SPD-703-1 - RADProductsOnline

SPD-703-1

G.703 Codirectional Rate and Interface Converter

Innovative Access Solutions

SPD-703-1

G.703 Codirectional Rate and Interface Converter

Installation and Operation Manual

Notice

This manual contains information that is proprietary to RAD Data Communications Ltd. ("RAD").

No part of this publication may be reproduced in any form whatsoever without prior written approval by RAD Data Communications.

Right, title and interest, all information, copyrights, patents, know-how, trade secrets and other intellectual property or other proprietary rights relating to this manual and to the SPD-703-1 and any software components contained therein are proprietary products of RAD protected under international copyright law and shall be and remain solely with RAD.

SPD-703-1 is a registered trademark of RAD. No right, license, or interest to such trademark is granted hereunder, and you agree that no such right, license, or interest shall be asserted by you with respect to such trademark.

You shall not copy, reverse compile or reverse assemble all or any portion of the Manual or the

SPD-703-1. You are prohibited from, and shall not, directly or indirectly, develop, market, distribute, license, or sell any product that supports substantially similar functionality as the SPD-

703-1, based on or derived in any way from the SPD-703-1. Your undertaking in this paragraph shall survive the termination of this Agreement.

This Agreement is effective upon your opening of the SPD-703-1 package and shall continue until terminated. RAD may terminate this Agreement upon the breach by you of any term hereof.

Upon such termination by RAD, you agree to return to RAD the SPD-703-1 and all copies and portions thereof.

For further information contact RAD at the address below or contact your local distributor.

International Headquarters

RAD Data Communications Ltd.

24 Raoul Wallenberg Street

Tel Aviv 69719, Israel

Tel: 972-3-6458181

Fax: 972-3-6498250, 6474436

E-mail: market@rad.com

©2005–2007 RAD Data Communications Ltd.

North America Headquarters

RAD Data Communications Inc.

900 Corporate Drive

Mahwah, NJ 07430, USA

Tel: (201) 5291100, Toll free: 1-800-4447234

Fax: (201) 5295777

E-mail: market@radusa.com

Publication No. 452-200-07/07

Limited Warranty

RAD warrants to DISTRIBUTOR that the hardware in the SPD-703-1 to be delivered hereunder shall be free of defects in material and workmanship under normal use and service for a period of twelve (12) months following the date of shipment to DISTRIBUTOR.

If, during the warranty period, any component part of the equipment becomes defective by reason of material or workmanship, and DISTRIBUTOR immediately notifies RAD of such defect,

RAD shall have the option to choose the appropriate corrective action: a) supply a replacement part, or b) request return of equipment to its plant for repair, or c) perform necessary repair at the equipment's location. In the event that RAD requests the return of equipment, each party shall pay one-way shipping costs.

RAD shall be released from all obligations under its warranty in the event that the equipment has been subjected to misuse, neglect, accident or improper installation, or if repairs or modifications were made by persons other than RAD's own authorized service personnel, unless such repairs by others were made with the written consent of RAD.

The above warranty is in lieu of all other warranties, expressed or implied. There are no warranties which extend beyond the face hereof, including, but not limited to, warranties of merchantability and fitness for a particular purpose, and in no event shall RAD be liable for consequential damages.

RAD shall not be liable to any person for any special or indirect damages, including, but not limited to, lost profits from any cause whatsoever arising from or in any way connected with the manufacture, sale, handling, repair, maintenance or use of the SPD-703-1, and in no event shall

RAD's liability exceed the purchase price of the SPD-703-1.

DISTRIBUTOR shall be responsible to its customers for any and all warranties which it makes relating to SPD-703-1 and for ensuring that replacements and other adjustments required in connection with the said warranties are satisfactory.

Software components in the SPD-703-1 are provided "as is" and without warranty of any kind.

RAD disclaims all warranties including the implied warranties of merchantability and fitness for a particular purpose. RAD shall not be liable for any loss of use, interruption of business or indirect, special, incidental or consequential damages of any kind. In spite of the above RAD shall do its best to provide error-free software products and shall offer free Software updates during the warranty period under this Agreement.

RAD's cumulative liability to you or any other party for any loss or damages resulting from any claims, demands, or actions arising out of or relating to this Agreement and the SPD-703-1 shall not exceed the sum paid to RAD for the purchase of the SPD-703-1. In no event shall RAD be liable for any indirect, incidental, consequential, special, or exemplary damages or lost profits, even if RAD has been advised of the possibility of such damages.

This Agreement shall be construed and governed in accordance with the laws of the State of

Israel.

Product Disposal

To facilitate the reuse, recycling and other forms of recovery of waste equipment in protecting the environment, the owner of this RAD product is required to refrain from disposing of this product as unsorted municipal waste at the end of its life cycle. Upon termination of the unit’s use, customers should provide for its collection for reuse, recycling or other form of environmentally conscientious disposal.

General Safety Instructions

The following instructions serve as a general guide for the safe installation and operation of telecommunications products. Additional instructions, if applicable, are included inside the manual.

Safety Symbols

Warning

This symbol may appear on the equipment or in the text. It indicates potential safety hazards regarding product operation or maintenance to operator or service personnel.

Danger of electric shock! Avoid any contact with the marked surface while the product is energized or connected to outdoor telecommunication lines.

Protective earth: the marked lug or terminal should be connected to the building protective earth bus.

Warning

Some products may be equipped with a laser diode. In such cases, a label with the laser class and other warnings as applicable will be attached near the optical transmitter. The laser warning symbol may be also attached.

Please observe the following precautions:

• Before turning on the equipment, make sure that the fiber optic cable is intact and is connected to the transmitter.

• Do not attempt to adjust the laser drive current.

• Do not use broken or unterminated fiber-optic cables/connectors or look straight at the laser beam.

• The use of optical devices with the equipment will increase eye hazard.

• Use of controls, adjustments or performing procedures other than those specified herein, may result in hazardous radiation exposure.

ATTENTION: The laser beam may be invisible!

In some cases, the users may insert their own SFP laser transceivers into the product. Users are alerted that RAD cannot be held responsible for any damage that may result if non-compliant transceivers are used. In particular, users are warned to use only agency approved products that comply with the local laser safety regulations for Class 1 laser products.

Always observe standard safety precautions during installation, operation and maintenance of this product. Only qualified and authorized service personnel should carry out adjustment, maintenance or repairs to this product. No installation, adjustment, maintenance or repairs should be performed by either the operator or the user.

Handling Energized Products

General Safety Practices

Do not touch or tamper with the power supply when the power cord is connected. Line voltages may be present inside certain products even when the power switch (if installed) is in the OFF position or a fuse is blown. For DC-powered products, although the voltages levels are usually not hazardous, energy hazards may still exist.

Before working on equipment connected to power lines or telecommunication lines, remove jewelry or any other metallic object that may come into contact with energized parts.

Unless otherwise specified, all products are intended to be grounded during normal use.

Grounding is provided by connecting the mains plug to a wall socket with a protective earth terminal. If an earth lug is provided on the product, it should be connected to the protective earth at all times, by a wire with a diameter of 18 AWG or wider. Rack-mounted equipment should be mounted only in earthed racks and cabinets.

Always make the ground connection first and disconnect it last. Do not connect telecommunication cables to ungrounded equipment. Make sure that all other cables are disconnected before disconnecting the ground.

Connecting AC Mains

Make sure that the electrical installation complies with local codes.

Always connect the AC plug to a wall socket with a protective ground.

The maximum permissible current capability of the branch distribution circuit that supplies power to the product is 16A. The circuit breaker in the building installation should have high breaking capacity and must operate at short-circuit current exceeding 35A.

Always connect the power cord first to the equipment and then to the wall socket. If a power switch is provided in the equipment, set it to the OFF position. If the power cord cannot be readily disconnected in case of emergency, make sure that a readily accessible circuit breaker or emergency switch is installed in the building installation.

In cases when the power distribution system is IT type, the switch must disconnect both poles simultaneously.

Connecting DC Power

Unless otherwise specified in the manual, the DC input to the equipment is floating in reference to the ground. Any single pole can be externally grounded.

Due to the high current capability of DC power systems, care should be taken when connecting the DC supply to avoid short-circuits and fire hazards.

DC units should be installed in a restricted access area, i.e. an area where access is authorized only to qualified service and maintenance personnel.

Make sure that the DC power supply is electrically isolated from any AC source and that the installation complies with the local codes.

The maximum permissible current capability of the branch distribution circuit that supplies power to the product is 16A. The circuit breaker in the building installation should have high breaking capacity and must operate at short-circuit current exceeding 35A.

