Desiccation Cracks Result in Preferential Flow

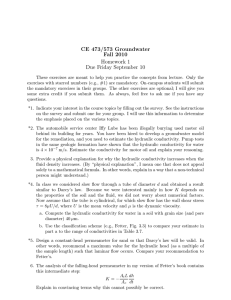

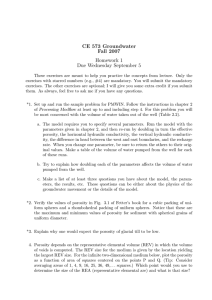

advertisement

ENVIRONMENTAL GEOTECHNICS Desiccation Cracks Result in Preferential Flow Eric C. Drumm, Daniel R. Boles, Glenn V. Wilson Introduction Recent research related to waste site closure caps and clay barriers has primarily focused upon conditions and proceduresfor barrier construction, and regulatory requirements to assure that clay barriers are constructed to minimize hydraulic conductivity. Less emphasis has been placed upon changes in hydraulic conductivity associated with post-compaction variations in water content. Little guidance is provided to assure protection during construction and maintenance during the facility service life. It has been generally assumed that desiccation problems are eliminatedafter placement of the upper protective layers (Daniel and Benson, 1990). However, soil water storage is not a static property of a soil, but a time dependent variablebased upon the rates of soil water inflow and outflow. Clay barriers can be expected to experience cycles of saturation and drying. Desiccation during construction has long been recognized as leading to increases in hydraulic conductivity (Kleppe and Olson, 1985). Field investigations of constructed clay liners have indicated that high hydraulic conductivities generally result from hydraulic defects in the clay due to construction methodologies and/or desiccation cracking due to inadequate protection after construction (Daniel, 1984; Day and Daniel, 1985; Benson and Daniel 1990; Elsbury et. al., 1990; Rogowski, 1990).Daniel and Wu (1993) suggested a methodology for modification of the hydraulic conductivity zone of acceptability (water content versus dry density) to minimize shrinkage potential. To properly assess the long-term integrity of compacted clay barriers and developappropriate maintenance measures, an understanding of the shrinkage induced volume changes and the development of preferential flow paths must be obtained. A laboratory investigation utilizing Iysimeters was conducted to 22 Geotechnical News, June 1997 measurement of the hydraulic gradient across the sample, yet permits the development of preferential flow paths between the shrinking intact clay aggregates (Phifer et al. 1995). Although more representative of the conditions occurring in the field, volumetric strain and density changes are more difficult to obtain in the Iysimeter than in the FWP. A series of laboratory Iysimeter tests was designed to evaluate the effects of desiccation cycles on the formation of preferential flow paths (cracks) in clay. 13 Stone and Water ~D § Base Filter Fabric Sand Collection Bonle Figure 1. Plan view of individual chambers of lysimeters (Top), Cross-section of lysimeter (Bottom) evaluate the effects of post-compaction water content variations on the saturated hydraulic conductivity of a soil that has been used for hydraulic barriers. Laboratory Lysimetersversus Flexible Wall Flexible Wall Permeameter (FWP) tests for hydraulic conductivity permit precise control over the hydraulic gradient during testing, and permit measurement of the volumetric strain due to desiccation. It has been suggested (Phifer et al. 1995) that the geometry of the FWP sample limits the formation of preferential flow paths. When subjected to drying events, FWP specimens undergo shrinkage of the intact clay aggregates. This results in an increase in density or decrease in void ratio and a corresponding decrease in hydraulic conductivity of the clay aggregate. In the field, clay barriers subjected to desiccation undergo shrinkage which may form preferential flow paths between aggregates. The geometry of thin laboratory Iysimeter specimens allows direct Lysimeter Construction The Iysimeters 'vere constructed of welded polyvinyl chloride (PVC), with a diameter of 0.75 m (29.5 in) and depth of 0.62 m (24 in), Figure I. To investigate the spatial variation of preferential flow within the sample, the Iysimeter outflow collector was divided into 14 sectors, each of which permitted an independent measurement of flow and calculation of hydraulic conductivity. The water collection sectors were 80 mm (3.2 in) tall, filled with compacted Ottawa sand, and covered with a layer of Supac@16NP-L17800 geosynthetic filter. The soil specimen was placed immediately above the geosynthetic filter. It was assumed that the sand and geosynthetic have a negligible effect on the hydraulic conductivity measurements of the barrier, provided the hydraulic conductivity, K, of the barrier is significantly lower than that