Recent Advances in Electrolytes for Electrochemical Double Layer

advertisement

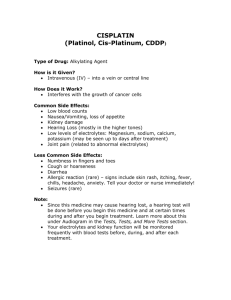

Recent Advances in Electrolytes for Electrochemical Double Layer Capacitors V. R. Koch Covalent Associates, Inc. 10 State Street Woburn, Massachusetts 01801 USA koch@covalentassociates.com 1.0 INTRODUCTION Over the past twenty-five years, advances in electrochemical double layer capacitor (EDLC) technology have been largely driven by improvements to their non-aqueous electrolytes. Such electrolytes typically employ quaternary ammonium salts solubilized in oxidatively stable solvents such as acetonitrile (AN) and propylene carbonate (PC) (1). Commercially available EDLC electrolytes provide an electrochemical window of greater than 4V at highly polished analytical working electrodes, and approximately 3V in commercially available EDLC devices, also known as “ultracapacitors”. The ~1V lower electrochemical window provided by commercial devices is due to the need for high surface area electrodes, which store practical amounts of charge. Such carbonaceous electrodes incorporate surface redox sites, which in turn truncate the available electrochemical window. The ideal EDLC electrolyte possesses the following characteristics: • • • • • A wide (>4V) electrochemical window in EDLC hardware A specific conductance in excess of 75 mS/cm at room temperature A thermal stability approaching 300°C A freezing point or glass transition temperature below -60°C Low toxicity and acceptable cost Of course, no such electrolyte presently exists. That said, a worldwide effort is underway to expand the performance envelope of EDLC electrolytes comprising non-aqueous solvents and salts that incorporate charge delocalized anions and cations. This paper focuses on the formulation, characterization and performance of some new ionic liquidbased electrolytes designed for low and high temperature performance in ultracapacitors. 2.0 IONIC LIQUID MATERIALS Covalent’s EDLC electrolyte technology is based on a family of salts known as hydrophobic ionic liquids (ILs). These materials possess a unique set of physical, chemical, and electrochemical properties that strongly favor their use as electrolytes in 1 EDLCs. Unlike ILs that incorporate reactive ions that decompose to form HF, the Covalent salts are thermally and hydrolytically stable. In this paper we focus on the formulation of task specific electrolytes derived from IL materials, which in and of themselves are suitable EDLC electrolyte media tailored for high temperature applications. Unlike molecular solvents that are charge neutral, ILs may be described as room temperature molten salts composed solely of polyatomic anions and cations. Covalent’s IL technology is based on the judicious pairing of delocalized heterocyclic organic cations and charge stabilized organic and inorganic anions shown in Figures 1 and 2 (25). N+ N N+ N N N Imidazolium Pyrazolium N+ N+ S O Thiazolium N+ Pyridazinium Inorganic Triazolium BR4PR6- N+ Oxazolium Organic _ RSO3(RSO2)2N(RSO2)3C- Pyridinium N N N+ N+ N+ Pyrimidnium Pyrazinium Figure 1: Cation Structures R = halide, CF3, C2F5, and other electronegative alkyl and aryl substituents. N Figure 2: Anion Structures Owing to the strong coulombic attraction between ions of opposite charge, ILs possess no measurable vapor pressure in contrast to highly volatile EDLC electrolytes derived from AN. A number of highly desirable properties of neat ILs as EDLC electrolytes follow: • • • • • Ion concentrations of from 4M to 6M Wide liquid range (-90°C to 400°C) Non-flammable with low toxicity Non-corrosive to electrode and packaging components at elevated temperatures Isothermal stabilities approaching 300°C with no measurable vapor pressure While this set of advantages is unprecedented in light of prior art, one must always be cognizant of EDLC electrolyte conductivity, which is dependent on ion mobility. Ion mobility in electrolytes is, in turn, governed by IL viscosity. While the strong coulombic attraction between ions of opposite charge is directly responsible for the manifold of desirable properties listed above, we have found that IL viscosities are minimally two 2 orders of magnitude greater than those of most common molecular solvents. Thus, the ionic conductivities of neat ILs, which typically range from 4 to 14 mS/cm at 22°C, are patently insufficient for EDLC applications at room temperature and below but are suitable for high temperature applications. Of course, one can reduce the viscosity