RigPro Manual No - SafetyLiftinGear

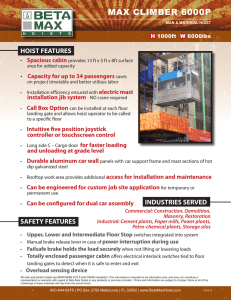

advertisement

ELECTRIC CHAIN HOIST Operating, Maintenance & Parts Manual DU-905 3-Phase, 1000Kg. \ Table of Contents Inspection & Maintenance 13 General Information 3 Preventive Maintenance 14 Safety Precautions 3 Hook Inspection 15 Chain Hoist Specifications 4 Chain 15 Application Information 6 Identification of Chain 16 Adverse Environmental Conditions 6 Chain Replacement with Chain In Lifting Motor 17 Lifting of Hazardous Loads 6 Chain Replacement with no Chain in Chain Hoist 17 Tandem Lifts and Multiple Lifts 6 Chain End Stop 18 Suspending Loads over People 6 Cutting Chain 18 Safety Information 6 Load Chain Cleaning 18 Installation 7 Overload Limiting Clutch 18 Power & Control System Requirement 7 Limiting Clutch Adjustment 18 Preliminary Checks 7 Wiring 19 Rigging & Motor Handling Instructions for Temporary Installation 8 Wiring Diagrams 20 De-rigging the hoist 10 Power Cord Precaution 22 Chain Hoist Operation Instruction 11 Lubrication 23 General 11 Chain Hoist Repairs 24 Overload Limit Clutch 12 Recommend Spare Parts 24 Chain Bag 12 Explosive Art for DU-905 Chain hoist 25 Operating Notes 13 Part list for DU-905 Chain hoist 26 Trouble Shooting 27 2 General Information All DUKE Electric Chain Hoists are thoroughly inspected and performance tested prior to shipment. If any properly maintained hoist develops a performance problem due to a material or workmanship defect, as verified by DUKE, repair or replacement of the unit will be made to the original purchaser without charge. This repair/replacement policy applies only to DUKE Hoists installed, maintained and operated as outlined in this manual, and specifically excludes parts subject to normal wear, abuse, improper installation, improper or inadequate maintenance, hostile environmental effects and unauthorized repairs/modifications. We reserve the right to change materials or design, if, in our opinion, such changes will improve our product. Abuse, repair by an unauthorized person, or use of non-DUKE replacement parts voids the guarantee and could lead to dangerous operation. SAFETY PRECAUTIONS Each DUKE Chain hoist is built in accordance with the specifications contained here in, and at the time of manufacture complies with our interpretation of applicable sections of European FEM or equivalent to American Society of Mechanical Engineers Code (ASME) B30.16 “Overhead Hoists,” the National Electrical Code (ANSI/NFPA 70) and the Occupational Safety and Health Act (OSHA). Since OSHA states the National Electrical Code applies to all electric chain hoists, installers are required to provide current overload protection and grounding on the branch circuit section in keeping with the code. Check each installation for compliance with the application, operation and maintenance sections of these articles. Improper operation of a hoist can create a potentially hazardous situation which, if not avoided, could result in death or serious injury. To avoid such a potentially hazardous situation, the operator shall: NOT operate a damaged, malfunctioning or unusually performing chain hoist. NOT operate the chain hoist until you have thoroughly read and understood the manufacturer’s Operating and Maintenance Instructions or Manuals. NOT operate a chain hoist, which has been modified without the manufacturer’s approval. NOT allow anyone under 18 years of age to operate the chain hoist. NOT lift more than rated load for the chain hoist. NOT operate a chain hoist unless it has been securely attached to a suitable support. NOT use chain hoists with load chains that are knotted, twisted, kinked, damaged, or worn. NOT use the chain hoist to lift, support, or otherwise transport people, without additional or mandatory local or national safety precautions. NOT let anyone stand beneath a moving load! NOT move a load in any manner that can endanger persons. NOT operate unless all persons are and remain clear of the supported load. NOT operate unless load is centered under chain hoist. NOT operate a chain hoist when it is restricted from forming a straight line from hook to hook in the direction of loading. NOT use load chain as a sling, or wrap the load chain around load. NOT apply the load to the tip of the hook or to the hook latch. NOT apply load unless load chain is properly seated in the chain sprocket(s). NOT apply load if bearing prevents equal loading on all load supporting chains. NOT operate beyond the limits of the load chain travel NOT use the chain hoist’s overload limiting clutch to measure load. NOT leave a load supported by the chain hoist unattended unless specific precautions have been taken. NOT allow the load chain or hook to be used as an electrical or welding ground. NOT allow the load chain or hook to be touched by a live welding electrode. NOT remove or obscure the warnings on the chain hoist. NOT operate a chain hoist on which the safety placards