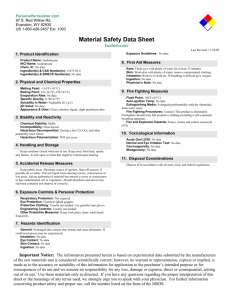

User information

advertisement

User information This user information relates to protective clothing designed and manufactured by Berendsen Sourcing AB – see sew-in CE-label with reference to relevant standards. All protective clothing related to this user instruction is designed in accordance with EC guideline 89/686/EEG. The clothing fulfils requirements in compliance with European standards for protective clothing including specifications below when provided with labels accordingly. General about USE, CARE and MAINTENANCE Improper use may not only endanger your own safety, but will also relieve the manufacturer of all liabilities. The clothing manufacturer cannot be held responsible when clothing has been incorrectly used. Damaged clothing must be repaired with the same material or replaced to ensure the safety of the wearer. - High Visibility Carefully see to that the garment is kept clean for best protective effect. The specified maximum number of washings is based on results of laboratory tests. The garments have not been soiled or exposed to wear. It is therefore of importance to make an evaluation of the fluorescent and reflecting ability of the garment after each wash. - Flame Retardency The clothing must be properly worn, meaning that the garment or a combination of garments shall be worn properly closed. Trousers and sleeveless coverall (“handy”) must always be worn together with a jacket or a shirt with equal protective performance. Protective shirts must be worn as jackets when welding, i.e they must not be tucked inside the trousers or coverall. Garments with ventilation at back offer better protection, but beware of risk for entangling. The limited flame spread properties will be reduced if the protective clothing is contamined with inflammable substances. - Chemical protection Garments with fluorocarbon treatment, i.e. garments with limited chemical protection (see label in the garment) must be regularly regularly get a f.c. reapplication (preferably after each wash) in a controlled washing and drying process in order to keep the repellency performance. For your safety clothing should be industrially washed only! Background material Reflexes High-visibility warning clothing can be approved in protection classes from 1 to 3, of which 3 is the highest. Class 3 may also be achieved in combination with a garment of lower protection classes if the total area visible (excluding overlapping) passes class 3. The classes are based on minimum visible surface in m2 for background material and reflexes: Background material Reflexes Class 1 0,14 m2 0,10 m2 Class 2 0,50 m2 0,13 m2 Class 3 0,80 m2 0,20 m2 X Visibility class of the garment; 3 classes, of which 3 is the highest Y Level of the reflecting material; 2 levels, of which 2 is the highest X Y EN ISO 11612:2008 Clothing to protect against heat and flame – has superseded EN 531 The clothing must protect the wearer against the effect of incidental contact with small flames and small splashes of molten metal drops. It also offers protection against radiation of convective heat of low intensity and/or against splashes of molten metal. The clothing must be properly worn, meaning that the garment or a combination of garments shall be properly closed. The limited flame spread properties will be reduced if the clothing is contaminated with flammable substances. Class 1 Class 2 Class 3 0,14 m² 0,10 m² 0,50 m² 0,13 m² 0,80 m² 0,20 m² The following information is specified in the marking of the garment: X Visibility class of the garment; 3 classes, of which 3 is the highest Code Requirements Performance level A1 Limited flame spread – surface ignition Compulsory: A1 and/or A2 A2 Limited flame spread – edge ignition Compulsory: A1 and/or A2 B Protection against convective heat B1-B3 C Protection against radiant heat C1-C4 D Protection against molten aluminium D1-D3 E Protection against molten iron E1-E3 F Protection against contact heat F1-F3 In the event of an accidental splash of chemical or flammable liquids on clothing, the wearer should immediately leave the work area and remove the garment, which shall be cleaned or removed from service. X The stated maximum number of cleaning cycles is not the only factor related to the lifetime of the garment. The lifetime will also depend on usage, care, storage etc. If the number of cleaning cycles is not specified, materials have been tested after minimum 5 cleaning cycles. Garments performing according to D and/or E levels: In the event of a molten metal splash the user shall leave the work area immediately and take off the garment. It is not excluded that a second degree burn may occur if the garment is worn directly next to the skin. EN 470-1:1995 Protective clothing for use in welding and allied processes – superseded by EN ISO 11611 The clothing must protect the wearer against the effect of incidental contact with small flames and small splashes of molten metal drops. This clothing provides protection against molten welding splatter and sparks as well as accidental contact with small flames. It