Standard drawings - water sewerage

advertisement

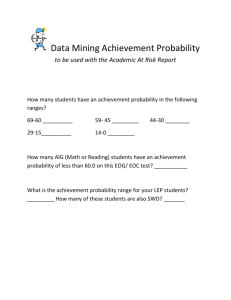

CABWATER STANDARD DRAWINGS GENERAL Drawing No. CAB-G01 CAB-G01-1 Rev. B X-orig. Date 08/06 08/07 Description Water and Sewerage Reticulation - As Constructed Details. Sewerage Reticulation - Typical Design Plan Details CAB-G01-2 X-orig. 08/07 Water / Recycle Reticulation - Typical Design Plan Details CAB-G01-3 X-orig. 08/07 Sewerage Reticulation - Typical Longitudinal Section Details CAB-G02 CAB-G03 A 08/07 X-orig. 10/03 Aluminium Access Lids - General Arrangement. Aluminium Access Lids - Details. CAB-G04 X-orig. 10/03 Aluminium Ladders - Details. WATER CAB-W01 B 08/06 CAB-W02 C 10/07 Typical Water Service & Conduit Details incl. Conduit Marker Detail. Water Meter Detail Greater than 50mm. CAB-W03 X-orig. 10/03 Fire Hydrant Box and Valve Box - Detail Plan. SEWERAGE CAB-S01 B 08/06 Sewerage House Drain Connection - Detail Plan. CAB-S01-1 X-orig. 08/07 Sewerage House Drain - Manhole Connection - Detail Plan CAB-S02 E 10/07 Submersible Pump Station - Typical Site Plan Details & Notes. CAB-S03 D 10/07 CAB-S04 C 07/07 2440 dia. Duplex Submersible Pump Station - Roof Slab Layout & Pipe Arrangement Plan. 2440 dia. Duplex Submersible Pump Station - Sectional Details. CAB-S05 E 10/07 CAB-S06 D 07/07 CAB-S07 B 02/07 CAB-S08 A 08/07 CAB-S09 A 08/06 ELECTRICAL A CAB-S20 01/08 CAB-S21 B 01/08 CAB-S22 B 01/08 CAB-S23 B 01/08 Simplex P.S. =<5.5Kw Equipment Schedule CAB-S24 B 01/08 Simplex P.S. =<5.5Kw Panel Arrangement and Const. Notes CAB-S25 X-orig. 01/08 CAB-S26 X-orig. 01/08 CAB-S27 X-orig. 01/08 CAB-S28 X-orig. 01/08 Duplex P.S. =<5.5Kw Equipment Schedule CAB-S29 X-orig. 01/08 Duplex P.S. =<5.5Kw Panel Arrangement and Const. Notes 1800dia. "Simplex" Submersible Lift Station - General Arrangement & Notes. 1800dia. "Simplex" Submersible Lift Station - Pipe Arrangement Plan & Sectional Details. Submersible Pump Station - General Details. 22/01/2008 2:31:29 PM, 1:1 Sewer Pressure mains Ø100 to Ø225 - Scour and Gas Release Valve Details. Sewer Rising Main Discharge to Gravity Sewer - Detail Plan Amendment 01/08 7 50 Ø 1 VC uP .54 1 78 P E H) TY ( S E 8 SN 14 HCB CH12.0 OFFSET 0.7m TYPE D SL 11.302 IL 10.255 9 Ø 5m 1. 11 LOT 10 RP123456 HCB CH7.1 OFFSET 2.5m TYPE E SL 11.878 IL 10.644 REVISIONS B REVISED NOTES, DIMENSIONS ADDED A REVISED SINGLE CONDUIT CROSSING ORIGINAL ISSUE .96 L9 Ø1 uP 50 68 VC . 3 T S N Y PE 2 8( SE 1 H) 12 SWABBING CHAMBER PRESSURE REDUCING VALVE NON-RETURN VALVE (REFLUX) LEGEND - SEWERAGE MANHOLE HOUSE CONNECTION BRANCH 2 4 L8 DIL 8.835 m 5.07 LOT 17 RP123456 INIT MANHOLE NUMBER LINE NUMBER .90 1m SEWER NOTES: 2 7 HCB CH4.0 OFFSET 1.2m TYPE E SL 11.751 IL 9.623 5 8.79 LOT 16 RP123456 3.1 UIL Ø150 uPVC 58.50 UIL 9.225 TYPE 1 SN8 (SEH) 3 HCB CH33.25 4.35m OFFSET 1.0m 7 TYPE E SL.13.425 SL 13.218 IL 9.873 CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. FLUSHING POINT 7 DI 1m STOP VALVE LOT 1 RP123456 RESERVE FOR PARK HCB CH5.0 OFFSET 2.8m TYPE D SL 11.555 IL 9.987 3m 5.7 UI 3.3 1m m 1.2 5 .25 m L 9 4.21 DI HCB CH2.52 OFFSET 1.3m TYPE E SL 13.106 IL 10.875 LOT 15 RP123456 LOT 9 RP123456 m HCB CH3.66 1.5 OFFSET 2.5m TYPE E SL 13.119 IL 11.667 FIRE HYDRANT CONDUIT 5.1 50 Ø1 VC uP .30 52 E 1 ) P H TY (SE 8m 8 3.9 SN HCB CH21.58 OFFSET 1.2m TYPE E SL 13.284 IL 11.867 LEGEND - WATER REDUCER 13 LOT 14 RP123456 m 13 8 LOT 11 RP123456 1.5 HCB CH44.0 OFFSET 2.6m TYPE D SL 11.345 IL 9.975 1.2m 1.5m SL.13.757 10 SL.11.000 m 1.2 4 .60 7 L9 UI 4 HCB CH29.81 OFFSET 2.8m TYPE D SL 14.553 IL 12.777 4 .5 5m LOT 8 RP123456 1.2m 19.57m 9.6 09 FLUSHING POINT 6 DIL 1 95 16 CL .2 10 PE LOT 12 RP123456 HCB CH0.0m OFFSET 2.7m TYPE STUB SL 13.757 IL 12.400 2 .8 8m TYPICAL MANHOLE (DIAGRAMMATIC) L DI 63 LOT 13 RP123456 4 2.42m LOT 7 RP123456 2m 1. SL.11.616 1. The identification number of any pump station within the shire shall be indicated where applicable. 