BHP Chronicle - S3 amazonaws com

advertisement

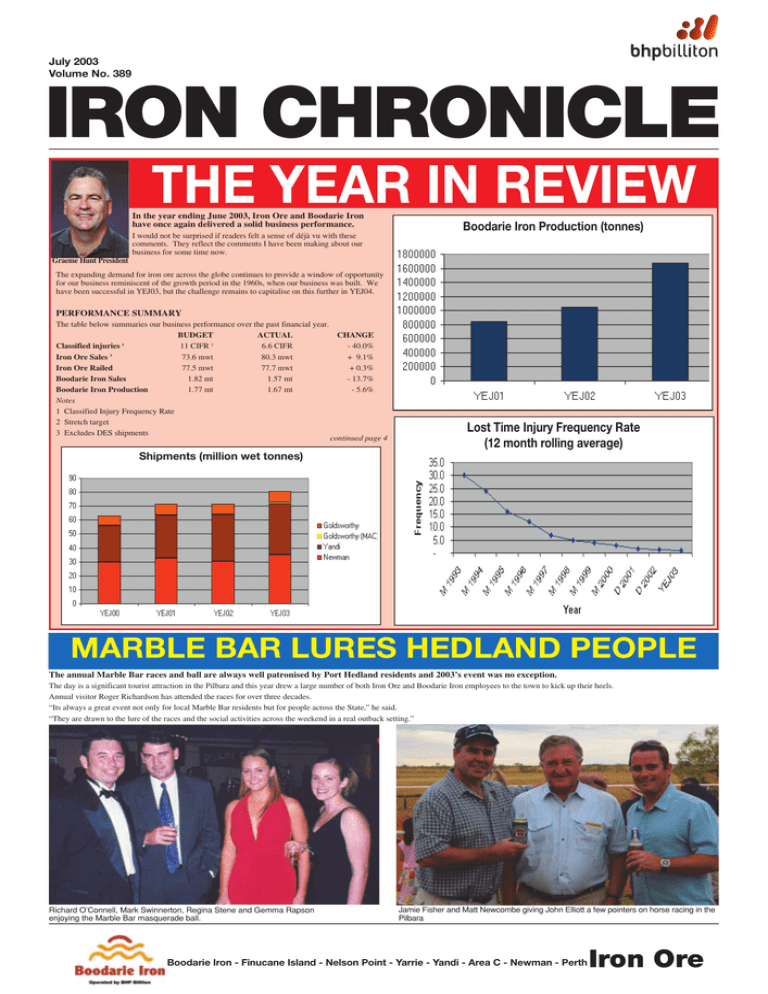

July 2003 Volume No. 389 IRON CHRONICLE THE YEAR IN REVIEW In the year ending June 2003, Iron Ore and Boodarie Iron have once again delivered a solid business performance. I would not be surprised if readers felt a sense of déjà vu with these comments. They reflect the comments I have been making about our business for some time now. Boodarie Iron Production (tonnes) Graeme Hunt President The expanding demand for iron ore across the globe continues to provide a window of opportunity for our business reminiscent of the growth period in the 1960s, when our business was built. We have been successful in YEJ03, but the challenge remains to capitalise on this further in YEJ04. PERFORMANCE SUMMARY The table below summaries our business performance over the past financial year. BUDGET ACTUAL CHANGE 11 CIFR 2 6.6 CIFR - 40.0% Classified injuries 1 Iron Ore Sales 3 73.6 mwt 80.3 mwt + 9.1% Iron Ore Railed 77.5 mwt 77.7 mwt + 0.3% Boodarie Iron Sales 1.82 mt 1.57 mt - 13.7% Boodarie Iron Production 1.77 mt 1.67 mt - 5.6% Notes 1 Classified Injury Frequency Rate 2 Stretch target 3 Excludes DES shipments continued page 4 Lost Time Injury Frequency Rate (12 month rolling average) Shipments (million wet tonnes) MARBLE BAR LURES HEDLAND PEOPLE The annual Marble Bar races and ball are always well patronised by Port Hedland residents and 2003’s event was no exception. The day is a significant tourist attraction in the Pilbara and this year drew a large number of both Iron Ore and Boodarie Iron employees to the town to kick up their heels. Annual visitor Roger Richardson has attended the races for over three decades. “Its always a great event not only for local Marble Bar residents but for people across the State,” he said. “They are drawn to the lure of the races and the social activities across the weekend in a real outback setting.” Richard O’Connell, Mark Swinnerton, Regina Stene and Gemma Rapson enjoying the Marble Bar masquerade ball. Jamie Fisher and Matt Newcombe giving John Elliott a few pointers on horse racing in the Pilbara Boodarie Iron - Finucane Island - Nelson Point - Yarrie - Yandi - Area C - Newman - Perth Iron Ore IRON CHRONICLE GENERAL NEWS PAGE 2 Connecting Customs for greater control The Australian Customs Service will be substantially upgrading its services in the North West, thanks to BHPBIO. Low dust levels around Whaleback Dust levels were at an all time low around Newman recently with only one higher reading due to activities unrelated to mining. By using existing optic fibre cabling through the subterranean tunnel, Customs will bring new Closed Circuit TV (CCTV) cameras on line on Finucane Island. This has resulted in a significant capital saving to Customs. Minister for Justice and Customs, Senator Chris Ellison visited Port Hedland recently to offer his thanks and gratitude to BHPBIO for providing infrastructure to Customs. Senator Ellison indicated that CCTV coverage is an important element in Customs capability to secure the port against threats. “The cooperation of BHP Billiton is a leading example of the Customs-business partnership which is strengthening border protection in the Pilbara,” he said. A/Vice President Ports, Bob Goodwin being interviewed by GWN Television regarding infrastructure for Customs. Around 800 bulk carriers arrive in Port Hedland each year and it is among the ten busiest ports in Australia. BHPBIO has been a member of the Customs Frontline program for some time. It is a program which brings industry and Customs together to protect Australia’s borders. As a member of Frontline, BHPBIO staff receive training to identify suspicious border activities and also to review our own security arrangements. Customs would like to acknowledge the support from Roger Richardson, Mark Frost and Lloyd Jones from Shipping for playing an integral role in this initiative. As part of the Company’s ongoing commitment to the environment, BHP Billiton Iron Ore has been carrying out air quality monitoring in and around its Mt Whaleback mine site since 1998. The program consists of seven High Volume Air Samplers (HiVols) located near the mine and around the Newman township. The HiVols are designed to draw air through a filter paper at a known constant rate over a 24hour period, and are run every six days, all year round, as recommended by the Australian Standards. Collected dust is weighed to determine the concentration in the air. The objective of this monitoring is to detail the dust levels near the mine site and the Newman township and determine whether the mining activities of BHPBIO are impacting on the local community. Environmental Superintendent Wendy Howell said the original locations of the sampling machines were chosen to give the best result and provide easy access. They are in permanent locations so that recorded data can be compared and a verifiable data base established. “Most of the machines are located out towards the highway and the airport, allowing us to monitor any dust generated by both Whaleback and Orebody 23/25 operations,” Wendy said. “One machine, located so as to provide baseline data by recording any naturally occurring dust in the air, will allow us to measure what is produced by mining and what is not. “The machines are very sensitive and record everything, including animal activity (like cattle) and dust from earthworks in the area. Our monitoring has shown that if the standard has been exceeded it has been due to these other activities, rather than our mining operations. “From January to March 2003 only one TSP (Total Suspended Particulates) guideline was exceeded, outside the Newman airshed and unrelated to BHPBIO’s mining activities. Some heavy rains in January led to an overall decline in ambient dust levels within the Newman airshed following the higher dust levels experienced during the drier weather from October to December 2002. Senator Ellison recognising the support provided by BHPBIO. Ore shipments grow Dean Dalla Valle watches on as the NSS Confidence leaves Port