Offsite Unplugged: The Potential for Offsite Production in New Zealand

advertisement

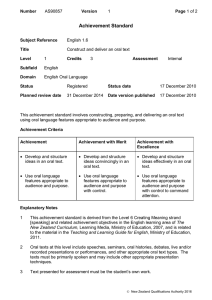

Offsite Unplugged: The Potential for Offsite Production in New Zealand Rosemary Scofield, Heavy Engineering Research Association NZ rosemary.scofield@hera.org.nz Regan Potangaroa, Unitec Institute of Technology Auckland NZ rpotangaroa@unitec.ac.nz Pamela Bell, Master of Architecture, Victoria University of Wellington NZ pam_bell@xtra.co.nz Abstract This paper further develops a recent UK conference publication based on a research project that examined the status of offsite production from analysing 150 interviews of construction professionals in Auckland, New Zealand. The findings from this research, and the conclusions of a Masters thesis on residential prefabrication in New Zealand provide the basis for this paper. A comparison is made between the present day factors that influence attitudes and construction approaches and the historical factors that contributed to the lack of development of the prefabrication industry. The paper examines how the current approaches to offsite methods of construction in New Zealand might be inhibited by local conditions and if the reluctance for construction industry uptake might change with developments in technology. The findings from the research suggest that the advantages of offsite production are not well understood in New Zealand. While there are aspects of prefabrication being exploited, the New Zealand construction industry does not seem ready or able to address the problems of fragmentation and poor quality that other economies are trying to solve. The paper makes suggestions as to why the potential is not fully realised in New Zealand. Finally the paper makes recommendations as to how this potentially high-quality, efficient and economical way of building could be encouraged and developed further in New Zealand. Keywords: Offsite, Construction, Culture, Prefabrication, New Zealand. 1. Introduction Prefabrication has a surprisingly long history in New Zealand (NZ). This paper explores the historical background to the present day situation in New Zealand prefabrication or offsite production, the typologies used and the relationship with local culture, climate and industry. The process of exploring and identifying historical and contemporary exemplars reveals specific attitudes and approaches. These are then compared with current industry perspectives to provide insight into the best way for NZ to realise benefits from establishing an offsite industry sector. 1.1 What is Prefabrication or Offsite? The two terms are often used synonymously but in fact do have slightly different meanings. Offsite is a term used to embrace the technologies and processes involving various forms of supply chain specifications, prefabrication and assembly that occurs away from the final site. Prefabrication is usually seen as a less holistic description for a manufacturing process that takes place within a factory-controlled environment. It is widely agreed that offsite methods, including prefabrication, can make more effective use of materials, speed up delivery, reduce time spent on site, enable high standards of design quality, improve on-site safety and overcome skills shortages in the construction industry. However, the process must be understood and managed correctly to gain such benefits. There are many historical misperceptions that such processes produce low-quality, “one-size-fits-all” buildings.1 Specialists around the world agree that prefabrication can be divided into at least four types, or levels of extent. In the United States these are described as stick, panel, module and box-form.2 The United Kingdom has mostly replaced the term ‘prefabricated’ with ‘offsite’, supported by an industry-wide umbrella organisation, Buildoffsite. Leading British researcher Alistair Gibb of Loughborough University defines four categories in a slightly different way - component sub-assembly, nonvolumetric pre-assembly, volumetric pre-assembly and complete buildings.3 He also identifies a fifth category, hybrid, for assemblies that use combinations of these typologies. This paper refers to these five types as Offsite construction methods. Stick or component prefabrication refers to lengths of timber which are pre-cut, pre-sized or preshaped puzzle-type pieces put together at site. Components or sub-assemblies are those multi-material assemblages such as windows and doors which are manufactured away from site and installed at site into other elements. This includes fixtures and fittings, and structural members such as pre-nailed roof trusses and wall frames. The use of pre-nailed components has become an accepted part of the construction process in New Zealand. Panelised or non-volumetric prefabrication is manufactured panels assembled as a flat-pack or kit-ofparts. This includes steel frames and wall panels (often with doors and windows included) stacked and shipped to be assembled at site. Prefabricated panel and non-volumetric