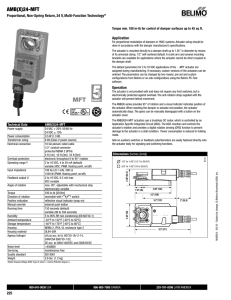

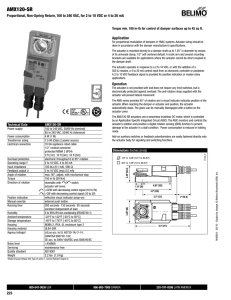

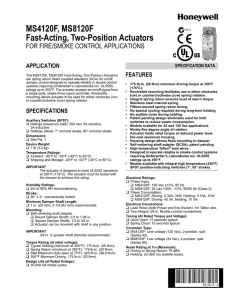

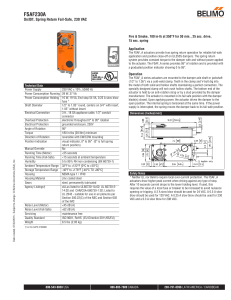

Damper Actuators

advertisement