or decals are missing or illegible. NOT operate a chain hoist unless load slings or other approved single attachments are properly sized and seated in the hook saddle. NOT allow your attention to be diverted from operating the chain hoist. NOT allow the chain hoist to be subjected to sharp contact with other chain hoists, structures, or objects 3 through misuse. NOT adjust or repair the chain hoist unless qualified to perform such adjustments or repairs. NOT attempt to lengthen the load chain or repair damaged load chain. NOT drag the load chain and/or chain hook across dirty, sandy of abrasive surfaces (concrete floors). NOT hold on to the load chain, which is dangerous for obvious reasons and hold on to the motor housing which is dangerous as this can get very hot. Holding onto the power or control pigtails is certainly not advised as well. Improper operation of a hoist can create a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. To avoid such a potentially hazardous situation, the operator shall: DO make sure that the weight of the load to be suspended is known, and in accordance to the lifting capacity of the chain hoist. In multiple lifts make sure a rigging plot is present. DO make sure that the hoist operator is in good physical and mental condition. DO check the chain hoist, suspension-hook, chain-hook, hook latches, as well as the load-chain itself, prior to each time of use for any damage, deformation or malfunction. DO make sure that the structure from which the DUKE chain hoist is suspended, as well as the slinging equipment is able to safely absorb the force resulting from the weight of the load and the chain hoist itself, multiplied by the dynamics of starting and stopping the lifting action. For the DUKE this is approximate 1.4 times the static load. DO check brake function by tensioning the chain hoist prior to each lift operation. DO shut down a chain hoist that malfunctions or performs unusually and report such malfunction. DO make sure hook travel is in the same direction as shown on the controls. DO maintain firm footing or be otherwise secured when operating the chain hoist. DO guide the chain hoist to take up slack chain carefully without twisting or knotting. DO make sure load is balanced and load holding action is secure before continuing lifting operation. DO always keep your attention to the chain hoist and the load that it is supporting. DO use hook latches. Latches are to retain slings, chains, etc. under slack conditions only. DO make sure the hook latches are closed and not supporting any parts of the load. DO make sure the load is free to move and will clear all obstructions. DO make sure the power (and control) cables and connectors have proper stress relieves and are never fully tight during lifting or lowering movement. DO warn personnel of an approaching load. DO avoid swinging the load or hook. DO inspect the chain hoist regularly, replace damaged or worn parts, and keep appropriate records of maintenance. DO use a protective cover for the chain hoist to prevent exposure to rainfall when applied outdoors. DO only use factory recommended parts when repairing the unit. DO protect the load chain from weld splatter or other damaging contaminants. DO lubricate load chain according to manufacturer’s recommendations. DO transport the chain hoist in a flight case or other sturdy & protective facility. CHAIN HOIST SPECIFICATIONS The DUKE is a rugged and portable chain hoist designed for the demands of rigging applications. With its compact construction and ability to operate inverted and it can be used to lift loads that are within its rated capacity. The mechanical features of these hoists include an alloy liftwheel, Load Protector, hardened steel chain guides, hardened steel load chain, hardened steel gear train, forged steel hooks, and lightweight steel frame. The electrical features included hoist-duty motor, rugged geared brake, and voltage conversion terminal block. DUKE chain-hoists come standard with handles to maneuver or guide the hoist in or out of a flight case, or position it over the load. 4 Item No. DU-905 Load capacity 1000kg Lifting Speed 50/ 60Hz standard m/min 6/7 Operating voltage 380V-3P-50/60HZ 4150V-3P-50/60HZ Motor power at 50/60Hz 2HP Power consumption at operation 3.3Amp Noise level 68db Load wheel 5 pocket Load chain DIN 5684 7,1 x 20,5mm Falls of chain 1 Weight of chain per meter lift 1.04Kgs/per meter Weight of body 40Kgs Type of control direct Type of connector CEE 16A-4p Suspension with swivel hook standard 5 APPLICATION INFORMATION The DUKE is intended for professional use in rigging applications to lift and support material loads within its rated capacity. It is designed as a component to be integrated into a rigging system. The user is responsible for ensuring the adequacy and reliability of their controller and power supply and the whole lifting system and operation as such. DUKE can not be held responsible