of the sand, yet large enough that the flow through the system is greater than the water storage capacity of the sand. Thus, it was assumed that the maximum hydraulic conductivity that could be measured in the Iysimeter was about I x \O-4cm/sec,and the smallest detectable conductivity was about 1 x \0-9 cm/s. The entire Iysimeter was elevated and erlenmeyer flasks were connected beneath each sector to collect the flow. , ENVIRONMENTAL GEOTECHNICS The two outer sectors (#13 and #14, Figure 1)were intended to intercept any sidewall leakage from water that passed between the sample and the lysimeter wall, and were not used in the conduc- tivity determination. The computed conductivity through each of the 12 internal sectors could then be computed and compared withthe overallhydraulic conductivity. 13 Figure 2. Map of Surface Cracks after First Desiccation Cycle Table 1 Hydraulic Conductivity by Sector for each Saturation Cycle Sector Initial Measurement, Saturation 1 (cm/sec) Saturation 2 (cm/sec) Saturtion 3 (cm/sec) 1 2 x 10-6 0.0 3 x 10-5 2 1 x 10-7 0.0 >1 x 10-4 3 2 x 10-7 0.0 >1 x 10-4 4 8 x 10-8 6 x 10-7 2 x 10-7 5 2 x 10-5 1 x 10-6 5 x 10-6 6 0.0 3 x 10-5 >1 x 10-4 7 1 x 10-6 2 x 10-6 >1 x 10-4 8 6 x 10-6 5 x 10-6 >1 x 10-4 9 0.0 7 X10-6 >1 x 10-4 10 6 x 10-7 7 x 10-5 >1 x 10-4 11 3 x 10-6 1 X10-7 >1 x 10-4 12 3 x 10-5 2 x 10-7 2 x 10-5 Overall (based on all sectors 1.3 x 10-6 7 x 10-6 1.4 x 10-4 Preparation of Clay Barrier Specimen The soil was obtained from the West Chestnut Ridge borrow area in eastern Tennessee and had been used for cap construction at the Department of Energy's Oak Ridge Operations site. This soil is similar to that investigated by Daniel and Benson (1990). A comparison of the shrinkage induced volume changes exhibited by this materialunder flexible wall permeameter conditions and laboratory lysimeter conditions was described by Phifer et aI. (1995). The soil is classified as a high plasticity clay, with a liquid limit =61 and plastic limit = 31. The Standard Proctor maximum dry density = 1.37 Mglm3 and the optimum volumetric water content =33 percent (Boles 1994).Kaolin is the primary clay mineral (Lee et aI. 1984). After being passed through a number 4 sieve,the soil was compacted at about 3 percent above optimum water content in two lifts to obtain a density of about 88 percent standard Proctor density.The final height of the specimen was about 76 mm (3 in). Toprevent swelling of the soil and simulate a topsoil overburden, a layer of gravel was placed on the soil resulting in a stress of approximately 6 kPa (0.9 Ibslin2). The gravel was separated from the soil by a layer of the geosynthetic material. Additional details are provided elsewhere (Boles 1994). Hydraulic Conductivity Measurements The specimen was saturated under a constant head of 0.33 m (13 in), and the flow from each sector collected in flasks. An additional flask was maintained to permit correctionfor anywater lost due to evaporation. The hydraulic conductivity was calculated by Darcy's Law based on the hydraulic gradient across the sample and the area of the collectionsector.The hydraulicconductivity measurements for each of the 12 sectors are listed in Table 1.Also shown is the overall hydraulic conductivity of the entire Iysimeter based on the sum of the flow and area from all 12 sectors. After reaching steady state flow and determining the hydraulic conductivity, the water and overburden were removed June 1997 2:J ENVIRONMENTAL GEOTECHNICS from about 1.3 x 10-6em/see to about 7 x 10.6 em/sec. This relatively modest increase in K was accompanied by a conductivity decrease in 8 of the Iysimeter sectors, and an increase in only 4 sectors. This suggests that the shrinkage-induced volume change decreases the conductivity in some crack-free sections of the barrier and . Overall K RUN t = 1.3 x 10-. cm/s RUN 2 OverallK =7.0 x 10-. cm/s LEGEND D Fl ~ F7l Ed 10-10em/. . 10-. em;' . 10-0 em/. .. . . EEillillJ 10-1 em/. II . 10-6 em/. 