elements include foundation systems, structurally insulated panels (SIPs), skylights, cabinetry, staircases, and ductwork 4. Modular or volumetric prefabrication refers to a three-dimensional unit being constructed away from site and transported to site where it is combined with other units or systems to create a whole dwelling. A structural three-dimensional object can be referred to as a volume or module, and a nonstructural object is called a pod or unit. A modular home is a type of building that meets building codes, is factory-assembled in full-dimensional units and then fixed onto a permanent foundation on site5. There is an established modular building industry in the United States, but not in New Zealand. Hybrid or semi-volumetric prefabrication enables the use of ‘volumetric units for the highly serviced areas such as kitchens and bathrooms and [to] construct the remainder of the building using panels or by another means’.6 This brings together the benefits of both modular and panelised prefabricated construction systems, while allowing for more flexibility and consumer choice. Box-form or complete buildings are commonly known in New Zealand as relocated, or relocatable, and transportable dwellings. They comprise volumetric prefabrication of entire completed buildings constructed in a factory or yard, which are then transported to site and attached to permanent foundations. These have been traditionally used for secondary dwellings, holiday homes or ‘baches’ and agriculture worker So how did this New Zealand context come about? 2. History of Prefabrication in New Zealand 2.1 Pre-European Maori housing Though Austin et al7 suggests that there were various innovations in the pre-settler Maori housing or “whare”, prefabrication did not appear to be one of them. Materials were essentially sourced locally and hence the prefabrication/offsite approach appeared with the first European settlers. Nonetheless, Dawie8 and Treadwell adopted and adapted some of these innovations in recent “deployable whares” designs as flat pack kit set houses. 2.2 Pre-1900: Early European Settlers Panelised or non-volumetric housing kits were first imported to New Zealand from the United Kingdom and the United States by the early settlers of the 1800’s. The components were used mainly for family homes but also for some enduring public buildings. The country’s most familiar precolonial house, known as the ‘Treaty House’, was brought by James Busby from Sydney to Waitangi in 1833 as a pre-cut frame with fittings and most materials. In Christchurch, Lyttelton and Akaroa, there were a great many ready-made houses shipped from England in sections and bolted together on site.9 And by the end of the nineteenth century, United States pattern-books had spread populist designs to New Zealand. This approach incorporated site-based construction of the basic structural shell according to plan guides, complemented by factory-produced ornamental components from catalogues of standardised parts such as ornate cornices, eaves, veranda posts and gable ends. 2.3 Early 1900s: Railway Houses Then in the early 1900’s the New Zealand Railways Department became the first and largest producer of prefabricated housing, some as early as the 1880s. By the 1920s a combination of standardised planning through pattern-books and use of prefabricated components was employed in railway house construction.10 Approximately 300 houses were produced by the Frankton factory up to 1926, for railway housing around the North Island. The official nine-year Railways scheme ended in 1930, its demise ironically attributed to efficiencies in production.11 In 1925 the government took on total state responsibility for every aspect of housing development which is seen as a precursor to the Labour government’s state housing scheme, developed in the 1930s. 2.4 Mid-1900s: Government Housing By the mid-twentieth century prefabrication techniques were popular in Britain, the United States and Australia which led the New Zealand government to conduct experiments with these techniques. Houses featured prefabricated wall sections, multi-storey concrete construction, or imported prefabricated technologies from Sweden and the United Kingdom. Transportation costs and quality defects meant that importation was not pursued as an option. A 1943 competition invited local architects to participate in the design of prefabricated dwellings which resulted in three houses being built in Christchurch.12 Prefabrication techniques were also used in Government hydro-electric schemes for worker housing. This facilitated the relocation of accommodation to areas with housing shortages and moving workers between schemes. Combinations of construction off site, transportation and relocation were used throughout the 1960s and 1970s for Otematata, Clyde and Twizel, Otematata was built in 1958 as a base for the construction of the Aviemore and Benmore Dams and was a base for the Electricity Corporation of New Zealand. Accommodation consisted of single men's quarters