for applications other than those for which the DUKE hoist is intended. Prior to installation and operation, we caution the user to review his application for abnormal environmental or handling conditions and to observe the applicable recommendations as follows: ADVERSE ENVIRONMENTAL CONDITIONS Do not use the chain hoist in areas containing flammable vapors, liquids, gases or any combustible dusts or fibers. Do not use this chain hoist in highly corrosive, abrasive or wet environments. Do not use this chain hoist in applications involving extended exposure to ambient temperatures below -20°C (-10°F) or above 50°C (130°F.) LIFTING Of HAZARDOUS LOADS This chain hoist is not recommended for use in lifting or transporting hazardous loads or materials which could cause widespread damage if dropped. The lifting of loads which could explode or create chemical or radioactive contamination if dropped requires fail-safe redundant supporting devices which are not incorporated into this chain hoist. TANDEM LIFTS AND MULTIPLE LIFTS Chain hoists – of any manufacturer unless otherwise stated - are basically designed to operate as a stand alone type of machinery. When two (or more) chain -hoists are used to lift one single load the risks increase considerably. Several countries around the world have legislation that in such cases it is mandatory to reduce the allowable amount of load lifted to 75% or even 66% of the rated capacity of the chain hoist. DUKE considers the application of the chain hoists in any other than stand alone situations as being the responsibility of the operator or user. DUKE strongly advises operators to acquire sufficient knowledge of the local, national or international rules and regulations when these types of lifting are applied. SUSPENDING LOADS OVER PEOPLE The suspension of loads over people demands the highest level of rigging knowledge, equipment, and equipment maintenance. The DUKE must be installed and used in accordance to local and national standards and regulations when suspending loads over people. These include the following important precautions. It is preferred that the load always be tied off with an auxiliary chain or cable (‘secondary’ or ‘safety’) before access to the area beneath the load is permitted. As an alternative, the system may be designed in such way that malfunction or failure of one chain hoists load bearing components does not cause load loss and/or overloading of any other chain hoists in the system. Note that in such a system, chain hoist performance and function must be monitored visually or should be monitored using load cells. Never operate the chain hoist while people are under the load. SAFETY INFORMATION 1. Follow all local electrical and safety codes, and applicable local standards. 2. The chain hoist must be securely and adequately grounded. The power cable includes a green/yellow lead for grounding. 3. Be careful when touching the exterior of an operating motor; it may be hot enough to be painful or cause injury. With modern motors this condition is normal if operated at rated load and voltage (modern motors are built to operate at higher temperatures). 4. Protect the power and control cables from coming in contact with sharp objects. 5. Do not kink the electrical cables and never allow them to come in contact with oil, grease, hot surfaces, or chemicals. 6. Make certain that the power source conforms to the requirements of your equipment. 7. Visually check the unit daily before operating chain hoist. 8. Cluttered areas and benches invite accidents. 9. The operator should not engage in any practice that will divert his attention while operating the chain hoist. 10. Before using the chain hoist, the operator should be certain that all personnel are clear of the load. 11. Do not operate chain hoist with loads exceeding its rated capacity. 6 12. Supporting frames or beams used as a chain hoist hanger must have a greater load capacity than the chain hoist. 13. Do not attempt to operate chain hoist beyond normal maximum lift range. 14. Align chain hoist for a straight vertical pull. Avoid side pull or end pull. 15. Do not operate chain hoist with twisted, knotted, damaged or corroded chain. 16. Do not operate a damaged or malfunctioning chain hoist until necessary adjustments or repairs have been made. 17. Do not use a chain hoist to lift people or to carry loads over people. 18. Do not leave a load suspended in the air unattended. 19. Always remove load before making repairs. 20. Do not remove or obscure capacity or warning decals. INSTALLATION POWER & CONTROL SYSTEM REQUIREMENTS The DUKE hoist comes in a direct control. They must be connected to a power and control system that is properly designed to operate the chain hoist and to handle the power consumption of the motor. DUKE hoists are standard wired for 380V-3ph-50Hz operations. For other voltages the chain hoist motor can be re-wired internally for ( 440V-3ph-50Hz and 220V-3ph-60Hz) PRELIMINARY CHECKS Before installing / starting to use the chain hoist, check the following: General: 1.After unpacking the unit, carefully inspect for any damage that may have occurred during transit. Check for loose, missing or damaged parts. Shipping damage claims must be filed with the carrier. Be sure that the voltage labeled on the unit matches your power supply. 