Hedland harbour with its record-breaking shipment. BHPBIO has broken its previous shipping record with 80.6million tonnes of iron ore shipped from Port Hedland in the year to June 30. The record broken was 71.3 million tonnes shipped in the year to June 2002. The NSS Confidence departed Port Hedland Harbour on Sunday 29 June at 8:30am under a cloudy drizzling sky headed for Japanese steel mills. To the many onlookers standing in the BHP Billiton Marapikurrinya Park the departing ship was just another of the increasing number using the harbour however the moment was a significant milestone for the company. Vice President Dean Dalla Valle who was there to watch the vessel help break the 80 million tonne mark said, the new record is a result of the enormous work performed by employees at the mine, rail and the port. “From the worker driving the haul truck, to a rail maintenance crew fixing sleepers down track and a worker replacing rollers on a conveyor, everyone played a part. “Breaking the 80 million tonne mark helps us realise that previously unthinkable targets can be achieved. The next challenge is to head towards 100 million tonnes. “I’m certain we can make it if we all continue to improve our performances and work as a united team. “We all should be extremely proud of what we have achieved,” he said. As shown in the February 1999 Chronicle, then Environmental Officer Wendy Howell and Environmental Assistant (now Environmental Technician) David Kaljuste collect data from the two types of High Volume Air Monitors located south of Mt Whaleback. Fortune meets Hedland on maiden voyage Last month’s busy shipping round saw the departure of the NSS Fortune’s maiden voyage from Port Hedland. NSS Fortune is the sixth and last in the current program of new vessels for Nippon Steel Shipping. To celebrate the voyage, a morning tea was held on board where BHP Billiton Iron Ore and Nippon Steel exchanged commemorative gifts. (L-R) Vice President Ports Dean Dalla Valle, with Nippon Steel’s Chief Engineer T Ono, Director Osamu Nagano and Captain S Yasutake. The 290 metre long vessel NSS Fortune on its maiden voyage. In 2003, Environmental Superintendent Wendy Howell discusses the operation of another HiVol Sampler north of Mt Whaleback with Environmental Officer Samantha Morley. Boodarie Iron recycles Flight Separator Fines On the back of successfully recycling Remet to the reactor plant feed, Boodarie Iron has been searching for a way to recycle Flight Separator Material. Flight Separator material is generated in the briquetting section of the plant and consists of DRI fines and briquette chips. Normally most of this material is recycled by the bucket elevators for re-pressing. However operating difficulties with the bucket elevators have resulted in a stockpile of approximately 165,000t of Flight Separator material. Most of this is a suitable size to feed to the reactors as an alternative to Remet; the remainder is oversize and is screened out and can be sold as briquette chips. Following test work by Newcastle Technology Centre confirming the suitability of the material to be fed to the FINMET process, a plant trial was conducted during February. The trial in partnership, with the Technology and Development Department, involved testing the ability of the plant to process increasing amounts of Flight Separator Fines up to a maximum of 15 percent. The trial was a success. A consumption strategy is now being developed to ensure that all the stocks of Remet and Flight Separator Fines are used on the plant. IRON CHRONICLE GENERAL NEWS Football Update The annual Telstra Countrywide Challenge football match was held recently between Newman and Fortescue leagues. The main game was won by Newman, while in the warm up match Jigalong defeated the Newman Colts. The Jigalong team travelled in to town at short notice, on a bus provided by BHPBIO, following the inability of the Tom Price Colts to attend the competition. The main match was followed by the presentation of Charlie Salmon Medal to Newman’s fairest and best player, Andrew Host. The medal is in honour of Charlie Salmon, who died in June 2000, while umpiring a local football match on the Capricorn Oval. Charlie was very well respected across the Pilbara, particularly in the Newman and Tom Price communities, and dedicated a significant amount of his time to all aspects of football. Chris Salmon presented the annual “Charlie Salmon Medal” to Newman’s fairest and best player, Andrew Host at Saints Clubrooms. Finucane plant crew learn from mine A recent visit to the Yarrie and Nimmingarra mine sites by the Finucane Island Beneficiation Plant Crew has been seen as a significant step forward in employees better understanding the part they play in the BHP Billiton Iron Ore business. Leading the day’s tour was Maintenance Improvement Coach, Rick Hockey. “The idea of a tour was generated by the team and strongly supported by Peter Priestly, Superintendent Maintenance on Finucane Island Once Peter got the go ahead, the enthusiasm for the trip grew,” he said. The visit included touring the Yarrie pit and understanding the challenges, such as managing ore sizes and dewatering, which are faced by the mine teams. “Better understanding the jobs on the mine provided an insight that is difficult to grasp over a telephone or through an email. The trip back was filled with enthusiastic discussion on just what goes on at the mine. “The benefit of team building shouldn’t be overlooked either. Having the opportunity to get to know each other was appreciated by all involved,” Rick said. The crew in front of Nimmingarra train loading facility (from left) Ahmad Morshid, Abdul Colin, Gary Annal, Andrew McLean, Omar Ridwan, Nick Mladenovic, Alan Pickles, Sid Arripin, Paul Rafferty, Peter Priestly, Rusdu Kalzee, Matthew Fry, Jessica Cowe, Abdol Kalzee, Eric McInnes and Rick Hockey. PAGE 3 Orange hard hats all ‘round From 1 July 2003 all Nelson Point and Finucane Island employees will receive brand new orange hard hats. With hard hats having a life span of only two years it is crucial replace retired hard