1m DATE B.M. 8/06 B.M. 3/04 DW NOT TO SCALE Manager Business & Planning Manager Design Engineer AB 15/08/2007 2:34:06 PM, 1:1.00303 1.2m m 2 LEVEL FOR "WORKS AS CONSTRUCTED" 13 36 5. 1.2m 5 LENGTH FOR "WORKS AS CONSTRUCTED" CL OF MANHOLE LOT 6 RP123456 4m Ø100 uPVC CL16 2.3 HCB CH45.3 OFFSET 0.7m TYPE D SL 12.087 IL 10.791 3 LEVEL FOR "WORKS AS CONSTRUCTED" 1 S WD S WD S WD W Sewerage Reticulation Notes E W R E E E RW RW RW S R W S R W SWD E E S 10. All house connections joining to sewers deeper than 2.1m are to be constructed of Suggden fittings. RW E 11. The location of existing services as shown are indicative only and the contractor must confirm the location of all services before commencing construction. RW SWD E W 159 E S W S W W 156 W E SWD SWD E W R RW S W 161 W 155 SWD SWD SWD W RW S SWD RW W 135 139 RW RW S SWD SWD 160 E STAGE # W SWD R E R W 137 SWD RW W D SW W RW 154 SWD SWD W RW RW RW RW RW W W W SWD SWD SWD W W W W W W W W W W W W W W W W W W RW W W SWD RW RW W 153 SWD 152 PATHWAY SWD W SWD W SWD W SWD W W W SWD 151 S 185 186 188 189 INIT 191 192 193 163 164 B.M. 8/07 CABWATER Cabwater Manager RW SWD DATE NOT TO SCALE ORIGINAL ISSUE 190 STAGE # REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITES. W 187 Planning & Design Manager Design Engineer STANDARD DRAWING SEWERAGE RETICULATION TYPICAL DESIGN PLAN DETAILS SWD DRAWING No. REV. CAB-G01-1 A3 15/08/2007 11:48:32 AM, 1:1 RW 162 136 SWD W RW SWD SWD RW 138 150 E S W 148 147 RW 12. Pipe bedding and trench compaction to conform to WSA-02 Sewerage Reticulation Code of Australia requirements. SWD SWD SWD R 134 E 146 149 Sewerage and roofwater connection points must be separated by at least 3.0m R W RW S W 157 W W RW 140 144 143 9. R W 145 142 Where sewers are located in adjoining properties, house connections shall extend 1.5m into the property being served. W D SW D SW D SW W 8. 11 W W All house connection branches shall be provided with plastic locating tape attached to the branch and brought 300mm minimum above finished surface level. S RW R SWD S W RW S S S SWD D SWD 7. S D S RW RW R 158 133 SW All road crossings shall be backfilled with approved sand between backs of kerbs. E E RW S E RW W SWD 6. RW SW S D RW D SW D SW D SW R D E SW W 194 SWD The finished surface levels shown on longitudinal sections are indicative only. Completed manhole tops shall conform to finished ground profile and be in accordance with the following: Manhole location Height above finished ground level Footpath 30mm Private Property 75mm 114 W SWD 132 141 RW 5. E RW RW SW W R RW Each lot shall be served by a 100mm dia. Class SN10/SEH house connection branch located 1.0 to 1.5m upstream of allotment boundaries. E RW R W E 257 4. W W 131 195 123 S D SW D SW D SW W 124 All sewer manholes are generally located 1.5m from front and rear boundaries, 1.0m from side boundaries and will be pegged by the project surveyor prior to commencement of construction. 