Before connecting the DC supply wires, ensure that power is removed from the DC circuit. Locate the circuit breaker of the panel board that services the equipment and switch it to the OFF position. When connecting the DC supply wires, first connect the ground wire to the corresponding terminal, then the positive pole and last the negative pole. Switch the circuit breaker back to the ON position.

A readily accessible disconnect device that is suitably rated and approved should be incorporated in the building installation.

If the DC power supply is floating, the switch must disconnect both poles simultaneously.

Connecting Data and Telecommunications Cables

Data and telecommunication interfaces are classified according to their safety status.

The following table lists the status of several standard interfaces. If the status of a given port differs from the standard one, a notice will be given in the manual.

V.11, V.28, V.35, V.36, RS-530, X.21,

10 BaseT, 100 BaseT, Unbalanced E1,

E2, E3, STM, DS-2, DS-3, S-Interface

ISDN, Analog voice E&M xDSL (without feeding voltage),

Balanced E1, T1, Sub E1/T1

SELV Safety Extra Low Voltage:

Ports which do not present a safety hazard. Usually up to 30 VAC or 60 VDC.

FXS (Foreign Exchange Subscriber)

FXO (Foreign Exchange Office), xDSL

(with feeding voltage), U-Interface

ISDN

TNV-1 Telecommunication Network Voltage-1:

Ports whose normal operating voltage is within the limits of SELV, on which overvoltages from telecommunications networks are possible.

TNV-2 Telecommunication Network Voltage-2:

Ports whose normal operating voltage exceeds the limits of SELV (usually up to 120 VDC or telephone ringing voltages), on which overvoltages from telecommunication networks are not possible. These ports are not permitted to be directly connected to external telephone and data lines.

TNV-3 Telecommunication Network Voltage-3:

Ports whose normal operating voltage exceeds the limits of SELV (usually up to 120 VDC or telephone ringing voltages), on which overvoltages from telecommunication networks are possible.

Always connect a given port to a port of the same safety status. If in doubt, seek the assistance of a qualified safety engineer.

Always make sure that the equipment is grounded before connecting telecommunication cables.

Do not disconnect the ground connection before disconnecting all telecommunications cables.

Some SELV and non-SELV circuits use the same connectors. Use caution when connecting cables.

Extra caution should be exercised during thunderstorms.

When using shielded or coaxial cables, verify that there is a good ground connection at both ends. The earthing and bonding of the ground connections should comply with the local codes.

The telecommunication wiring in the building may be damaged or present a fire hazard in case of contact between exposed external wires and the AC power lines. In order to reduce the risk,

there are restrictions on the diameter of wires in the telecom cables, between the equipment and the mating connectors.

Caution To reduce the risk of fire, use only No. 26 AWG or larger telecommunication line cords.

Attention Pour réduire les risques s’incendie, utiliser seulement des conducteurs de télécommunications 26 AWG ou de section supérieure.

Some ports are suitable for connection to intra-building or non-exposed wiring or cabling only. In such cases, a notice will be given in the installation instructions.

Do not attempt to tamper with any carrier-provided equipment or connection hardware.

Electromagnetic Compatibility (EMC)

The equipment is designed and approved to comply with the electromagnetic regulations of major regulatory bodies. The following instructions may enhance the performance of the equipment and will provide better protection against excessive emission and better immunity against disturbances.

A good earth connection is essential. When installing the equipment in a rack, make sure to remove all traces of paint from the mounting points. Use suitable lock-washers and torque. If an external grounding lug is provided, connect it to the earth bus using braided wire as short as possible.

The equipment is designed to comply with EMC requirements when connecting it with unshielded twisted pair (UTP) cables. However, the use of shielded wires is always recommended, especially for high-rate data. In some cases, when unshielded wires are used, ferrite cores should be installed on certain cables. In such cases, special instructions are provided in the manual.

Disconnect all wires which are not in permanent use, such as cables used for one-time configuration.

The compliance of the equipment with the regulations for conducted emission on the data lines is dependent on the cable quality. The emission is tested for UTP with 80 dB longitudinal conversion loss (LCL).

Unless otherwise specified or described in the manual, TNV-1 and TNV-3 ports provide secondary protection against surges on the data lines. Primary protectors should be provided in the building installation.

The equipment is designed to provide adequate protection against electro-static discharge (ESD).

However, it is good working practice to use caution when connecting cables terminated with plastic connectors (without a grounded metal hood, such as flat cables) to sensitive data lines.

Before connecting such cables, discharge yourself by touching earth ground or wear an ESD preventive wrist strap.

FCC-15 User Information

This equipment has been tested and found to comply with the limits of the Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the Installation and Operation manual, may cause harmful interference to the radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Canadian Emission Requirements

This Class A digital apparatus meets all the requirements of the Canadian Interference-Causing

Equipment Regulation.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Warning

Warning per EN 55022 (CISPR-22)

This is a class A product. In a domestic environment, this product may cause radio interference, in which case the user will be required to take adequate measures.

Avertissement Cet appareil est un appareil de Classe A. Dans un environnement résidentiel, cet appareil peut provoquer des brouillages radioélectriques. Dans ces cas, il peut être demandé à l’utilisateur de prendre les mesures appropriées.

Achtung Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei

Betrieb dieses Gerätes Rundfunkströrungen auftreten, in welchen Fällen der

Benutzer für entsprechende Gegenmaßnahmen verantwortlich ist.

Quick Start Guide

Installation of SPD-703-1 should be carried out only by an experienced technician. If you are familiar with SPD-703-1, use this quick start guide to set it up for operation.

This guide describes the standalone version of the converter. Perform the installation procedures for both the local and the remote units.

Instructions given below detail the settings that you have to make in order to configure SPD-703-1 for proper operation. The table, which comes after the configuration instruction lists the SPD-703-1 internal jumpers and their possible settings.

Configuring SPD-703-1

To configure SPD-703-1:

1. Disconnect all the cables connected to SPD-703-1.

2. Turn the unit over (bottom facing up).

3. Unscrew the four cover screws and keep them in a safe place.

4. Turn the unit over (bottom facing down).

5. Remove the SPD-703-1 top cover by pulling it straight up.

6. Set internal jumpers.

7. Close the SPD-703-1 cover by reversing the procedure described in steps 2-5.

Jumper Description

CHASS, JP1

Values

Controls the connection between the SPD-703-1 signal ground and the frame (chassis) ground

CONNECT – Signal ground is connected to the frame ground

DISCONNECT – Signal ground is disconnected from the frame ground

CONNECT

Note

Setting the CHASS jumper to DISCONNECT may render the equipment unsafe for connection to unprotected telecommunication networks in locations where permanent excessive voltage is present on the lines.

Quick Start Guide SPD-703-1 Installation and Operation Manual

Jumper Description

TC G.703, J9 Selects the transmit timing source

Jumper Description

BAUD RATE,

J1

CONNECT

TO, J10

Selects the DTE rate

Selects a type of the user unit connected to the DTE interface of SPD-703-1

V.54 DELAY,

J5

POLR, J2

Controls the V.54 delay to prevent multiple loopbacks in tail-end applications

Selects coding method for binary 1 on the receive line

POLX, J3

RDL, J6

Selects coding method for binary 1 on the transmit line

Controls remote digital loopback activation at the remote unit

Values

LBT – The TX pair timing is the recovered clock from the G.703 RX pair

EXT – The TX pair from the G.703 side and the transmit timing from the digital interface side are externally provided

INT – The TX pair and the transmit timing are from the internal source

LBT

Values

64K – 64 kbps

56K – 56 kbps

48K – 48 kbps

64K

DTE – Connection to DTE, with transmit and receive timing derived from the SPD-703-1 recovered clock

DCE – Connection to DCE, while both the

DCE and SPD-703-1 operate with external transmit timing

DCE21 – Connection to X.21 DCE. The

SPD-703-1 transmit and receive timing are derived from the

DCE

DTE (for test purposes)

ON – V.54 delay is enabled

OFF – V.54 delay is disabled

ON

“1” – Binary one is coded as 1100 and binary zero is coded as 1010

“0” – Binary one is coded as 1010 and binary zero is coded as 1100

“1” – Binary one is coded as 1100 and binary zero is coded as 1010

“0” – Binary one is coded as 1010 and binary zero is coded as 1100

“1”

“1”

EN – Remote digital loopback activation is enabled at the remote unit

DIS – Remote digital loopback activation is disabled at the remote unit

EN

SPD-703-1

SPD-703-1 Installation and Operation Manual Quick Start Guide

Connecting the Cables

Connecting the Line

To connect the line:

• Connect the line cable to the terminal block connector on the SPD-703-1 rear panel.

