INSIDEUSW@WORK

“

Rebuilding America’s manufacturing base is

central to rebuilding our nation’s economy.

Richard Trumka

AFL-CIO President, May 4, 2011

”

I N T E R N AT I O N A L E X E C U T I V E B O A R D

Leo W. Gerard

International President

04

Stan Johnson

Int’l. Secretary-Treasurer

Thomas M. Conway

Int’l. Vice President

(Administration)

Fred Redmond

Int’l. Vice President

(Human Affairs)

08

ARTISTRY IN METAL

RG STEEL

USW members working for Wendell August

Forge maintain a tradition of quality craftsmanship at the decorative metalwork business, which

burned to the ground a year ago in 2010.

Some 6,000 USW members have ratified

a contract with newly-formed RG Steel,

which purchased facilities from Severstal,

the Russian steelmaker.

Ken Neumann

Nat’l. Dir. for Canada

Jon Geenen

Int’l. Vice President

Gary Beevers

Int’l. Vice President

Carol Landry

Vice President at Large

DIRECTORS

David R. McCall, District 1

Michael Bolton, District 2

Stephen Hunt, District 3

12

14

INTERNATIONAL PAPER

WE ARE ONE

USW members at 15 local unions at International Paper Co. mill locations overwhelmingly

ratified a new four-year contract that covers

6,000 workers and sets a bargaining standard.

F E AT U R E S

Speaking Out

CAPITOL LETTERS

News Bytes

03

33

34

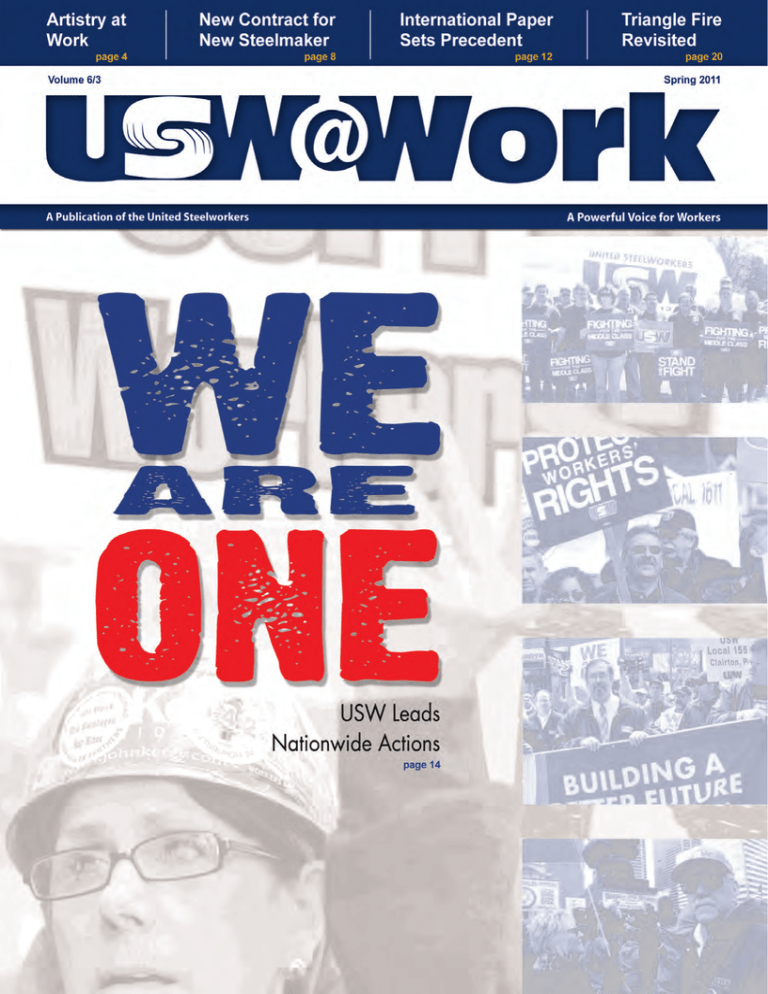

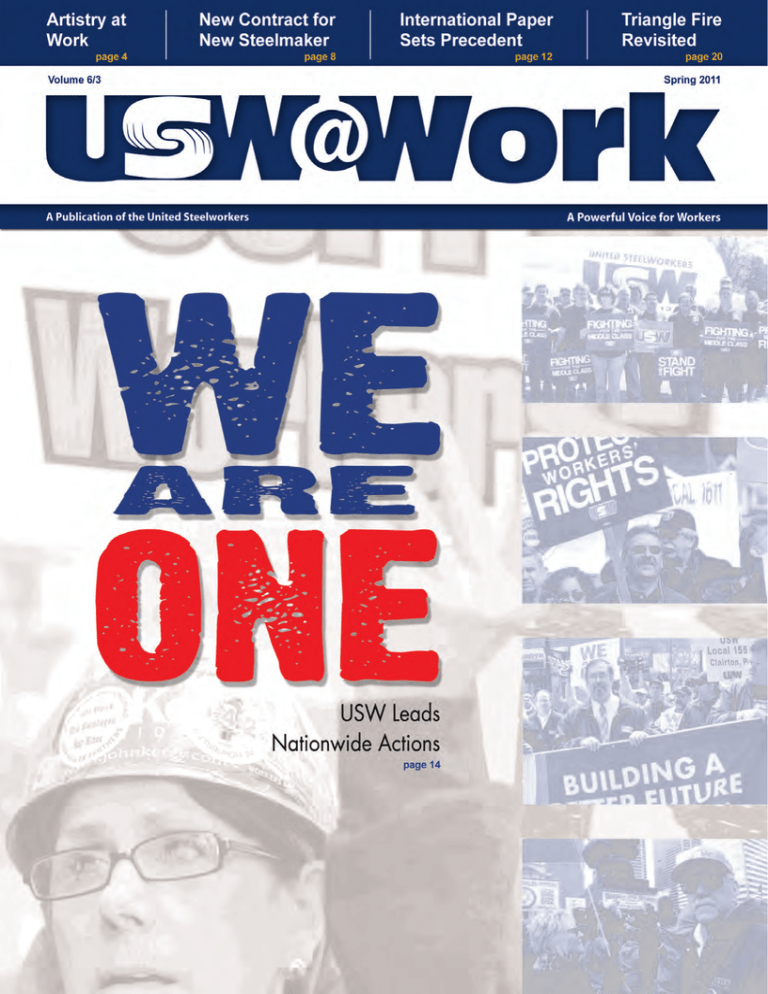

The USW participated in multiple rallies on

April 4 as part of the AFL-CIO’s “We Are One”

campaign, meant to pay tribute to Dr. Martin

Luther King Jr. and his fight for social justice.

ON THE COVER

Union activists participate in USW-led rallies across the country.

William J. Pienta, District 4

Daniel Roy, District 5

Wayne Fraser, District 6

Jim Robinson, District 7

Volume 06/No.3

Ernest R. “Billy” Thompson, District 8

Daniel Flippo, District 9

John DeFazio, District 10

Robert Bratulich, District 11

Robert LaVenture, District 12

J.M. “Mickey” Breaux, District 13

C O M M U N I C AT I O N S S TA F F :

Jim McKay, Editor

Wayne Ranick, Director of Communications

Gary Hubbard, Director of Public Affairs, Washington, D.C.

Aaron Hudson and Kenny Carlisle, Designers

Lynne Baker, Jim Coleman, Deb Davidek,

Connie Mabin, Tony Montana, Scott Weaver,

Barbara White Stack

Spring 2011

Official publication of the United Steelworkers

Direct inquiries and articles for USW@Work to:

United Steelworkers Communications Department

Five Gateway Center

Pittsburgh, PA 15222

phone 412-562-2400

fax 412-562-2445

online: www.usw.org

USW@Work (ISSN 1931-6658) is published four times a year by the United Steelworkers AFL-CIO•CLC Five Gateway Center, Pittsburgh,

PA 15222. Subscriptions to non-members: $12 for one year; $20 for two years. Periodicals postage paid at Pittsburgh, PA and additional

mailing offices.

POSTMASTER: Send address changes to: USW@Work, USW Membership Department, 3340 Perimeter Hill Drive, Nashville, TN 37211

Copyright 2011 by United Steelworkers, AFL-CIO•CLC. All rights reserved. No part of this publication may be reproduced without the

written consent of the United Steelworkers.

