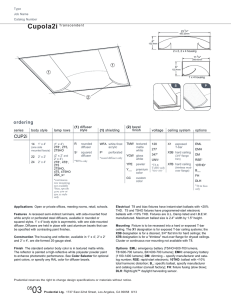

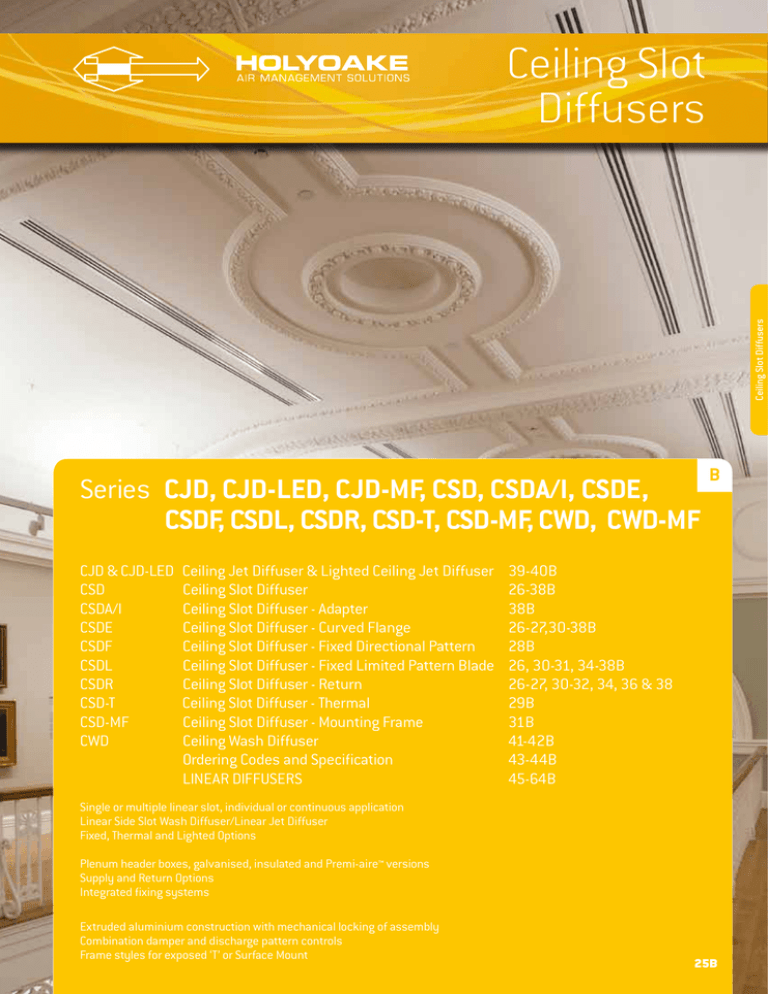

Ceiling Slot Diffusers

advertisement