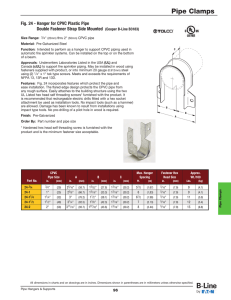

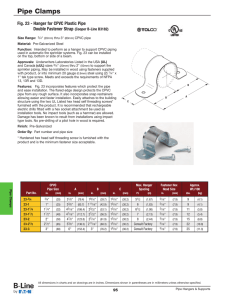

CPVC Fire Sprinkler Products

advertisement