2

U S W @ Wo r k • S p r i n g 2 0 1 1

Big Money Waiting to Pounce

This is an open letter to all those naive under

age 60 people who say the era of the labor union

is past. They have the idea that benefits such as

the 40-hour week, time and one-half for overtime,

vacations, health care, pensions, safe working conditions and other benefits were won, and we don’t

need to worry about those things anymore.

Well guess what, big money hasn’t given up.

They were waiting for the right moment to pounce

and wipe those benefits out. All the blood, sweat

and tears of my father’s generation and my generation that were put into gaining a respectable life for

the working person can be gone in an instant, and

politicians are doing it right in front of our eyes.

I am 84 and it won’t harm me much, but

younger folks are going to get a hard lesson in reality. Greedy people are like hogs at a feed bin. They

push one another out so the biggest hog can get

more. That’s what is happening with your pay day

and good-paying jobs.

Donald Renzenbrink, Local 2879

Poland, Ohio

VEBA Thank You

Thank you for the VEBA (trust fund benefits

for retirees who lost health care coverage in bankruptcies). I sincerely appreciate the union. My late

husband was a member from 1955 to 1982, retiring

from the LTV Cleveland Works. Thank you for

being there for us retirees and surviving spouses.

You have been a life savior to me.

Novella Reese

Mountain City, Tenn.

Buy American, But How?

I am retired. All I read is buy union and buy

American made, but I don’t see any articles that

tell us what is made in this country. I believe

unions should help us make American decisions.

Vince Castelli, SOAR

Levittown, Pa.

Praying for Jobs and Workers

I am thankful for the fact that my husband

worked for Goodyear Tire at Union City, Tenn.,

before he died with Alzheimer’s disease in l987.

His union affiliation has been a godsend for me.

I am troubled that Republicans are trying to

bust the unions … I’m 78 years old and praying

for good union jobs and workers. We need jobs

here and more goods made in America.

Bless all union leaders and workers. I’m so

proud of workers in Wisconsin, Indiana, Ohio and

all who stand against the Scott Walkers of this

world.

Patsy Wilkerson

Dresden, Tenn.

Fighting for Everyone

For a while there I was really worried that

people just didn’t get unions and were going to do

nothing. I really love what I’m seeing. I now know

there are a lot of people who get it. Even nonunion

people get it. Unions are the backbone of this country. They fight for everyone.

Glen Dunaway, Local 735 President

Cleveland, Ohio

Proud to Stand Up

I am very proud to stand in unity with union

brothers and sisters who stood beside us during our

lockout by one of the biggest union busting corporations in the world: Honeywell International.

Only with the help of the USW International

could a small local of 230 dare stand up to our employer. Now we are road warriors and attend rallies

to support others in their fight against those trying

to destroy the middle class.

In Wisconsin, Indiana and Iowa – at every

event we find new friends and allies in the war

against the middle class.

Luckie Atkinson, Local 7-669

Metropolis, Ill.

Don’t Worry About What I Watch

I am a very proud, vocal union member who

actually attends my local union meetings without

fail. Now that said I would like to make it clear that

I don’t agree with your blatant partisan politics.

Do you really think that I am going to suddenly

tune in Ed Schultz because it is approved by the

higher ups at the USW? Are you kidding me?

Both sides in this little culture war are idiots.

How about concerning yourself more with the

needs of the rank and file and not worrying so

much about how we vote or what we watch on TV?

Douglas Hansen, Local 12934

Weidman, Mich.

We’re Being Screwed

I was a member of USW for 30 years until

Northwestern Steel and Wire of Sterling, Ill. shut

down. I was and still am proud to have been a

union member.

But the reason I am writing is that I am very

unhappy with the state of America. We the people

are being screwed in every way possible and in my

opinion there are only a couple of ways to fix this.

One way is an American Bastille Day, but this

would be an all-out revolution. A better way would

be to have a national union with all working people

as members. If someone is getting screwed over,

the entire country would be with them.

Rick Stoudt, Retired Local 63

Rock Falls, Ill.

USW active and retired

members and their

families are invited to

“speak out” on these

pages. Letters should be

short and to the point.

We reserve the right to

edit for length.

Mail to:

USW@Work

Five Gateway Center,

Pittsburgh PA 15222

or e-mail:

editor@usw.org

U S W @ Wo r k • S p r i n g

2011

3

Greg Summerville, left, and

Bill Saunders, work polishing wheels

USW Photos by Steve Dietz

4

U S W @ Wo r k • S p r i n g 2 0 1 1

W

alk into any home

where a hand-crafted

piece of Wendell

August Forge giftware

is displayed and you might think you

are viewing an exquisite heirloom

made by European artisans.

In reality, Wendell August Forge

is American-made artwork produced

by Steelworkers who are keeping

alive a business that has for 88 years

furnished generations with distinctive decorative metalwork.

With the help of its employees,

customers and the local community,

the company is rising like a phoenix

from the ashes of a devastating fire

that destroyed its shop last year on

March 6.

“It’s rewarding for me to make

something that customers will

value as a keepsake gift, something

that they will cherish,’’ said Jason

Fleischer, a member of Local 634615 and one of 40 employees hired

by Wendell August after the fire

completely destroyed the shop in

Grove City, Pa.

The USW represents about 40

production workers at Wendell August. Total employment, including

distribution, sales and management,

is 115.

“I really wanted to find a job

where I would be doing something

that I believe in, where I would be

rewarded through the concept of

hard work,” he said.

The destroyed factory, a tourist

attraction where customers walked

among the craftspeople, was listed

on the National Register of Historic

Places before the fire burned it and

a gift shop to the ground within a

couple of hours.

All was not lost though. The

company’s heritage – more than

4,000 unique dies used to imprint

designs onto end products – was

spared from the fire. About 35 percent of the dies were in a fire proof

vault. The rest required painstaking

restoration, a task that is not yet

complete.

Digging through the rubble

Employees searching through the

remains of the old building found

much more than the dies that were

needed to continue the operation,

said Local Unit Chair Ed Hodge.

“We dug through the rubble,

recovering anvils, hammers and

various scorched but salvageable

tools,” he said.

Will Knecht, the company’s

president and current owner, said

employees “have done a phenomenal job” in getting the business up

and running in a temporary location.

“They literally worked around

the clock after the fire, never a

complaint; an amazing group of employees,” he said. “I am proud to be

associated with workers who have

a true dedication to their job, and a

work ethic that is beyond compare.”

Knecht said during the fire, “Everyone was watching, wondering, as

our building was engulfed in flames,

‘have I just lost my job?’

“But we rose together as a group,

digging our dies from the still smoldering ashes to begin the renewal

process. The fire was a galvanizing

moment for all of us.”

The business quickly reorganized to fill the biggest order in the

company’s history – 20,000 pieces

commissioned two days before

the fire by the Pittsburgh Penguins

hockey team.

There was only four weeks to

complete the huge order – each

piece a metal image of a ticket from

the final NHL game played at the

now closed Mellon Arena.

“Five days after the fire we had

our first hammering ceremony,”

Knecht said. “Everyone agreed

to work around the clock, six and

seven days a week – and this work is

very physical.”

The order was delivered on time.

Jason Fletcher

Established in 1923

The forge was established in

1923 by Wendell August, a coal broker who got the idea after he asked

a mine blacksmith, Ottone “Tony”

Pisoni, to make him decorative door

latches. The business started out

making ornamental iron fireplace

andirons, candlesticks, latches, railings and the like.

Eventually, August, who had lost

his coal mine interests in the 1929

stock market crash, got involved

with aluminum, then a new wonder

metal produced by Aluminum

U S W @ Wo r k • S p r i n g 2 0 1 1

5

Company of America, now Alcoa.

The blacksmith Pisoni, who had

been apprenticed to an ornamental

iron maker in Italy, applied his old

art to the new metal and learned

to make architectural elements.

Rust-free aluminum was lighter than

iron and thus easier and cheaper to

install.

Alcoa, looking for new markets

and wanting to dress up the front

of its new research laboratory near

Pittsburgh, awarded Wendell August

a contract to make elaborate entrance gates.

The product line grew over the

years to include a wide variety of

hand-hammered metal items including Christmas ornaments, trophies,

serving trays and even a line of

jewelry.

