501-140

Qualification Test

Report

05Jan04 Rev A

All Para Revised EC 0990-1788-03

AMP-BARREL* Terminals

1.

INTRODUCTION

1.1.

Purpose

Testing was performed on AMP-BARREL* Terminals to determine their conformance to the

requirements of Product Specification 108-6025, Revision F.

1.2.

Scope

This report covers the electrical, mechanical, and environmental performance of AMP-BARREL

Terminals. Testing was performed using solid wire at the Engineering Assurance Product Test

Laboratory between 22Oct90 and 06Mar91; testing using stranded wire was performed between

16Apr01 and 17Oct03. The test file number for solid wire testing is CTL 1212-016-002; for stranded wire

testing, the test file numbers are CTL 1222-004 and -005. This documentation is on file at and available

from the Engineering Assurance Product Test Laboratory.

1.3.

Conclusion

The AMP-BARREL Terminals listed in paragraph 1.5., conformed to the electrical, mechanical, and

environmental performance requirements of Product Specification 108-6025, Revision F.

1.4.

Product Description

AMP-BARREL Terminals are insulation displacement terminals suitable for use in most printed circuit

boards from .047 to .125 inch thick. Four different barrel diameters are available - .070, .090, .125, and

.156 inch. The insulation displacement end of the terminal accepts a wire range from 28 to 18 AWG

dependent on terminal size. The .070, .090 and .125 inch diameter terminals accept one or two wires of

the same gage and type, while the .156 inch diameter terminal accepts one wire. All terminal diameters

will accept solid or stranded wire. Terminals may be permanently soldered to the printed circuit board or

temporarily press fit into the printed circuit board hole for later removal. Termination is achieved by

placing the end of a pre-cut insulated wire in the insulation displacement slot of the terminal with the wire

parallel to the printed circuit board. Wire insertion to the proper depth is then accomplished by the use of

a screwdriver type tool or plastic stuffer cap, which terminates the wire in the insulation displacement

slot.

1.5.

Test Specimens

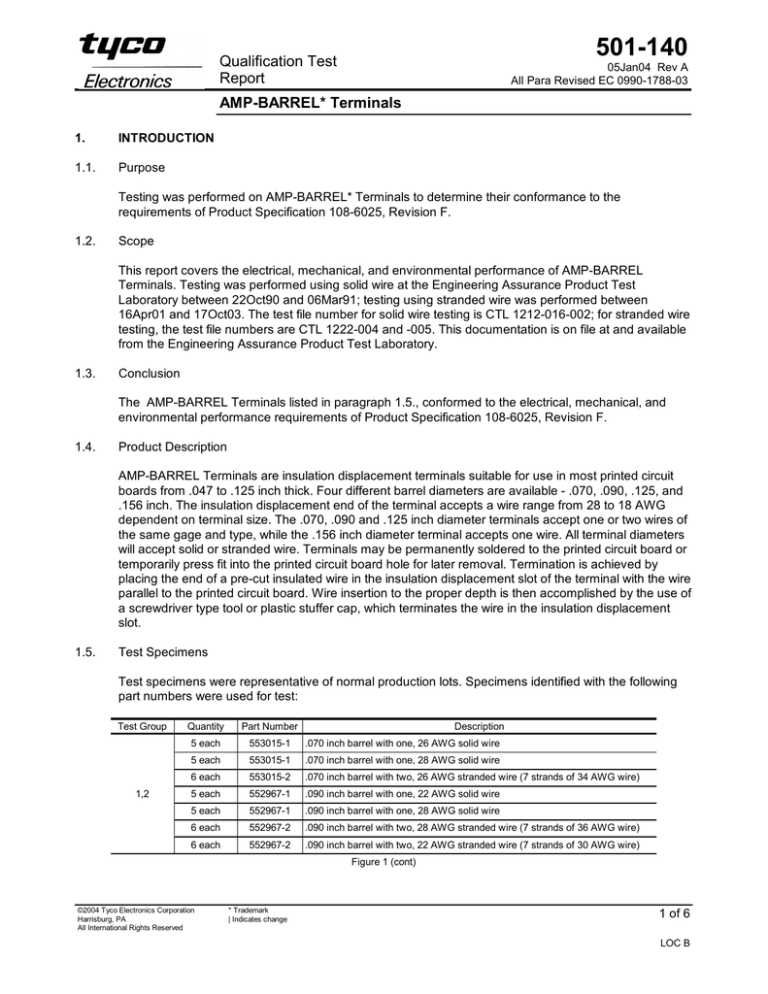

Test specimens were representative of normal production lots. Specimens identified with the following

part numbers were used for test:

Test Group

1,2

Quantity

Part Number

5 each

553015-1

.070 inch barrel with one, 26 AWG solid wire

Description

5 each

553015-1

.070 inch barrel with one, 28 AWG solid wire

6 each

553015-2

.070 inch barrel with two, 26 AWG stranded wire (7 strands of 34 AWG wire)

5 each

552967-1

.090 inch barrel with one, 22 AWG solid wire

5 each

552967-1

.090 inch barrel with one, 28 AWG solid wire

6 each

552967-2

.090 inch barrel with two, 28 AWG stranded wire (7 strands of 36 AWG wire)

6 each

552967-2

.090 inch barrel with two, 22 AWG stranded wire (7 strands of 30 AWG wire)

Figure 1 (cont)

©2004 Tyco Electronics Corporation

Harrisburg, PA

All International Rights Reserved

* Trademark

| Indicates change

1 of 6

LOC B

501-140

Test Group

1,2

3,4

Quantity

Part Number

5 each

552699-1

.125 inch barrel with one, 28 AWG solid wire

Description

5 each

552699-1

.125 inch barrel with one, 18 AWG solid wire

6 each

552699-2

.125 inch barrel with two, 28 AWG stranded wire (7 strands of 36 AWG wire)

6 each

552699-2

.125 inch barrel with two, 18 AWG stranded wire (7 strands of 26 AWG wire)

6 each

552699-2

.125 inch barrel with two, 18 AWG stranded wire (19 strands of 30 AWG wire)

5 each

552770-1

.156 inch barrel with one, 24 AWG solid wire

5 each

552770-1

.156 inch barrel with one, 18 AWG solid wire

6 each

552770-2

.156 inch barrel with one, 24 AWG stranded wire (7 strands of 32 AWG wire)

6 each

552770-2

.156 inch barrel with one, 18 AWG stranded wire (7 strands of 26 AWG wire)

6 each

552770-2

.156 inch barrel with one, 18 AWG stranded wire (19 strands of 30 AWG wire)

5 each

553015-1

.070 inch barrel with one, 26 AWG solid wire

5 each

553015-1

.070 inch barrel with one, 28 AWG solid wire

6 each

553015-2

.070 inch barrel with two, 26 AWG stranded wire (7 strands of 34 AWG wire)

5 each

552967-1

.090 inch barrel with one, 22 AWG solid wire

5 each

552967-1

.090 inch barrel with one, 28 AWG solid wire

6 each

552967-2

.090 inch barrel with two, 28 AWG stranded wire (7 strands of 36 AWG wire)

6 each

552967-2

.090 inch barrel with two, 22 AWG stranded wire (7 strands of 30 AWG wire)

5 each

552699-1

.125 inch barrel with one, 28 AWG solid wire

5 each

552699-1

.125 inch barrel with one, 18 AWG solid wire

6 each

552699-2

.125 inch barrel with two, 28 AWG stranded wire (7 strands of 36 AWG wire)

6 each

552699-2

.125 inch barrel with two, 18 AWG stranded wire (7 strands of 26 AWG wire)

5 each

552770-1

.156 inch barrel with one, 24 AWG solid wire

5 each

552770-1

.156 inch barrel with one, 18 AWG solid wire

6 each

552770-2

.156 inch barrel with one, 24 AWG stranded wire (7 strands of 32 AWG wire)

6 each

552770-2

.156 inch barrel with one, 18 AWG stranded wire (7 strands of 26 AWG wire)

Figure 1 (end)

1.6.

Environmental Conditions

Unless otherwise stated, the following environmental conditions prevailed during testing:

!

!

Rev A

Temperature:

Relative Humidity:

15 to 35/C

25 to 75%

2 of 6

501-140

1.7.

Qualification Test Sequence

Test or Examination

1

2

3

4

Initial examination of product

1

1

1

1

Low level contact resistance

2,5

2,4

2,5

Temperature rise vs current

3

Current cycling

2

Vibration

3

Mechanical shock, half-sine

4

Thermal shock

3

Humidity-temperature cycling

4

Temperature life

3

Final examination of product

NOTE

(a)

(b)

6

5

6

4

See paragraph 1.5.

Numbers indicate sequence in which tests are performed.

Figure 2

2.

SUMMARY OF TESTING

2.1.

Initial Examination of Product - All Test Groups

All specimens submitted for testing were representative of normal production lots. A Certificate of

Conformance was issued by Product Assurance. Specimens were visually examined and no evidence

of physical damage detrimental to product performance was observed.

2.2.

Low Level Contact Resistance - Test Groups 1, 2 and 3

All low level contact resistance measurements, taken at 100 milliamperes maximum and 20 millivolts

maximum open circuit voltage had a change in resistance ()R) of less than 5 milliohms after testing.