hats across site regularly. Environmental Officer Chris Serginson said the issuing of new hard hats across site provided an excellent opportunity to recycle the old hard hats all at one time. “Instead of the hats ending up in landfill, the old hard hats will be sent to a plastics recycling company in Perth called SARPOL, which will melt down the plastic and use it to construct items such as bollards and fence posts.” Once employees have received their orange hard hat, they are asked to recycle their old hard hat by placing it in one of the recycling skip bins. The bins are marked “Hard hat Recycling Only” and have been placed at the following locations: • Finucane Island, behind the First Aid building • Nelson Point, in front of Shift Operations • Nelson Point, TCB1 Sample Prep • Nelson Point, main carpark in front of Loco Overhaul Workshop • Nelson Point, washbay near Vehicle Maintenance Workshop Alternatively, old hard hats can be stockpiled in work areas and collected by Cleanaway. To arrange this please contact the Cleanaway Site Coordinator on 0417 723 466. All visitors hard hats will remain blue. For further information, please contact Mark Laverty on 9173 6764 or Chris Serginson on 9173 6623. 2nd year Mechanical Apprentice Sally McIlrath modeling a blue visitors hard hat and 3rd year Electrical Apprentice Justin Dhu sporting a new orange hard hat. Refit for Shovel 23 Shovel 23’s recent boom change was completed ahead of schedule and almost injury free. The Shovel, Mt Whaleback’s largest, was commissioned in 1987 and is the only remaining electric rope shovel on site. It weighs in at about 950 tonnes and has a bucket that can pick up 60 tonnes with each pass. The boom required replacing due to the The Shovel 23 boom replacement job nears completion. A component hours and loaded 240 tonne truck is used to adjust the saddle blocks worn shipper shaft for the dipper handles bushes. It was accomplished using a refurbished and reconditioned boom from Shovel 24. Mechanical Engineer Marcus Lang, who oversaw the job, said the good result was due to cooperation and planning. “The replacement boom was at the Shovel Pad for a few months while we fitted in refurbishment jobs on it around our other work, and when we had it ready to go, we liaised with Planning and Mining for an appropriate window to take the machine out of production. Mining also constructed the earth pad where we completed the job at short notice due to another site becoming unsuitable. “Some of the tasks on the replacement boom included replacing gearbox components, the shipper shaft, boom foot pins, sheaves and bushes. The replacement of the boom was planned to take a week, but we had the machine back to work two days ahead of schedule. “All Field Maintenance crews participated in the preparation work for the job, as well as personnel from Mining, Electrical and Crane Services, and it wouldn’t have been possible to achieve such a good result without the co-operation received from all.” “Having said that, the B5 and B6 crews must be commended on their excellent effort in bringing this job in ahead of time and with only one minor first aid injury,” said Marcus. Working on the Shovel 23 replacement boom are (left to right) Scott Bull, Des Fu (Terex Mining), Richard White, Dave Cabassi and Chris Outram. IRON CHRONICLE GENERAL NEWS PAGE 4 THE YEAR IN REVIEW Iron Ore Sales Per Customer Country Year Ending 2003 Boodarie Sales Per Customer Country Year Ending 2003 Railroad - Locomotive Fuel Consumption Ore Railed Per Mine (million wet tonnes) continued from Page 1 SAFETY PERFORMANCE Before I turn to our operating results, I would like to applaud all our employees and contractors on achieving an exceptional level of safety throughout the year. We not only achieved the stretch target established 12 months ago for classified injuries (11 CIFR), but reduced them by half as much again (5.6 CIFR) and with much lower rates of severe injuries. This continues a trend that has been established over the past 5 – 10 years. This is an outstanding result and I would like to extend my congratulations to everyone across the organisation. Our workplace has been safer in the last 12 months than it ever has in the past. This is in no small part due to strong leadership on safety matters and a growing culture of people looking after and caring for their colleagues. As always, I deliver this message with caution. In the year just ended, there were 27 incidents that had the potential for fatal results, such as heavy / mobile equipment accidents and electrical shocks. Although this number of significant incidents is an improvement over the past, it underscores the need for continued vigilance and commitment to working in a safe and responsible manner. OPERATING PERFORMANCE In the February 2003 edition of The Chronicle, I made the following statement: “It was extremely satisfying to report that BHP Billiton’s Iron Ore operations in Western Australia set new operating records in the quarter. I hope these results bring a great deal of satisfaction to you as well.” I reiterate these comments for the full year results that we have just announced. The details of our record operating performance are covered in the feature section of this edition. Right now, I want to concentrate on the WHY. I see three critical factors behind the results that we, in Iron Ore and Boodarie Iron, are delivering for our owners and other stakeholders. The single most critical factor that has driven our performance has been the surging global demand for iron ore. The recent period of demand growth has been extraordinary, and our forecasts indicate that this trend will continue in the short term at least. The main driver of this demand is the growth in China, and we are making sure our iron ore products are able to meet the requirements of this market, as well as our traditional markets, especially Japan. Securing higher sales to China and other markets is critical to our long-term growth and we must be able to demonstrate to these customers that we have capacity and the will to be a reliable and flexible