also offers protection against radiation of convective heat of low intensity and/or against splashes of molten metal. The clothing must be properly worn, meaning that the garment or a combination of garments shall be worn properly closed. The limited flame spread properties will be reduced if the clothing is contamined with flammable substances. Important advice: The protective clothing itself does not provide protection against electric shock. The electrical insulation effect will be reduced by wetness, humidity or sweat. An increase of oxygen content in the air will reduce the protection of welder’s clothing against flame. Care should be taken when welding in confined spaces if it is possible that the atmosphere may become enriched with oxygen. The following information is specified in the marking of the garment (the higher the level, the better the protection): Code ReguirementsPerformance level A Limited flame spread One compulsory B Protection against convective heat B1-B5 C Protection against radiant heat C1-C4 D Protection against molten aluminium D1-D3 E Protection against molten iron E1-E3 EN 1149-5:2008 Electrostatic properties – material performance and design requirements The clothing decreases explosion risks due to anti-static properties. The garment must be correctly fastened and shall permanently cover all noncomplying materials during normal use, incl. bending and movement. The following information is specified in the marking of the garment: The following information is specified in the marking of the garment (the higher the level, the better the protection): High visibility warning clothing can be approved in protection classes from 1 to 3, of which 3 is the highest. Class 3 may also be achieved in combination with a garment of lower protection classes, if the total area visible (excluding overlapping) passes class 3. The classes are based on minimum visible surface in m² for background material and reflexes: EN 471+A1:2007 High-visibility warning clothing for professional use – superseded by EN ISO 20471 If the requirements are met by the use of a combination of garments, this is declared on the labels of all garments involved. EN ISO 20471:2013 High visibility clothing – has superseded EN 471 EN 531:1995 Protective clothing for workers exposed to heat – superseded by EN ISO 11612 EN ISO 11611:2007 Protective clothing for use in welding and allied processes – has superseded EN 470-1 Class 1: Protection against less hazardous welding techniques and situations, causing lower levels of spatter and radiant heat. Class 2: Protection against more hazardous welding techniques and situations, causing higher levels of spatter and radiant heat. The clothing is intended to protect against hazards such as flames, molten metal spatter, radiant heat and short term accidental contact. Additional partial body protection may be required, e.g. for welding above the head. For operational reasons not all welding voltage parts of arc welding installations can be protected against direct contact. The garment is only intended to protect against brief inadvertent contact with live parts of an arc welding circuit, and additional electrical insulation layers will be required where there is an increased risk of electric shock. Even when used in combination with additional partial protective garments, the primary garment shall be at least class 1. Electrostatic dissipative protective clothing shall not be removed whilst in the presence of a flammable or explosive atmosphere or while handling flammable or explosive substances. The person wearing the electrostatic dissipative protective clothing shall be properly earthed. The resistance between the person and the earth shall be less than 108 Ω., e.g. by wearing adequate footwear. The clothing shall not be used in an oxygen-enriched atmosphere without the approval of the responsible safety engineer. Performance of the electrostatic dissipative protective clothing can be affected by wear and tear, laundering and possible contamination. EN 1149-3 Electrostatic properties test method for measurement of charge decay Antistatic properties of fabric is tested according to EN 1149-3. Due to the anti-static properties cannot be removed by washing and therefore offer permanent properties in this respect. However, there must be a connection to earth and anti-static footwear shall be worn. Improper use: The level of protection against flame will be reduced if the welder’s protective clothing is contaminated with flammable substances. An increase in the oxygen content of the air will reduce considerably the protection of the welders’ protective clothing against flame. Care should be taken when welding in confined spaces, e.g. if it is possible that the atmosphere may become enriched with oxygen. The electrical insulation provided by clothing will be reduced when the clothing is wet, dirty or soaked with sweat. For two-piece protective clothing, both items shall be worn together to provide the specified level of protection. EN 13034+A1:2009 / type PB[6] partial protection Performance requirements for chemical