2310LED

advertisement

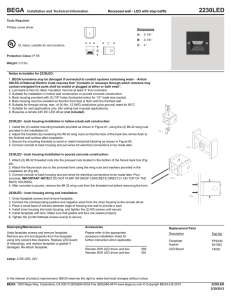

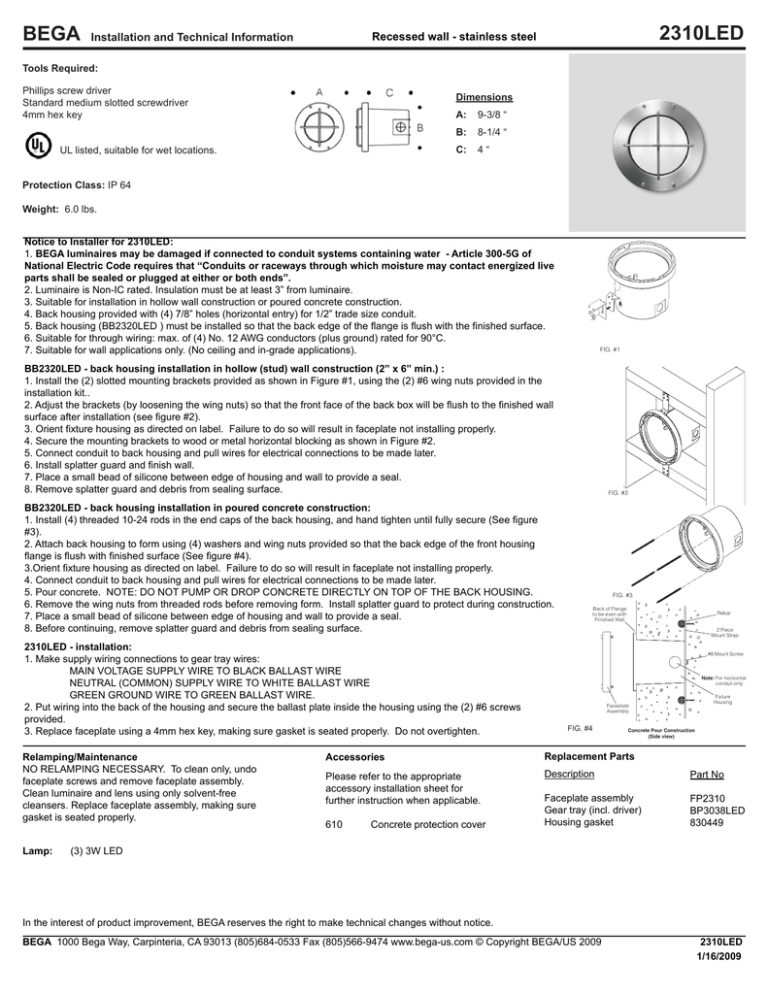

BEGA 2310LED Recessed wall - stainless steel Installation and Technical Information Tools Required: Phillips screw driver Standard medium slotted screwdriver 4mm hex key Dimensions UL listed, suitable for wet locations. A: 9-3/8 “ B: 8-1/4 “ C: 4“ Protection Class: IP 64 Weight: 6.0 lbs. Notice to Installer for 2310LED: 1. BEGA luminaires may be damaged if connected to conduit systems containing water - Article 300-5G of National Electric Code requires that “Conduits or raceways through which moisture may contact energized live parts shall be sealed or plugged at either or both ends”. 2. Luminaire is Non-IC rated. Insulation must be at least 3” from luminaire. 3. Suitable for installation in hollow wall construction or poured concrete construction. 4. Back housing provided with (4) 7/8” holes (horizontal entry) for 1/2” trade size conduit. 5. Back housing (BB2320LED ) must be installed so that the back edge of the flange is flush with the finished surface. 6. Suitable for through wiring: max. of (4) No. 12 AWG conductors (plus ground) rated for 90°C. 7. Suitable for wall applications only. (No ceiling and in-grade applications). FIG. #1 BB2320LED - back housing installation in hollow (stud) wall construction (2” x 6” min.) : 1. Install the (2) slotted mounting brackets provided as shown in Figure #1, using the (2) #6 wing nuts provided in the installation kit.. 2. Adjust the brackets (by loosening the wing nuts) so that the front face of the back box will be flush to the finished wall surface after installation (see figure #2). 3. Orient fixture housing as directed on label. Failure to do so will result in faceplate not installing properly. 4. Secure the mounting brackets to wood or metal horizontal blocking as shown in Figure #2. 5. Connect conduit to back housing and pull wires for electrical connections to be made later. 6. Install splatter guard and finish wall. 7. Place a small bead of silicone between edge of housing and wall to provide a seal. 8. Remove splatter guard and debris from sealing surface. BB2320LED - back housing installation in poured concrete construction: 1. Install (4) threaded 10-24 rods in the end caps of the back housing, and hand tighten until fully secure (See figure #3). 2. Attach back housing to form using (4) washers and wing nuts provided so that the back edge of the front housing flange is flush with finished surface (See figure #4). 3.Orient fixture housing as directed on label. Failure to do so will result in faceplate not installing properly. 4. Connect conduit to back housing and pull wires for electrical connections to be made later. 5. Pour concrete. NOTE: DO NOT PUMP OR DROP CONCRETE DIRECTLY ON TOP OF THE BACK HOUSING. 6. Remove the wing nuts from threaded rods before removing form. Install splatter guard to protect during construction. 7. Place a small bead of silicone between edge of housing and wall to provide a seal. 8. Before continuing, remove splatter guard and debris from sealing surface. 2310LED - installation: 1. Make supply wiring connections to gear tray wires: MAIN VOLTAGE SUPPLY WIRE TO BLACK BALLAST WIRE NEUTRAL (COMMON) SUPPLY WIRE TO WHITE BALLAST WIRE GREEN GROUND WIRE TO GREEN BALLAST WIRE. 2. Put wiring into the back of the housing and secure the ballast plate inside the housing using the (2) #6 screws provided. 3. Replace faceplate using a 4mm hex key, making sure gasket is seated properly. Do not overtighten. Relamping/Maintenance NO RELAMPING NECESSARY. To clean only, undo faceplate screws and remove faceplate assembly. Clean luminaire and lens using only solvent-free cleansers. Replace faceplate assembly, making sure gasket is seated properly. Lamp: FIG. #2 FIG. #3 Back of Flange to be even with Finished Wall Rebar 2 Piece Mount Strap #8 Mount Screw Note: For horizontal conduit only Fixture Housing Faceplate Assembly FIG. #4 Concrete Pour Construction (Side view) Accessories Replacement Parts Please refer to the appropriate accessory installation sheet for further instruction when applicable. Description Part No Faceplate assembly Gear tray (incl. driver) Housing gasket FP2310 BP3038LED 830449 610 Concrete protection cover (3) 3W LED In the interest of product improvement, BEGA reserves the right to make technical changes without notice. BEGA 1000 Bega Way, Carpinteria, CA 93013 (805)684-0533 Fax (805)566-9474 www.bega-us.com © Copyright BEGA/US 2009 2310LED 1/16/2009