2. Make sure all supporting structures and attaching devices have the strength to safety absorb the weight of the intended loads. If in doubt, consult a qualified structural Power cables to chain hoists must include a ground conductor. If in doubt, consult a qualified structural engineer. 3. Chain hoists should not experience voltage drops of more than 10% of the supply voltage. It is critical to use adequate sized power cable. 4. The user’s control board must be grounded in accordance with the electrical codes that are applicable in the local area. Power cable to chain hoists must include a ground conductor. The power cable includes a yellow/green ground conductor. 5. The installation area must provide safe operating conditions for the operator, including sufficient room for the operator and other personnel to stand clear of the load at all times. 7 RIGGING & MOTOR HANDLING INSTRUCTIONS FOR TEMPORARY INSTALLATIONS RIGGING 1. Before each use, visually inspect the hoist and all load bearing parts of the hoist, like hook and chain. 2. Make sure the intended structural support component is able to safely absorb the chain hoist lifting capacity. 3. Attach the chain bag to the chain bag ring. 4. Put the chain into the chain bag and make sure there are no twists or knots in the chain in the chain bag. 5. Attach the chain hook to the main structural support member, either direct to an existing eyebolt or lug-plate, or using a bracket or beam clamp. It is also possible to use a sling or bridle. Avoid slinging on sharp edges. 6. Connect the power (and control) cable and make sure these will have proper stress relieves and sufficient slack in every direction of planned tilting of the load. Use Velcro or cable-strings to tie the cable to the hoist body or lifting hook. 7. Lower the chain hook by letting the chain run out to the required height. 8. Put the load under the chain hook. 9. Attach the load to the chain hook, either to a lug plate, eyebolt or using one or more slings. 8 10. 11. 12. Run the chain up until the load chain just taut. Check all lifting and slinging connections, and lift the load until it is freely floating of the ground. Visually check the whole lifting structure from chain hoist and cable through the load chain down to the load. 13. Remove all people from the area before you start lifting the load. Do not allow any people to stand under the moving load. 14. Make sure you have a full visual view on the complete travel path of the load. 15. Lift the load to the required height. 16. Add a secondary in between support structure and the load when persons have to get under the load. 17. Make sure this secondary is as tight as possible, preferably using clutch-chains. 9 DE-RIGGING THE HOIST 1. Remove the secondary (when present). 2. Check the direction of travel. If the pre-selection switch on the controller is in the down-direction the chain hoist should run in down-direction. 3. Check if both the lifting directions work properly (lifting and lowering). 4. Remove all people from the area before you start lowering the load. Do not allow any people to stand under the moving load. 5. Make sure you have a full visual view on the complete travel path of the load. 6. Bring the load down until within reach for further dismantling. 7. Remove all parts of the load and slings attached the chain hook. 8. Disconnect the power and control cables. 9. Remove the chain hoist from the suspension structure and bring it down. 10. Put the chain hoist and the chain bag in their compartments of the flight case (when applicable). 11. Remove any bracket, beam clamp or sling from the main structure elements. 10 CHAIN HOIST OPERATION INSTRUCTIONS General: 1. Check to ensure that the load point is in the line with the hoist head. 2. When applying a load, it must be directly in line with hoist. Avoid off-center loading of any kind. 3. Take up a slack load chain carefully and start load easily to avoid shock and jerking of hoist load chain. if there is any evidence of overloading, immediately lower the load and remove the excess load. 4. Do not allow the load to swing or twist while lifting. 5. Do not allow the load and/or attachments to bear against the hook latch and/or hook tip. Apply load to hook bowl or saddle only. 6. When installing a three phase chain hoist, check and make sure the chain hoist travels in the direction intended when operating the controls. To correct improper motor travel, reverse any two wires (except the yellow/ green ground wire) at the power source. Do not change the connection in the chain hoist. Once the direction of travel is verified to be correct, permanent connections can be made at the power source. 