115 R 130 EXISTING STAGE # 125 3. RW 126 S S E 129 127 W E 116 W D SWWD S WD S E D D 128 W D SWWD S WD S E SW W R W S S E All 150 dia. pipes shall be uPVC Class SN8/SEH rubber ring jointed unless shown otherwise. Non-metallic sewer mains to be installed with detectable marker tape in accordance with Caboolture Shire Council requirements. W SW E D SW W R W R E 2. R 196 D SW D W R D SW All work shall be constructed in accordance with the current Caboolture Shire Council Design and Development manual and standard drawings, and WSA-02 Sewerage Reticulation Code of Australia. R W W 122 D S E E SW D E SW W W R W R SW S SW S W WD D D 1. 117 S W E W W R W 120 121 W S SWD W W 119 W E S E RW E S D EXISTING STAGE # S E D RW E S W R RW 195 SW R W W S RW R W E D SW W R RW SW E W R E RW W W R D S E 196 SW D W R D SW D D E SW E W SW W R W SW R W S E S R 257 D E W RW S SWD S 141 RW RW W W S E R E SWD W R E S W S RW E W E S R E W R S E 139 S SWD E R W R W R R E E SWD W S R 148 RW 149 W W E E W RW RW 146 STAGE # S W R 144 W 145 143 SWD SWD RW 140 W E R S S R W R SWD SWD W SWD SW D R W R SWD S RW W RW SWD S RW R D E SW R 194 142 W S E SW E S SWD E W 138 147 137 1 136 RW SWD R R RW SWD SWD PATHW AY S 187 188 S 189 190 RW S 191 192 SWD SWD RW SWD REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. INIT DATE NOT TO SCALE ORIGINAL ISSUE B.M. 8/07 CABWATER Cabwater Manager Planning & Design Manager Design Engineer STANDARD DRAWING WATER / RECYCLE RETICULATION TYPICAL DESIGN PLAN DETAILS DRAWING No. REV. CAB-G01-2 A3 15/08/2007 2:09:07 PM, 1:1 SWD 186 SWD D R S R 185 E 153 S W R R E R S RW SWD W R R E R S S 151 152 RW SWD RW R RW R RW SW RW R RW S RW 150 CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITES. INIT DATE NOT TO SCALE ORIGINAL ISSUE B.M. 8/07 CABWATER Cabwater Manager Planning & Design Manager Design Engineer STANDARD DRAWING SEWERAGE RETICULATION TYPICAL LONGITUDINAL SECTION DETAILS DRAWING No. REV. CAB-G01-3 A3 15/08/2007 11:54:19 AM, 1:1 REVISIONS 1000 CLEAR OPENING 50 50 1000 CLEAR OPENING 50 NOTES 25 75 50 75 50 50 50 50 150 MIN. 50 HINGED SAFETY GRATING 'SAFE HATCH' BELOW ACCESS LIDS WHERE SPECIFIED. 1000 1000 6mm THICK ALUMINIUM CHEQUER PLATE LIDS WITH BITUMINOUS COATING TO TOP B RETRACTABLE HANDLES A B 1. All components to be fabricated from grade 6061-t6 aluminium (unless noted otherwise). 2. All nuts, bolts, screw and washers to be grade 316 stainless steel. 3. All welding to be weld quality b in accordance with as1665. 4. All welds to be fillet continuous using filler alloy 4043. 5. Cover to be fabricated from grade 5251 aluminium chequer plate and have a bituminous coating. 6. All surfaces to be embedded in concrete are to have two coats of bitumen based paint. 7. Most welds have been omitted for clarity. 8. Cover dimensions may change to suit the size of openings. 9. To be read in conjunction with drawing CAB-G03 2000 CLEAR OPENING 50 100 50 1000 750 C 6mm THICK ALUMINIUM CHEQUER PLATE LIDS WITH BITUMINOUS COATING TO TOP WELD TO LID WELD TO FRAME 50x50x6 ANGLE STIFFENER WELDED TO UNDERSIDE OF LID 1000 CLEAR OPENING HINGED SAFETY GRATING 'SAFE HATCH' BELOW ACCESS LIDS WHERE SPECIFIED. 950 6 PLATE WELDED TO UNDERSIDE OF LID 1000 1000 CLEAR OPENING 750 50x50x6 ANGLE WELDED TO UNDERSIDE OF LID 50 25 WELD TO LID WELD TO FRAME WELD TO LID 50 50 50 WELD TO LID 1050 1075 PLAN 1100 PLAN HANDGRIP REFER DETAIL B HINGE REFER DETAIL C PLAN LID TO STRUT BRACKET REFER DETAIL E HINGE REFER DETAIL C FRAME TO STRUT BRACKET REFER DETAIL D LID STRUT REFER DETAIL A LID STRUT REFER DETAIL A SECTION A-A SECTION B-B REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. A C 23/08/2007 8:32:45 AM, 1:1.00303 2000 CLEAR OPENING 200 'SAFE HATCH' DETAILS ADDED ORIGINAL ISSUE INIT B.M. D.W. 30x6 ANCHORS 250 LONG @ 300 CRS SECTION C-C DATE 8/07 NOT TO SCALE Manager Business & Planning Manager Design Engineer A RP BOUNDARY RP BOUNDARY RECYCLED WATERMAIN Conduit 600mm (min. cover) below lip of kerb and channel or 150 below bottom of box, whichever is greater. 