Connecting the DTE

To connect the DTE:

• Connect the DTE cable to the appropriate SPD-703-1 rear panel connector.

Quick Start Guide SPD-703-1 Installation and Operation Manual

Connecting to the Power

• Connect the power cable to the power connector on the rear panel.

The unit has no power switch. It starts operating when the power connector at the rear is connected to the mains.

SPD-703-1

SPD-703-1 Installation and Operation Manual Quick Start Guide

SPD-703-1 does not require operator attention once installed and configured.

Verifying Performance

When data is being transferred, observe that the following front panel LEDs light or blink:

Indicator Status

PWR ON

TD Blinking or OFF

RD Blinking or OFF

LOS OFF

ERR OFF

TEST OFF

Quick Start Guide SPD-703-1 Installation and Operation Manual

SPD-703-1

Contents

Chapter 1. Introduction

1.1

1.2

1.3

1.4

Chapter 2. Installation and Setup

2.1

2.2

2.3

Chapter 3. Operation

3.1

3.2

Chapter 4. Troubleshooting and Diagnostics

4.1

4.2

SPD-703-1 i

Table of Contents

Chapter 5. SPD-703-1/R Card

5.1

5.2

5.3

5.4

Installing SPD-703-1/R into the ASM-MN-214 Card Cage..........................................

Appendix A. Connector Wiring

Appendix B. IR-ETH Interface Module ii SPD-703-1

Chapter 1

Introduction

1.1 Overview

SPD-703-1 is an advanced rate and interface converter that converts the G.703 codirectional interface to several standard data communication interfaces.

Versions

SPD-703-1 is available in two versions:

• SPD-703-1 standalone unit

• SPD-703-1/R card, designed to fit RAD’s ASM-MN-214, 19-inch modem rack.

Application

shows a typical application in which SPD-703-1 acts as an interface and rate converter to connect data communications equipment to PCM transmission equipment.

DTE

V35

48 kbps

SPD-703-1

64 kbps

Channel

Bank or PCM

Equipment

PCM

Network

64 kbps

Channel

Bank or PCM

Equipment

SPD-703-1

Figure 1-1. Typical SPD-703-1 Application

V35

48 kbps

DTE

Features

SPD-703-1 has the following features:

• Conversion between G.703 codirectional interface and V.24, V.35, V.36

(RS-422), X.21, RS-530 interfaces, or a built-in Ethernet bridge (IR-ETH)

• Selectable data rates: 48, 56, 64 kbps

• Selectable transmit timing source

• Line protection circuits

• Meets G.823 jitter requirements

• V.54 diagnostic (loops 2 and 3)

• Internal test pattern generator

• ITU V.110 compatible (conversion from 56 to 64 kbps)

• Second asynchronous subchannel operating at up to 1.2 kbps.

SPD-703-1 Overview 1-1

Chapter 1 Introduction SPD-703-1 Installation and Operation Manual

shows a 3D view of the standalone SPD-703-1 unit.

Figure 1-2. SPD-703-1 3D View

The controls and indicators are on the front panel. For a description of the front panel, refer to

Front Panel Indicators and Switches in Chapter 3 .

The interface and power connectors are on the rear panel. For a description of

the rear panel, refer to Connecting the Interfaces in

SPD-703-1 converts the G.703 codirectional interface to standard data communication interfaces. SPD-703-1 can perform both interface and rate conversions, and also features diagnostic testing capabilities.

Main Principles of Operation

Interface Conversion

SPD-703-1 converts from the G.703 codirectional interface to the following interfaces: V.24, V.35, V.36/RS-422, X.21, RS-530 or built-in Ethernet bridge.

The composite timing/data signal conveys the 64 kHz bit-timing information, the

8 kHz octet information (by introducing violations into the signal) and the 64 kbps data pattern.

G.703 codirectional signals, in each transmission direction, are coded as follows:

• A binary one (64 kbps bit period) is coded as a block of the following four bits: 1 1 0 0

• A binary zero (64 kbps bit period) is coded as a block of the following four bits: 1 0 1 0.

The binary signal is converted into a three-level signal by alternating the polarity of the blocks. The alternation of the block polarity is violated every eight blocks as illustrated in

.

The bit stream from the DTE can be inverted, prior to the conversion to G.703.

The received binary signal to the DTE is inverted at the same time.

1-2 Functional Description SPD-703-1

SPD-703-1 Installation and Operation Manual

Bit No.

Chapter 1 Introduction

6 7 8 1 2 3 4 5 6 7 8 1

64 kbit/s data 0 0 0 1 1 0 1 0 1 1 1 0

Binary Data

Three-level Data

Violated Data

Figure 1-3. G.703 Code Conversion

Rate Conversion

Using SPD-703-1 as a rate converter, you can connect terminal equipment with a data rate of 48 or 56 kbps to a 64 kbps G.703 service interface line. At 48 or

56 kbps, the extra bandwidth can be used for one of several purposes

(user-selectable):

• To guarantee the “ones density” requirement, by insertion of a “1” after every 7 bits (for 56 kbps only)

• To pass a control signal end-to-end

• As a 1200 bps asynchronous secondary subchannel for connecting additional data terminal equipment over the same link.

Conversion from 64 to 56 kbps is performed by suppressing bit position number

8. This bit position coincides with the introduced violation (

) and thus

Chapter 1 Introduction SPD-703-1 Installation and Operation Manual conforms to the requirements of the ITU V.110 standard (56 to 64 kbps rate conversion).

The suppressed bit is optionally used for RTS-DCD end-to-end signaling (or async secondary channel). T1 (1.544 Mbps) applications require this bit position to be set to a binary “1”. This is achieved by leaving the RTS pin open (not connected) and selecting “MARK=1” (with the data polarity jumper). Conversion from 64 to

48 kbps is performed by suppressing bit position number 7 and bit position number 8. The suppressed bits are used as described above for 64 to 56 kbps conversion.

Asynchronous Subchannel

End-to-End Signaling

End-to-end signaling (local RTS to remote DCD) is sometimes not used with the high-speed data channel, in which case it can be used for a full-duplex transparent asynchronous subchannel.

Sampling

The subchannel is multi-sampled into the 64 kbps trunk. The sampling rate is at least 8 kHz. The bit rate can be up to 1200 bps, asynchronous. (There is no need to send the async parameters, start, stop, character length etc.)

Control Signals

No control signals are associated with this asynchronous subchannel.

Timing

The G.703 codirectional signal is made up of two balanced signals, each carrying timing and information:

• Receive signal

• Transmit signal.

The timing signal associated with each direction of transmission is in the same direction as the information signal as illustrated in

1-4 Functional Description SPD-703-1

SPD-703-1 Installation and Operation Manual

PCM

EQUIP.

SPD-703-1

Chapter 1 Introduction

DATA COMM. EQUIP.

ASYNCHRONOUS

TERMINAL

Information signal

Timing signal

Figure 1-4. G.703 Codirectional Signaling

The transmit clock is set to one of the following modes:

• Internal timing mode: uses the SPD-703-1 internal clock (used primarily for testing and diagnostic purposes)

• External timing mode: uses the external transmit clock on the data communications side

• G.703 receive timing mode: uses the recovered clock from the G.703 receive pair.

Each of these is illustrated in its own section below.

Internal Clock Timing Mode

The internal oscillator is usually used for testing purposes, to check the G.703 transmit timing, but it can be also be used with systems that do not have a clock source as illustrated in

.

PCM

EQUIPMENT

ELASTIC

BUFFER

OSCILLATOR

DATA

COMMUNICATIONS

EQUIPMENT

SPD 703-1

Information signal

Timing signal

Figure 1-5. Internal Clock Timing Mode

Chapter 1 Introduction SPD-703-1 Installation and Operation Manual

External Transmit Clock Timing Mode

When the external transmit clock on the data communications side is used for

G.703 transmit timing, the receive and transmit directions of transmission within

SPD-703-1 are totally independent as illustrated in

.

PCM

EQUIPMENT

ELASTIC

BUFFER

ELASTIC

BUFFER

SPD-703-1

DATA

COMMUNICATIONS

EQUIPMENT

Information signal

PCM

EQUIPMENT

Timing signal

Figure 1-6. External Transmit Clock Timing Mode

G.703 Receive Timing Mode

When G.703 receive timing is used for G.703 transmit timing, three timing options for the data communication side, associated with the loopback timing

(LBT) on the G.703 side, are available:

• Receive clock and transmit clock are both outputs from the SPD-703-1, serving as a DCE as illustrated in

ELASTIC

BUFFER

ELASTIC

BUFFER

48/56/64 kbps

DTE

DATA

TERMINAL

EQUIPMENT

SPD-703-1

Information signal

Timing signal

Figure 1-7. LBT-DTE Connection

• Receive Clock is the output from SPD-703-1, while Transmit Clock is the input to SPD-703-1 from an external DCE, for connection to a tail circuit as illustrated in

.