and a series of different houses from small worker houses, staff houses for teachers and professionals, and larger houses for engineers and other high-status residents. Most houses were prefabricated, and intended to be portable. Some were brought from Otematata, and some were moved to Clyde for the next hydroelectricity project The Ministry of Works set up a carpentry workshop at Otematata to build 250 houses on a production line. Other housing was provided by contractors such as Keith Hay Homes, Martin Homes of Timaru and De Geest Construction of Oamaru. De Geest constructed 549 complete houses for Twizel electricity village and 350 componentised houses for sites at Cromwell for construction workers on the Clyde dam from their purpose-built factory.13 2.5 1950s-70s: Modernism A number of prefabricated homes were available in the 1950s to 1970s, including architect Roger Walker’s Vintage Homes, Robert Lockwood’s Modulock Homes, and Keith Clark’s Industrialised Building Systems (IBS). Few of these prefabricated housing businesses survive in their original form. In the late 1960s Industrialised Building Systems (IBS) began under the leadership of Palmerston North property developer Keith Clark. The IBS team ambitiously planned for three separate consortia in New Zealand and six in Australia with each factory forecast to produce up to 1200 homes per annum, or 25 per week.14 The IBS design was based on a system of room modules which enabled ‘parts [to] be re-sold back to the factory, additional ones bought, and worn out ones replaced’.15 By 1972 a 1400 square foot family house, a motel unit and a weekend home were built in the IBS factory at Avondale. Stage Two of IBS was the creation of Xibis (pronounced Zybiss), a house consisting of ground floor modules, with roof panels installed on site to create the second storey. Despite considerable interest from customers in New Zealand, Australia and the United States, IBS collapsed in 1978 during the economic recession. IBS left a legacy of enduring successes, one of them being that they created the first one-piece fibreglass showers, which are still evident in New Zealand homes today. 2.6 1980s-90s: Consumerism Two companies that managed to survive to the 1980s and 1990s, the era of emerging consumerism, were Keith Hay Homes (KHH) and Lockwood. In 1949, Keith Hay pioneered Keith Hay Homes when he began shifting and relocating second-hand buildings after a foray into caravan-building and home renovations. Construction of complete houses began in the controlled environment of the KHH Morningside yard. Hay advocated the use of pine instead of native timber to speed up production processes, as well as cutting labour costs, and incorporating new plastics and other innovative materials into home construction. Today, KHH, under the reigns of son David Hay, continues to offer a range of affordable, commercial and lifestyle transportable or site-built buildings.16 In 1951 Johannes La Grouw (Senior) and John Van Loghem arrived in New Zealand from Holland combined their construction and marketing experience and began producing prefabricated houses in Wainuiomata and Wellington. By 1954 they had moved to Rotorua to be near the pine forest industry and formed Lockwood Homes from a factory where they produced five houses a week for the holiday home market. They developed a franchise system which enabled the Lockwood brand to have national exposure. Lockwood built New Zealand’s 1970 Expo pavilion at Osaka, Japan, which led to international sales, and by 2002 they had built over 30,000 houses in New Zealand and offshore. The patented Lockwood component-based system consists of aluminium-laminated solid-timber boards which interlock both with each other and with aluminium jointing profiles. Components are manufactured in the factory and assembled on site in about half the time of a traditional stick-built house.17 This enables an infinite range of house plans and forms, either designed from scratch or modified from the custom designs in their plan-book. Lockwood is now under the leadership of Joe La Grouw Junior and remains New Zealand’s primary prefabricated house company with 28 franchisees and a line of more affordable transportable homes under their Initial Homes brand. In 2003, they introduced the Pete Bossley architect-designed series to revitalise their product range. In 2008 they launched the EcoSmart home series designed by architect Dave Strachan as a way to bring sustainable design to the upper-end of the housing market. 