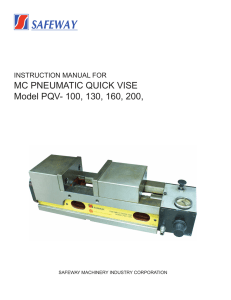

Production Vises

advertisement