1-6 Functional Description SPD-703-1

SPD-703-1 Installation and Operation Manual

ELASTIC

BUFFER

ELASTIC

BUFFER

Chapter 1 Introduction

DATA

COMMUNICATIONS

EQUIPMENT

Cross cable

PCM

EQUIPMENT

Figure 1-8. LBT-DCE Connection

• Receive Clock and Transmit Clock are both inputs to SPD-703-1 (with X.21 interface only) serving as a DTE as illustrated in

. In order to operate error-free, both the PCM equipment clock and the DCE clock have to be synchronized.

ELASTIC

BUFFER

ELASTIC

BUFFER

SPD-703-1

DATA

COMMUNICATIONS

EQUIPMENT

Information signal

Timing signal

Figure 1-9. DCE21 Connection

Tail-End Clocking

Transmit clock from the external DTE source is provided for applications requiring modems in order to reach a remote DTE as illustrated in

. Use the LBT

- DCE timing mode with SPD-703-1 as illustrated in

.

Figure 1-10. Tail Circuit Application

Chapter 1 Introduction

Diagnostics

SPD-703-1 Installation and Operation Manual

V.54 Diagnostics

SPD-703-1 performs V.54 diagnostics, which includes remote digital loopback, local digital loopback and local analog loopback testing. The local digital loopback is activated manually from the front panel. The remote digital loopback and the local analog loopback can be activated manually from the front panel or via the

DTE interface.

V.52 Diagnostics

SPD-703-1 performs V.52 diagnostics, using a built-in BER tester to test the local and the remote units and the link between them. When you activate the PATT button on the front panel, the circuit sends and checks a pseudo-random proprietary pattern. The ERR LED flashes for each bit error detected. The test can be carried out in local analog loopback, in remote digital loopback or in normal point-to-point operation opposite a remote SPD-703-1.

G.703

Interface

Type

Line

Codirectional 64 kbps

4-wire, 19 to 26 AWG

Physical

Range

Impedance

Balance

Terminal block

Up to 800m (0.5 mile) over 24 AWG

120 Ω nominal

Better than 45 dB (up to 256 kHz)

Better than 35 dB (up to 384 kHz)

Return Loss Better than 20 dB (up to 256 kHz)

Better than 14 dB (up to 384 kHz)

Clock Frequency 64 kHz

Frequency Tracking ± 500 ppm

“Pulse” Amplitude 1.0V nominal

“Zero” Amplitude 0V ± 0.1V max

Jitter Performance According to G.823 requirements

Line Protection According to ITU K.21 requirements

1-8 Technical Specifications SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 1 Introduction

DTE Interface

Type

Data Rates

V.24, V.35, V.36, X.21, RS-530,

48, 56 or 64 kbps

Spare Bandwidth at

48 or 56 kbps

An additional asynchronous channel at 1.2 kbps

Transfer of RTS to DCD control signal, end-to-end

Fixed “1” to guarantee “1”s density over the T1 network

Physical Interface • V.24, 25 pin, D-type, female

• V.35, 34 pin, female

• X.21, 15 pin, D-type, female

• RS-530, 25 pin, D-type, female

• V.36, 37 pin, D-type, female via 30 cm adapter cable

• Ethernet, via UTP/RJ-45 connector or via BNC connector

G.703

Transmit

Timing

Loopback Derived from the G.703 receive pair:

• RC and TC from SPD-703-1 to a DTE

• RC from SPD-703-1 and TC from an external tail modem

• RC and TC from an external DCE to SPD-703-1

External Derived from the DTE clock

Diagnostics

Physical

Internal Supplied by internal oscillator

Local Digital

Loopback

(V.54 loop 1)

Remote Digital

Loopback

(V.54 loop 2)

Activated by a front panel switch (DIG)

Activated by a front panel switch (REM), or from the DTE interface (except for X.21 and Ethernet)

Analog Loopback

(V.54 loop 3)

Activated by a front panel switch (ANA), or from the DTE interface (except for X.21 and Ethernet)

Internal BER Tester Generating a 511-bit pseudo-random test pattern via a front panel switch (PATT)

SPD-703-1

Height

Width

4.4 cm / 1.7 in

21.5 cm / 8.5 in

Chapter 1 Introduction

Depth

Weight

SPD-703-1/R

Weight

Power Supply

AC/DC Source

DC Source

Environment

Temperature

Humidity

SPD-703-1 Installation and Operation Manual

24.0 cm / 9.6 in

1.4 kg / 3.1 lb.

Fits one slot of the ASM-MN-214 modem rack

360g / 0.8 lb

Wide range power supply:

100–240 VAC ( ± 10%), 50 or 60 Hz, 5W

Or

40–72 VDC, 5W

24 VDC (18 to 32 VDC), 5W

0–50 ° C / 32–122 ° F

Up to 90%, non-condensing

1-10 Technical Specifications SPD-703-1

Chapter 2

Installation and Setup

This chapter describes installation and setup procedures for the standalone

SPD-703-1 unit.

SPD-703-1 is delivered completely assembled. It is designed for tabletop or

19-inch rack installation. For instructions on installation of a single unit or two units in a 19-inch rack, refer to the rack mounting kit for 19-inch racks guide that comes with the RM kit.

After installing the unit, refer to Chapter 3 to assure normal operation.

In case a problem encountered, refer to Chapter 4 for test and diagnostic

instructions.

Warning

Internal settings, adjustment, maintenance, and repairs may be performed only by a skilled technician who is aware of the hazards involved.

Always observe standard safety precautions during installation, operation, and maintenance of this product.

2.1 Site Requirements and Prerequisites

AC/DC powered SPD-703-1 units should be installed within 1.5 m (5 feet) of an easily accessible grounded AC outlet capable of furnishing a supply voltage in the range of 100 to 240 VAC of 40-72 VDC.

DC powered SPD-703-1 units require a 24 VDC power source.

Allow at least 90 cm (36 in) of frontal clearance for operating and maintenance accessibility. Allow at least 10 cm (4 in) clearance at the rear of the unit for signal lines and interface cables.

The ambient operating temperature of SPD-703-1 is 0 to 50 ° C (32 to 122 ° F) at relative humidity of 90%, non-condensing.

SPD-703-1 Site Requirements and Prerequisites 2-1

Chapter 2 Installation and Setup SPD-703-1 Installation and Operation Manual

The SPD-703-1 package includes the following items:

• One SPD-703-1 or SPD-703-1/R unit

• Ethernet over SDH/SONET and Converters CD

• CBL-530/449 adapter cable for the SPD-703-1 units with V.36 interface

• Power connection accessories (depending on the power option ordered):

Power cord (VAC) and AC/DC plug (-48 VDC)

Terminal block kit (24 VDC)

• RM-17 rack mount kit (if ordered).

This section describes how to configure SPD-703-1 by setting the internal jumpers and switches as required for your application.

To install SPD-703-1:

1. Determine the required configuration of SPD-703-1 and set the internal jumpers accordingly.

2. Connect the DTE. Refer to

for additional information.

3. Connect the line. Refer to

for additional information.

4. If required, connect asynchronous subchannel. Refer to

for additional information.

5. Connect power to the unit. Refer to

for additional information.

Warning

Access to the inside of the equipment is permitted only to the authorized and qualified personnel.

To avoid accidental electric shock, always disconnect the interface cables and the power cord before removing the unit from its casing.

Line voltages are present inside SPD-703-1 when it is connected to power and/or the lines. Moreover, under certain fault conditions, dangerous voltages may appear on the lines connected to the unit.

Any adjustment, maintenance and repair of the opened instrument under voltage must be avoided as much as possible and, when inevitable, should be carried out only by a skilled technician who is aware of the hazard involved. Capacitors inside the unit may still be charged even after the unit has been disconnected from its source of power.

2-2 Installing SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 2 Installation and Setup

Caution

SPD-703-1 contains components sensitive to electrostatic discharge (ESD). To prevent ESD damage, avoid touching the internal components. Before moving jumpers, touch the SPD-703-1 rear panel.

Configuring SPD-703-1

illustrates the layout of the SPD-703-1 printed-circuit board.

provides details on the functions of the internal jumpers and their default settings.