300 600 POTABLE WATERMAIN 1800 1200 BALL VALVE 300 DEEP ELEVATION BRASS SERVICE CONDUIT MARKER DISC FIXED TO KERB FACE REC YCL 200 MIN. 300 300 300 E SE ES W R S VICE H IN WIT CON DUIT PLAN READYTAP CONNECTOR OR EQUIVILENT POTABLE RECYCLED BALL VALVE BOUNDARY BALL VALVE RECYCLED POTABLE R V IC RECYCLED POTABLE DUIT BOUNDARY WA SE T ER CON CASH #2 ITHIN #1 CONDUIT TO EXTEND 300 min. PAST BACK OF KERB KERB & CHANNEL CRESCENT Readytap connector (or equivalent) For urban areas only KERB & CHANNEL RECYCLE MAIN Recycle Water Main WATERMAIN 300 min. 15° Potable Water Main BALL VALVE (TYP.) #4 Marker tape Refer Note 5. SEALING PLUG 300 FROM FRONT PROPERTY BOUNDARY MIN. 150 CLEARANCE POTABLE RECYCLED White/Lilac peg at end of Service. Refer Note 13. Ball valve Refer note 12. Polyethylene Pipe INDIVIDUAL SERVICES ARE REQUIRED TO EVERY LOT BOUNDARY Marker tape Refer Note 5. #3 White/Lilac peg at end of Service. Refer Note 13. FINISHED SURFACE LEVEL Brass marker to be positioned directly over service conduit Ø25 6 Ball valve Refer note 12. 300 100 Polyethylene Pipe 85 1 - 16 15° Ø3 LOCATION OF BRASS MARKERS BRASS SERVICE CONDUIT MARKER DISC REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. B A INIT Sealing plug Potable Water Main 300 FROM FRONT PROPERTY BOUNDARY Recycled Water Main WATER SERVICE CONNECTION DETAIL DATE RECYCLE SERVICE AND CONDUIT DETAILS ADDED B.M. 8/06 SINGLE CONDUIT CROSSING B.M. 3/04 ORIGINAL ISSUE T.C. NOT TO SCALE Manager Business & Planning Manager Design Engineer AB 15/08/2007 1:36:40 PM, 1:1.00291 NOTES 1. Water service conduits and 20mm dia services shall be provided and installed in locations shown on the project drawings. 2. The location of the conduits shall be indicated by brass service conduit marker discs positioned in kerb & channel directly above the conduit. 3. Temporary polystyrene or approved equivalent plugs or stops shall be inserted in the end of the conduits to prevent the entry of dirt or foreign matter. 4. Provide sand or rock bedding thoroughly compacted up to the underside of the pavement box. Trench width shall be 300mm as per specification. 5. A plastic tape (lilac for recycle) is to be provided between the surface marker and the end of the conduit. 6. Where conduits cross roads on the diagonal they are to be aligned on the extension of the property boundary to the kerb. 7. Where possible Telstra and waters service conduits are to be placed in a common trench, if such a situation is unavoidable, a minimum horizontal separation of 300mm is required, under no circumstances are conduits to be placed on top of each other. 8. All conduits are to have each end exposed for inspection by Council's Inspector. 9. Electrical conduits are not to be placed in the same trench as water conduits a minimum seperation of 1m is required. 10. A 20mm service is to be provided using a pre-tapped Readytap Connector (or approved equivalent). Up to four services 20mm dia can be provided off each connector (two for each side of the road). 11. Two 20mm poly services are to be laid within conduit, the service is to be PN16 black (lilac for recycle) poly pipe. 12. The ball valve is the service connection termination, which is to be left in the closed position after construction and with the handle in the vertical position. The ball valve shall have a sealing plug inserted and a marker is to be placed to enable location from the surface level. 