11 OVERLOAD LIMITING CLUTCH The overload limiting clutch is designed to allow the intermediate gear to slip on an excessive overload. An overload is indicated when the hoist will not raise the load. Also, some clutching noise may be heard if the hoist is loaded beyond rated capacity. This condition should be avoided by immediately releasing the “UP” button and reducing the load to within the rated capacity of the chain hoist. When the excessive load is removed, normal hoist operation is automatically restored. Caution: If the load being lifted exceeds the lifting capability of the overload clutch, the motor will continue to run, causing overheating of both clutch and motor. Under no circumstance should the clutch be allowed to slip for more than a few seconds. CHAIN BAG 1. It is strongly recommend to use a chain bag with the DUKE. Chain bags like shown in below photo are available from the manufacturer/supplier. The bags, which are colored black, fit closely to the chain hoist and are as inconspicuous as possible. The bag comes with an acrylic bottom plate which distributes the chain weight evenly. 2. Any other chain bags used should be capable of safely supporting the weight of the full length of the load chain, and preferable have a drainage hole at the end side to prevent accumulation of rainwater in case of outdoor use. 12 OPERATING NOTES Points which must be observed at all times to maintain proper operations: 1. Know the weight of the load to be lifted. Never overload the chain hoist. 2. Do not operate if direction of travel is not the same as indicated on button being pushed. Make sure phases are corrected until direction of travel is coherent with push button operation. 3. Do not make side pulls with the chain hoist. 4. Do not sling the chain hoist load chain around an attachment point. Use a separate and proper sling. 5. Run the motor until the load chain is as good as taut. 6. Check the load being held securely in the hook or sling chains, before it is raised. 7. Never stand or allow people beneath a moving load. 8. Do not move a load in such a manner as to endanger personnel. 9. Do not move the load by intermittent use of the control button. 10. Do not lower into areas where visibility is obscured unless a specific person is guiding the operation. 11. Do not operate when chain hoist is not over the center of gravity of the load. 12. Do not operate a damaged or malfunctioning chain hoist. INSPECTIONS & MAINTAINANCE To maintain continuous and satisfactory operation, a regular inspection procedure must be initiated to replace worn or damaged parts before they become unsafe. Inspection intervals must be determined by the individual application and are based on the type of service to which the hoist will be subjected to the degree of exposure to wear, deterioration or malfunction of the critical components. The type of service to which the hoist is subjected can be classified as Normal, Heavy, or Severe. Normal Service: Involves operation with randomly distributed loads within the rated load limit, or uniform loads less than 65% of rated load for not more than 25% of the time. Heavy Service: Involves operating the hoist within the rated load limit which exceeds normal service. Severe Service: Normal or heavy service with abnormal operating conditions. Two classes of inspection- frequent and periodic – must be performed. Frequent Inspections: These inspections are visual examinations by the operator or other designated personnel. Records of such inspections are not required. The frequent inspections are to be performed monthly for normal service, weekly to monthly for heavy service, and daily to weekly for severe service, and they should 13 Include those items listed in below. Periodic Inspections: These inspections are visual inspections of external conditions by an appointed person. Records of periodic inspections are to be kept for continuing evaluation of the condition of the hoist. Periodic inspections are to be performed yearly for normal service, semi-annually for heavy service and quarterly for severe service, and they are to include those items listed in below. CAUTIONS: Any deficiencies are to be corrected before the hoist is returned to service. Also, the external conditions may show the need of disassembly to permit a more detailed inspection, which, in turn, may require use of nondestructive type testing. PREVENTIVE MAINTENANCE In addition to the above inspection procedure, a preventive maintenance program should be established to prolong the useful life of the hoist and maintain its reliability and continued safe use. The program should include the periodic and frequent inspections with particular attention being paid to the lubrication of the various components using the recommended lubricants. Minimum Frequent Inspections TYPE OF SERVICE Normal