11II 10-0 emf. RUN:t Overall K > 1.4 x 10-' cm/s 10-4 emf. Figure 3. Measured Hydraulic Conductivity by Lysimeter Sector and the sample permitted to dry. The drying resulted in a number of cracks on the surface of the clay specimen, as mapped in Figure 2. The overburden was then replaced and the constant head flow condition restored. After reaching steady flow, the desiccation process was repeated. Swelling of the clay due to the removal of the overburden was observed to be negligible. of the computed hydraulic conductivity in each of the Iysimeter sectors, for each of the three saturation (two dry-back) cycles. The Iysimeter sectors are shaded in proportion to the computed value of hydraulic conductivity. The following observations can be made: . Results The specimen had an initial overall hydraulic conductivity of about 1.3 x 10-6 em/see, which increased to about 7 x 10-6em/see after the first cycle of drying (gravimetric water content decrease of about 4.5 percent). After the second desiccation cycle, corresponding to a water content decrease of an additional 4 percent, the conductivity increased to more than 10.4 em/sec. Figure 3 is a schematic 24 GeotechnicalNews, June 1997 . Prior to being subjected to drying, the relatively homogeneous compacted clay barrier yielded measurements of hydraulic conductivity that varied 3 orders of magnitude across the sample. This suggests that hydraulic conductivity measurements are dependent upon the soil volume through which the flow is measured. Internal or invisible defects in the barrier may contribute to the quantity of flow. After the first drying cycle the overall hydraulic conductivity increased . causes cracks and conductivity creases in other sections. in- After drying, the sections in which cracks were observed tended to produce conductivities on the order of that of the entire sample, while the sections with fewer cracks tended to have lower values of K. Therefore, it can be concluded that the regions with cracks tended to dominate the conductivity of the entire sample, and that measurements of conductivity should be made over areas sufficiently large to reflect the overall barrier properties. After the second, more severe dryback cycle corresponding to nearly a 9 percent decrease from the compaction water content, the hydraulic conductivity exceeded the upper limit at which hydraulic conductivity can be recorded in the Iysimeters (1 x 10-4 em/see). The value of conductivity increased in all but one Iysimeter segment. In general, the 4 sectors with K <10-4 em/see were those with no visible cracks. Summary A series of laboratory Iysimeter tests was conducted to investigate the variation in hydraulic conductivity of a compacted clay barrier material due to cycles of desiccation. To investigate the spatial variation of hydraulic conductivity within the sample, the water collection chamber of the Iysimeter was divided into sectors. Independent measurements of flow and calculation of hydraulic conductivity were obtained for each sector. After reaching steady flow and determining the hydraulic conductivity,the samples were permitted to dry. This resulted in a number of cracks on the surfaceof the clay specimen. This saturation/dryback cycle was repeated twice. Even before the initial desiccation, , ENVIRONMENTAL GEOTECHNICS the conductivity determined in the individual sectors varied by three orders of magnitude. After desiccation, the development of preferential flow paths in the clay barrier resulted in a conductivity increase in 4 sectors, and shrinkage of the intact clay matrix resulted in a decrease in 8 sectors. In general, the high hydraulic conductivities corresponded to the sections of clay barrier where cracks were observed on the surface. After the second dessication event, the overall K was determined to be greater than 1 x 10-4 cm/sec, and K increased in all but one lysimeter sector. Under these conditions, the use of Darcy=s law and a continuum porous flow model may not be appropriate. Acknowledgments This work was supported, in whole or in part, by a DOE cooperative agreement DE-FC05-920R22056. This support does not constitute an endorsement by DOE of the views expressed herein. The authors are grateful for this support. The authors are also grateful to Phillips Fibers for providing the Supac@ 16NPL17800 filter fabric, and to Jennie Ducker for preparing the figures. References Benson, C. H. and Daniel D. E. (1990). "Influence of Clods on Hydraulic Conductivity of Compacted Clay," Journal of Geotechnical Engineering,ASCE, Vol.116,No. 8,pp.12311248. Boles, D.R. (1994) "The Effects of Water Content Variation on Laboratory Samples Simulating Low Permeable Clay Barriers," thesis presented to the University of Tennessee, Knoxville in partial fulfillment of the requirement for the degree of Master of Science. Daniel, D. E. (1984). "Predicting Hydraulic Conductivity of Clay Liners," Journal of Geotechnical Engineering, ASCE, Vol. 110,No.2, pp. 285-300. Daniel, D. E. and Benson, C. H. (1990). "Water Content-Density Criteria for Compacted Soil Liners," Journal of Geotechnical Engineering, ASCE, Vol. 116, No. 12, pp. 1811-1830. Daniel, D. E. and Wu, Y.