At one time, there were more

than 200 companies making handhammered aluminum giftware. Wendell August Forge now claims to be

the last hand forge of its kind in the

United States, if not the world.

Craftsmen cross-trained

All of the shop’s craftsmen are

cross-trained in the production process. It can take up to three years to

become proficient at each phase of

the operation.

A unique part of the work is dieengraving and hammering. Master

die engraver David Bruck, a 31-year

veteran, taught Len Youngo, a 30year veteran, the artistry of drawing, hammering and chiseling dies.

Youngo is now passing the knowledge to the next generation, his son

Mike, an apprentice.

“Because we don’t have color,

we work towards creating different

shades. We use texture to imitate

color,” Bruck said. “Everything

we do is shallow so we try to

create minute depth.”

The intricacies like leaves

on a tree or details of bird feathers are no easy task. Depending

on the size and detail, it takes

from one day to eight weeks to

create each die.

The engravers begin with a

drawing. Then, using various sized

hammers and carbide chisels, they

create the image into a one-inch

thick piece of malleable tool steel.

6

U S W @ Wo r k • S p r i n g 2 0 1 1

Remarkably, the design is chiseled in reverse image. Once finished,

the die will be annealed to harden

the steel.

The die’s image is then transferred into the metal using a technique called repousee – pressing

or hammering on the reverse of the

metal to form a raised design on the

front.

Metal sheets, in most cases

aluminum but sometimes copper,

pewter or bronze, are placed on top

of the die and then a craftsman hammers the metal into the chiseled out

portions of the die to create a raised

design.

Old world craftsmanship

USW craftsmen then use an anvil

to smooth rough edges created when

the metal is cut. They then add hammered, scalloped edge marks one

hammer swing at a time.

The design is brought to life with

black coloring that is applied before

buffing. Polishing removes most of

that color, leaving just enough to

help “pop” the design. Finally, the

piece is polished with a bees wax

electric buffing wheel to enhance the

shine.

USW master craftsman Bill

Saunders describes their work as,

“quality, hand-made, old-world

craftsmanship with a modern flair.”

Fleischer is happily living the

amazing story of recovery and

renewal. He said his grandfather

worked as a Steelworker for over 30

years at Armco Steel, and frequently

reminded him that a “job worth doing is worth doing right.”

Fleischer said he believes in the

quality and value of the hand-made

craftsmanship visible throughout the

shop floor. The outcome is extraordinary hand-crafted heirloom metal

gifts.

Today’s customers, he said, seem

drawn to quality goods made in

America by skilled craftsmen who

earn their livelihood in good familysupporting jobs.

“Consumers want to make quality purchases, items that will last,

just like what we create here,” he

said. “My entire life outlook has improved since I started working here.”

Ed Hodge, Unit Chair Local 6346-15,

hammers edges on a piece of aluminum

USW Photos by Steve Dietz

U S W @ Wo r k • S p r i n g 2 0 1 1

7

S

ome 6,000 USW members who

have worked for a variety of

owners and been through the

bankruptcy process multiple

times are now employees of newlyformed RG Steel.

The former Wheeling Pittsburgh

Steel, Bethlehem Steel – Sparrows Point

and WCI Steel workers ratified a new

contract with RG Steel on May 5 when

ballots were counted in Pittsburgh.

RG Steel had purchased the facilities

in Maryland, Ohio and West Virginia

from Severstal, the Russian steelmaker

that had acquired them in 2008 as U.S.

steel prices surged, only to idle capacity

following the global financial crisis.

“Our members and our retirees at

these plants have endured some of the

most difficult challenges related to the

steel industry, and they have more than

earned the security that comes with

working for a viable employer,’’ International President Leo W. Gerard said.

USW District 1 Director David McCall, who chairs the USW’s RG Steel

negotiating committee, said, “The road

to RG Steel was not the fastest or easiest,

but with the support and solidarity of our

brothers and sisters on the shop floor, we

ended up in the right place.”

McCall was referring to the fact that

the USW committee was hamstrung

in negotiations with Severstal North

America for over two years while the

company changed business and operating

plans several times, then announced it

was looking to sell its USW-represented

facilities.

The first meeting between a negotiating committee representing eight units of

hourly production, maintenance, office

and clerical employees from what were

then three separate companies took place

in October 2008 with Severstal after it

purchased the plants.

After all, back in the first three

quarters of 2008, integrated steel producers were reporting record shipments and

profits. For many reasons, Severstal’s

purchase of the USW facilities in Wheeling, Warren and Sparrows Point, Md.,

made perfect sense.

Seeking viable employer

Severstal wanted a greater presence in

the U.S. market and the union supported

and encouraged the company to purchase

the facilities because it believed a third,

8

U S W @ Wo r k • S p r i n g 2 0 1 1

consolidated integrated steel producer

would be a more viable company in the

long term and better equipped to provide

members and retirees with economic,

employment and retirement security.

A strong and stable Severstal never

materialized. Instead, the global economic collapse that began in October

2008, literally while the USW and

Severstal bargaining committees were

trying to wrap up negotiations, changed

everything.

Beginning in 2009, the business and

operating challenges of the industry

changed Severstal’s focus, and the company’s inability to develop and maintain

a clear vision and strategy in regard to

its USW-represented plants eventually

made success impossible. The company

also could not understand the needs of

USW members for real security and

sustainability, which became a major

impediment to moving forward with

Severstal management.

Before long, due to circumstances far

beyond our control, thousands of USW

members were laid off, and to make matters worse, the negotiating committee

was challenged in bargaining for over

two years of month-to-month (and sometimes day-to-day) contract extensions,

just to maintain the status quo.

The delegation from USW Local 9477

counts ratification ballots on May 5, 2011

at USW headquarters in Pittsburgh.

“

A “stand alone” Wheeling-Pittsburgh

Steel, Bethlehem-Sparrows Point or

WCI Steel would almost certainly have

been bankrupt by the end of 2009, if not

for our consolidation efforts. Instead,

members remain protected by the provisions of their Basic Labor Agreement.

Health care coverage and supplemental

unemployment benefits were protected

under agreements with Severstal, which

required the company to continue its

obligations to pension funds and laid-off

members.

After an excruciatingly long sales

process, where realistic bidders and

potential new owners with plans to keep

making steel in our plants were few and

far between, RG Steel signed an agreement to purchase the USW-represented

facilities of Severstal in early March

2011.

Having withstood the crisis in steel

from 1998 to 2003, when over 50

American steel companies – including

all of these plants’ previous employers – sought protection from creditors

in federal bankruptcy court, the USW

applied some of the lessons learned from

the past to protect the future.

At that time, the USW provided the

leadership that was needed to consolidate and restructure the industry, create

THE ROAD TO RG STEEL WAS NOT THE

FASTEST OR EASIEST, BUT WITH THE

SUPPORT AND SOLIDARITY OF OUR

BROTHERS AND SISTERS ON THE SHOP

”

FLOOR, WE ENDED UP IN THE RIGHT PLACE.

When the time came, the committee supported and in fact demanded that

Severstal sell the facilities, knowing that

with the right strategy and the right owners they would be successful. However,

it should be recognized that without

Severstal, the plants could have been

shut down during the collapse of 20082009 and our “safety nets” (health care

continuation and supplemental unemployment) might have been lost.

job security, improve retirement security

and ensure that incomes and other benefits would be protected in good times

and bad.

Unity and determination have been

our strongest allies in the struggle to

achieve our goals, and for the first time

since the global economic collapse

in late 2008, we are working with an

employer that has a clear vision and

business plan for the future.

U S W @ Wo r k • S p r i n g 2 0 1 1

9

U

SW members at Gamesa Technology Corp. in

Pennsylvania are expected to help build 51 wind

turbines for a utility-scale wind farm in the Central

American Republic of Honduras.

The project won Gamesa the 2011 Renewable Energy Exporter of the Year award from the Export-Import Bank of the

United States. The award was presented at the bank’s annual

conference in Washington, D.C. on March 31.

“Gamesa is an excellent example of how innovative,

renewable-energy companies can help meet energy needs

across the globe and create jobs here at home,’’ said Ex-Im

Bank Chairman Fred Hochberg.

