Williams Mining Product Catalogue

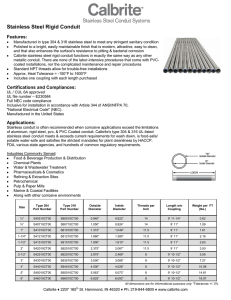

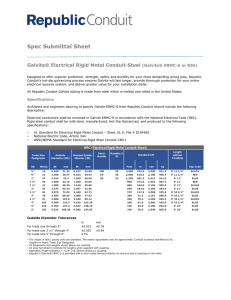

advertisement