(1993). "Com- pacted Clay Liners and Covers for Arid Sites," Journal of Geotechnical Engineering, ASCE, Vol. 119,No.2, pp.223-237. Day, S. R. and Daniel D. E. (1985). "Hydraulic Conductivity of Two Prototype Clay Liners," Journal of Geotechnical Engineering, ASCE, Vol. 111,No.8, pp.957-970. Elsbury,B. R., Daniel, D. E., Sraders, G. A., and Anderson, D. C. (1990). "Lessons Learned from Compacted Clay Liner," Journal of Geotechnical Engineering, ASCE, Vol. 116, No. 11, pp. 1641-1660. Kleppe, J. H. and Olson, R. E. (1985). "Desiccation Cracking of Soil Barriers," Hydraulic Barriers in Soil and Rock, ASTM STP 874, pp. 263-275. Lee, S.Y, Kopp, O.C., and Lietzke, D.A. (1984) "Mineralogy of West Chestnut Ridge Soils" Report to Oak Ridge National Laboratory ORNLffM-9361. Phifer, M. A., Drumm, E. C., and Wilson, G. V. (1994). "Effects of Post CompactionWaterContentVariation on Saturated Conductivity," ASTM STP 1142 Hydraulic Conductivity and WasteContaminant Transport in Soils, David E. Daniel and Stephen J. Trautwein,Eds., AmericanSociety for Testing and Materials, Philadelphia. Phifer, M., Boles, D., Drumm, E., Wilson, G. (1995) "Comparative Response of Two Barrier Soils to Post Compaction Water Content Variations," Geotechnical Specialty Publication No. 46 and Proceedings, ASCE SpecialtyConference-Geoenvironment 2000: "Characterization, Containment, Remediation, and Performance in Environmental Geotechnics, New Orleans, LA, pp 591-607. Rogowski, A. S. (1990). "Relationship of Laboratory- and Field- Determined Hydraulic Conductivity in Compacted Clay Layer." Report No. EPA/600/2-90/025, United States Environmental Protection Agency, Cincinnati, Ohio. Eric C. Drumm, Department of Civil and Environmental Engineering, The University of Tennessee,Knoxville, TN 37996-2020 Tel: (423)974-7715 Fax: (423)974-2608 e-mail: edrumm@utk.edu Daniel R. Boles, Law Engineering and Environmental Services, 1725 Louisville Drive, Knoxville, TN 37921 Glenn V. Wilson, Desert Research Institute, WRC, 755 E. Flamingo Road, Las Vegas, NV 89119 Assessment of Barrier Containment Technologies: A Comprehensive Treatment for Environmental Remediation Applications, edited by Ralph R. Rumer and James K. Mitchell, National Technical Information Service, Springfield, VA, Publication #PB96 -180583, 437 pages, 1995 (prepared under the auspices of U.S. Department of Energy, U.S. Environmental Protection Agency, and DuPont Company) Because of mutual interests and similar needs in determining what was known and understood about containment technologies and the level of information needed to support consistent decision making relative to their application in remediation, the U. S. Department of Energy and the U. S. Environmental Protection Agency collaborated with DuPont Company in organizing and sponsoring the International Containment Technology Workshop, held in Baltimore, MD, August 29-31, 1995. This publication is a result of that workshop. The workshop was organized into small working sessions, each dealing with a particular aspect of barrier containment technologies, to provide opportunity for the invited participants to share information, exchange opinions, and achieve consensus on what was known, what was not known, and what was needed concerning the application of containment technologies in remediation. The working sessions dealt with a range of topics, including: design and construction of vertical barriers (including sheet piles), barrier floors (indigenous and artificial), caps, geomembrane applications, barrier materials (soilbased and chemical-based), permeable Geotechnical News, June 1997 25 ENVIRONMENTAL GEOTECHNICS reactivebarriers, contaminanttransport modeling,performancemonitoring,and emplacement verification. Each working sessionwas chairedby a recognized leader(s)in the field who was responsibleforpreparingthe summaryreport for his or her working session. This publication contains the edited summary reports from each working session.Althoughparticular individuals have been credited with the preparation of each section, other significant contributors are also identified. Each section contains extensive references. A full listing of all participants can be found in an appendix to the publication. The design of this publication, the artwork,and the index were all professionally prepared. A listing of each section with principal author(s) is given below: "Soil- and Cement-Based Vertical Barriers with Focus on Materials": J. C. Evans (41 p.) "Design, Construction, and Performance of Soil- andCement-Based Vertical Barriers": G. M. Filz and J. K. Mitchell (33 p.) . "Vertical Barriers: Sheet Piles": D. R. McMahon (19 p.) . "Vertical Barriers: Geomembranes": R. M. Koernerand 1.L. Guglielmetti (25 p.) "Caps": D. E. Daniel