Piezo Speaker Strobe Notification Reference

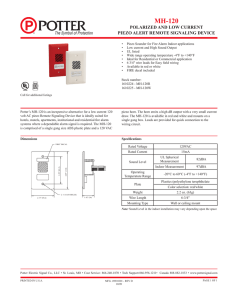

advertisement