A few days after the Ex-Im Bank award, Gamesa was

in the spotlight again when President Obama stopped by its

plant in Fairless Hills, Pa. to tout his administration’s energy

program, among other topics.

Glimpse of the future

“I think what you do here is a glimpse of the future, and

it’s a future that is less dependent on foreign oil, more reliant

on clean energy produced by workers like you,’’ Obama told

employees gathered for a town hall-style meeting.

The Ex-Im Bank, an independent federal agency, is financing the project with a direct $159 million loan to Energia

Eolica de Honduras SA for the Cerro de Hula Wind Farm, the

first large-scale wind power project in Honduras.

Obama said projects like this, aided by financing through

the Ex-Im Bank, will help meet his goal of doubling U.S.

President Obama greets USW members

at the Gamesa plant in Fairless Hills, Pa.

Photo courtesy of Gamesa

10

U S W @ Wo r k • S p r i n g 2 0 1 1

exports over the next five years.

“The way countries succeed over the long term is by making stuff and selling it to somebody else,’’ the president said

to applause from the workers around him.

“We’ve got the best technology. We’ve got the best workers in the world. But we are such a big market that a lot of

times we’ve been focused more internally than thinking about

how can we sell to other countries. And we can’t be afraid of

competition. We’ve got to go after it.”

When operational, the wind farm will be the fourth largest

power generator in Honduras, producing about 6 percent of

the country’s power needs.

Gamesa employs 900 here

Gamesa employs 900 in the United States, including about

800 at manufacturing facilities in Pennsylvania where the

USW represents production workers. Gamesa, based in Spain,

opened its U.S. operations in 2005.

“It’s a remarkable story when a Spanish company such as

Gamesa invests in high-paying U.S. jobs in Pennsylvania and

then is able to export wind turbines to customers in Central

America,” Hochberg added.

The mechanical part of a wind turbine – nacelles and the

equipment inside them – are assembled in Fairless Hills on

the site of a former U.S. Steel Corp. plant. Gamesa spent an

estimated $70 million to develop the site.

Wind turbine nacelles sit on top of a large steel tower and

house a drive train that consists of a gearbox, connecting

shafts, support bearings, a generator and other equipment.

Gamesa also produces wing-shaped blades at a USWrepresented plant in Ebensburg, Pa. that it spent $80 million

to develop. But those blades, Gamesa’s newest design, are

larger than what is required for the Honduran project.

Smaller blades of an older design more suited to the wind

in Honduras are expected to be built for the project by LM

Glasfiber Inc. in North Dakota, a Gamesa supplier.

Critical for our nation’s future

Obama’s visit to Gamesa in Fairless Hills was his second

one. The president had campaigned at the plant three years

earlier while a candidate for president.

Employees heard the president tell them that the type of

energy they make possible is “absolutely critical” for the

future of our country.

Within a decade, the president said he wants the nation to

cut by one-third the amount of oil we import. He also wants

to double the amount of electricity that the nation generates

from clean sources including renewables like wind and solar,

as well as natural gas, clean coal and nuclear power.

“If we follow through on this, if we actually tackle this

challenge, here’s what will happen. Our economy will be

less vulnerable to wild swings in oil prices. Our nation will

no longer be beholden to the countries that we now rely on

for oil imports. We won’t be sending billions of dollars a

day to the Middle East. We can potentially keep some of that

invested right here at home.

“We’ll reduce the pollution that’s disrupting our climate

and threatening the planet that we leave for our children and

our grandchildren. We’ll become more energy independent.

And we’ll spark innovation and entrepreneurship across

America.”

Making a difference

While at Gamesa, Obama called out for Jim Bauer, a

former Steelworker who lost his job at U.S. Steel some eight

years ago when the company closed its Fairless Hills plant.

“This has made a difference in the community. It has

made a difference for folks like Jim Bauer,” the president

said. “This company brought back jobs to these floors. Buildings that were dark, they’re now humming again.”

Bauer had 25 years of service with U.S. Steel when the

closure of the Fairless Hills plant sent him into early retirement and computer school. He then came across a helpwanted ad that offered travel abroad and a high-paying job in

a new venture.

Bauer got the job and in 2006, Gamesa sent him to Spain

for training in production techniques. He came back as a

USW member, and for a time led a team of workers who built

giant hubs for wind turbines. Today he works in administration.

“Jim’s story should give us hope,” Obama said. “It should

give us some idea of the promise of clean energy for our

country.”

Windmill blade under construction at

Gamesa plant in Ebensburg, Pa. USW

Photo by Steve Dietz

U S W @ Wo r k • S p r i n g 2 0 1 1

11

U

SW members at 15 local unions at International

Paper (IP) mill locations overwhelmingly ratified

a new four-year contract that covers 6,000 workers

and sets a bargaining standard for the paper industry.

The agreement was approved by a 73 percent voting

margin, the USW and IP jointly announced May 3. A tentative

agreement was reached in April and had been recommended

for approval by an 80-member union bargaining committee.

The new agreement includes wage increases in each year of

the agreement, improvements to pensions and 401(k) retirement savings plans, health care cost stabilization and employment security.

The second generation Master Economic Agreement builds

on a previous contract that gave USW members benchmark

language to protect them in the event of a sale.

Strong local leadership

International President Leo W. Gerard said strong leadership and solidarity among local USW members at each of

the IP locations was vital to reaching the agreement with the

company, the union’s largest paper employer.

“The USW is extremely proud of the progress made by our

members in the paper sector,’’ Gerard said. “The success of our

local unions here sets a precedent for bargaining in the rest of

the industry.”

USW members covered by the contract include those represented by local unions in Augusta, Ga.; Campti, La.; Cantonment, Fla.; Courtland, Ala.; Georgetown, S.C.; Pine Hill,

Ala.; Port Hueneme, Calif.; Prattville, Ala.; Riegelwood, N.C.;

Savannah, Ga.; Selma, Ala.; Texarkana, Texas; Ticonderoga,

N.Y.; Valliant, Okla.; and Vicksburg, Miss.

Activism and the participation of local unions made the

12

U S W @ Wo r k • S p r i n g 2 0 1 1

difference in the negotiations. They were engaged, active and

vocal about their priorities and it paid off, said International

Secretary-Treasurer Stan Johnson, who chaired the union’s

bargaining committee at IP.

“Local leadership did an outstanding job of representing the

bargaining objectives of its membership,’’ Johnson said. “And

the membership’s resolve was demonstrated by its solidarity

throughout these negotiations.”

Year of planning, strategic meetings

The agreement was reached after nearly a year of planning

and strategic meetings, culminating with face-to-face discussions between IP and the 80-person bargaining committee

representing the 15 locals.

In the years since the 2005 merger that brought PACE into

the USW, the union has changed bargaining in the paper sector to make it more centralized, an approach that gives USW

members more bargaining power and more say on the shop

floor.

International Vice President Jon Geenen, who leads the

union’s paper sector bargaining, sees the accord with IP as an

historic moment for USW members, an important foundation

for members to have more of a voice than ever before at the

bargaining table.

No longer does the union engage in company-dominated,

table-to-table, location-by-location negotiations where management implements a national agenda locally.

“We really succeeded in everyone having a voice in shaping the contract package,’’ Geenen said. “Long gone are the

days of the union bargaining site-by-site, while the company

negotiates from an overall national strategy.”

S

aying thousands of American

jobs are at risk, International

Vice President Tom Conway

has urged the U.S. International

Trade Commission (ITC) to continue

trade actions against hot-rolled and flatrolled carbon steel products from Brazil,

Japan and Russia.

Accompanied by USW members

who make those products in the United

States, Conway told the ITC in April

that the domestic industry remains vulnerable from the severe recession that

began in 2008.

“Fortunately, the market has begun

to recover, but that recovery is by no

means complete or even certain, and

the industry is still far from healthy,’’

Conway said.

Under World Trade Organization

rules agreed to in Uruguay, the ITC and

the U.S. Commerce Department must

revisit trade actions every five years

to determine whether they should be

continued or revoked.

Specifically, the ITC is reviewing

a countervailing duty order on certain

hot-rolled, flat-rolled carbon quality

steel products from Brazil, antidumping

duty orders on products from Brazil and

Japan and a suspended investigation on

hot-rolled steel from Russia.