partner. Over the past year, we have demonstrated this type of flexibility through innovation and new practices across the business. We will need to continue in this vein if we are to capitalise on the opportunities in the current iron ore market. In essence, we cannot remain shackled to the pier, if we are to rise with the demand tide. Second, there is no question that the business is performing a whole lot better thanks to the improvement processes that we have introduced, using the Operating Excellence (OE) framework as the driving force. Delivering the value from business improvement has become more critical as the rising A$ means we get relatively less for our products. Improvement projects are now delivering some $30 million in added value to the business and I am committed to improving on this. There is an enormous amount of value to be extracted yet, and this can only be achieved through greater integration with our daily business processes. I should point out that in Iron Ore and Boodarie Iron, we now have 10 accredited OE coaches, which is equivalent to one-third of the 29 accredited coached across BHP Billiton globally. This is a remarkable figure and one of which I am immensely proud. The expertise and resources of these coaches (and those currently in the training and accreditation phase) will assist the improvement projects deliver the value required to take us to the next level of efficiency. Finally, I’d like to recognise the commitment of our employees and contractors in assisting the business to keep pace with demand. There is no doubt that the changes we have made in recent years have been the catalyst for the impovements in operating performance at all levels of the business. More than 75% of our employees are now working in a way that provides the business flexibility to be able to respond quickly to meet rapid changes in market demand, such as we are currently experiencing. I believe that the working arrangements we have introduced have also led to greater job satisfaction and personal reward for effort. For these reasons, over the past year we were able to stretch the capacity of our existing operations to participate in this growth period and maintain our market share. Importantly, we have also been driving an expansion program worth over $1 billion that includes a new mine (Area C), a spur line linking with our existing railway and the development of a new western stockyard at Finucane Island. This program will deliver additional capacity over the upcoming months and enable us to meet the continued growth in demand that we expect to see over the coming years. The year ending June 2003 provided a fistful of challenges, not least of all the cyclone-induced deluge in the early months of this year. Our ability to tackle these challenges and deliver consistently good results is very pleasing and I look forward to delivering similar improvements over the next 12 months. In appreciation of the business performance over the past year, I have requested that an appropriate memento be produced for all employees. This will be distributed to you over the next month. Thank you once again, and I look forward to announcing that we have further increased the capacity of our business at the conclusion of the year ending June 2004. Graeme Hunt President IRON CHRONICLE GENERAL NEWS PAGE 5 ASSET DEVELOPMENT PROJECTS UPDATE OVERVIEW Everyone at BHP Billiton Iron Ore and Boodarie Iron should now be aware of our capacity expansion program that involves the development of a new mine, called Area C as well as port and rail expansions to cope with increased throughput. The authorised capital cost for these expansion projects is over A$1 billion, comprising US$213m (100% terms) for Area C and US$351m (100% terms) for the product and capacity expansion, otherwise known as PACE. As you can see from the progress chart below, these projects have progressed ahead of schedule. Importantly, they are also running according to budget. The official opening of the Area C mine is due to be held on 30 October. PROJECT SNAP SHOTS AREA C • • • Plant and supporting infrastructure installation work is virtually complete. Load Commissioning occurred on 21 July 2003. Rehabilitation work is generally complete at the aerodrome, old bulk sample campsite and access road. Work on demobilising the Packsaddle construction village is due to commence soon. • RAIL • ADP PROGRESS Project Completion % Plan Actual 86.5 92.1 89.9 92.1 56.4 54.2 71.5 72.8 Area C Area C Rail PACE Overall ADP Progress* * see chart below The bulk earthworks are now complete. Track laying is well advanced with all concrete sleepers placed onto the formation, and steel laying past the half way mark. Total of 3.3M bcm of excavation on the project with over 2.4M bcm drill and blast through hard rock. The Yandicoogina Creek Bridge is also complete and ready for traffic. The BHPBIO mobile flashbutt welding crew is carrying out all the rail welding using their new machine and have achieved excellent welding rates. A new high speed turnout has also been installed at the Yandi Mine to allow the train from Area C to maintain track speed. • • • OVERALL PROJECT PROGRESS (AREA C & PACE) PACE 100% • • • 80% Current Plan Actual The structural/mechanical contractor at Nelson Point has successfully completed all major shutdowns. The construction of the new berth at Finucane Island is progressing to schedule. The structural/mechanical contractors at Finucane Island have successfully mobilised and commenced structural steel erection. The erection of new stackers and reclaimer is progressing to schedule. Erection of the shiploader is underway in Fremantle. It is due to be transported to the new Finucane Island berth in mid October 2003. The Finucane Island electrical contractor has successfully mobilised and commenced construction. The water supply upgrade contractor has successfully mobilised to site and commenced works at the Water Corporation Port Hedland Pumping Station. 