Light-Emitting Diode Junction-Temperature Sensing using

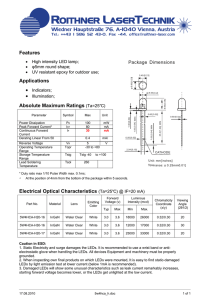

advertisement