D2IG22 with Landis - Password Services

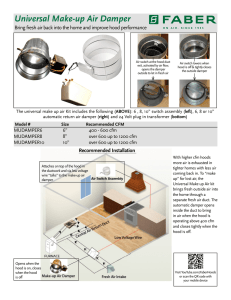

advertisement