of an IL by simply blending it with a molecular solvent. While such blends afford excellent room and low temperature conductivities, non-flammability may be lost and issues of toxicity must again be addressed, particularly in respect to the use of AN as a co-solvent. We have solved these problems by designing one class of EDLC electrolytes that perform well at room temperature and below, and another class of electrolytes formulated for high temperature applications. We consider each in turn. 3.0 ROOM TEMPERATURE/LOW TEMPERATURE EDLC ELECTROLYTES 3.1 Blended Electrolytes Because of its low viscosity (0.33 cP at 30°C), wide electrochemical window (> 4V), and large dielectric constant (37.5), AN is the solvent of choice for use in EDLC electrolytes where high device power is required. However, in addition to flammability a more serious problem involves its acute toxicity. AN may readily be inhaled and absorbed through the skin where it is converted by the liver to formic acid and HCN. An alternative solvent for use in formulating EDLC electrolytes is methyl formate (MF). MF has a viscosity similar to that of AN (0.33 cP at 25°C), but a lower dielectric constant (8.5) and narrower electrochemical window (~ 3.2V). Although flammable, MF does not possess AN’s acute toxicity. Figure 3 shows an overlay of two linear sweep voltammograms for AN and MF, both 2M in 1-ethyl-3-methylimidazolium hexafluorophosphate (EMIPF6) (I) obtained at a glassy carbon working electrode. The overlay clearly reveals the advantage that AN has over MF in respect to the electrochemical window. N N I 3 PF6- Current µA/cm2 2M EMIPF6/MF 2M EMIPF6/AN Potential (V) Figure 3: Linear sweep voltammograms obtained at a glassy C working electrode vs. a Ag wire quasi-reference electrode. 3.2 Non-Flammable Blended Electrolytes In an effort to develop safer electrolytes for EDLC applications, we have reformulated a number of IL/molecular solvent blends with and without AN. The room temperature conductivity, electrochemical window, and flammability of these electrolytes were evaluated. The electrochemical window was assessed by linear sweep voltammetry at a glassy carbon working electrode. The cutoff voltages were taken at the very conservative current density of 20 µA/cm2. Flammability was determined by a modified Underwriters Laboratories test (UL 94 Standard). In this test a 10 cm length of glass fiber wick was suspended horizontally in a fume hood. The middle 5 cm of wick was thoroughly soaked with electrolyte, then exposed to the flame from a propane torch. Those electrolytes that burst into flame were designated as “flammable”. Those that smoked but did not ignite were designated as “non-flammable”. Table 1 presents electrochemical data for several formulated AN-containing electrolytes and compares them with their flammable analogs. “Im” refers to the bis(trifluoromethylsulfonyl)imide anion [(CF3SO2)2N-], “TEA” refers to the tetraethylammonium cation [Et4N+], and “NF” refers to non-flammable. 4 Table 1: AN-Based EDLC Electrolytes Electrolyte σ, mS/cm at 25 °C UE, V 2M EMIPF6/AN 2M EMIPF6/AN-NF 65 58 4.16 4.06 2M EMIIm/AN 2M EMIIm/AN-NF 47 44 4.16 4.05 1.5M TEABF4/AN 1.5M TEABF4/AN-NF 55 44 4.27 4.25 Table 1 reveals that a small price in conductivity and UE is paid for the benefit of nonflammability. The room temperature conductivities of the NF electrolytes are somewhat lower, and the electrochemical window contracts slightly. Nonetheless, the 2M EMIPF6/AN electrolytes possess both a higher ion concentration and ionic conductivity than the saturated quaternary ammonium salt/AN electrolyte, which offers an advantage in UE. The thermally stable EMIIm-based electrolytes provide a wide electrochemical window, albeit with lower conductivity due to the significantly larger ionic radius of Imcompared to PF6-. In Table 2, we present data for a group of AN-free electrolytes. Here we do not pay a penalty in UE on going from a flammable to a reformulated non-flammable electrolyte. However, the ionic conductivity is lowered for all non-flammable formulations as seen Table 2: AN-Free EDLC Electrolytes σ, mS/cm at 25 °C UE, V 2M EMIPF6/MF 2M EMIPF6/MF-NF 46 34 3.10 3.10 Covalent 031 Covalent 031-NF 39 36 3.25 3.25 Covalent 111 Covalent 111-NF 29 27 3.30 3.30 Covalent 211 Covalent 211-NF 22 19 3.60 3.60 Electrolyte previously in the AN-based electrolytes. Three new AN-free blends designated as Covalent 031, 111, and 211 manifest either good conductivity coupled with a truncated electrochemical window, or a wide electrochemical window coupled with lower 5 conductivity. These new formulations would be particularly attractive for those device applications that preclude the presence of AN. 3.3 Summary of Room Temperature/Low Temperature Electrolytes We have demonstrated the utility of a number of non-flammable and AN-free electrolytes designed to operate at room temperature and below. Such electrolytes possess various advantages and disadvantages in respect to flammability and toxicity that must be carefully weighed in choosing an electrolyte for a specific EDLC application. 