To configure SPD-703-1:

1. Disconnect all the cables connected to SPD-703-1.

2. Turn the unit over (bottom facing up).

3. Unscrew the four cover screws and keep them in a safe place.

4. Turn the unit over (bottom facing down).

5. Remove the SPD-703-1 top cover by pulling it straight up.

6. Set internal jumpers.

7. Close the SPD-703-1 cover by reversing the procedure described in steps 2-5.

64K

56K

48K

BAUD RATE

“1”

“0”

POLX

“1”

POLR “0”

V.54 DLY

OFF

ON

TC G.703

INT

EXT

LBT

CONNECT TO:

DTE

DCE

DCE21

RDL

DIS

EN

DISCONN

CONNECT

Figure 2-1. SPD-703-1 PCB Layout

SPD-703-1 Installing SPD-703-1 2-3

Chapter 2 Installation and Setup SPD-703-1 Installation and Operation Manual

Jumper Description

Table 2-1. SPD-703-1 Internal Jumpers

Values

CHASS, JP1

Controls the connection between the SPD-703-1 signal ground and the frame (chassis) ground

CONNECT – Signal ground is connected to the frame ground

DISCONNECT – Signal ground is disconnected from the frame ground

CONNECT

Note : Setting the CHASS jumper to DISCONNECT can make the equipment unsafe for connection to unprotected telecommunication networks in certain places where permanent excessive voltages are present on the lines.

TC G.703, J9 Selects the transmit timing source

BAUD RATE,

J1

Selects the DTE rate

LBT – The TX pair timing is the recovered clock from the G.703 RX pair

EXT – The TX pair from the G.703 side and the transmit timing from the digital interface side are externally provided

INT – The TX pair and the transmit timing are from the internal source

LBT

64K – 64 kbps

56K – 56 kbps

48K – 48 kbps

64K

2-4 Installing SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 2 Installation and Setup

Table 2-1. SPD-703-1 Internal Jumpers (Cont.)

Jumper Description Values

CONNECT

TO, J10

Selects a type of the user unit connected to the DTE interface of SPD-703-1

V.54 DELAY,

J5

POLR, J2

Controls the V.54 delay to prevent multiple loopbacks in tail-end applications

Selects coding method for binary 1 on the receive line

DTE – Connection to DTE, with transmit and receive timing derived from the SPD-703-1 recovered clock

DCE – Connection to DCE, while both the

DCE and SPD-703-1 operate with external transmit timing

DCE21 – Connection to X.21 DCE. The

SPD-703-1 transmit and receive timing are derived from the

DCE

DTE (for test purposes)

ON – V.54 delay is enabled

OFF – V.54 delay is disabled

ON

POLX, J3

RDL, J6

Selects coding method for binary 1 on the transmit line

Controls remote digital loopback activation at the remote unit

“1” – Binary one is coded as 1100 and binary zero is coded as 1010

“0” – Binary one is coded as 1010 and binary zero is coded as 1100

“1” – Binary one is coded as 1100 and binary zero is coded as 1010

“0” – Binary one is coded as 1010 and binary zero is coded as 1100

“1”

“1”

EN – Remote digital loopback activation is enabled at the remote unit

DIS – Remote digital loopback activation is disabled at the remote unit

EN

SPD-703-1 Installing SPD-703-1 2-5

Chapter 2 Installation and Setup SPD-703-1 Installation and Operation Manual

Connecting the Interfaces

illustrates the AC-powered SPD-703-1 unit rear panel.

DTE

XMT RCV GND

Figure 2-2. SPD-703-1 Rear Panel, AC Version

Connecting the Line Interface

The terminal block provides four connecting points to the transmit and receive twisted pair lines and a fifth one for ground connection. The transmit and receive pairs are polarity insensitive.

To connect the line interface:

1. Connect the transmit pair to the terminals marked XMT (data output of

SPD-703-1).

2. Connect the receive pair to the terminals marked RCV (data input to

SPD-703-1).

Warning

Do not touch bare line wires.

2-6 Installing SPD-703-1

SPD-703-1 Installation and Operation Manual

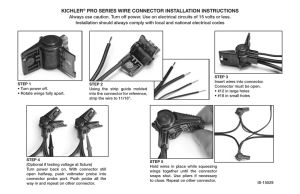

To insert the wires:

1. Insert the screwdriver into a square hole.

Chapter 2 Installation and Setup

Figure 2-3. Connecting the Terminal Block – Step 1

2. Raise the inserted screwdriver, putting pressure on the ramp within the square hole.

Figure 2-4. Connecting the Terminal Block – Step 2

3. Insert the stripped end of the wire and remove the screwdriver.

Figure 2-5. Connecting the Terminal Block – Step 3

SPD-703-1 Installing SPD-703-1 2-7

Chapter 2 Installation and Setup SPD-703-1 Installation and Operation Manual

Connecting the DTE Interface

The rear-panel DTE connector provides interface for data input/output and clock reference between SPD-703-1 and the DTE. RAD offers interface cables for the

DTE connection, refer to

for the DTE interface connector description.

Table 2-2. DTE Interfaces and Matching Connector Cables

DTE Interface Description RAD Cable

V.24 (RS-232)

25-pin, D-type, female. Refer to Appendix A for the connector

pinout.

V.35

CBL-HBT/V24

34-pin, female. Refer to Appendix A for the connector pinout.

CBL-HBT/V35

Table 2-2. DTE Interfaces and Matching Connector Cables (Cont.)

DTE Interface Description

RS-530

25-pin, D-type. Refer to Appendix A for the connector pinout.

V.36

X.21

IR-ETH

Via adapter cable converting between RS-530 connector and 37-pin,

D-type, female connector. Refer to Appendix A for the cable pinout.

15-pin, D-type, female. Refer to Appendix A for the connector

pinout.

RJ-45 or BNC. Refer to Appendix B for the module description.

RAD Cable

CBL-HBT/RS-530

CBL-530/449

CBL-HBT/X21

2-8 Installing SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 2 Installation and Setup

Note

Connecting an Asynchronous Subchannel

To connect an asynchronous subchannel, use a special split cable (

). The cable connects the primary and the secondary channels via the DTE connector.

The asynchronous subchannel can operate only when the primary channel is run at 48 or 56 kbps on clear channel, and when there are SPD-703-1 units at both local and remote ends.

SPD-703-1

Connector

DTE

Connector

TD TD

RD RD

TC TC

RC RC

DCD

RTS

CTS

SG

PG

DSR

DCD

RTS

CTS

SG

PG

DSR

N.C.

Async

XMT. Data

Async

RCV. Data

7 SG

1 PG

6 DSR

8 DCD

3 RD

2 TD

4 RTS

5 CTS

Async Terminal Connector

Figure 2-6. Connecting an Asynchronous Subchannel to SPD-703-1

Note

• Signal ground and protective ground are used for the high speed synchronous channel as well as for the asynchronous channel.

• The DCD and RTS pins are used only to receive and transmit data for the asynchronous channel. They cannot be used as control signals with the high speed synchronous channel.

SPD-703-1 Installing SPD-703-1 2-9

Chapter 2 Installation and Setup SPD-703-1 Installation and Operation Manual

Connecting to Power

The wide-range AC/DC power supply inside SPD-703-1 accepts current from both

AC and DC sources. From an AC source, the power supply can receive any voltage in the range of 100 to 240 VAC. From a DC source, the 48 VDC power supply can receive any voltage in the range of 40 to 72 VDC.

When connecting the DC power, the PWR pin must be connected to the ungrounded line of the central battery (either − or + ). The RTN pin must be connected to the grounded line of the central battery. The GND pin must be connected to the protected earth of the building installation.

Warning

Before powering this unit, the protective earth terminals of the instrument must be connected to the protective ground conductor of the power cord. The power plug may only be inserted in a power outlet provided with a protective earth contact. The protective action must not be negated by the use of an extension cord (power cable) without a protective conductor (grounding).

Whenever it is likely that the protection offered by the internal fuses has been impaired, the instrument must be made inoperative and be secured against any unintended operation.

Connecting to AC/DC Power

SPD-703-1 is supplied with a Wide Range AC/DC power supply. This unit is equipped with a standard AC-type 3-prong power input connector located on the unit rear panel. This power input connector can be used for both AC and DC voltage inputs. AC or DC power should be supplied to SPD-703-1 through the 5feet (1.5m) standard power cable terminated by a standard 3-prong plug.

To connect SPD-703-1 to AC power:

1. Connect the power cable to the connector on the SPD-703-1 rear panel.

2. Connect the power cable to the electricity outlet.

To connect SPD-703-1 to 48 VDC power:

• Refer to the AC/DC connection supplement at the end of this manual.

