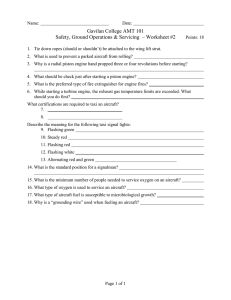

Aircraft Technology Improvements

advertisement