2.7 2000-current: Contemporary Prefab Contemporary prefabricated housing comes in a range of typologies: the component-based bachkit, Triboard and Maxim board panels used by transportable and site-built housing contractors, De Geest modular bathroom pods, and a range of established complete building providers. Bachkit is an elegant minimal pavilion designed by Andre Hodgskin Architects which was sold to Replica Architects in 2001. The design is based on a modular planning system, with a number of pre-cut elements and prenailed components, such as steelwork, sub-floor timber, wall framing, doors and shutters, track system, roof ellipse, and flat-pack internal cabinetry. De Geest Construction started in 1955 as a house-building company when Albert de Geest emigrated from Holland. He built one of the first housing factories which then supplied complete houses to the Waitaki hydro-power scheme. De Geest went on to construct pre-built modular bathrooms and since 1983 has supplied over 7,500 units to hotels, motels, apartments and hospitals throughout New Zealand, Australia and the Pacific. Today, it maintains its focus as a construction company while undertaking some commercial development and crane hire, with the bathroom pods making up to fifty percent of their workload.18 There are a number of emerging prefabricated housing products coming to market in 2008 and beyond. These are mostly complete building typologies focussed on the bach or second home market. Ingenious designs overcome the restrictive transportation dimensions with unfolding elements to create more floor area, such as port-a-bach’s fold-down deck, and HABODE’s butterfly roof form, both of which emerge from a shipping-container shell. Recent and prospective entrants to New Zealand’s prefabricated housing industry can learn valuable lessons from the success and failures of past ventures in New Zealand. These can be grouped into three areas: economic, technical and socio-cultural. Large production runs matched by market demand are required to make most systems economically viable.19 New Zealand is challenged by a small consumer market and volatility to international macroeconomic conditions. Economic recession was responsible for the demise of innovative prefabrication systems such as IBS in the 1970s. Yet government investment into research and development to explore design and manufacture enabled it to extend its regulatory role to lead change throughout the mid-twentieth century. Further government investment into large hydro projects enabled several enduring businesses to become established. With that historical context what are the present attitudes towards offsite construction? 3. Contemporary perspectives on Prefabrication in New Zealand This was studied via a structured questionnaire of 96 building sites in Auckland between March and June 2008. The questions asked were at an ‘instance’ level (the example of offsite being examined) and at a project level (the site where it was to be installed). They mapped when the decision was made to use offsite and what were the reasons for that decision, what factors were less than what they should have been and what were the main barriers. Figure 4 – Stages at which decisions are made The major offsite opportunities at present were offered by timber and steel framing, kitchen and bathroom pods and modular buildings. Architects do not appear to be taking a leading role in designing for offsite methods of construction, even though the decision to use offsite is usually made in the concept stage. This might imply that most of the projects using offsite were not designed by architects, but were developed through design-and-build processes. High quality is becoming much more sought after and provides a competitive advantage which is regarded as more achievable using prefabricated components. It is felt that in New Zealand there is the need for a much wider range of products for offsite solutions. Although offsite is seen by some as a way to use innovative techniques to build on difficult sites, shorten the construction time on site, and to achieve a much higher quality of finish, most companies are still not expecting to progress their use of this technique much in the near future. A clear majority of people interviewed feel that offsite is being used sufficiently at present. Inability to freeze the design early on in the design and construction process is seen as a major problem. The reason for this is unclear but may be due to the fact that the drawings were not properly completed in the early stages and leave the contract in an insecure state. Freedom to continue modifying a design as it is being built often adds cost and time uncertainty and can be a cause of major budget blow-outs. This is a common occurrence and possibly freezing the design and having more discipline in the process would assist with budget management. The main barriers to taking a more proactive approach are perceived to include a lack of production capability and knowhow, insufficient marketing to builders of the benefits of using offsite manufacturing, inability to be flexible in making changes later in the construction programme and overly complex interfacing between trades. RANKING Barrier Definitely a Not Sure Not a Barrier Table 2 – Barriers to offsite production % % % % % % Manufacturing capacity 15 12 3 35 35 1 Site specifics and constraints and transportation 8 15 19 31 27 2 Difficulty of achieving economies of scale 8 8 42 12 31 3 Inability to freeze the design early on 15 15 19 31 19 4 Complex