protective clothing offering limited protective performance against liquid chemicals The following chemicals are tested for repellency and penetration: - Sulphuric acid, H2SO4 30%; penetration index class 3 (<1%) - Sodium hydroxide, NaOH 10%; penetration index class 3 (<1%) - O-xylene, undiluted - 1-butanol, undiluted Type PB[6] for partial protection has not been tested to whole suit test. A fluorocarbon treated fabric comply with requirements of prEN 13034 / type 6, but must regularly get a f.c. reapplication to keep its performance. The clothing offers a limited protective performance against small splashes of chemicals when combined with gloves, boots and/or other PPE equipment. Important advice: The clothing must be properly worn. It must be professionally washed regularly according to specific instructions to ensure that soiling does not damage the protective properties. If chemicals are accidently splashed on the garment, the wearer must immediately move away and carefully remove the garment, ensuring chemicals or liquids not to come in contact with the skin. The garment must be cleaned or taken out of use. EN/ IEC 61482-1-2:2007 Determination of arc protection class of material and clothing (box test) For the tests a low voltage procedure is used. The test can optionally be carried out in two fixed test classes, selected by the amount of prospective short circuit current: Class 1; 4kA (146 kJ/cm²) Class 2; 7 kA (427 kJ/cm²) The defied duration of the electric arc is 500 ms in both test classes. Acceptance criteria for tests on materials ParameterCriterion Burning time <5s Melting No melting through to the inner side Hole formation No hole bigger than 5mm in every direction (in the innermost layer) Heat flux All eight value pairs (Eit - tmax) are below corresponding Stoll values EN 343:A1:2007 Protection against rain Resistance to water penetration and water vapour resistance are the two main properties which are tested in the EN 343. X Resistance to water penetration - 3 levels, of which 3 is the highest Resistance to water penetration of fabric and seams is the most important quality for an adequate protection. The resistance to water penetration is expressed in kPa, but a more understandable expression is in millimetre water column. Y Water vapour resistance - 3 levels, of which 3 offers the highest breathability and ability to transport moisture. Garments with water vapour resistance class 1 may increase the heat stress in certain climatic conditions, see table below for recommended wearing time. The classic unit for breathability was defined in g/m² per 24 hours. However EN 343 uses a water vapour resistance value Ret (m². Pa/W). The higher the Ret value, the higher the resistance of the fabric and the less vapour passes through. Recommended maximum continuous wearing time for a complete suit consisting of jacket and trousers without thermal lining Class Temperature of working environment °C 1: Ret above 40 min 2: 20 < Ret < above 40 min 3: Ret < 20 min 25 60 105 205 20 75 250 ---- 15 100 ---- ---- 10 240 ---- ---- 5 ---- ---- ---- “-“ means: no limit for wearing time IEC 61482-2:2009 Protective clothing against thermal hazards of electric arc Table valid for medium physiological strain M = 150 W/m², standard-man, at 5+% relative humidity, and wind speed va = 0,5 m/s. When tested in accordance with EN/IEC 61482-1-2 the protective clothing shall be assigned a Class 1 or Class 2 depending on the test conditions and the resulting arc thermal protection. The garments should be inspected before each use. Protective clothing that are contamined or damaged to the extent their protective qualities are impaired (e.g. holes in the garments, not functioning closure) should not be used. Protective items that become contamined with grease, oil or flammable liquids or combustible materials should not be used. The user should treat carefully the protective clothing. The protective clothing shall be worn in the closed state. No garments such as shirts, undergarments or underwear made of e.g. polyamide, polyester or acrylic fibers, should be used as they melt under arc exposures. It is strongly recommended to consider national prescriptions and regulations where protective clothing are to be used. Damaged garments should be repaired - replacement of a button or other minor work in accordance with instruction – to be downloaded from Universe – or replaced. In the event of tearing, such damage should not be repaired. Other garments worn together with protective clothing and dirty protective clothing can reduce the protection. Although the protective clothing is designed for flame protection, contamination can reduce the protective function against electric arc exposure. The protective clothing should therefore be cleaned when necessary. The above types of protective clothing are developed and produced by Berendsen Sourcing AB, Sweden. The Finnish Institute of Occupational Health in Finland, notified body no 0403 for personal protective equipment has CE type examined the products according to directive 89/686/EEC and its amendments. (2014-02-11)