71.5% 72.8% • • Progress 60% • 40% • Planned Cumulative Progress Forecast Cumulative Progress Actual Cumulative Progress Current Plan Cumulative Progress 20% 0% Mar-02 Jun-02 Sep-02 Dec-02 Mar-03 Jun-03 Project Months Sep-03 Dec-03 Mar-04 Jun-04 SAFETY At BHP Billiton Iron Ore and Boodarie Iron, we have made a great commitment to the goal of becoming not just the most efficient and profitable iron ore producer in the Pilbara, but also the safest. Achieving change that provides a safer workplace is a difficult, yet critical challenge, especially in the context of our accelerated expansion projects. The safety record of these projects, which is set out below, is enviable and sets a benchmark for other projects to achieve in the future. Classified Injury Frequency Rate • • • Area C PACE Area C Rail ADP TOTAL 2.3 3.2 2.0 3.4 This record has been achieved by maintaining a focus on the foundations of our safety approach, which apply right across the business: • Strong leadership and commitment to achieving zero harm to our people, which starts at the top and goes right through the length and breadth of our workforce; • Safety management systems that are developed in collaboration with the workforce; and • Developing a more mature perception of hazards and approach to risk taking behaviour by our employees. The new shiploader is being constructed in Fremantle. COMMUNITY As part of its commitment to being valued by the communities in which we operate, the ADP team supports LivingWorks to conduct suicide intervention and training programs in the Pilbara. The LivingWorks program is designed to raise awareness of suicide and suicidal behaviours and prepare the community to be able to engage and intervene with those at risk of suicide. During the year ending June 2003, the program trained 135 people through 9 applied Suicide Intervention Skills Training Workshops. More importantly, there were 18 known cases where people who were suicidal were identified and treated through the program. The ADP team has raised nearly $160,000 over the life of the projects, an outcome that everyone involved should be very pleased with. LIVING WORKS Donations for June Port Hedland • Young Achievers Australia • Burrup Bouncers Skipping Demonstration Team • HARTZ • • South Hedland Bowling and Tennis Club Port Hedland Chamber of Commerce • Hedland Tee Ball Association • Youth Involvement Council • St Cecilia’s Middle School • South Hedland Junior Football • Port Hedland Primary School • St John’s Ambulance • Port Hedland Junior Cricket Association • Newman Campdraft & Rodeo • Port Hedland Regional Hospital • Newman Community Centre • Boodarie Bowls • Electrical Expo • Matt Dann Cultural Centre • WA Police Legacy Newman PAGE 6 Training awards build futures Graduating mechanical apprentice Mathew Wheeler was named BHPBIO 2003 Apprentice of the Year at the Apprentice and Clerical Awards held at the Cooke Point Recreation Club during June. In a new addition to the apprentice Awards, Leila Pattison was recognised for her outstanding achievement with the Clerical Trainee of the Year Award. Awards were also presented to individual apprentices as formal recognition of their high level of achievement and performance throughout the year. Candidates were assessed on areas such as level of skills knowledge, attendance records, rotation reports, commitment and dedication, enthusiasm, attitude and college or trade test marks. The final results are as follows: Best 1st Year Apprentice for 2002 Adam Drury Best 2nd Year Apprentice for 2002 Jairus Angel Best 3rd Year Apprentice for 2002 Remy Syed Best 4th Year Apprentice for 2002 Glenn Edmonds Overall Apprentice of the Year Mathew Wheeler Encouragement Award for 2002 Glen Sadler Encouragement Award for 2002 Andre Charlesworth 4th Year Achievement Award for 2002 – Shaun Edmonds The evening was well attended attracting approximately 120 guests made up of those nominated for awards, their friends and families. Dean Dalla Valle, Vice President Ports, commented on the importance of investment into the community because it provides skilled young people who can help bolster our local economy. “I’m also extremely proud that BHP Billiton are helping young men and women in our community build their futures,” he said. A special thanks is extended to the following sponsors for making the night a huge success: Rexcel, Coventry’s, Blackwoods Hardware, Pilbara TAFE, Department of Training, Apprenticeships Western Australia, O’Donnell Griffin, New Apprenticeship Centre, Inline Engineering and Downer RML. IRON CHRONICLE GENERAL NEWS The Apprenticeship & Training Support Network sponsored the new Clerical Trainee of the Year Award New apprentices commencing with BHPBIO were formally recognised with the signing of their indenture papers. These included: Natasha Arnold Raimie Ayat Andre Blagotinsek Tim Forbes Ivan Knezovic Colin McKie Shaun Montague Nathan Podmore Steven Sclater Kane Stocker The successful 2003 Engineering Cadet (Mechanical), Darryl Jones was also congratulated and welcomed to BHPBIO. Nelson Point welcomed the following clerical trainees for 2003: Evelyn Craig Stephanie Hyde David Kitaura Kristy McMaster Emma Mollet-Wright Electrical and mechanical fourth year apprentices were congratulated for their efforts and success. These included: Electrical apprentices: Damien Barbi Shaun Edmonds Jason Browning Mathew Stanley Mechanical apprentices: Mathew Wheeler (Apprentice of the year) Glenn Edmonds Robert Bertram Kai Shanks (Left earlier this year) Presentations were also made to the following graduating clerical trainees for their commitment over the past 18 months to BHPBIO: Shaun Cowe Sally Denton Amanda Foster Leila Pattison (Trainee of the year) Shaydeen Thompson Safety pilot program for Hedland housing Home electrical safety in BHPBIO housing will be upgraded in a pilot project which is currently underway. Over the coming year, 180 properties within Port and South Hedland will have improved electrical circuitry. Items to be upgraded include: • replacement of existing electrical switchboards with a new unit complete with earth leakage protection (residual current device or RCD) • installation of smoke detectors and emergency