USW members produce hot-rolled

T

steel in the United States at over 20

facilities and supporting operations including coke and iron ore suppliers. The

industry supports 21,000 employees.

“Let me emphasize,” Conway said,

“those jobs are at risk from unfairly

traded, dumped and subsidized imports.

That is what we are fighting for today.”

International Vice President Tom Conway

Conway told the ITC that USW

members working in the industry can

beat import competition from any country so long as the competition is fair.

“USW members work very hard and

play by the rules and they expect others

to do so as well,” Conway testified.

“They also expect that our government will make foreign producers play

by the rules by enforcing the trade

laws.”

The union, its members and retirees

he U.S. International Trade Commission (ITC) has voted

to back countervailing and antidumping duties on imports

of most aluminum extrusions from China.

The USW said it was pleased with the April 28 ruling,

which clears the way for the U.S. Commerce Department to

impose antidumping duties of about 33 percent and countervailing duties of 8 percent to 374 percent beginning in May

for five years.

“Our members and employers deserve a fair shake in the

marketplace,’’ said International President Leo W. Gerard.

“Leveling the playing field with duties on illegally dumped

and subsidized foreign goods is a step in the right direction.”

The union and its partners in the Aluminum Extrusions

Fair Trade Committee argued that Chinese extrusions are being sold in the United States at less than fair value.

Extrusions are shapes squeezed out of aluminum alloys

and often used in construction products such as windows and

door frames. The products in question accounted for $503

million of imports last year. Heatsinks, used in computers and

electronics, were excluded from the tariffs.

have done everything possible to ensure

the viability of an industry hurt over the

years by unfair trade, Conway said.

“Factors like unfair trade are beyond

our control, but they are within your

control,” he told the ITC. “These orders

must be continued, particularly following the deep recession from which the

industry is only just starting to emerge.”

During those profitable years, the

USW insisted that steel companies contribute into voluntary employee benefit

funds, or VEBAs, to help provide health

care, prescription drug benefits and

supplemental Medicare for current and

future retirees.

Demand for steel products plummeted in the recession. That led to lost jobs,

idled furnaces and rolling mills, deferred or cancelled capital expenditures,

deferred VEBA payments, and lost

incentive payments at some facilities.

“We are just starting to see mills

reopen and steelworkers getting back to

work,” Conway said.

“But for this recovery to continue,

the mills need to be able to increase

prices to cover rising raw material costs

and to regain profitability at reasonable

levels. They need to be able to increase

production and sales so that they can

continue to reopen facilities and put

steelworkers back to work.”

T

he USW has joined the labor movement in Colombia in

opposing a modified free trade agreement (FTA) between

the United States and the South American country.

The USW said it was disappointed and outraged to learn

that the Obama administration had in April reached a tentative

agreement with Colombian President Juan Manuel Santos.

The USW has opposed a FTA with Colombia ever since

former President Bush in 2007 signed an agreement with then

Colombian President Alvaro Uribe that was never ratified.

Then, as now, the USW opposes an FTA with Colombia because of decades of uncontrolled violence and murder against

union leaders and workers.

The White House said Colombia agreed to expand protections of trade unionists, enforce its labor laws with greater

vigor and hire new labor inspectors.

The USW said the reality on the ground in Colombia has

not changed since the first agreement was signed. A record 52

unionists were killed in Colombia last year.

The Confederation of Workers (CUT), Colombia’s largest

labor federation, is protesting the U.S.-Colombia FTA deal,

because of the continued killings.

U S W @ Wo r k • S p r i n g 2 0 1 1

13

14

U S W @ Wo r k • S p r i n g 2 0 1 1

F

orty-three years ago, on April 4, 1968,

Dr. Martin Luther King Jr. was assassinated in Memphis, where he had

gone to stand with sanitation workers demanding their dream: The right

to bargain collectively for a voice at

work and a better life.

Today, around the nation, we are fighting to

keep Dr. King’s dream alive as we continue fighting for economic and social justice. While the ultrarich and big corporations get tax breaks, working

families are being hit with anti-union legislation in

several states, the elimination of collective bargaining, and big cuts to education, transportation and

other essential programs.

“We’re fighting not just for a voice on the job,

but also for an economy that is equitable for all.

Unions – and in particular our union – are the last

line of defense against the renegade corporate

greed and power that are threatening these rights,”

said International President Leo W. Gerard. “The

dream Dr. King died for is at risk and it’s up to us

to keep fighting to keep it alive.”

Paying tribute through protest

On April 4, the United Steelworkers led

multiple actions as part of the AFL-CIO’s “We

Are One” campaign meant to pay tribute to King.

Actions included a massive march and protest in

Pittsburgh, the USW’s headquarters city; a fish fry

and sign-making party that included a viewing of a

documentary about King’s final days on the picket

line in Memphis; church services recognizing the

moral attack we’re facing and rallies in all 50 states

including Connecticut, New Hampshire, Ohio,

Indiana and Washington.

“What started in Wisconsin has spread to every

state across the country as working people stand

together to say ‘enough.’ The immense activity is a direct result of the backlash provoked by

overreaching governors and state legislatures,”

said AFL-CIO President Richard Trumka. “Working people’s energy and commitment to coming

together will continue until the priorities of many

of our politicians are realigned to create jobs rather

than undermine the middle class.”

Many of the USW events were put on in

partnership with civil rights, religious, student and

community organizations.

“Just like the movement led by Dr. King and

others all those years ago, today’s grass-roots

movement for good jobs and economic and social

justice is being driven by hard-working Americans

from diverse backgrounds. This isn’t any corporatefunded Tea Party. This is a real movement for real

change driven by real people,” said Fred Redmond,

international vice president for human affairs.

Union members rally in Pittsburgh on April 4.

USW Photo by Steve Dietz

U S W @ Wo r k • S p r i n g 2 0 1 1

15

Now is the time to be active

The USW’s Rapid Response network of local

union activists showed up in full force on April 4,

leading hundreds of actions including posting “I

Support Workers’ Rights” signs in local businesses

and on car windows.

“Once again, we’re under attack and local union

activists are fired up and working hard as we do

what Steelworkers do, which is stand up and fight

back,” said Kim Miller, director of the USW’s

Rapid Response program. “Now is the time for

every single USW local and member to be

educated and active.”

“Greedy corporations and CEOs and the politicians they bought and paid for are trying to cut the

throats of working Americans and the unions who

fight for them,” Gerard said. “They’re using phony

budget crises and wedge issues that have nothing to

do with creating jobs as a way to try to take more

from us. Meanwhile, they’re paying themselves

huge bonuses and getting away with paying little or

no taxes.

“We’re uniting as a labor movement with community, faith, environmental, student and other

groups to send a clear message: We are one and we

Union members and

supporters march in

Pittsburgh.

USW Photo by Steve Dietz

16

U S W @ Wo r k • S p r i n g 2 0 1 1 2 0 1 1

are not going down without a fight.”

For more information about how the USW is

leading this fight, visit our website at www.usw.

org, hit the like button on our Facebook page at

www.facebook.com/steelworkers and follow us at

www.twitter.com/steelworkers.

USW

Nation:

Standing and Fighting Everywhere

I

n every state, Steelworkers are leading the fight

back against corporate-funded politicians who

are trying to bust unions while cutting education, health care, benefits for the sick and disabled

and other priorities as they give tax breaks to their

rich friends. Your energy has been inspiring.

There are thousands of photos from actions

across the nation on our Flickr stream at:

www.flickr.com/unitedsteelworkers and daily

updates from you on our Facebook page at:

www.facebook.com/steelworkers. There are

video highlights on our YoutTube channel at:

www.youtube.com/steelworkers, too! Check it

out and keep it up!

California

Olympia, Wash.

Blaine, Wash.

New Bedford, Mass.

Pittsburgh

Oklahoma

New Haven, Conn.

Madison, Wis.

Pittsburgh

New Haven, Conn.

Austin, Texas

Little Rock, Ark.

Columbus, Ohio

Indianapolis, Ind.

New Hampshire

Texarkana, Ark.

Portland, Ore.

Philadelphia, Pa.

U S W @ Wo r k • S p r i n g 2 0 1 1

17

W

hile millions of Americans are struggling,

worrying about holding on to their homes and

their jobs, paychecks for top American executives are growing again – by leaps and bounds.