13. A small WHITE painted marker peg is to be placed at the end of all water services. A small LILAC painted marker peg is to be placed at the end of all recycled services. 14. Service conduit to be 100Ø PVC CL20 or SEH for residential A & rural residential and 200dia for residential B & C Commercial & Industrial zones Multiple services to be laid in conduits in residential areas. 15. A minimum of 1m clear is required between a water service connection point and and electrical pillar box. HOUSE CONNECTION HOUSE CONNECTION INSPECTION OPENING 50 MIN SEWER 50 MIN SEWER BEND AS REQUIRED NATURAL SURFACE 300 MAX BEND TO SUIT 600 MIN. 1500 MAX. GLUED CAP (REFER NOTE 4.) BEND TO SUIT INSPECTION OPENING GLUED CAP (REFER NOTE 4.) 45° BEND INSPECTION OPENING PIPE BEDDING X HOUSE CONNECTION CONCRETE INVERT LEVEL (I.L.) TO BE SHOWN ON DESIGN AND AS-CONSTRUCTED DRAWINGS 1000 INSPECTION OPENING GLUED CAP (REFER NOTE 4.) DEPTHS GREATER THAN 1.5m 45° RUBBER RING JUNCTION 1000 CONCRETE HOUSE DRAIN BY DRAINER INCL. 45° 'Y' JUNCTION INVERT LEVEL (I.L.) TO BE SHOWN ON AS-CONSTRUCTED DRAWINGS HOUSE CONNECTION HOUSE DRAIN BY DRAINER PIPE BEDDING ELEVATION 0 M IN 45° RUBBER RING JUNCTION (REFER NOTE 5) TYPE D (HOUSE CONNECTION WHEN SEWER LESS THAN 1.5m DEEP) (EXTEND DIST X WHEN HOUSE CONNECTION LOCATED IN ADJACENT BOUNDARY) 45° RUBBER RING JUNCTION (REFER NOTE 5) 1. Where internal drainage exists or is to be constructed as part of the property connection works, inspection openings shall be finished off with concrete surround, min. 50mm above finished surface level. 2. Contractor to bring location markers to surface. 3. Where noted Grade N20 concrete is required. 4. House Drainer to bring bolted trap screw to surface. 5. Connections < 2.1m deep do not require GRP heavy duty extended drop junction. HOUSE CONNECTION CONCRETE HOUSE DRAIN BY DRAINER INCL. 45° 'Y' JUNCTION 150 MIN COMPACTED SAND SURROUND INVERT LEVEL (I.L.) TO BE SHOWN ON AS-CONSTRUCTED DRAWINGS GRP HEAVY DUTY EXTENDED DROP JUNCTION "HARDIE IPLEX" OR SIMILAR APPROVED. (REFER NOTE 5) IF DEPTH UNDER 2.1m RUBBER RING 45° Y-JUNCTION WITH 45° BEND IS ACCEPTABLE. (SEE INSERT A) CONCRETE CONCRETE INSERT A ELEVATION (VERTICAL DROP WHEN SEWER GREATER THAN 1.5m DEEP AND LOCATED IN LOT BEING SERVICED) (HOUSE CONNECTION WHEN SEWER IS OVER 1.5m DEEP AND LOCATED IN ADJACENT BOUNDARY TO LOT BEING SERVICED) REVISIONS B DESIGN & AS-CONST. LEVEL NOTE ADDED A REVISED REFERENCE NOTE 4 ORIGINAL ISSUE INIT DATE B.M. B.M. DW 8/06 3/04 ELEVATION TYPE F TYPE E CONSTRUCTION NOTES CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. 45° BEND 10 > 2100 GRP JUNCTION REQUIRED < 2100 Y JUNCTION WITH 45 BEND REQUIRED 300 MAX CONCRETE 1.5m (MIN) NATURAL SURFACE 1000 300 MAX PIPE BEDDING PROPERTY CONNECTION MARKER INVERT LEVEL (I.L.) TO BE SHOWN ON DESIGN DRAWINGS NATURAL SURFACE INSPECTION OPENING TO SURFACE BY DRAINER (REFER NOTE 1.) INVERT LEVEL (I.L.) TO BE SHOWN ON DESIGN DRAWINGS NOT TO SCALE Manager Business & Planning Manager Design Engineer AB 15/08/2007 1:43:19 PM, 1:1.00296 INSPECTION OPENING TO SURFACE BY DRAINER (REFER NOTE 1.) INSPECTION OPENING TO SURFACE BY DRAINER (REFER NOTE 1.) PROPERTY CONNECTION MARKER 300 MAX PROPERTY CONNECTION MARKER PLAN PLAN PROPERTY BOUNDARY PLAN 600 MIN. 1500 MAX. BEND AS REQUIRED 600 MIN. 1500 MAX. 50 MIN INSPECTION OPENING INSPECTION OPENING INSPECTION OPENING SEWER HOUSE CONNECTION HOUSE CONNECTION