lighting; and • installation of functional switches for stoves. Current vacant and rental properties will be first to receive the safety upgrades. They will also be included on the list of eligible improvements under the company’s Home Purchase Schemes. Details of the arrangements will be notified to employees by the Housing Office. “We are very proud to be leading the way in Australia by retro-fitting RCDs to our employee housing. We have been retro-fitting RCDs to upgraded properties, but this project is a proactive additional step to improve household safety,” said Manager Site Administration Services, Tim O’Neill. RCDs have been mandatory in new houses and when modifications are made to existing houses since 1992. More recently it has included lighting circuits. Functional switches on stoves are a requirement under AS3000, and provide the ability for the householder to cut power to the stove in the event of an emergency. Hard-wired smoke detectors are also becoming mandatory in new houses. Personnel on the move -July DEPARTURES PORT HEDLAND (BHPB Iron Ore) PORT HEDLAND (Boodarie) Shayne Pettersen, Wayne Mascord, Production Controllers. Gemma Rapson, Public Affairs Officer. Lindsay Tynan, Track Technician. Rory MacKinlay, Maintenance Technician. Garry Baker, Crew Leader Gold. Jeffrey Tite, Turnaround Coordinator. Kerrie Waldron, Human Resources Administrator. PORT HEDLAND (BHPB Iron Ore) Edward Roberts, Rail Transport Coordinator. Jeffrey Powell, Mineworker. Abbas Maswari, Electrical Tradesperson. Luciano Pecoraro, Stephen Clark, Engineering Technicians. Gary Ahrens, Resource Coordinator. Andrea Healey, Supply Officer. NEWMAN Tara Jones, Administration Assistant. David Gerrard, Mine Geologist. Michael Hawkins, Natasha Rutherford, Timothy Bell, Scott Adshead, Catherine O’Brien, Ernie Hodder, David Parke, Mark Reynolds, Timothy Hudson, Mark Draper, Production Technicians. PERTH David Reid, Resource Geologist. NEWMAN TRANSFERS OUT David Cartwright, Engineering Tradesperson. Carolyn Jensen, Peter Jensen, Production Technicians. Boris Jovanovich, Process Technician. David Daines, Mine Study Coordinator (Newman to Perth). Matthew Carson, Senior Planning Geologist (Yarrie to Perth). Christopher Newman, Program Manager (Newman to Perth). David Tibbles, Communications and Monitoring Engineer (Boodarie to NSW Dendrobium). NEW STARTERS PORT HEDLAND (Boodarie) TRANSFERS IN Randall Findlay, Conveyor Technician. Mark Bushell, Emergency Services Team Leader. Samantha Thompson, Joseph Stadler, Financial Analysts. Bryan Hughes, HSE Advisor. Craig Ibbs, Heath Parish, Maintenance Technicians. Segundo Delgado, Senior Operations Engineer. Akhilesh Khare, Shutdown Planning Team Leader. Christopher Allen, Business Analyst (Melbourne to Perth). Training method stimulates interest Interested employees from Mt Whaleback and the Satellite Orebodies were recently invited to try their hand at operating an earth moving truck simulator with Immersive Technologies. The machine was en route to an expo in Darwin, and the owners agreed to stop off at the mine to give our operators and supervision the chance to experience the sophisticated technology. The Australian owned and manufactured simulator is designed to safely train haul truck operators in a workplace environment, without wear and tear on machinery, and avoids having to take an expensive machine out of production. BHP Billiton Coal operations share a simulator at their operations at South Walker Creek with BHP Mitsubishi Alliance mines in Queensland. Ekati Diamond Mine in Canada and Escondida copper mine in Chile also use them to effectively train operators. Geoff Stocker watches while son Kane Stocker signs his 1st year Apprentice Indenture papers in the presence of Dean Dalla Valle, Vice President Ports. Mathew Wheeler (left), recipient of the BHPBIO 2003 Apprentice of the Year award with presenter Clint Watson of Coventry’s. Photographed in the operators seat of the simulator is Senior Production Technician – Lloyd Shay, watched by Supervisor Operations Training - Geoff Green and Graeme Rutherford from Immersive Technologies. IRON CHRONICLE GENERAL NEWS PAGE 7 5 Year celebratory dinner at Boodarie Boodarie Iron recently recognised their employees who had reached 5 years of continuous employment at the plant which dominates the Port Hedland landscape. Forty seven employees plus partners were invited to celebrate this milestone at a celebratory dinner at the Mecure Inn Port Hedland. We would like to acknowledge the following employees on their tireless efforts over the last 5 years of continuous service at Boodarie Iron. Barry Allen Wayne Archer Steve Attkins Garry Baker David Bercene Benita Breslin Graham Burton Adrian Button Kaye Cagney John Cheape Mark Cleaver Colin Connelly Allyn Cooper Andrew Cox Chris Dul Tony Elliott Christopher Englebrecht Marcus Etto Noelito Fabio Bryan Goldsbury Danni - Lee Grace Bruce Grange Paul Hannan Chris Hart Paul Hinton Stephen Hubbard James Keijzer Simon Kingdon Dougal Lamph Peter Long Onsite learning for St Cecilias Earlier this term, St Cecilia’s Middle School students asked Nelson Point employees to assist them with their Term 2 focus on “Our Community”. The students were asked to study BHP Billiton Iron Ore to determine how it fits in to the Port Hedland community. It was an opportunity for the students to get a sense of how the company operates and gave them an insight to possible career options. They applied the knowledge they gained from the company across all of their subjects including Social Economics, Environment, Maths and Science. The project commenced on 5 May with a site tour of Nelson Point and welcomes from BHPBIO staff. During the project, employees were asked to assist by providing information in talks to classes and by participating in group discussions. At the conclusion of the five week project, the students presented their findings to their teachers, parents and BHPBIO. According to staff from BHPBIO the presentations were highly professional and the students were commended for the effort and research that they put into their