Heavy ITEM Severe Daily to weekly Weekly to Monthly Monthly a) Brake for evidence of slippage. b) d) Control functions for proper operation. Hooks for damage, cracks, twists, excessive throat opening, latch engagement and latch operation. Load chain for adequate lubrication, as well as signs of wear or damaged links. e) Load chain for proper reeving and twists. c) Minimum Periodic Inspections ITEM TYPE OF SERVICE Normal Heavy Severe a) All items in minimum frequent inspections b) External evidence of loose screws, bolts or nuts. c) External evidence of worn, corroded, cracked or distorted hook block, suspension screws, gears, bearings, chain stop and chain guide. d) External evidence of damage to hook retaining nut and pin. Also check the upper suspension adapter making sure it is fully seated in the hoist frame and that both screws are tight. External evidence of excessive wear of brake parts. e) f) g) h) Checking the operation of the control station making sure the buttons operate freely and do not stick in either position. Inspect the electrical cords and cables and control station enclosure for damaged insulation. Inspect the suspension hook for excess free play or rotation. Replace worn parts as evidence by excess free play or rotation. 14 HOOK INSPECTION Hooks damaged from chemicals, deformations or cracks, or that have more than a 10 degree twist from the hook’s unbent plane, excessive opening or seat wear must be replaced. Also, hooks that are opened and allow the latch to not engage the tip must be replaced. Any hook that is twisted or has excessive throat opening indicates abuse or overloading of the unit. Inspect other load sustaining parts, hook block screws, load pins and hook block bodies for damage. Check to make sure that the latch is not damaged or bent and that is operates properly with sufficient spring pressure to keep the latch tightly against the tip of the hook and allow the latch to spring back to the tip when released. If the latch does not operate properly, it should be replaced. To Measure opening, depress latch against hook body as show. Replace the hooks when opening is greater than 38mm. Hook dimension CHAIN 1. Clean chain with a non-caustic/non-acid type solvent and make a link by link inspection for nicks, gouges, twisted links, weld splatter, corrosion pits, striations, cracks in weld areas, wear and stretching. Chain with any one of these defects must be replaced. 2. Slack the portion if the chain that normally passes over the liftwheel. Examine the interlink area for the point of maximum wear. Measure and record the stock diameter at this point of the link. Then measure stock diameter in the same area on a link that does not pass over the liftwheel and compare these two measurements. 15 3. Also check chain for stretch using a larger caliper as show below to measure the outside length of a convenient number of links about 11(pitchs). Measure the same number of links in a used section of chain and calculate the percentage increase in length of the worn chain. 4. Chain is to be kept clean and lubricated. Visually check chain every time chain hoist is used. As oil needs to sit at the bearing surface of each chain link, it is advised to submerge the chain in oil for 30 min. Take it out and let the chain hang dripping for 24 hours before putting in the hoist. IDENTIFICATION OF CHAIN: FEC load chain can be recognized and determined original by the following marks on the chain Chain specifications: • diameter-7.1mm • pitch-20.2mm • grade-Grade 80 • type of marking-see sample picture below. Every 15 links. • max. working load-1000kgs • minimum breaking strength-6300kgs • weight per meter- 1.12kg/m For replacement load chains use FEC chain only. 16 CHAIN REPLACEMENT WITH CHAIN IN LIFTING MOTOR 1. 2. 3. 4. 5. 6. 7. With the unit placing on workbench or motor up position, run the hook to its up limit. Remove the load block assembly from the old chain. Make a “C” link, attach the new chain to the load end of the old chain. Carefully jog the “UP” button and run the joined pieces of chain into the lifting motor until about 40cm of new chain comes out the other side. Remove the “C” link and the old chain. Remove the chain stop from the old chain by a hex head screwdriver. Attach the chain stop to the slack end of the new chain by capturing the 12th link with the two stop halves. Be sure there are no twists in the chain. Attach the load block on new chain by a hex head screwdriver. CHAIN REPLACEMENT WITH NO CHAIN IN CHAIN HOIST 1. 2. 3. 4. 5. 6. 7. 8. With the unit placing on workbench, run the hook to its up limit. Remove the load block assembly from the old chain. Remove the chain stop from the old chain. Carefully jog the “UP” button and detach the old chain out of the lifting motor. Insert the new chain into the load sheave. Feed the new chain into the chain hoist by jogging the “DOWN” button. Allow about 40cm of chain below the chain hoist on the slack end. Attached the chain stop and load block assembly. Be sure there are no twists in the chain. 