The CEOs of the nation’s largest companies received

average compensation last year of $11.4 million, a whopping

23 percent annual increase, and enough to cover the salaries

of 700 minimum wage workers or 28 U.S. Presidents.

The data was disclosed by the AFL-CIO in its annual

Executive PayWatch, a searchable database of publicly

available pay data gleaned from corporate proxy statements

(www.paywatch.org).

“Despite the collapse of the financial market at the hands

of executives less than three years ago, the disparity between

CEO and workers’ pay has continued to grow to levels that

are simply stunning,” AFL-CIO President Richard Trumka

said.

The data was released as part of an AFL-CIO campaign

to strengthen Wall Street reform, close corporate tax

loopholes and ensure that middle-class Americans are no

longer required to pay for the greed of those at the top.

Compare CEO pay to yours

Users can search the database to get information by state

and industry and compare the pay of top-paid CEOs with the

median pay of nurses, teachers, firefighters and other workers. Facebook users can access the data for the first time.

Specifically, the AFL-CIO looked at the pay practices

of 299 companies on the S&P 500 index. The chief executives of those companies received combined compensation

totaling $3.4 billion in 2010, enough to support 102,325 jobs

paying median wages. The median wage for all occupations

was $33,109 in 2009, the most recent year for which data is

available from the Bureau of Labor Statistics.

Over the past decade, CEOs of the largest American

companies received more compensation than ever before in

U.S. history while shareholders – including workers – lost

trillions of dollars in retirement savings through the collapse

of the Internet and real estate stock bubbles, corporate accounting scandals and the Wall Street financial crisis.

Executives whose compensation was highlighted by the

AFL-CIO included Viacom CEO Philippe Dauman, 54, who

was awarded salary, stock and other benefits totaling $84.5

million during the first nine months of 2010, more than double his 2009 compensation of $34 million. The company’s

brands include MTV Networks and Paramount Pictures.

Occidental Petroleum CEO Ray Irani, 76, was paid more

than $76 million in compensation in 2010, followed by Oracle CEO Lawrence Ellison, 66, who received $70 million.

New tools to fight back

While CEO pay is still out of control in corporate

America, shareholders have new tools to fight back. CEOs

must now give shareholders a “say on pay” thanks to the

Dodd-Frank Wall Street Reform and Consumer Protection

Act signed by President Obama in July 2010.

While the advisory votes of shareholders on executive

18

U S W @ Wo r k • S p r i n g 2 0 1 1

compensation are not binding, they hopefully will encourage corporate boards of directors to reform executive pay

practices.

“For the first time, we have hope that things can

change,’’ Trumka said, referring to the Wall Street Reform

and Consumer Protection Act.

Executives seem to particularly dislike the act’s

requirement that companies disclose to investors the pay

disparity between the CEO and a typical worker. Investors

appear to be increasingly concerned about growing CEO

pay and pay disparities within companies.

“The law will help investors and the public learn

which companies provide fair wages and good jobs to

their employees, compared with those that have outrageous CEO-to-worker pay disparities,” Trumka said.

Practices under microscope

The legislation is putting pressure on companies to

eliminate practices that may catch the attention of investors. Golden parachutes, corporate jet travel, preferential

pensions and perquisites unrelated to performance are

under the microscope.

The 2010 Dodd-Frank Act requires the compensation

committees of a company’s board be composed of independent directors and financial companies must ensure

that their incentive pay plans to not create excessive risk.

Pointing to attacks by some large banks and Wall

Street lobbyists on the Dodd-Frank Act, Trumka said the

AFL-CIO campaign will work hard to defend historic

reform. “Their brazen attempts to undermine reform surprise

and offend me, and I think they will surprise and offend

most Americans.” Trumka said. “Apparently Wall Street

doesn’t want people to know that while working Americans paid for the economic crisis with their jobs, their

homes and their retirement savings, these Teflon CEOs

escaped unscathed.”

A

merican multinational corporations threw patriotism

to the wind when it came to hiring in the global

economy over the last decade, according to new data

from the U.S. Commerce Department.

The brand name companies that employ a fifth of all Americans cut their work forces in the United States by 2.9 million

people in the first 10 years of the new century while increasing

employment overseas by 2.4 million.

That’s a big switch from the 1990s. Back then U.S. multinationals added more jobs in the United States than overseas: 4.4

million here and 2.7 million abroad.

The data underscores the vulnerability of the U.S. economy

at a time when unemployment is high and wages are stagnant.

Jobs at multinational companies usually pay well and are a

ticket to the middle class.

Overall, U.S. multinationals employed 21.1 million people

in this country in 2009 and 10.3 million people elsewhere. The

new jobs created overseas were increasingly higher skilled.

Some big companies are shrinking employment at home and

abroad while improving productivity. Others are hiring abroad

while cutting jobs at home. Some are hiring everywhere.

General Electric, for example, has been reducing the size

of its work forces domestically and internationally with more

of the job cuts coming in the United States than overseas. The

company cut 28,000 workers in the United States between 2005

and 2010 and 1,000 overseas.

GE Chief Executive Jeffrey Immelt, recently appointed by

President Obama as his chief outside economic advisor, confirmed that the globalization of jobs involves more than poorly

paid work that Americans shun. GE, Immelt said, is following

its customers, not looking for the world’s lowest wages.

“We’ve globalized around markets, not cheap labor,’’ Immelt said. “The era of globalization around cheap labor is over.

Today, we go to China, we go to India, because that’s where the

customers are.”

U S W @ Wo r k • S p r i n g 2 0 1 1

19

A

century ago, the Triangle Shirtwaist factory

fire that killed 146 garment workers in New

York struck a deep nerve with the American

people, who demanded reforms that remade

the nation’s industrial landscape and helped to build the

middle class.

The fire on March 25, 1911, can only be described as

horrific. Workers, mostly immigrant women and teenagers, were trapped on the upper floors of the factory building by fire and locked exit doors.

Witnesses including reporters and crowds of Saturday

strollers in nearby Washington Square watched helplessly

as terrified women jumped from the top floors of the burning building, their bodies falling like bales of cloth.

Today, the garment industry is global and the sweatshops that make clothing are mainly overseas. Yet history

continues to repeat itself with astounding parallels.

Just three months before the 100th anniversary of the

Triangle fire, on Dec. 14, 2010, 29 women garment workers in Bangladesh who were sewing clothing for American

retailers died in a multi-story fire that also injured 100

others.

“The fire alarms did not go off and the emergency

exits were blocked on the ninth floor,” said Charles Kernaghan, executive director of the USW-backed Institute

for Global Labour and Human Rights.

A century earlier, the Triangle fire started on a lower

floor of the former Asch Building, now part of New York

University. Flames came through the eighth floor and hit

oiled rags under the sewing machines, creating an inferno.

Fire escape collapsed

The regular exit door was engulfed and the fire escape

collapsed under the weight of workers trying to flee.

An emergency exit was also locked, apparently to deter

theft. Some say the doors were locked to keep out union

organizers.

Just as trapped workers in the Triangle fire jumped

from open windows, Kernaghan said workers trapped in

the Hameem Apparel Group factory in Savar, Bangladesh,

leapt from the 11th floor. In both cases, firefighters could

not reach the top floors of the burning factory buildings.

Workers at the Hameem factory said security guards

were ordered to lock exit gates during fire to prevent garments from being stolen in the chaos. Hameem supplies

major multinational retailers including Gap, JCPenney

and Wal-Mart.

While the New York tragedy 100 years earlier led to

decades of positive labor reform, there has been no public

outrage in Bangladesh and no serious investigation.

Trapped in race to bottom

“We are racing backward in the global economy,

competing over who will accept the lowest wages and the

most miserable living and working conditions,’’ Kernaghan said.

The public was inflamed by the tragedy a century

ago in New York City. Some 100,000 people marched in

a funeral procession through the city streets as another

400,000 people lined their path.

20

U S W @ Wo r k • S p r i n g 2 0 1 1

To see a USW-produced video on the fire,

go to the Steelworkers’ channel on YouTube:

http://www.youtube.com/Steelworkers

and click on the Triangle Shirtwaist Fire icon

displayed on the right side of the page.