2.3.

Temperature Rise vs Current - Test Group 4

All specimens had a temperature rise less than 30/C above ambient when tested at 125% of the DC

current shown in Figure 3.

Wire Size

(AWG

18

19

20

22

24

26

28

Rated Current

(amperes)

7.5

6.5

6.0

5.0

4.0

2.5

1.5

Figure 3

Rev A

3 of 6

501-140

2.4.

Current Cycling - Test Group 4

No evidence of physical damage was visible as a result of 500 cycles of current cycling.

2.5.

Vibration - Test Group 1

No discontinuities were detected during vibration testing. Following vibration testing, no cracks, breaks,

or loose parts on the specimens were visible.

2.6.

Mechanical Shock, Half-sine - Test Group 1

No discontinuities were detected during mechanical shock testing. Following mechanical shock testing,

no cracks, breaks, or loose parts on the specimens were visible.

2.7.

Thermal Shock - Test Group 3

No evidence of physical damage was visible as a result of thermal shock testing.

2.8.

Humidity-temperature Cycling - Test Group 3

No evidence of physical damage was visible as a result of humidity-temperature cycling.

2.9.

Temperature Life - Test Group 2

No evidence of physical damage was visible as a result of temperature life testing.

2.10.

Final Examination of Product - All Test Groups

Specimens were visually examined and no evidence of physical damage detrimental to product

performance was observed.

3.

TEST METHODS

3.1.

Initial Examination of Product

A Certificate of Conformance was issued stating that all specimens in this test package were produced,

inspected, and accepted as conforming to product drawing requirements, and were manufactured using

the same core manufacturing processes and technologies as production parts.

3.2.

Low Level Contact Resistance

Low level contact resistance measurements were made using a 4 terminal measuring technique (Figure

4). The test current was maintained at 100 milliamperes maximum with a 20 millivolt maximum open

circuit voltage.

Rev A

4 of 6

501-140

Figure 4

Low Level Contact Resistance Measurement Points

3.3.

Temperature Rise vs Current

Thermocouples were attached to individual contacts to measure their temperatures. Specimens were

connected in a series circuit and energized at 125% of the DC current shown in Figure 3. When the

temperature rise of 3 consecutive readings taken at 5 minute intervals did not differ by more than 1/C,

the temperature measurement was recorded. The ambient temperature was then subtracted from this

measured temperature to find the temperature rise.

3.4.

Current Cycling

Specimens were connected in a series circuit and subjected to 500 cycles of current cycling. Each cycle

consisted of being energized for 15 minutes at 150% of the DC current shown in Figure 3 followed by 15

minutes un-energized. Temperatures were monitored just prior to the end of each energized portion of

the cycle.

3.5.

Vibration, Sinusoidal

Specimens were subjected to sinusoidal vibration, having a simple harmonic motion with an amplitude

of 0.06 inch, double amplitude. The vibration frequency was varied uniformly between the limits of 10

and 55 Hz and returned to 10 Hz in 1 minute. This cycle was performed 120 times in each of 3 mutually

perpendicular planes for a total vibration time of 6 hours. Specimens were monitored for discontinuities

of 1 microsecond or greater using a current of 100 milliamperes DC. The connector wire assemblies

were secured straight out from the connector at the edge of the printed circuit board.

3.6.

Mechanical Shock, Half-sine

Specimens were subjected to a mechanical shock test having a half-sine waveform of 50 gravity units (g

peak) and a duration of 11 milliseconds. Three shocks in each direction were applied along the 3

mutually perpendicular planes for a total of 18 shocks. Specimens were monitored for discontinuities of

1 microsecond or greater using a current of 100 milliamperes DC. The connector wire assemblies were

secured straight out from the connector at the edge of the printed circuit board.

Rev A

5 of 6

501-140

3.7.

Thermal Shock

Specimens were subjected to 25 cycles of thermal shock with each cycle consisting of 30 minute dwells

at -55 and 85/C. The transition between temperatures was less than 1 minute.

3.8.

Humidity-temperature Cycling

Specimens were exposed to 10 cycles of humidity-temperature cycling. Each cycle lasted 24 hours and

consisted of cycling the temperature between 25 and 65/C twice while maintaining high humidity (Figure

5).

Figure 5

Typical Humidity-Temperature Cycling Profile

3.9.

Temperature Life

Specimens were exposed to a temperature of 85/C for 792 hours (33 days).

3.10.

Final Examination of Product

Specimens were visually examined for evidence of physical damage detrimental to product

performance.

Rev A

6 of 6