assignments. Year 9 student Shakira Shaik who was involved in the project said she had fun learning about the different roles at BHPBIO. “I learnt about what the Occupational Health & Safety Officers do and what rules employees have to follow. The project was much more interesting than working from text books because it was something relating to our community and us,” she said. Teacher Terri Van Zetten said the project was a great success. “It was the first time the students and teachers had undertaken such a large integrated project. “It was amazing to see students who wouldn’t read a sentence out loud in class two months ago, present a well polished presentation to a room full of peers, employees, teachers and parents. We are lucky to have a company in our community so supportive of the education of our children.” Jim McNish Shoena Messner Glen Oliver Mark Ontronen Mark Palladino Stephen Prior Jamie Procter Peter Razbocan Sunil Rodrigues David Ross Brian Scott Walter Stocco Walter Tugby Gavin Watts Keith Wenban Richard Whittaker Stewart Wilson BHPBIO funds Skatepark The park, located on Mindarra Drive, Newman, is under construction at present and is expected to be completed before the end of the year. Fundraising for the project has been a joint effort between the Newman community, the Shire (which will maintain the area) and BHP Billiton Iron Ore. Vice President Mining James Shaw recently presented a cheque for $20,000 towards the construction of a new Skate Park to Skatepark Committee Chairperson and Manager Recreation & Sport Danielle Cooper (centre) and Committee Member Jacqui Stutt. Al makes 30 years on the job Senior Production Technician, Al Jessop recently celebrated 30 years of service in Port Headland with friends and colleagues of past and present. During the presentations, the audience were captivated. 1978 was a good year Celebrating his 25th anniversary in Redmont Accommodation Village this month was Track Foreman, Joe Marevich. Josip (Joe) Marevich joined the company in 1978 as a mineworker in the Hedland Track Maintenance gang. He then became a motor vehicle driver until 1979 when he was promoted to Thermit Foreman. During 1983 Joe was appointed Foreman of Thermit 4 (welding gang) at Newman. After 11 years in the position he was promoted to Track Foreman – Newman before being transferred to Track Foreman – Redmont in 1997 where he remains until now. Whilst in Redmont for a meeting with IO Vice President, Graeme Hunt celebrated the anniversary with Joe and his workmates. Joe thanked BHPBIO for the job opportunity and declared that it was more rewarding than driving trucks around Perth. Congratulations Joe on Joe Marevich receives his watch and certificate from reaching this milestone. Graeme Hunt. Al enjoyed reminiscing over morning tea about the early days with the company. He proudly highlighted his time in A-Shift Operations and their achievement of 22 consecutive years with no lost time injuries. “The only reason this record was achieved was because of the team work – guys working together for a common goal,” he said. He went on to say that he’d enjoyed working for BHPBIO. “One thing I can say about Port Hedland is that it’s a great community with great people.” Al was congratulated by Manager Port Operations, Paul Donaldson. “Al is viewed as a true gentleman who has a strong commitment to both work and the community,” he said. “Thirty years is truly a remarkable achievement and we look forward to Al’s contribution in the future.” Al’s commitment to the Port Hedland community is evident by his role as President to the local RSL. Manager Port Operations, Paul Donaldson congratulates Al Jessop. GENERAL NEWS PAGE 8 Pub to port for charity The 33rd annual Black Rock Stakes ran recently with BHPBIO team 10 Megahurts once again featuring as strong contenders. With the 5:36:14 overall record under their belt since 2001, 10 Megahurts unfortunately fell short of breaking their record this year coming in at 5:48:00. Commencing the race in high spirit at the Whim Creek start line chanting “Eye of a Tiger”, an overwhelmed 10 Megahurts crossed the Wedge Street finish line bearing sore limbs, although thrilled to finish the race for another year. Perth based team Oresome Power attempted to snatch the record on the day, but fell short by just under two minutes. However, they did manage to achieve a new mixed team record. Asked what makes them fill a wheelbarrow with 11kg of iron ore, and run for six hours through 120km of Australia’s hottest country, here is what 10 Megahurts said; “Charity, madness and a desire to try everything at least once!” said Rachel Curry. “The race itself is horrible, grueling, tiring (mentally and physically) but the fundraising for the charity, backed by tradition and Mr Walsh (founder of Black Rock Stakes) along with the sense of achievement and absolute relief after crossing the finish line make it an unforgettable event,” from Ryan Harrington And from Trina Yardley; “you may think we are insane … but the feeling you get when you cross that finish line is a HUGE sense of achievement.” 10 Megahurts were the highest fundraisers this year handing over a cheque for $5,100. Monies raised through the event will be distributed to local organisations during the coming months. Congratulations 10 Megahurts for keeping the tradition alive. BHPBIO continues to sponsor the organising committee and providing support vehicles to teams competing. Thanks must go to the major sponsors C & F Boilermaking, Hedland Sheetmetal and Auslec and the minor sponsors Blastworks. Geographe, Trevelle Engineering, Excel, Blackwoods, J.K’s Aluminium and Astute Promotions. IRON CHRONICLE Cricket camp prepares for Pilbara game Twenty-four talented and enthusiastic junior cricketers from Port Hedland and Newman were selected for the annual BHP Billiton Pilbara Talent Camp in July. During the four day camp the Under 13 players benefited from daily skill sessions and specialist coaching by WACA Cricket Officers Joe Sarsero, Noel Knight and Andrew Dawe. The camp concluded with a hotly contested test match, which also