and B. A. Gross (23 p.) "Floors and Bottom Barriers: Indigenous": G. P.Boutwell andT.Hueckel (45 p.) "Artificially Emplaced Floors and Bottom Barriers6: M. E. Peterson and R. C. Landis (27 p.) "Chemical-Based Barrier Materials": 1.M. Whang (37 p.) "Contaminant Transport Modeling": A. J. Rabideau (55 p.) "Permeable ReactiveBarriers": S. H. Shoemaker, 1. F. Greiner, and R. W. Gillham (55 p.) "Performance Monitoring and Evaluation": H. I. Inyang (47 p.) . . . . . . . . . Summary of the 1997 International Containment Technology Conference and Exhibition The 1997 International Containment TechnologyConference and Exhibition was conducted on February 9-12, 1997 26 GeotechnicalNews. June1997 in St. Petersburg,Florida. Over 500 participants from 22 countries attended the conference, including individuals from industry, government, and academia. Many participants were from the U.S. Environmental Protection Agency due to the growing importance of containment systems as a cost effective regulatory technology. This highly successful conference resulted from an intensive workshop on containment technology systems conducted in August of 1997 in Baltimore, Maryland. The primary sponsoring organizations of the conference were the U.S. Department of Energy,the DuPont Company and the U.S. Environmental Protection Agency. The co-sponsoring organizations were the Florida State University,U.S. Air Force Armstrong Laboratory - Environics Directorate,American Societyof Civil Engineers and the Society of American Military Engineers. Following the opening plenary session, there were 19concurrent technical sessions, 30 poster presentations and 10 student poster presentations, addressing issues related to state-of-the-art approaches and innovative technologies for containment systems designed for contaminated sites, both surface and sub-surface. The technical sessions and poster presentationsaddressed topics on geomembranes, sheet piles, modeling, grouting, performance criteria and monitoring, slurry walls, caps, permeable reactive materials and walls, slurry walls, and other related topics.The closing plenary session utilized a panel of eight experts from U.S. and non-U.S. industry, academia and the National Academy of Sciences, to provide a review of the technical sessions and insights as to the future of containment technology. The exhibition included vendor and agency booths and provided a venue for commercialization of containment technologies worldwide. Two well attended training seminars were conducted. These seminars focused on Barrier Emplacement Quality Assurance & Monitoring Strategies and Quality Control for Vertical Barriers, both of which provided information on topics pertinent to containment technology systems.A sitetour of the U.S.DOE Pinellas Plant wasconducted. These ex- tracurricular events were extremely effective and well attended. An important component of the 1997 conference was the Business Commercialization Center which provide a venue for business negotiations and marketing opportunities for conference delegates. As a result of the overwhelming success of the 1997conference, the Second International Containment Technology Conference and Exhibition will be conducted in 1999.For more informationon on, or to be added to the mailing list for the 1999 conference, please contact Loreen Kollar, Conference Coordinator at Florida State University, 2035 East Paul Dirac Drive, 226 Morgan Building, Tallahassee, Florida, 32310-3700, 904644-5524 (voice), 904-574-6704 (fax), or ICTCE@mailer.fsu.edu (e-mail). In Situ Remediation '97 In Situ Remediation '97 is a key element in ASCE's Annual Convention. The conference to be held October 5-7, 1997 in Minneapolis, MN will bring together more than 40 paper presentations and two plenary speakers. James K. Mitchell, Virginia Polytechnic Institute & State University,will open the conference with his plenary topic: "Waste Containment Barriers: Evaluation of the Technology." Michael Kavanaugh of Malcom Pirnie will follow with his plenary topic "Treatment Technologies for In Situ Remediation." The following list of session topics will be covered in the two and one-half day conference: Permeable Reactive Barriers Soil Vapor Extraction & Air Sparging In Situ Containment Technologies . Non-Aqueous Phase Liquids Integrated In Situ Remedial Technologies Stabilization/Solidification Collection Technologies Case Studies Including Bioremediation Developing Technologies: Electrokinetics and Radio-Frequency Heating .. . . .. . . For further information, contact ASCE at 1-800-548-2723 ext. 6300 (USA) or 703-295-6300 (International), email: conf@asce.org.