17 Make a “C” link CHAIN END STOP The end stop on the dead-end chain should be mounted on the 11th link. (No less than 11 links should be in between the dead-end and the chain stop). CUTTING CHAINS FEC load chain is hardened and therefore difficult to cut. The following methods are recommended when cutting a length of new chain from stock or cutting worn chain. a) Use a grinder and nick the link on both sides, then secure the link in a vise and break of with a hammer. Cutting chain by Nicking b) Use a bolt cutter with special cutter jaws for cutting hardened chain. Cutting chain with a Bolt Cutter LOAD CHAIN CLEANING Clean the load chain with acid-free solvent and coat with new ISO VG-320 or equivalent gear oil. Wipe excess Oil to prevent dripping. Never apply grease to the chain. OVERLOAD LIMITING CLUTCH The parts of limiting clutch are mounted free on the gear input shaft. The adjustable slip clutch, fitted as an overload safety device. This device has been calibrated at the factory and is engineered for low maintenance and also serve as an overload protection. LMITING CLUTCH ADJUSTMENT 1. 2. 3. 4. Hook a load of 1.25 times the nominal load into the hoist. Remove the cover no.1 and fasten any 2 nuts back into gear cover side. Tighten the adjustable clutch nut by torque spanner set in 20.3Nm. Raise the load and check if the movement and noise. The slipping clutch is now adjusted. Tighten this adjustable nut Torque spanner set to 20.3Nm 18 WIRING 3-phase units(220V/380V) are wired for 380V as standard unless otherwise specified when ordering. Conversion of multiple voltage units can be done simply and quickly as follows. 1. Disconnect chain hoist from power supply and remove motor cover. 2. Find the 2 ways terminal block, Relay rectifier, 3 wires power input wires tag with different number. 3. Make sure that all of the screw clamps on the terminal block are tightened. Tug on the connected wires to ensure they are securely connected and match the diagram to ensure proper wiring. 4. Check the operation of the chain hoist, ensuring that the direction of travel is connect. Important: Always refer to the wiring diagram located on the inside of the motor cover when performing electrical repairs. Make sure all terminals are securely fastened and check for damaged insulation. SIGNS OF INADEQUATE ELECTRICAL POWER: The hoist must be supplied with adequate electrical power in order to operate properly. The signs of low voltage are: •Noisy hoist operation due to brake and /or chattering. •Dimming of lights or slowing of motors connected to the same circuit. •Heating of the hoist motor and other internal components as well as heating of the wires and connectors in the circuit feeding the hoists. •Failure of the hoist to lift the load due to motor stalling. •Blowing of fuses of tripping of circuit breaker 19 20 21 Low voltage may also be caused by using an undersized cord and/or connectors to supply power to the hoist. The following chart should be used to determine the size wires in the extension cord in order to minimize the voltage drop between the power source and the hoist. Three phase hoists Length of extension cord Minimum wire size Up to 50 feet (15M) #16AWG (1.6mmsq) 80 feet (24M) #16AWG (1.6mmsq) 120 feet (36M) #14AWG (2.0mmsq) 200 feet (61M) #14AWG (2.0mmsq) 300 feet (91M) #12AWG (2.7mmsq) POWER CORD PRECAUTIONS: The following are the conductor color code for mains cable, break ins, break outs and multi cable: MAINS CABLE Wire Color Pin L1/R1 Red 1 L2/S2 White 2 L3/T3 Black 3 Ground Yellow/Green GND 22 LUBRICATION Proper lubrication is necessary to ensure a long and reliable chain hoist life. Refer to the following and the RECOMMENDED LUBRICATION SCHEDULE for lubrication points, type of lubricant, and frequency of lubrication. Note: If the chain hoist is used in an atmosphere containing abrasive dust, frequent cleaning and oiling may be necessary. Figure & reference no. Component Type of lubricant ( use only new lubricant) Type of service and frequency of lubrication NORMAL HEAVY SEVERE Monthly Weekly Figure 48 Load Chain ISO VG(HD)-320 gear oil Occasionally Figure 13/18/29 &38 Gearing Moly extreme pressure grease At periodic inspection (yearly replacement is advised) Figure 44 Load hook bearing Moly extreme pressure grease 23 Yearly Monthly Weekly CHAIN HOIST REPAIRS Note: If you do not have an experienced mechanic to do your repair work, we recommend that you send your chain hoist to an approved service station for repairs. Use authorized repair parts only. RECOMMENDED SPARE PARTS To insure continued service of the DUKE hoist, the following is a list of parts that are recommended to be kept on hand at all time to replace parts that have worn or failed. Parts Number Part Name Quantity for each hoist in service Parts No.55 Magnetic Contactor 2 Parts No.11 Brake Coil 1 Parts No.57 