gave the parents the opportunity to attend a Level One coaching course. This is the first time the talent camp has been held in Newman. It has previously been hosted by the Port Hedland Junior Cricket Association. The camp was organised under the guidance of BHPBIO Junior Cricket Program Co- ordinator Greg Haines. It is part of the WACA talent identification and development pathway and provides players in Newman and Port Hedland the opportunity to aspire to regional and state levels. Greg Haines said during the BHP Billiton Iron Ore / WACA partnership, the number of under 13s players had grown markedly in both towns. “Recently, NJCA President Grant Withers and I organised two teams that visited Port Hedland for inter-town matches. This augurs well for both towns as they develop squads for the Pilbara Championships, held annually in the under 16’s age-group. “The camp was a great success and the WACA Cricket Officers commended the players on their behaviour, attitude and skills level shown during the camp,” said Greg. The 10 Megahurts team (from left) Ryan Harrington with barrow, driver Terry Burnham, Andrew Shearing, Nicole Plint, Rachel Curry, Doug Yardley, Regina Stene, Trina Yardley, Gordon McLeod and Mark Bray (absent are Catherine Properzi and Paul Hanley). BHP Billiton Iron Ore Junior Cricket Program Co-ordinator Greg Haines, (third left) with WACA Cricket Officers Joe Sarsero, (left) Noel Knight and Andrew Dawe, the talented junior cricketers from Port Hedland and Newman and parents from Port Hedland John Gibbons and Peter Harris (at rear). Andrew Shearing takes over from Doug Yardley cheered on by 10 Megahurts (from left) Jason Brooks, Regina Stene, Gordon McLeod and Paul Hanley. Newman hosts Northwest Netball The annual Northwest Regional Netball championship was hosted recently in Newman, with 392 participants from 28 teams. Sponsors of the 10 Megahurts team. Doctor crosses the line Company Doctor Martyn Flahive and his wife Sandra ran in the grueling 89 kilometre Comrades Marathon in South Africa recently. The race began in 1921 and was organised by Vic Clapham, a returned soldier who established the event as a living memory to those who had fallen in the Great War. The direction of the race alternates each year, creating the ‘up’ and ‘down’ runs, each with their own set of challenges, not the least being that the runners need to finish inside 12 hours or they will be recorded as not finishing. This year’s race attracted about 12,500 starters, with around 11,400 finishing the run inside the specified cut-off time of 12 hours. Martyn and Sandra crossed the line together in just eight hours and 53 minutes. Martyn is a strong advocate for running as a form of exercise, however, he acknowledges it is not necessary to train as hard as he and Sandra do to gain an improvement in general health. “Recent studies have shown running promotes a longer and healthier life. It has a positive effect on general physical health, lowering blood pressure and reducing the incidence of heart disease and obesity. Walking is also known to have good results, however the more vigorous the exercise, the better. “A good target to meet is 45 minutes to an hour a day of exercise, five days a week. Running is good, however you must have healthy joints so it’s a good idea to be checked by a doctor before you start an exercise program. Company Doctor Martyn Flahive and wife Sandra cross the finish line of the 2003 Comrades Marathon in Durban, South Africa in a time of eight hours and 53 minutes. The race follows a hilly 89 kilomEtres course from Pietermaritzburg to Durban and runners need to complete the race inside the cut-off time of 12 hours or their efforts are unrecognised. Results for the Newman Teams were – Newman Under 13s - runner up. Newman Under 15s - third. Newman B - third. Newman Masters - Runner up. Newman A – third. Newman Netball Association President Tamara Dearlove said the championship weekend went very well, despite the rain on Sunday during the finals. “This year more individuals were selected for talent identification opportunities than in previous years, and this is partly due to the expanded partnership between BHP Billiton Iron Ore and WA Netball, and also to the efforts of the local coaches and players. “I was very pleased with the achievements of all the Newman teams and would like to thank all of those who were involved in organising the weekend, including all of our sponsors, particularly the Ministry of Sport and Recreation, Healthways and BHP Billiton Iron Ore for their support,” said Tamara. Newman Under 15’s team at the Northwest Championships in Newman recently. Back row (from left) Rachael Houpapa, Jenni Cumbers, Tarian Reuben, Skye Reuben. Meray Baramily. (Front row): Katherine Evans, Regina Nelson, Amy Downes, Sophie Tomalin. Warriors win BHPBIO cricket premiership Under blustery conditions at the town oval, the South Hedland Warriors came up against the Port Hedland Bulls to decide who would be the 2003 BHP Billiton Iron Ore Junior Cricket season premiers. The Warriors won the toss and elected to bat, but the Bulls struck early to take three quick wickets, before a match winning partnership between Jamie Rasmussen (24no) and Mitchell Williams (44no) steadied the innings. Further contributions from Aaron Neech (33no) and Drennan Goodall who made 21 pushed the total to an imposing 186. Waisea Emmitt was the pick of the Bulls’ bowlers and claimed 2/8 from his two overs. In reply the Bulls batted without ever threatening the target, eventually reaching 105 off their allotted 24 overs. Bryce Liddle batted well to make 20 and Mark Lynch, Alan Cowen and Will Thomas all made 14. Mitch Williams capped off a man of the match performance to claim 2/3 and Warriors captain for the day Michael Rasmussen bowled a wicket maiden to help his team to victory. Back row L-R -Beaudee Harris, Jamie Rasmussen, Aaron Neech, Mitchell Williams, Kim Rasmussen ( COACH ) Jake Saville, Jake Barrett, Nathan Miller. Front row L-R Jason Gaugg, Bradley Podmore, Michael Rasmussen, Drennan Goodall, Felix McKenzieRae, Heath Johncock.