HOUSE CONNECTION HOUSE CONNECTION INSPECTION OPENING INSPECTION OPENING INSPECTION OPENING 600 MIN. 1500 MAX. CONCRETE INVERT LEVEL (I.L.) TO BE SHOWN ON DESIGN AND AS-CONSTRUCTED DRAWINGS GLUED CAP (REFER NOTE 4.) HOUSE DRAIN BY DRAINER INCL. 45° 'Y' JUNCTION INVERT LEVEL (I.L.) TO BE SHOWN ON AS-CONSTRUCTED DRAWINGS HOUSE CONNECTION HOUSE DRAIN BY DRAINER BENCH TO SUIT HOUSE CONNECTION PIPE BEDDING CONCRETE ELEVATION ELEVATION END CAP BENCH TO SUIT HOUSE CONNECTION ELEVATION M.H. STUB (HOUSE CONNECTION WHEN MANHOLE LESS THAN 1.5m DEEP AND MANHOLE IS LOCATED IN LOT BEING SERVICED) M.H. TYPE E M.H. TYPE D (HOUSE CONNECTION WHEN MANHOLE AND SEWER CONNECTION IS OVER 1.5m DEEP AND MANHOLE IS LOCATED IN ADJACENT BOUNDARY TO LOT BEING SERVICED) (HOUSE CONNECTION WHEN MANHOLE LESS THAN 1.5m DEEP) (HOUSE CONNECTION LOCATED IN ADJACENT BOUNDARY) CONSTRUCTION NOTES M.H. TYPE F (Refer WSA STD. DWG. SEW-1303) 1. Where internal drainage exists or is to be constructed as part of the property connection works, inspection openings shall be finished off with concrete surround, min. 50mm above finished surface level. 2. Contractor to bring location markers to surface. 3. Where noted Grade N20 concrete is required. 4. House Drainer to bring bolted trap screw to surface. CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. SEWER MANHOLE CONCRETE 100 MIN HOUSE CONNECTION INSPECTION OPENING (HOUSE CONNECTION WHEN MANHOLE IS MORE THAN 1.5m DEEP AND MANHOLE IS LOCATED IN LOT BEING SERVICED) REVISIONS INIT DATE NOT TO SCALE ORIGINAL ISSUE B.M. Manager Business & Planning Manager Design Engineer 23/08/2007 1:18:35 PM, 1:1.00291 PIPE BEDDING 1000 1500 MAX. DEPTHS GREATER THAN 1.5m CONCRETE BEND TO SUIT INSPECTION OPENING PROPERTY CONNECTION MARKER INVERT LEVEL (I.L.) TO BE SHOWN ON DESIGN DRAWINGS 300 MAX 300 MAX 1000 GLUED CAP (REFER NOTE 4.) INSPECTION OPENING TO SURFACE BY DRAINER (REFER NOTE 1.) 1.5m (MIN) NATURAL SURFACE NATURAL SURFACE 1500 MAX. PROPERTY CONNECTION MARKER 600 MIN. 1500 MAX. INSPECTION OPENING TO SURFACE BY DRAINER (REFER NOTE 1.) PLAN PROPERTY BOUNDARY 1.5m (MIN) PLAN SEWER MANHOLE PROPERTY BOUNDARY PROPERTY CONNECTION MARKER SEWER SEWER SEWER PLAN SEWER MANHOLE END CAP ROCKER PIPE 0.60m ROCKER PIPE 0.60m BENCH TO SUIT HOUSE CONNECTION INSPECTION OPENING HANDGRIP 40Ø NB HEAVY CLASS PIPE. ALL HEAVY DUTY GALV. (REFER PLATE DETAIL) 300 1200 SUITABLE STAINLESS STEEL SUPPORT/SAFETY CLIPS ARE TO BE INSTALLED TO SEPERATELY ACCOMODATE EACH PUMP'S MOTOR CABLE AND LIFTING CHAIN EMERGENCY PUMPING POINT Ø100 CAMLOK COUPLING DISMANTLING JOINT TOP OF SLAB ("A") 300 75 300 MAX. WELL WASHER COLLECTOR MAINTENANCE HOLE EXTENSION SPINDLE BRACKETS OF APPROVED TYPE @ 1500 MAX. CTRS. (2 No. MIN.) PUMP INFORMATION Ø100 FLOOR DRAIN WITH WATER SEAL AND FLAP SEAL PUMP MANUFACTURER PUMP MODEL No. S.S. KNIFE GATE VALVE SUPPORT BEAM WITH APPROVED BRACKET DUTY POINT (FLOW @ HEAD) STANDBY CUT-IN ("C1") MOTOR SIZE CUT-OUT BWL 150 L.L. ALARM 1 1 FLOOR 1.5 1.5 mm l/s @ m kW ("D") ("E") ("F") PUMPSTATION CONTROL LEVELS (A.H.D.) A B C C1 D E F TOP OF SLAB m HIGH LEVEL ALARM m DUTY CUT-IN LEVEL m STANDBY CUT-IN LEVEL m CUT-OUT LEVEL m LOW LEVEL ALARM m FLOOR LEVEL m PUMP OPERATING LEVELS AND DEFAULT SETTINGS SHALL BE AS PER THE SEWAGE PUMPING STATION CODE OF AUSTRALIA (WSA 04) 2440 PUMPS TO BE ANCHORED TO BASE WITH S.S. BOLTS SET INTO BASE. SIZE & MIN. EMBEDMENT OF BOLTS TO PUMP MANUFACTURER'S SPECIFICATION. SECTION A-A REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. C B A ROOFSLAB SAFETY CHAIN & POSTS