4.0 HIGH TEMPERATURE EDLC ELECTROLYTES Two different ionic liquid-based electrolytes designated Covalent 400 series and 500 series were used in this study. The electrolytes were evaluated in respect to ionic conductivity and electrochemical window at temperatures up to 175°C. The long-term compatibility of electrolyte with electrode materials was studied over a 1000 hr storage period at 150°C. EDLC cycling and capacity retention experiments were accomplished in unoptimized 2325 crimped coin cells. Electrode disks were punched from two different materials: SpectraCarb 2220 woven carbon cloth (SpectraCorp), and a carbonaceous electrode material bonded to an Al current collector (EC150X1) kindly provided by W. L. Gore & Associates, Inc. 4.1 Electrolyte Properties as a Function of Temperature Ionic conductivity: Figure 4 presents a plot of specific conductance vs. temperature. At 150°C, the highest cycling temperature used in this project, the 400 series electrolyte was found to possess a conductivity of 60 mS/cm while that for the 500 series electrolyte was 36 mS/cm. These values are similar to those for room temperature acetonitrile-based EDLC electrolyte formulations where acetonitrile’s viscosity is an order of magnitude lower compared to those for ionic liquid materials. 6 120 Conductivity (mS/cm) 100 400 80 500 60 40 20 0 0 50 100 150 o Temperature ( C) 200 250 Figure 4: Specific conductance of 400 and 500 series electrolytes vs. temperature. Electrochemical window: Figure 5 presents an overlay of cyclic voltammograms obtained at three different temperatures on electrolyte 400. The electrochemical window, ∆V, was observed to rapidly contract with increasing temperature in accordance with the formalism of the Nearnst equation. At room temperature ∆V approaches 4V, but falls to less than 1.5V at 200°C. The electrochemical window of an electrolyte would be expected to further contract when high surface area electrodes incorporating unspecified and reactive surface sites are substituted for an analytical working electrode employed in CV studies. 0.20 o 25 C o o 100 C 2 Current (mA/cm ) 200 C 0.00 -0.20 -2.50 -1.50 -0.50 0.50 1.50 2.50 E (V vs. Ag ) Figure 5: Cyclic voltammograms obtained at a glassy C working electrode on 400 series electrolyte at various temperatures. The sweep rate was 20 mV/s. 7 Electrode/Electrolyte Compatibility: To assess the long-term stability of the Gore electrode at elevated temperatures, we immersed electrode disks in electrolytes 400 and 500 under Ar in Teflon bottles. The bottles were stored in an oven at 150°C for 1000 hr. Figure 6 presents an overlay of linear sweep voltammograms obtained in electrolyte 400 after storage, and these data are virtually identical to those obtained with electrolyte 500. B A 2 Current (mA/cm ) 0.2 C B 0 C A -0.2 -3 -2 -1 0 1 2 3 E (V vs. Ag) Figure 6: Linear sweep voltammograms obtained at a glassy C working electrode on electrolyte 400 at room temperature: A) before exposure to 150°C soak; B) after 1000 hr soak at 150°C; C) after 1000 hr soak at 150°C with the Gore electrode. The sweep rate was 20 mV/s. The three linear sweep voltammograms reveal that the ionic liquid-based electrolytes are thermally stable at 150°C over very long periods of time. With the exception of a small cathodic peak observed for C at –2V, there were no deleterious interactions between the Gore electrode and the 400 and 500 electrolytes. Indeed, the Gore Al current collectors were found to be smooth and shiny, i.e., unchanged after the 1000 hr soak at 150°C indicative of the lack of corrosive processes. 4.2 EDLC Cycling Results at Elevated Temperatures Four sets of 2325 coin cells were constructed. These cells incorporated SpectraCarb and the Gore electrode materials along with electrolytes 400 and 500. Duplicate cells were cycled symmetrically at the 4C rate to 2.5V at 100°C, and to 1.75V at 150°C. Figures 7 and 8 each present a plot of capacity vs. cycle life for the first 500 cycles. Over the first 50 cycles at 100°C, cells with SpectraCarb electrode material were observed to fade slightly while those with the Gore electrode material did not. At 150°C, irrespective of the electrode material, the coin cells were observed to cycle in parallel. 