Connecting to DC Power

Caution

To connect SPD-703-1 to 24V DC power:

• Refer to the DC connection terminal block connector supplement at the end of this manual.

The DC installation procedure must be performed by a qualified technician.

2-10 Installing SPD-703-1

Chapter 3

Operation

This chapter provides the following information for the standalone SPD-703-1:

• SPD-703-1 front-panel indicators and controls

• Operating procedures (turn-on, front-panel indications, performance monitoring and turn-off).

Installation procedures provided in

Chapter 2 must be completed and checked

before attempting to operate SPD-703-1.

3.1 Front Panel Indicators and Switches

shows the SPD-703-1 standalone unit front panel. The front panel is equipped with push button controls and LED indicators.

lists the functions of the controls and indicators.

DIG ANA REM PATT

PWR TD RD LOS TEST ERR

Figure 3-1. SPD-703-1 Front Panel

Table 3-1. SPD-703-1 Front Panel Controls and Indicators

Name Type Function

PWR

TD

RD

LOS

TEST

ERR

DIG

Green LED ON – Power is on

Yellow LED ON – Steady SPACE is being transmitted

Blinks – Data is transmitted

Yellow LED ON – Steady SPACE is being received

Blinks – Data is received

Red LED

Red LED

ON – RX pair does not contain the violations required

ON – SPD-703-1 is in any of the three loopback modes, or the

PATT pushbutton is pressed

Yellow LED ON or blinks – Errors are present in the test pattern.

Pushbutton The digital loopback pushbutton causes the local SPD-703-1 to

loop received data to its transmitter ( Figure 4-3 ).

Note

If the LOS LED is ON, verify that the line is connected properly.

SPD-703-1 Front Panel Indicators and Switches 3-1

Chapter 3 Operation SPD-703-1 Installation and Operation Manual

Table 3-1. SPD-703-1 Front Panel Controls and Indicators (Cont.)

Name Type Function

ANA Pushbutton The local loopback (V.54 loop 3) pushbutton causes the local SPD-

703-1 to loop its transmitter output back to its receiver

( Figure 4-1 ). This loopback may also be activated from the DTE

(excluding X.21 and Ethernet interfaces).

REM

PATT

Pushbutton The remote digital loopback (V.54 Loop 2) pushbutton causes the remote SPD-703-1 to loop received data to its transmitter

( Figure 4-2 ). This loopback may be also activated from the DTE

(excluding X.21 and Ethernet interfaces).

Pushbutton The PATT switch causes SPD-703-1 to send and receive a test pattern. If errors are encountered, the ERR indicator lights up.

Turning On SPD-703-1

SPD-703-1 is turned on as soon as power is connected. When power is connected, the PWR indicator lights up and remains lit as long as SPD-703-1 receives power.

SPD-703-1 requires no operator attention once installed, with the exception of occasional monitoring of front panel indicators. Intervention is only required when the converter must be configured to new operational requirements, or the diagnostic tests must be performed.

Normal Indications

shows the correct status of the SPD-703-1 indicators after the local and remote modems are synchronized and data is being transferred.

Table 3-2. SPD-703-1 Indicator Status

Indicator Status

PWR ON

TD Blinking or OFF

RD Blinking or OFF

LOS OFF

ERR OFF

TEST OFF

If the LEDs do not reflect the above status, ensure that:

• The units are synchronized.

• The four front-panel pushbuttons are in the OFF position.

3-2 Operating SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 3 Operation

Turning Off SPD-703-1

To turn off the unit, remove the power cord from the power source.

Chapter 3 Operation SPD-703-1 Installation and Operation Manual

3-4 Operating SPD-703-1

SPD-703-1

Chapter 4

Troubleshooting and

Diagnostics

This chapter describes how to perform diagnostics tests on SPD-703-1.

Diagnostic tests on SPD-703-1 consist of the following:

• Check that the system is operating normally

• Isolate faulty equipment or cables

• Identify other sources of system malfunction.

The tests are activated by control pushbuttons on the SPD-703-1 front panel and monitored via LED indicators. For description of SPD-703-1 controls and

indicators and their functionality, refer to Chapter 3 .

SPD-703-1 supports several types of loopback tests for evaluating the operation of the data system equipment and its line circuits. Using these loopbacks, you can test communication between the attached equipment, internal circuitry of the local and remote modems.

Loopback test are best performed in the following order:

1. Local analog loopback

2. Remote digital loopback

3. Local digital loopback.

Before testing the operation of the data system equipment and line circuits, ensure that all the units are powered up and configured properly.

V.54 Loopbacks 4-1

Chapter 4 Troubleshooting and Diagnostics SPD-703-1 Installation and Operation Manual

Local Analog Loopback (LLB)

The local analog loopback (LLB) test checks the performance of the local

SPD-703-1, the local DTE, and the connections between them (

).

Perform the test separately at the local and the remote site.

ANA

Pressed

Data

Clock Transmit

DTE

Line

Interface

Clock

Data Receive

SPD-703-1

Figure 4-1. Local Analog Loopback

Note

To run the local analog loopback:

1. Press the ANA pushbutton.

The TEST LED on the SPD-703-1 front panel lights up. The unit's transmit output is now connected to its own receiver.

2. Execute the local analog loopback with one of the following methods:

Using the DTE configured to the half duplex operation and checking the echoed data stream.

Using an external BER tester.

If the BER test indicates an error-free data stream, but the DTE test indicates a fault, verify that the cable between the DTE and SPD-703-1 is properly connected. If the problem persists, follow the DTE manufacturer's test procedures.

3. To isolate a communication line problem, perform the LLB loopback at the opposite end. If both LLB tests are error-free, the fault is probably in the communication line or in the line interfaces.

4. After completing the test or correcting the fault, press ANA pushbutton again to restore it to the Off position.

You can also activate the local analog loopback via the appropriate pin of the DTE interface. The loopback activation via the DTE pins is not available for the X.21 and Ethernet interfaces.

4-2 V.54 SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 4 Troubleshooting and Diagnostics

Remote Digital Loopback (RLB)

The Remote Digital Loopback (RLB) test checks the performance of the local and the remote SPD-703-1 units and their connecting lines. The Remote Digital

Loopback sets a loop at the remote SPD-703-1 unit from the terminal coupled to the local unit (

).

REM

Pressed

Data

Clock

Transmit Receive

Local

DTE

Link

Interface

Link

Interface

Remote

DTE

Clock

Data

Receive Transmit

Local SPD-703-1 Remote SPD-703-1

Figure 4-2. Remote Digital Loopback

Note

To run remote digital loopback:

1. Press the REM pushbutton on the local SPD-703-1 front panel.

The TEST LED on each SPD-703-1 front panel lights up. The receive output of the remote modem is looped back to the receiver.

2. Perform the BERT test as explained above for the local analog loopback test.

If an error occurs, while the local analog loopback test described above, was successful for both the local and remote modems, the line or the line circuits of the local or the remote unit are not operating properly.

3. After completing the test or correcting the fault, press REM pushbutton again to restore it to the Off position.

• You can also activate the remote digital loopback via the appropriate pin of the DTE interface. The loopback activation via the DTE pins is not available for the X.21 and Ethernet interfaces.

• If the REM pushbutton is pressed, verify that the unit is set to the INT or EXT mode of operation (J9).

SPD-703-1 V.54 Loopbacks 4-3

Chapter 4 Troubleshooting and Diagnostics SPD-703-1 Installation and Operation Manual

Local Digital Loopback (DIG)

The local digital loopback (DIG) test allows the operator at the remote end to check the performance of the local and remote SPD-703-1 units, and their connecting lines. The DIG test loops the received data back to the remote

SPD-703-1 (

). The local digital loopback test is equivalent to activating the remote loopback from the remote SPD-703-1.

DIG

Pressed

Transmit Receive

Data

Clock

Local

DTE

Link

Interface

Link

Interface

Remote

DTE

Note

Receive Transmit

Data

Clock

Local SPD-703-1 Remote SPD-703-1

Figure 4-3. Local Digital Loopback

To activate the local digital loopback:

• Press the DIG pushbutton on the local SPD-703-1 front panel.

The TEST LED lights up.

If the DIG pushbutton is pressed, verify that the unit is set to the LBT mode of operation and the other unit is set to the INT or EXT mode of operation (J9).