REMOVED WELL WASHER ADDED REVISED DETAILS ORIGINAL ISSUE INIT DATE T.C. 7/07 T.C. 2/07 B.M. 8/06 DW NOT TO SCALE Manager Business & Planning Manager Design Engineer AB C 15/08/2007 1:49:27 PM, 1:1.00303 ALUMINIUM LADDER. REFER CABWATER STD DRAWING BENCHING IMPELLOR Ø H.L. ALARM ("B") DUTY CUT-IN ("C") TWL HIGH DENSITY POLYETHELENE PIPE DROPPER PIPE IMPELLOR TYPE (eg GRINDER) MINIMUM CLEAR SPACE FOR LADDER ACCESS (REFER FIG 5.1 AS1657) COLLECTOR MAINTENANCE HOLE DISMANTLING JOINTS DISTANCES AS SPECIFIED BY FLOWMETER MANUFACTURER OVERFLOW GRAVITY SEWER PUMP DISCHARGE MINIMUM CLEAR SPACE FOR LADDER ACCESS (REFER FIG 5.1 AS1657) PRESSURE TEST POINT. REFER WSA 04-2005 "PRESSURE MAIN TAPPINGS" HANDGRIP 40Ø NB HEAVY CLASS PIPE. ALL HEAVY DUTY GALV. (REFER PLATE DETAIL) CONCRETE SLAB SUITABLE STAINLESS STEEL SUPPORT/SAFETY CLIPS ARE TO BE INSTALLED TO SEPERATELY ACCOMODATE EACH PUMP'S MOTOR CABLE AND LIFTING CHAIN 6000 HIGH TAPERED STEEL VENT POLE. REFER TO DETAIL. HANDGRIP 40Ø NB HEAVY CLASS PIPE. ALL HEAVY DUTY GALV. (REFER PLATE DETAIL) 300 75 TOP OF SLAB ("A") OUTFLOW MAINTENANCE HOLE EXTENSION SPINDLE BRACKETS OF APPROVED TYPE @ 1500 MAX. CTRS. (2 No. MIN.) COLLECTOR MAINTENANCE HOLE OUTFLOW MAINTENANCE HOLE O'FLOW ("G") OVERFLOW MAGNETIC FLOWMETER (ABB FLOWMETER OR EQUIVALENT SPECIFICATION) ALUMINIUM LADDER. REFER CABWATER STD DRAWING WELL WASHER PUMP DISCHARGE S.S. KNIFE GATE VALVE GRAVITY SEWER H.L. ALARM ("B") DISMANTLING JOINTS DUTY CUT-IN ("C") TWL HIGH DENSITY POLYETHELENE PIPE Ø100 FLOOR DRAIN WITH WATER SEAL AND FLAP SEAL BALL VALVE CUT-OUT BWL ("D") PUMP INFORMATION PUMP MODEL No. mm l/s @ 1800 REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. INIT DW ("F") TOP OF SLAB m HIGH LEVEL ALARM m DUTY CUT-IN LEVEL m CUT-OUT LEVEL m LOW LEVEL ALARM m FLOOR LEVEL m OVERFLOW LEVEL m PUMP OPERATING LEVELS AND DEFAULT SETTINGS SHALL BE AS PER THE SEWAGE PUMPING STATION CODE OF AUSTRALIA (WSA 04) DATE NOT TO SCALE ORIGINAL ISSUE ("E") PUMPS TO BE ANCHORED TO BASE WITH S.S. BOLTS SET INTO BASE. SIZE & MIN. EMBEDMENT OF BOLTS TO PUMP MANUFACTURER'S SPECIFICATION. m kW FLOOR 1.5 1.5 IMPELLOR Ø MOTOR SIZE 1 1 IMPELLOR TYPE (eg GRINDER) DUTY POINT (FLOW @ HEAD) L.L. ALARM 150 PUMP MANUFACTURER A B C D E F G Manager Business & Planning Manager Design Engineer A B C D 15/08/2007 11:25:03 AM, 1:1.00298 PUMPSTATION CONTROL LEVELS (A.H.D.) 3xM16 S.S. CHEMSET OR MASONRY ANCHOR BOLTS 2 SLOTTED HOLES IN BEAM ONLY; Ø18x40 LONG TELEMETRY ANTENNA ALUMINIUM CLEAT 80x180x12 THICK CONDUIT TABLE MOTOR CAPACITY CONDUIT SIZE Ø150 100 22 kW MAX. INDIVIDUALLY SIZED TO SUIT PLUG SIZE 350 PACK WITH 3:1 CEMENT MORTAR AFTER LEVELLING 150 Ø27 HOLES FOR Ø24 HOLDING DOWN BOLTS 50 Ø265 POLE BASE BUTT WELD BOTH SIDES. 12 VENT BASE PLATE DETAIL SECTIONAL ELEVATION PLAN BEAM SUPPORT BRACKET DETAIL Ø18 HOLES 15 R117 .5 R97 0" 45 ' °0 °0 '0 " 45 210 45°0'0" 140 50 155 75 ALUMINIUM PLATE 12 THICK 50 175 NO WELD ON BEAM SIDE. VENT DETAILS 50 6mm FILLET WELD Ø170 HOLE FOR Ø150 uPVC VENT PIPE 125 Ø24 S.S. HOLDING DOWN BOLT WITH S.S. HEX. NUTS AND 2 No. S.S. WASHERS PER BOLT. BOLTS TO BE 765 LONG. PROVIDE 1 LEVELLING NUT PER BOLT UNDER BASE PLATE. BOLTS TO BE THREADED 90mm AND COGGED MIN. OF 150mm 200x80 ALUMINIUM PARALLEL FLANGE CHANNEL SECTION 100 75 >22 Kw MIN. 16 THICK F.M.S. BASE PLATE PAINT UNDERSIDE WITH BITUMEN Ø18 HOLES FOR M16 S.S. BOLTS & WASHERS TO SUIT 100 TAPERED SECTIONAL STEEL POWER POLE MIN. 1.42mm THICK 100 ID AT TOP, 265 ID AT BOTTOM; HOT DIP GALVANISED AFTER FABRICATION 350 uPVC CABLE CONDUIT IF REQUIRED(REFER TABLE) SWITCHBOARD BOLTED TO BRACKETS ON POLE. 50 Ø90 uPVC 'STORMWATER' VENT PIPE OPTIONAL LIGHTING TOP OF SWITCHBOARD 2100 6000 NOM. HEIGHT MIN. 