8 0.7 0.6 Capacity (mAh) 100oC Gore 0.5 SpectraCarb 0.4 0.3 0.2 0.1 0.0 0 100 200 300 400 500 Cycle number Figure 7: Capacity vs. cycle number for electrolyte 400 at 100ºC. 0.5 150oC Gore Capacity (mAh) 0.4 0.3 SpectraCarb 0.2 0.1 0.0 0 100 200 300 400 500 Cycle number Figure 8: Capacity vs. cycle number for electrolyte 400 at 150ºC. 4.3 EDLC Capacity Retention at 150ºC The ability to retain charge on open circuit is an important parameter in capacitor technology. Coin cells incorporating the Gore and SpectraCarb electrodes underwent a number of charge/discharge cycles at 150ºC before being charged to 1.75V, and then switched to open circuit. The voltage/time behavior on open circuit of the Gore electrodes after 100 and 600 cycles was found to be virtually identical as shown in Figure 9. Upon discharge after the 2-hour soak at 150ºC, coin cells containing the Gore 9 electrodes retained 78% of their initial capacity while coin cells containing the SpectraCarb electrodes retained 70% of their initial capacity. 2.00 150oC Voltage (V) 1.50 1.00 0.50 after 100 cycles after 600 cycles 0.00 0 20 40 60 80 100 120 140 Time (min) Figure 9: Capacity retention on OCV for Gore electrodes and electrolyte 400 at 150ºC. Table 3 summarizes the data collected to date on the 400 and 500 electrolytes. These data are compared to those collected by Sato and coworkers who studied the behavior a quaternary ammonium tetrafluoroborate ionic liquid electrolyte in EDLCs as a function of temperature. 10 Table 3: Electrode/electrolyte performance data at various temperatures. Electrolyte R4NBF4 400b 500b a Electrode material T, C Applied potential, V C, F/g Coulombic efficiency, % pyrolyzed phenol resin 22 100 150 2.50 2.50 2.50 25.4 23.7 17.5 98.5 78.5 33.7 Gore SpectraCarb 100 100 2.50 2.50 20.4 27.5 99 99 Gore SpectraCarb 150 150 1.75 1.75 18.4 26.2 99 98 Gore SpectraCarb 100 100 2.50 2.50 19.8 26.2 99 99 Gore SpectraCarb 150 150 1.75 1.75 17.6 23.1 99 99 Gore SpectraCarb 175 175 1.50 1.50 15.9 21.5 99 99 o a T. Sato, et al., Electrochimica Acta, 49, 3603 (2004); cycling data collected at the C rate. b Cycling data collected at the 4C rate. Of particular interest are the coulombic efficiency values derived from the 400 and 500 electrolytes at elevated temperatures from both the Gore and SpectraCarb electrode materials. These values (obtained at the 4C rate) greatly exceed those of Sato and coworkers (obtained at the C rate). The SpectraCarb electrode material afforded higher capacitance values compared to the Gore electrode material (presumably due to a more open pore structure). However, practical EDLC devices require a wound construction that is not readily accomplished with a woven carbon cloth electrode material. Thus, Covalent’s ionic liquid-based electrolytes in concert with the Gore electrodes provide a solution to those EDLC power sources required to operate at high temperatures. The data shown in Table 3 highlight the tradeoff between the conflicting requirements of high device power and long cycle life at elevated temperatures. Because of thermodynamic limitations relating to electrolyte stability at high potentials and the activation of the carbonaceous electrode surface, device engineers must choose between high power densities with a truncated cycle life, or lower power densities with a longer cycle life. 4.4 Summary of High Temperature Electrolytes The careful formulation of ionic liquid electrolyte components enables high temperature EDLC applications. Such electrolytes ensure: 11 • • • • • Long-term thermal stability High coulombic efficiency Excellent capacity retention Non-flammable electrolyte materials with low toxicity Compatibility with “off the shelf” electrode materials and packaging components 5.0 CONCLUSIONS No single electrolyte formulation will meet all of the industry’s performance requirements. However, we have demonstrated that task specific electrolytes may be designed for EDLC applications over various thermal envelopes. Covalent is presently working with device manufacturers to bring such EDLC devices to the market. 6.0 REFERENCES 1. 2. 3. 4. 5. M. Ue, et al., J. Electrochem. Soc., 144, 2684 (1997). U.S. Patent 5,827,602 U.S. Patent 5,965,054 U.S. Patent 5,973,913 U.S. Patent 6,531,241 12