interfacing between systems 23 4 23 35 15 5 Higher Capital cost 23 12 30 12 23 6 Reluctance to innovate 31 15 31 12 15 7 offsite 31 15 23 12 19 8 Nature of the planning system 32 15 23 15 15 9 Fragmented industry structure 21 15 23 23 8 10 team 35 15 27 0 23 11 Legal issues 38 12 23 19 8 12 Skills shortage 46 0 35 4 15 13 Lack of previous experience with offsite 31 19 38 4 8 14 Risk averse culture 31 31 30 4 4 15 Organisational mechanism unfavourable with Lack of long term co-operation between project Attitudinal barriers due to historic failures 42 38 8 4 8 16 Client scepticism 54 23 11 8 4 17 As far as the future is concerned, a significant number of respondents said they had no feel for how much their use would increase over the next 3-5 years. Acceptance was indicated, but a lack of confidence in the ability to deliver was observed, as was a need for more training and improvement of techniques to assist offsite development. It would appear that despite a grounded history in offsite, that the approach and the industry are stagnant and not advancing as seen overseas. Table 3 – How usage of Offsite will change in the future in NZ 4. Future directions for the New Zealand offsite industry as established from the research This research has found a need for more emphasis on professional marketing and communication tools, and a need for increased research and development initiatives, collaboration and investment. These are the key areas of challenge and opportunity for prefabricated construction in New Zealand. The first key need is for marketing and communication, particularly to address the issue of widespread misperceptions and lack of coordination by a holistic industry organisation. Internal marketing strategies are within the control of individual prefab housing businesses while industry cooperation is needed for large-scale marketing and communication initiatives. Le Corbusier advocated for cultural change in order for prefabrication to be accepted when he wrote, “it is essential to create the right state of mind for living in mass-production houses”.20 A second key need is for research and development, particularly to address a lack of established industry relationships and potential for investigations into alternate typologies. Both industry and government support for research and development will enable technical design to be tested and evaluated thoroughly before being brought to market. This future focus on communication, cooperation and research and development is consistent with recommendations from the top onehundred United Kingdom house-builders.21 Several prefabrication businesses failed because of a lack of robust financing and marketing planning in place from business inception. There continues to be a large emphasis on the technical design and prototyping process prior to other business strategy. These priorities should be reassessed. Greater use of off-the-shelf components is a recommended means of reducing supply risks and lowering costs. Historical examples of mechanical utility pods are a precursor to a hybrid prefabrication typology that combines volumetric modules with other prefabricated and site-based construction methods. Examples of this hybrid module-plus-panel typology are coming to market offshore, but have not been explored locally. Flexible outcomes from combining custom design with off-the-shelf parts make the hybrid typology worthy of more focused research and development. There is evidence that consumers and contractors would both benefit from increased clustering and pre-packaging of existing building elements through prefabrication techniques. Identified areas for future research and design focus are in sustainable materials, consumer markets, design aesthetics and alternative typologies. There is particular potential to research and develop a new hybrid moduleplus-panel housing solution that utilises existing off-the-shelf components, cuts down sub-contractor work at the site and eliminates unwanted materials. This could be advanced by university-led designbased research, collaborative industry consortiums, and prototype demonstration and testing. Increasingly the globalised economy offers opportunities in offshore markets for both supply and demand of prefabricated housing. China is now the source for manufacture of several New Zealand prefabricated dwellings, and is likely to be the location of more in the future. As international construction industries become established in the production of different building components, it will become increasingly important for New Zealand’s prefabrication industry to identify its own specialised niche. This may be in the supply of prefabricated timber structural components. 