Photos of the 1911 Triangle Shirtwaist

fire, left, and 2010 fire in Bangladesh,

right, provided by the Institute for

Global Labour and Human Rights

Within two months of the Triangle fire, an investigatory

committee was established and 2,000 New York factories were

inspected. There was a surge in organizing by the International

Ladies Garment Workers Union, which for a time became the

most powerful workers’ union in the country.

“Triangle outraged the public and offered a grisly example

of how powerless workers are without collective bargaining,

because unionized workers received better pay and had safer

conditions,” U.S. Secretary of Labor Hilda Solis said in commemorating the 100th anniversary of the fire.

Calls for reform came from a broad coalition of unions, religious leaders and the middle class. Laws were enacted requiring mandatory fire drills, automatic sprinkler systems and exits

that opened outward and could not be locked. Factory owners

fought back but lost.

Frances Perkins, who later became Secretary of Labor under

President Franklin D. Roosevelt, was an eyewitness to the

Triangle tragedy. “The New Deal was born after watching these

people jumping from the windows,’’ she recalled.

Union power accelerated

Kernaghan said the Triangle fire victims did not die in vain.

“Unions’ power accelerated after the fire, providing a push that

just wouldn’t stop,” he said. Positive labor reforms continued

for the next 40 years.

“By 1938, sweatshops were wiped out in the United States.

Minimum wage laws were in place. There were limits on working hours and extra pay for overtime work,” Kernaghan said.

“By the 1950s, 34 percent of all American workers were

organized, and the middle class was built. People worked hard

and their lives were improved.”

Today in Bangladesh, the Hameem workers toil seven days

a week, 12 to 14 hours a day with an eight-hour shift on Fridays. A century after the Triangle fire, senior sewing operators

earn just 28 cents an hour, or $2.24 for an eight-hour day.

Prior to both events workers were trying to organize in the

hope of achieving dignity in the workplace and modest improvements in their economic existence.

Starting in February 1909, garment workers in New York

City struck and won union-only shops in hundreds of factories.

Triangle management, however, successfully fought to remain

nonunion.

If the Triangle workers had formed a union, Kernaghan said

it is possible that the exit would not have been blocked, and the

fire would have been less tragic.

In 2008, Hameem management busted a union organizing

drive at their factory, imprisoning the union leader and firing

19 activists even though a majority of the workers had shown

support.

Workers’ rights still under siege

The lack of unions continues to be a common denominator in such tragedies. Consider the 2010 explosion at the Big

Branch coal mine in West Virginia, where 29 nonunion miners

perished, and the 1991 fire at an Imperial Foods chicken processing plant in North Carolina that killed 25 people who were

locked inside.

When you hear the often-repeated rhetoric that labor unions

are no longer necessary in the modern world, remember those

workers who died behind locked doors.

U S W @ Wo r k • S p r i n g 2 0 1 1

21

T

his year’s annual USW Rapid

Response conference for union

activists began with USW officers inspiring the hundreds of

attendees to fight for their rights.

It continued with instruction on how

to combat the efforts of conservative

state lawmakers to foreclose on collective bargaining rights. And it ended

with USW activists meeting with former

House Speaker Nancy Pelosi.

The activists who converged on

Washington, D.C. from local unions

across the country for the conference

learned how crucial their efforts were in

labor’s confrontation with conservative

state lawmakers who are voting from

Florida to Michigan to end the routine

practice of collecting union dues from

workers’ paychecks, to unilaterally cut

public sector workers’ pay, and to allow workers to freeload by refusing to

pay union dues while receiving union

benefits.

Conference instructors urged activism on the state level not just because

the USW has 20,000 public sector

workers, but also because these conservative campaigns against unions actually

are aimed at reducing labor’s political

power.

“You are the front line troops to

bring the message

to the workplace, to the church, to your

community group, to your family at the

dinner table, to the whacked out uncle

who doesn’t get it – everybody has one,”

International President Leo W. Gerard

told the group.

“I want to sit in my rocking chair

and know that my grandson will have as

good a chance in life as I did,” Gerard

continued, “and that will only happen if

we push. We’ve got to get out there and

fight.”

International Secretary-Treasurer

Stan Johnson explained that the conservatives in state houses across the country

aren’t just cutting public sector workers’

wages and rights, they’re attempting to

enfeeble labor politically by reducing the

number of unionized workers, and, as

a result, reducing the number of dollars

union workers contribute to political action committees.

“This is about silencing your voice,”

Johnson said, “This is about destroying local union finances, international

union finances, and impeding our ability

to fight. That is what they want to do –

destroy your ability to fight.

“If we do not do something in the

next two to three years,” he warned,

“look at everyone in this

room and

think about who is here and who will not

be here. . . If you are ever going to fight,

now is the time. It is not the time to be

aggravated with your union. It is the time

to be aggravated with the system that has

put us in the situation we are in.”

International Vice President Tom

Conway agreed, noting that the conservatives are dishonestly blaming firefighters, policemen and teachers for state

deficits. Referring to the conservatives,

he said, “They mean to break your back

and if you don’t fight now, they will

break your back.”

For all of the bluster, Conway said

the American public is not fooled. They

know the deficits occurred after gambling by Wall Street banksters collapsed

the economy. “The country knows we

are right,” he said. “The country is with

us.”

On the last day of the conference,

more than 700 activists converged on

Capitol Hill, thanking lawmakers including U.S. Rep. Joe Baca, (D-Calif.), who

has voted against every free trade agreement during his time in the House, and

urging lawmakers like U.S. Sen. Jon Kyl

(R-Ariz.) to preserve trade adjustment

assistance for workers such as the USW

members laid off by auto parts maker

Cooper Standard in Bowling Green,

Ohio.

Speaking out at USW Rapid Response conference.

USW Photo by Steve Dietz

22

U S W @ Wo r k • S p r i n g 2 0 1 1

They took a break mid-day to conduct

a press conference with former Speaker of

the House Nancy Pelosi, (D-Calif.), who

said the primary job of Congress should

be creating jobs. “Democrats will measure

every effort to see if it creates jobs and

strengthens the middle class,’ Pelosi said

to cheers from the group crowded into a

Congressional meeting room.

“If we make it in America, then American families can make it in America,” she

said.

Aaron Patterson, president of Local

1152 at Cooper Standard in Bowling Green,

asked Pelosi to create policies that sustain

American jobs. Cooper Standard had announced the week before that it was moving

his plant to Mexico, destroying 200 U.S.

jobs and devastating 200 Ohio families.

Patterson and 24 other Cooper Standard

workers who had driven from Ohio to the

Rapid Response conference went from

the press event to Kyl’s office to ask for

passage of trade adjustment assistance that

would help the 200 workers get new skills

for new jobs.

When a young man at Kyl’s reception desk said the group could not see the

senator, Patterson asked him to pass on the

message that trade adjustment assistance

is critical to families like his and the other

Cooper Standard workers.

Local 1152 members at Cooper Standard

USW Photo by Steve Diez

A

clean environment requires construction such as assembling

wind turbines and retrofitting buildings, projects that provide

good, family-supporting jobs.

That was the message of the 2011 Good Jobs Green Jobs

National Conference conducted by the BlueGreen Alliance Foundation in

Washington D.C. prior to the annual USW Rapid Response Conference.

“We need a jobs plan and a green energy plan and a carbon reduction

plan, and they can all fit together,” International President Leo W. Gerard,

a plenary speaker, told 2,500 conference delegates.

Gerard noted that the modern wind turbine was invented in Sandusky,

Ohio, and asked, “Why build that elsewhere when we invented it here?”

Research and development follows manufacturing, and when U.S.

factories move offshore, high tech and research jobs go with them, Gerard

noted.

“If we don’t succeed in creating the next level of green jobs here, we

will lose the next level of research and development, and I don’t know

how we will catch up then,” he said.

Stopping illegal practices

Last October, the USW filed a petition under Section 301 of U.S. trade

laws that attempts to stop illegal practices by China that have enabled it to

surpass the United States in production of certain green technologies.

These violations have damaged American green industries, costing

good American jobs. Illegal practices cited in the petition include China’s

massive subsidies to exporters, technology transfer requirements and

restricting access to critical raw materials. In some cases, these practices

prompted American companies to move production to China, eliminating

hundreds of good, green jobs in the United States.

Late last year, the Obama administration agreed to investigate the

issues raised in the Section 301 complaint and in December announced

that it would take the next step, which is consulting with China to resolve

those issues where the data and evidence provided by the USW appear to

be irrefutable.