4.2 Internal BERT Circuit Operation

SPD-703-1 has a built-in BERT circuit consisting of a pattern generator and a pattern tester. This circuit acts in conjunction with the V.54 diagnostic loops and a remote BERT to verify Normal system operation and isolate faulty equipment in the event of system failure. The pattern transmitted is a RAD proprietary, pseudo-random pattern.

The SPD-703-1 built-in BERT circuit can be used for the following tests:

• SPD-703-1 Self-Test: the pattern transmitted by the BERT is looped back to the BERT for comparison.

• Two-BERT Test: the pattern transmitted by the BERT is received by another

SPD-703-1 unit.

Each of these tests is described in its own section below. When used opposite another SPD-703-1, the complete link is tested.

4-4 Internal BERT Circuit Operation SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 4 Troubleshooting and Diagnostics

Running Self-Test

The SPD-703-1 Self-Test verifies that the converter is operating properly

(

).

To perform the test:

1. Set the TC G.703 jumper (J9) to INT ( Figure 2-1 and Table 2-1 ).

2. Set the CONNECT TO jumper (J10) to DTE ( Figure 2-1 and Table 2-1 ).

3. Press the ANA button on the SPD-703-1 front panel; wait for the TEST LED to light.

4. Press the PATT button; verify that:

The TEST LED is still lit

The ERR LED is off (it might light up momentarily, which is normal).

If the ERR LED lights up or blinks, then the SPD-703-1 communication system is faulty. If the test executes correctly, restore all buttons to the OFF positions.

PATT

Pressed

ANA

Pressed

Pattern

Generator

Transmitter

Pattern

Tester

SPD-703-1

Figure 4-4. Self-Test

Receiver

SPD-703-1 Internal BERT Circuit Operation 4-5

Chapter 4 Troubleshooting and Diagnostics SPD-703-1 Installation and Operation Manual

Running Two-BER Test

The Two-BER test checks the link between the units (

).

To perform the test:

• Press the PATT button on both devices.

The ERR LED lights up momentarily and then goes off. If errors are encountered, the ERR LED lights up continuously (for continuous errors) or blinks (for intermittent errors).

PATT

Pressed

(Disconnects External BERT)

PATT

Pressed

(Disconnects External BERT)

Data Flow

Pattern

Generator

Pattern

Tester

Line

Interface

Line

Interface

Pattern

Tester

SPD-703-1

Figure 4-5. Two-BER Test

Pattern

Generator

SPD-703-1

4-6 Internal BERT Circuit Operation SPD-703-1

Chapter 5

SPD-703-1/R Card

This chapter describes the SPD-703-1/R card, designed for installation in the

ASM-MN-214 card cage. The chapter contains the following sections:

• ASM-MN-214 card cage

• ASM-MN-214 power supply

• SPD-703-1/R front panel

• Installing the SPD-703-1/R card.

5.1 ASM-MN-214 Card Cage

The ASM-MN-214 card cage contains one or two power supplies and up to

14 plug-in cards. The card types can be SPD-703-1/R or other RAD rack version modems/converters – any combination of up to 14 plug-in cards.

For each of the 14 cards, the rear panel (

) contains a male connector for the terminal block and a DB-25 connector. A protection cover protects the terminal block connectors.

Line Connector

The terminal block (

) is to be attached to the rear panel terminal block connectors. It contains screws for connecting the transmit and receive pairs and ground, if present.

The ASM-MN-214 card cage is also available with BNC coaxial unbalanced or RJ-45 balanced line connectors.

DB-25 DTE Connector

The 25-pin D-type female interface connector provides all interface signals for the digital interfaces. Modems with X.21 or V.35 interface require an external mechanical adapter. Two optional interface attachments, CIA/X21/1 and

CIA/V.35/1, can be ordered separately from RAD. CIA/X.21/1 converts one DB-25 connector to an X.21 15-pin connector. CIA/V.35/1 converts one DB-25 connector to a V.35 34-pin connector.

V.36 cards are supplied with a RAD adapter cable CBL 530/449F, which converts between the DB-25 connector and a V.36 37-pin connector.

SPD-703-1/R with IR-ETH interface module uses a CIA/ETH interface adapter, which converts one DB-25 connector to an RJ-45 connector.

SPD-703-1 ASM-MN-214 Card Cage 5-1

Chapter 5 SPD-703-1/R Card

Terminal

Block

SPD-703-1 Installation and Operation Manual

Protection

Cover

CIA/V.35/1

CIA/X.21/1

CIA/ETH

CBL-530/449

Figure 5-1. ASM-MN-214 Rear Panel

5-2 ASM-MN-214 Card Cage SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 5 SPD-703-1/R Card

5.2 ASM-MN-214 Power Supply

Power is supplied to the SPD-703-1/R card from the ASM-MN-214 power supply via the chassis.

The ASM-MN-214 card cage can accept both AC or DC power supplies. LED indicators located on the ASM-MN-214 front panel (

) indicate activity when the power supply is connected to the mains plug. The power supply supports the full card cage with any combination of cards.

AC Supply

The AC power supply of the ASM-MN-214 is 100, 115, or 230 VAC, ± 10%,

47 to 63 Hz.

DC Supply

The DC power supply is -48 VDC (-36 to -72 VDC) or 24 VDC (18 to 32 VDC). It uses a DC/DC converter module to provide the power required for the cards.

Power Supply with Redundancy

This special ordering option is equipped with two separate power supplies, operating together and sharing the load of the whole card cage. If either of the power supplies fails, the other one will continue to supply power to the full card cage.

Two LED indicators show activity of each power supply. They should both light when mains power is provided.

Note

It is possible to combine AC and DC power supplies in the same cage.

SPD-703-1 ASM-MN-214 Power Supply 5-3

Chapter 5 SPD-703-1/R Card SPD-703-1 Installation and Operation Manual

5.3 SPD-703-1/R Front Panel

shows the SPD-703-1/R card front panel. The LEDs and pushbuttons of the card version are identical in their functionality to those of the standalone

device. For additional information, refer to Front Panel Indicators and Switches in

PWR

TD

RD

LOS

TEST

ERR

DIG

ANA

REM

PATT

SPD-703-1

Figure 5-2. SPD-703-1/R Front Panel

5-4 SPD-703-1/R Front Panel SPD-703-1

SPD-703-1 Installation and Operation Manual Chapter 5 SPD-703-1/R Card

Figure 5-3. ASM-MN-214 Front Panel

SPD-703-1 SPD-703-1/R Front Panel 5-5

Chapter 5 SPD-703-1/R Card SPD-703-1 Installation and Operation Manual

5.4 Installing the SPD-703-1/R Card

Setting Internal Jumpers and Switches

The SPD-703-1/R internal jumpers and switches are similar in their functionality to those of the standalone unit. For the details on the internal settings, refer to

Installing SPD-703-1/R into the ASM-MN-214 Card Cage

To install the SPD-703-1/R card in the ASM-MN-214 card cage:

1. Install the ASM-MN-214 card cage in a 19-inch rack.

2. Insert the SPD-703-1/R card into one of the ASM-MN-214 slots.

3. Push the card into the cage until it is fully inserted into the edge connector inside the rack.

4. Tighten the screws on front panel of the card.

Connecting the Interfaces

SPD-703-1/R uses the ASM-MN-214 rear panel terminal block ports for the line connections. The 25-pin D-type female connector serves as a DTE port.

1. Remove the protection cover from the terminal block connectors.

2. Connect the terminal block to the ASM-MN-214 terminal block connector.

3. Connect the line to the terminal block as follows:

Connect the transmit pair to the terminals marked XMT

Connect the receive pair to the terminals marked RCV

Connect the fifth screw to ground (optional).

4. If required, attach the appropriate CIA (CIA/X.21/1, CIA/V.35/1, CIA/ETH) or

V.36 adapter cable to the DB-25 connector on the card cage rear panel.

5. Connect the DTE cable to the DB-25 connector, other side of CIA, or adapter cable (depending on your version of the card interface).

6. Connect power to the ASM-MN-214 card cage:

To connect AC power, connect the power cable to the mains supply.

To connect DC power, refer to DC power supply connection supplement of the ASM-MN-214 installation and operation manual.

Warning

The ASM MN 214 card cage has no power switch. Operation starts when the power is applied to the rear panel POWER connector. When applying power, first connect the plug of the power cord to the ASM MN 214 POWER connector and then to the mains power source (outlet).

5-6 Installing the SPD-703-1/R Card SPD-703-1

Appendix A

Connector Wiring

A.1 V.24, V.35 and X.21 Interface Connectors

describes the signal assignments for the SPD-703-1 V.24, V.35 and

X.21 DTE interface connectors.

