirements according to the specific situation. Therefore, such specific cases are outside our control, and are the excIusive responsibility of the customer. A pertinent agreement is necessary in case a binding assurance of specific parameters is required. Customers and users of our products must them selves observe possible patent rights, existing legislation and regulations. This publication does not represent a license, nor does it authorize infringement of any type of patent. Note: This version superse des and replaces all previous publications on this subject. Bakelite® is a registered trademark of Bakelite AG in Europe. Rütaphen ® is a registered trademark of Bakelite AG in the United States and Canada.