United States Trade Representative Ron Kirk said of the case, “The

USW has raised issues covering a wide array of Chinese government policies affecting trade and investment in green technologies. This is a vitally

important sector for the United States. Green technology will be an engine

for the jobs of the future, and this administration is committed to ensuring

a level playing field for American workers, businesses and green technology entrepreneurs.”

This was a crucial victory for the USW and for American jobs, Gerard

told the conference, “We want to build a supply chain. We want these jobs

here. We can’t compete when China is breaking every rule they agreed

to.”

The three-day conference in Washington, D.C. was sponsored by the

BlueGreen Alliance, a coalition of labor and environmental groups created

by the USW and Sierra Club.

U S W @ Wo r k • S p r i n g 2 0 1 1

23

T

he USW is calling for improvements to anti-terrorism

standards for high-risk chemical facilities, including strong

protections for whistleblowers.

The union unveiled its position at

a March 31 hearing before the U.S.

House Subcommittee on Energy and the

Environment regarding legislation (H.R.

908) that would extend for seven years

the Department of Homeland Security’s

Chemical Facility Anti-Terrorism Standards (CFATS) program.

The CFATS program monitors more

than 4,000 high-risk chemical facilities

such as chemical plants, electrical generating facilities, refineries and universities, requiring them to identify and assess

security facility risks and develop and

implement security plans to protect those

facilities.

James Frederick, the USW’s assistant

director for health, safety and the environment, said the union is part of a broad

coalition that believes legislation must

be passed to improve chemical industry

workplace safety and security.

Frederick argued, however, that more

should be done than simply extending

existing interim measures that took effect

in 2007, as the proposed House legislation (H.R. 908) would do.

“We believe that this is absolutely

necessary to properly protect the communities where our members and their

neighbors live and work,” Frederick

testified.

In a statement supporting Frederick’s

testimony, International President Leo W.

24

U S W @ Wo r k • S p r i n g 2 0 1 1

Gerard criticized H.R. 908 for maintaining CFATS without improvements.

“It would jeopardize the hundreds of

thousands of USW members employed at

chemical-related facilities and residents

who live in surrounding communities,”

Gerard said.

USW supports Lautenberg bills

Gerard said the union supports more

comprehensive bills introduced by

U.S. Sen. Frank Lautenberg (D-N.J.) to

address the preventable hazards chemical plants pose. Those bills include the

“Secure Water Facilities Act” and the

“Secure Chemical Facilities Act,” which

require changes for the highest-risk

facilities while preventing undue burdens

on small, lower-risk facilities.

The USW has long been involved in

chemical plant security and represents

more than 125,000 members who work in

800-plus chemical industry workplaces,

Frederick told the hearing.

“Our union has always been actively

engaged and involved with our employers, communities, regulators and legislators to improve workplace safety for our

members as well as their families and the

community,” he said.

Changes sought by the USW include

the addition of “strong and effective

whistleblower protection” that would

make worker participation in the process

more effective.

The current anti-terrorism standards

fail to involve knowledgeable employees in the development of vulnerability

assessments and security plans or protect

employees from excessive background

checks.

Although there are no requirements

to involve workers, the Department of

Homeland Security (DHS) has suggested

that facilities “may involve” employees

in their security efforts. But Frederick

said too many employers have chosen not

to do so.

Employee involvement beneficial

In cases of other regulations, such as

the Occupational Safety and Health Administration’s standards, the government

encourages employees and employee representatives to be engaged and involved

in the process to assess and address

unsafe conditions and hazards.

“Time and time again, this inclusion has been beneficial to the employer

and regulator alike,’’ Frederick said.

“Workers are the best source to identify

vulnerable hazards and often have much

more hands-on experience to recommend

solutions.’’

Frederick identified a number of other

problems with CFATS. Among them,

the CFATS prohibits the Department of

Homeland Security from requiring any

specific security measure.

That means the standards, if reinstated

without changes, will continue to allow

employers to determine how they comply

with the rules, which typically result in

cost and productivity taking precedence

over safety.

Frederick said the CFATS fail to

develop smart security – safer and more

secure chemical processes that can cost-

T

effectively prevent terrorists from triggering chemical disasters.

CFATS also explicitly exempts too

many at-risk workplaces, Frederick testified. Thousands of chemical and port facilities are exempt including 2,400 water

treatment facilities and more than 400

facilities on navigable waters, including

the majority of oil refineries.

The standards also fail to address

the pervasive problem of risk shifting,

such as when a company moves chemical hazards to unguarded locations such

as railroad sidings. In addition, CFATS

denies the public information needed to

ensure an effective, accountable program,

Frederick said.

The USW believes legislation should

achieve the following:

• Require facilities that pose the

greatest risk to assess safer chemical processes and conditionally

require the use of safer chemical processes where feasible and

commercially available, and include a technical appeals process

to challenge Homeland Security

decisions;

• Provide resources to assist facilities to use safer and more secure

processes;

• Require worker involvement

in the development of security

plans and provide protections for

whistleblowers and limit background check abuses;

• Preserve state authority to establish stronger security standards.

he AFL-CIO has chosen the

National Union of Mine, Metal, Steel and Allied Workers

of the Mexican Republic, also

known as Los Mineros, and its leader,

Napoleón Gómez Urrutia, to receive the

federation’s prestigious human rights

award this year.

The annual Meany-Kirkland Human Rights Award, created in 1980 and

named for the first two presidents of

the AFL-CIO, recognizes outstanding

examples of the international struggle

for human rights through trade unions.

The 2011 Meany-Kirkland award

was approved by the AFL-CIO Executive Council on April 18 and will be

formally presented later this year.

Over the past five years, the Mexican government has unleashed a systematic attack on workers’ rights. Some

of the most egregious attacks have been

on Los Mineros and its leader.

USW a key supporter

“This is an important public recognition that the fight of Napoleón Gómez,

his union and the democratic labor

movement in Mexico is just and will be

vindicated,” said International President

Leo W. Gerard.

“The Mexican government’s flouting

of international labor and human rights

norms has been exposed by the global

trade union movement and should be

condemned by all nations.”

The USW has been a key supporter

of Los Mineros, providing assistance to

striking workers in Mexico, support for

organizing campaigns and office space

in Vancouver, Canada, where Gómez

lives after being forced to leave Mexico.

In June 2010, the two unions set up

a joint task force to “propose immediate

measures to increase strategic cooperation between our organizations as well

as the steps required to form a unified

organization.”

Gomez, who was elected general secretary of Los Mineros in 2002,

incurred the wrath of the Mexican government by demanding higher wages

and resisting government efforts to

control the miners’ union. He also built

alliances with the global trade union

movement, including the USW.

When a February 2006 explosion at

Grupo Mexico’s Pasta de Conchos mine

killed 65 mineworkers, Gómez publicly

accused the government of “industrial

homicide.”

In response to this criticism, the

government filed criminal charges

against Gómez and other union leaders.

It also froze the union’s bank accounts,

assisted employers to set up company

unions in Los Mineros-represented

workplaces and declared the union’s

strikes illegal and sent troops to suppress them.

Four union members were murdered

and key union leaders were jailed. In

the face of this campaign of repression, Gómez left Mexico for Vancouver

with USW support. From there he has

waged a five-year effort to win justice

for his union and for all democratic

unions in Mexico.

Despite the massive repression,

the Mexican union has continued to

bargain contracts and organize new

workplaces with the help of trade union

allies around the world. Gómez has won

major legal victories, as Mexican courts

have thrown out the criminal charges

against him and rejected the government’s appeals.

On April 28, a Mexican appeals

court ruled against the government and

threw out the final remaining criminal

charge against Gomez. That same day, a

separate court ordered the government

to release funds in union bank accounts

that it froze years ago.

USW and Mineros leaders with Gomez (center) in Canada.

U S W @ Wo r k • S p r i n g 2 0 1 1

25

T

he USW in Canada is undertaking an unusual private prosecution of a forest products company in the death of a sawmill

worker who was smothered by wood

debris.

The union is pursuing criminal negligence charges against U.S.-based Weyerhaeuser for the death of member Lyle

Hewer under the Westray Amendment to

the Criminal Code of Canada.