Signal

Function

Protective

Ground

Signal

Ground

Transmitted

Data

Received

Data

Request to

Send

Clear to Send

V.24

DB-25

Standalone and Card

Cage

1

DB-25

Card

Cage

V.35

34-Pin

Standalone

Pin Circuit

7 7 B Signal 102

GND

2 9

11

P TD(A) 103

S TD(B) 103

4

5

1

4

5

Table A-1. DTE Interface Signal Assignments

A Frame 101

3 12

13

R RD(A) 104

T RD(B) 104

C RTS 105

D CTS 106

DB-25

Card

Cage

X.21

DB-15

Standalone

Pin Circuit

(Function)

Description

1

2

14

1 ----

(Shield)

Chassis Ground. It may be isolated from Signal

Ground.

7 8 ----

(GND)

Common signal and DC power supply ground.

2 T(A)

9 T(B)

(Transmit)

Serial digital data from

DTE. In sync applications, the data translations must occur on the rising edge of the transmit clock.

3

16

4

19

4 R(A)

11 R(B)

(Receive)

Serial output from the modem receiver. In sync applications, the data translations occur on the rising edge of the clock.

3 C(A)

10 C(B)

(Control)

A positive level to

SPD-703-1 when data transmission is desired.

A positive level from

SPD-703-1 with delay, after receipt of Request to

Send, and when

SPD-703-1 is ready to transmit.

SPD-703-1 V.24, V.35 and X.21 Interface Connectors A-1

Appendix A Connector Wiring

Signal

Function

Data Set

Ready

SPD-703-1 Installation and Operation Manual

V.24

DB-25

Standalone and Card

Cage

6

20

Table A-1. DTE Interface Signal Assignments (Cont.)

DB-25

Card

Cage

6

20

V.35

34-Pin

Standalone

Pin Circuit

E DSR 107

DB-25

Card

Cage

X.21

DB-15

Standalone

Pin Circuit

(Function)

H DTR 108

Description

A positive level from

SPD-703-1 when power is on, and SPD-703-1 is (a) not in digital loopback mode, or (b) has not received a remote loopback signal from the remote unit.

Not used Data

Terminal

Ready

Carrier

Detect

8 8 F DCD 109 8

10

External

Transmit

Clock

Transmit

Clock

Receive

Clock

Local Analog

Loop

Remote

Digital Loop

Test

Indicator

24 19

16

U SCTE(A) 113

W SCTE(B) 113

24

11

15 14

10

Y SCT(A) 114 a SCT(B) 114

15

12

17 23

22

V SCR(A) 115

X SCR(B) 115

18

21

25

18

21

25

L and j

N and h n and k

5 I(A)

12 I(B)

(Indication)

A positive level from

SPD-703-1, except when a loss of the received signal is detected or when Data Set

Ready is negative.

7 (A)*

14 (B)*

Positive clock translations must correspond to data transmissions.

6 S(A)

13 S(B)

(Signal

Timing)

A transmit data rate clock for use by an external data source. Positive clock translations correspond to data translations.

A receive data rate clock output used by an external data sink. Positive clock translations correspond to data translations.

A control signal input, which, when on, sets

SPD-703-1 into local analog loopback (V.54

Loop 3).

A control signal input which, when on, commands SPD-703-1 to send a remote loopback command (V.54 Loop 2) to the remote SPD-703-1.

A Control Signal output from SPD-703-1; positive during any test mode.

A-2 V.24, V.35 and X.21 Interface Connectors SPD-703-1

SPD-703-1 Installation and Operation Manual Appendix A Connector Wiring

Signal Function

Protective Ground

A.2 RS-530 and V.36 Interface Connectors

The SPD-703-1 V.36 interface is provided via an adapter cable converting between 25-pin RS-530 connector and 37-pin V.36 connector.

lists the cable wiring.

Table A-2. Cable Converting between RS-530 and V.36 Interfaces, Pin Assignment

Pin

1

V.36, 37-Pin

Circuit

Shield

Pin

1

RS-530, 25-pin

Circuit

DTE Common Return

DCE Common Return

Transmitted Data

Received Data

Request to Send

Clear to Send

Data Set Ready

Data Terminal Ready

Carrier Detect 13

31

External Transmit Clock 17

35

Transmit Clock 5

23

9

27

11

29

12

30

37

20

4

22

6

24

7

25

Receive Clock 8

26

Local Analog Loopback 10

Remote Loopback

Test Indicator

14

18

CS (A)

CS (B)

DM (A)

DM (B)

TR (A)

TR (B)

RR (A)

RR (B)

TT (A)

TT (B)

SC

RC

SD (A)

SD (B)

RD (A)

RD (B)

RS (A)

RS (B)

ST (A)

ST (B)

RT (A)

RT (B)

LL

RL

TM

8

10

24

11

5

13

6

22

20

23

2

14

3

16

4

19

15

12

17

9

18

21

25

CB (A)

CB (B)

CC (A)

CC (B)

CD (A)

CD (B)

CF (A)

CF (B)

DA (A)

DA (B)

BA (A)

BA (B)

BB (A)

BB (B)

CA (A)

CA (B)

DB (A)

DB (B)

DD (A)

DD (B)

LL

RL

TM

SPD-703-1 RS-530 and V.36 Interface Connectors A-3

Appendix A Connector Wiring SPD-703-1 Installation and Operation Manual

A.3 SPD-703-1/R with Ethernet Interface, DTE

Connection

SPD-703-1/R with the IR-ETH Ethernet interface module uses a CIA/ETH interface adapter, which converts one DB-25 connector to an RJ-45 connector. If you intend to prepare a DB-25/RJ-45 adapter cable yourself, refer to

and

for the pin designations and their assignment.

7

9

11

12

13

Figure A-1. Pin Designation in the DB-25 Connector of ASM-MN-214 Card Cage

Table A-3. DB-25 and RJ-45 Pinout, Ethernet

Pin

RJ-45 DB-25

Function

– 7 GND

A-4 SPD-703-1/R with Ethernet Interface, DTE Connection SPD-703-1

Appendix B

IR-ETH Interface Module

IR-ETH is an interface module for RAD modems and converters. IR-ETH is used for converting the Ethernet (10BaseT or 10Base2) electrical levels to the modem/converter TTL levels. It also converts the Ethernet protocol to HDLC to enable long distance transmission and avoid the Ethernet collision limitation.

IR-ETH includes an internal, self-learning Ethernet bridge, which enables a high performance link between two Ethernet segments at a low transmission rate. The low-speed HDLC transmission is sent over the link using the modem modulation technique, and then converted back to an Ethernet signal at the remote modem.

shows a typical application using an Ethernet interface bridge. Each modem/converter is connected to an Ethernet network via the Ethernet interface bridge.

SPD-703-1 SPD-703-1

Figure B-1. Typical Application of SPD-703-1 with IR-ETH Interface Module

B.1 IR-ETH Connector Options

and

show the rear panel of the standalone SPD-703-1 with the IR-ETH interface module (RJ-45 and BNC connectors).

lists the RJ-45 connector pinout. Appendix A describes the pinout of the DB-25 connector serving for the LAN connection of the SPD-703-1/R card.

LINK

COLL

DTE

RX

TX

10BASE-T

XMT RCV GND

Figure B-2. Rear Panel of SPD-703-1 with IR-ETH Module (RJ-45 Connector)

SPD-703-1 IR-ETH Connector Options B-1

Appendix B IR-ETH Interface Module SPD-703-1 Installation and Operation Manual

COLL

DTE

RX

TX

10BASE-2

XMT RCV GND

Figure B-3. Rear Panel of SPD-703-1 with IR-ETH Module (BNC Connector)

Table B-1. RJ-45 Connector Pinout

Pin Function

– GND

General

LAN

WAN

LAN Table

Filtering and Forwarding

Buffer

Delay

Standard

Data Rate

Connectors

Protocol

Data Rate

10,000 addresses

15,000 pps

256 frames

1 frame

Conforms to IEEE 802.3/Ethernet

10 Mbps (20 Mbps 10BaseT FDX)

• 10BaseT (UTP): Shielded RJ-45

• 10Base2: BNC connector

HDLC

According to the modem transmission rate

B-2 Technical SPD-703-1

SPD-703-1 Installation and Operation Manual Appendix B IR-ETH Interface Module

B.3 Installation and Operation

shows the Ethernet bridge layout, the location of the SW-1 DIP switch, and the rear panel components.

1

2

3

4

Figure B-4. IR-ETH Layout (UTP Option)

DIP Switch Settings

describes functions and default settings of the DIP switch SW-1 sections.

Table B-2. DIP Switch Settings

Section