5. Conclusions and the way forward for New Zealand Future emphasis on communication within the design and construction industry, together with increased levels of development investment, will lead the way forward for the uptake of prefabrication or offsite in New Zealand. A key technology is the increasing advent of Building Information Models (BIM). BIM, along with the greater participation of clients in the building process, greater emphasis and documented evidence of sustainability, the move towards further design integration and the greater realisation of the value of design to both building owners and occupants will be integral in New Zealand’s future design and construction industry if it wishes to keep up with international precedents. Such phenomena will “inevitably change not only in technology but the industry processes and actors’ roles, tasks and responsibilities in the value network. Among the main impacts are the increasing value of information throughout the lifecycle of the buildings, more efficient use of different simulation and analysis tools in the early phases of design, improved and semi-automated design coordination, and more accurate and efficient investment and lifecycle cost management.” 22 For New Zealand to participate effectively in construction related global business, to achieve export growth, to improve productivity and to enhance its own internal standards of living, several key motivators must exist. Customers must demand that products arrive at their final destination in a much more holistic and controlled way. Construction industry managers must demand far greater certainty of price, quality and assembly time. Contractors in the value chain must demand that manufacturers supply the products they want, at the right time and in the most appropriate way. Information must be readily available, in a useful and accurate form. Facilitating a New Zealand offsite culture as part of a wider change occurring in the industry will go a long way towards satisfying these motivators. The potential move from a paper-based document system to an integrated BIM has probably not been seen before in New Zealand’s design and construction history. Hence, this is undiscovered terrain, particularly for the international companies participating in the survey outlined in this paper. Future offsite research needs to study how such companies can make the cultural changes required for these new roles, organisational frameworks and business models. Building on overseas experience, New Zealand collective business has an immediate opportunity to grow a cohesive industry organisation, such as BuildOffsite in the UK, with strategies for on-going research, education and training, up-skilling of manufacturers and development of new products and systems to support the expansion of the offsite concept. As shown historically, communication with the wider community and development assistance from government and industry investment are more likely to make such a venture successful. References 1 Hart, S (2003) ‘Prefabrication, the Speculative Builder’s Tool, Has Been Discovered by Modernist Designers’, Architectural Record, 191, 12 (2003), 123-26. 2 Arieff, A and Burkhart, B (2002) Prefab (Layton: Gibbs Smith); Buchanan, M (2004) Prefab Home (Salt Lake City: Gibbs Smith); and Kelly, B (1951) The Prefabrication of Houses (New York: MIT). 3 Gibb, A and Pendlebury, M (2007) ‘Glossary of Terms v1.3’, www.buildoffsite.co.uk (accessed 14 March 2008). 4 McLendon, S (2005) Prefab Elements (New York: HarperCollins). 5 Reidelbach, J Jr., (1971) Modular Housing (Boston: Cahners). 6 Gorgolewski, M.T (2005) ‘The Potential for Prefabrication in UK Housing to Improve Sustainability’, in P. Brandon, J. Yang, and A. Sidwell (eds.), Smart and Sustainable Built Environments (Oxford: Blackwell), 124. 7 Austin, M and Treadwell, J (2009) ‘Constructing the Maori Whare’ Proceedings of the 26th International SAHANZ Conference, (University of Auckland July 2009)kland, New Zealand, 2 – 5 July 2009 8 Dawie, C (2008) ‘Deployable Whares’ MArch thesis, Unitec, Auckland 2008 9 Toomath, W (1996) Built in New Zealand: The Houses We Live In (Auckland: Harper Collins). 10 Bowron, G and Mace, T (2007) ‘State Housing: A Thematic Survey’, Unpublished report, Housing NZ Corporation, Wellington. 11 Kellaway, L (1993) ‘The Railway House in New Zealand’, MArch thesis, The University of Auckland, 1993. 12 Bowron, G and Mace, T (2007) ‘State Housing: A Thematic Survey’, Unpublished report, Housing NZ Corporation, Wellington. 13 Kinsella, F (2008) Email to the author, 25 March 2008. 14 Mountier, M (1973) ‘IBS’, Designscape, 50, 16. 15 Mountier, M (1972) ‘IBS: An Idea Whose Time Has Come’, Designscape, 35, n.p. 16 Hay, D Email to the author, 26 November 2007. 17 Gainsford, J (2006) Lockwood: From Innovation to Icon in 50 Years (Tauranga: NZ Historic Places Trust). 18 De Geest, B (2008) Personal Communication, 22 February 2008. 19 Kelly, B (1951) The Prefabrication of Houses (New York: MIT). 20 Le Corbusier (1927) Towards a New Architecture Trans. Frederick Etchells (London: Architectural Press, 1946), 245. 21 Pan, W, Gibb, A, and Dainty, A (2005) Offsite Modern Methods of Construction in Housebuilding (Loughborough: Loughborough UP). 22 Kiviniemi, A and Kokkala, M (2008) Integrated Design Solutions Scoping Document, CIB Theme IDS – 1 April 2008.