Regulator 1 24 Explosive Art for DU-905 3-phase 1 ton chain hoist: 25 Parts list for DU-905 3-phase 1 ton chain hoist: DU-905 PARTS DESCRIPTION 1 Gear end housing 33 Chain Guide 2 Nut 34 Chain 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 21-1 22 23 24 25 26 27 27-1 28 29 30 31 31-1 31-2 32 Brake assembly attaching screws Brake Frame Brake Disc Fixing spring Nut Brake intermediate plate Spring Screw Brake coil Brake base plate Bearing Drive shaft key Drive shaft Bearing Gear Bearing Rod of gear shaft Fixing base of gear shaft Bearing Key Gear Shaft Gear hub Rod of gear shaft Bearing Gear Chain Guide Shaft Bearing Gear frame Screw Screw Side Cover Screw Screw Limit Cover 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 49-1 50 51 52 53 54 55 56 57 58 59 60 61 62 62-1 70 71 72 Limit disconnector Limit switch base Screw Ring Loose end link Lifting hook block Screw Nut Lifting hook Chain stop block Chain bag Fix Rod Fix Rod Fix Rod Suspension hook Hook base block Motor frame Motor frame screws Motor Screw Circuit board Magnetic Contactor Circuit board holder Regulator Power Cord Cable gland Motor end housing Control Cord Control switch w/o cord Emergency Stop Guard Limit switch ass'y Fix Spring Chain Guid Spring 26 Trouble TROUBLE SHOOTING FOR CH-1000 CHAIN HOIST Probable Cause Check and Remedy 1. Lifting motor does not respond to pushbutton A) Power failure in supply line B) Wrong voltage or frequency A) Check circuit, breakers, switch and connection in power supply line B) Check voltage and frequency of power supply against the rating on the nameplate of the motor. C) Improper connections in chain hoist of push button C) Check all connections at line D) Brake does not release 2. Hook does not stop promptly A) Chain hoist overloaded B) Brake not holding 3. Hook moves in wrong direction A) Three phase reverse B) Improper connection 4. Chain hoist hesitates to lift when energized A) Chain hoist overloaded connectors and on terminal block. D) Check brake coil connection for open or short circuit. Check wiring for relay rectifier. A) Reduce load within rated capacity of chain hoist. B) Check brake and it may be necessary to replace discs. A) Reverse any two wires (expect the ground wire) at the power source. B) Check all connections against wiring diagram. A) Reduce load within rated capacity of chain hoist. B) Worn overload limiting clutch B) Check and adjust limiting clutch C) Low voltage C) Determine cause of low voltage and bring up to within plus or minus 10% of the voltage specified on the motor. Measure voltage at the lifting motor in terminal block power input. 5. Hook raises but will not lower A) “Down” circuit open B) Broken conductor in pushbutton cable 27 A) Check circuit for loose connections. B) Check each conductor in the cable. If one is broken, reduce entire cable. 6. Hook lowers but will not raise A) Lifting motor overload B) Low voltage C) “UP” circuit open A) Reduce load to within rated capacity of chain hoist. B) Determine cause of low voltage and bring up to within plus or minus 10% of the voltage specified on the motor. Measure voltage at the lifting motor in terminal block power input. C) Check circuit for loose connections D) Broken conductor in pushbutton cable D) Check each conductor in the cable. If one is broken, replace entire cable. E) Worn overload limiting clutch E) Adjust or replace overload clutch assembly. F) Loose screw clamps F) Ensure that screw clamps are tightened on the terminal blocks. 7. Motor overheats A) Excessive load A) Reduce load to within rated capacity of chain hoist B) Low voltage B) Determine cause of low voltage and bring up to within plus or minus 10% of the voltage specified on the motor. Measure voltage at the lifting motor in terminal block power input. C) Frequent starting or reversing C) Excessive inching, jogging or reversing should be avoided since this type of operation will drastically shorten the life of motor and brake. D) Brake dragging D) Replace brake assembly 8. Lack of proper lifting speed A) Chain hoist overload A) Reduce load to within rated capacity of chain hoist B) Brake dragging B) Replace brake assembly 28 C) Low voltage C) Determine cause of low voltage and bring up to within plus or minus 10% of the voltage specified on the motor. Measure voltage at the lifting motor in terminal block power input. D) Overload limiting clutch intermittently slipping D) Adjust or replace overload limiting clutch assembly. 9. Motor brake noise or chatter (while starting chain hoist) 10. Motor brake “buzz” (anytime chain hoist is running) A) Brake needs replacement A) Replace brake assembly B) Low voltage B) Determine cause of low voltage and bring up to within plus or minus 10% of the voltage specified on the motor. Measure voltage at the lifting motor in terminal block power input. A) Brake needs replacement A) Replace brake assembly B) Broken brake coil B) Replace the brake coil and check the relay rectifier. 30