'ODOUR WARRIOR' VENT POLE CAP (or equivalent) REQUIRED 2xM16 S.S. BOLTS 15 BUTT WELD BOTH SIDES 50 50 Ø18 HOLE TO SUIT M16 BOLT (150 LONG) HANDGRIP ANCHOR PLATE DETAIL CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. B A 75 325 150 PLAN END PIPE SUPPORT BRACKET (TYP. Ø150) REVISIONS INIT DATE TELEMETRY AND LIGHT ADDED TO VENT POLE 'ODOUR WARRIOR' VENT POLE CAP ADDED ORIGINAL ISSUE T.C. B.M. DW 2/07 8/06 NOT TO SCALE Manager Business & Planning Manager Design Engineer A B 15/08/2007 11:27:00 AM, 1:1.00303 75 12 THICK PLATE VENT POLE REFER CABWATER STD DRAWING APPROVED CONCRETE MAINTENANCE HOLE C/W GAS TIGHT CAST IRON LID APPROVED CONCRETE MAINTENANCE HOLE C/W GAS TIGHT CAST IRON LID APPROVED GAS RELEASE VALVE. SPECIAL DESIGN REQUIRED FOR DUAL ORIFICE VALVE APPROVED Ø100 CAMLOCK COUPLING CONVIENENT TO OPENING DUCTILE IRON THRUST CONNECTOR APPROVED INTERNAL PROTECTIVE LINING TO MAINTENANCE HOLE 400x400 SUMP CONVENIENT TO OPENING SCOUR TEE WITH FLANGED BRANCH Ø100 FLANGE-SOCKET VALVE WITH SPINDLE RISER SCOUR DETAIL 15/08/2007 11:37:21 AM, 1:1.00303 GAS RELEASE DETAIL 400x400 SUMP CONVENIENT TO OPENING NOTES: 1. Short pipes as shown shall be 300mm minimum and 600mm maximum length. Care shall be taken to ensure any concrete is kept clear of flexible joints. 2. All fittings to be DICL PN35 or otherwise approved. REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. INIT DATE NOT TO SCALE ORIGINAL ISSUE DW Manager Business & Planning Manager Design Engineer A DISCHARGE MAINTENANCE HOLE WITH LID AND VENT IN ACCORDANCE WITH STANDARD DRAWING. RETICULATION MAINTENANCE HOLE WITH LID IN ACCORDANCE WITH STANDARD DRAWING. ACID RESISTANT LINER 1200 MIN. TO UNDERSIDE OF ROOF SLAB 1100 MIN. TO UNDERSIDE OF ROOF SLAB REAM O WN-ST IZE A S D W ER E S AM E S S Y IT G RA V 100mm MIN SEWAGE LEVEL 225 50 FALL ACROSS M.H. 600 MAX. 600 MAX. 150 FLOW GRAVITY SEWER FLOW INVERT LEVELS 1, 2 AND 3 TO BE PROVIDED FOR EACH INDIVIDUAL PROJECT. 1m MIN. 10m MAX. RISING MAIN 150 MIN. 150 ANCHOR BLOCK SIZE VARIES WITH PIPE SIZE. 90° ELBOW FLEXIBLE JOINT PART SECTIONAL ELEVATION PRESSURE MAIN DISCHARGE MAINTENANCE HOLE 1. Benching not shown for clarity. 2. Sewers downstream of pressure main discharge maintenance hole shall be of non-corrosive pipe for the greater length of 100m or the total length of the runs connecting the two maintenance holes downstream of the discharge maintenance hole. 3. The discharge maintenance hole and the first and second maintenance holes downstream of the discharge maintenance hole, shall incorporate an acid resistant liner of a type approved by Council. 4. The benching and underside of the top slab shall be approved epoxy coated. 5. Vent at discharge maintenance hole required. refer C.S.C. standard drawing. 6. Special approval required for discharge maintenance hole located in private property. 90° BEND 600 MAX FLEXIBLE COUPLING 45° BEND BENCH TO SUIT FLOW GRAVITY SEWER RISING MAIN FLOW PART SECTIONAL ELEVATION PRESSURE MAIN DISCHARGE MAINTENANCE HOLE FOR 'SIMPLEX' SUBMERSIBLE LIFT STATION REVISIONS CABOOLTURE SHIRE SUPPORTS FACILITIES AND ACCESS FOR PERSONS WITH A DISABILITY. PLEASE ENSURE PROVISION AND/OR REINSTATEMENT OF FACILITIES. A DISCHARGE MAINTENANCE HOLE AMENDED ORIGINAL ISSUE INIT B.M. BM DATE 8/06 NOT TO SCALE Manager Business & Planning Manager Design Engineer A 15/08/2007 11:43:26 AM, 1:1.00293 NOTES: