Extending the life of aluminium capacitors

advertisement

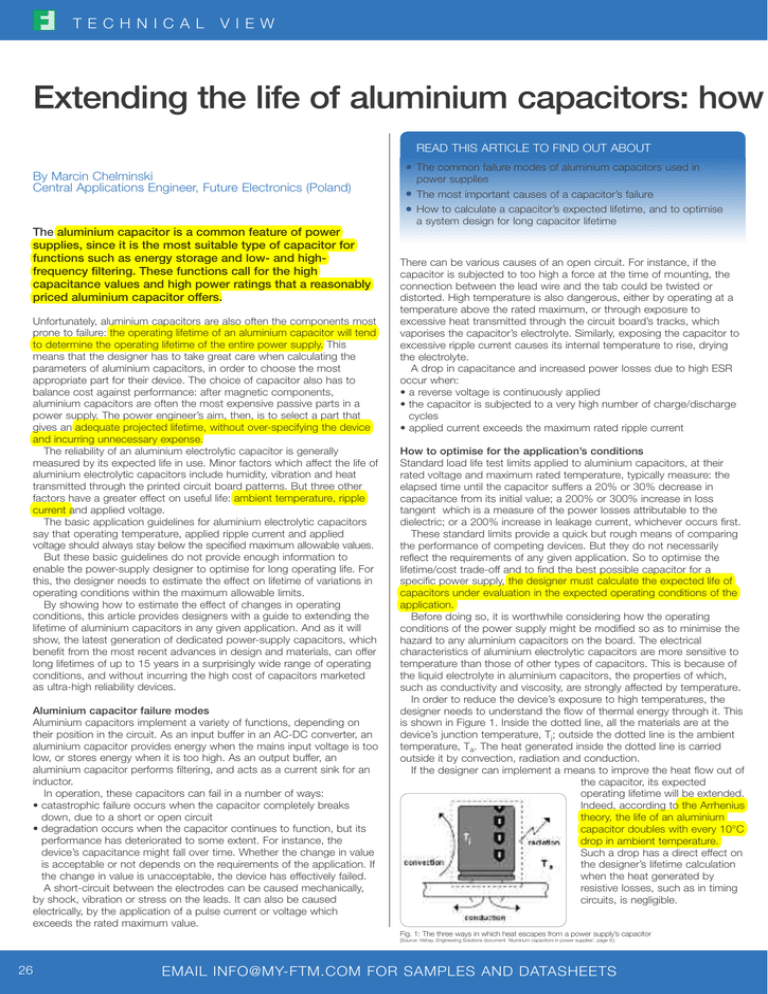

TECHNICAL VIEW Extending the life of aluminium capacitors: how READ THIS ARTICLE TO FIND OUT ABOUT By Marcin Chelminski Central Applications Engineer, Future Electronics (Poland) The aluminium capacitor is a common feature of power supplies, since it is the most suitable type of capacitor for functions such as energy storage and low- and highfrequency filtering. These functions call for the high capacitance values and high power ratings that a reasonably priced aluminium capacitor offers. Unfortunately, aluminium capacitors are also often the components most prone to failure: the operating lifetime of an aluminium capacitor will tend to determine the operating lifetime of the entire power supply. This means that the designer has to take great care when calculating the parameters of aluminium capacitors, in order to choose the most appropriate part for their device. The choice of capacitor also has to balance cost against performance: after magnetic components, aluminium capacitors are often the most expensive passive parts in a power supply. The power engineer’s aim, then, is to select a part that gives an adequate projected lifetime, without over-specifying the device and incurring unnecessary expense. The reliability of an aluminium electrolytic capacitor is generally measured by its expected life in use. Minor factors which affect the life of aluminium electrolytic capacitors include humidity, vibration and heat transmitted through the printed circuit board patterns. But three other factors have a greater effect on useful life: ambient temperature, ripple current and applied voltage. The basic application guidelines for aluminium electrolytic capacitors say that operating temperature, applied ripple current and applied voltage should always stay below the specified maximum allowable values. But these basic guidelines do not provide enough information to enable the power-supply designer to optimise for long operating life. For this, the designer needs to estimate the effect on lifetime of variations in operating conditions within the maximum allowable limits. By showing how to estimate the effect of changes in operating conditions, this article provides designers with a guide to extending the lifetime of aluminium capacitors in any given application. And as it will show, the latest generation of dedicated power-supply capacitors, which benefit from the most recent advances in design and materials, can offer long lifetimes of up to 15 years in a surprisingly wide range of operating conditions, and without incurring the high cost of capacitors marketed as ultra-high reliability devices. Aluminium capacitor failure modes Aluminium capacitors implement a variety of functions, depending on their position in the circuit. As an input buffer in an AC-DC converter, an aluminium capacitor provides energy when the mains input voltage is too low, or stores energy when it is too high. As an output buffer, an aluminium capacitor performs filtering, and acts as a current sink for an inductor. In operation, these capacitors can fail in a number of ways: • catastrophic failure occurs when the capacitor completely breaks down, due to a short or open circuit • degradation occurs when the capacitor continues to function, but its performance has deteriorated to some extent. For instance, the device’s capacitance might fall over time. Whether the change in value is acceptable or not depends on the requirements of the application. If the change in value is unacceptable, the device has effectively failed. A short-circuit between the electrodes can be caused mechanically, by shock, vibration or stress on the leads. It can also be caused electrically, by the application of a pulse current or voltage which exceeds the rated maximum value. • The common failure modes of aluminium capacitors used in power supplies • The most important causes of a capacitor’s failure • How to calculate a capacitor’s expected lifetime, and to optimise a system design for long capacitor lifetime There can be various causes of an open circuit. For instance, if the capacitor is subjected to too high a force at the time of mounting, the connection between the lead wire and the tab could be twisted or distorted. High temperature is also dangerous, either by operating at a temperature above the rated maximum, or through exposure to excessive heat transmitted through the circuit board’s tracks, which vaporises the capacitor’s electrolyte. Similarly, exposing the capacitor to excessive ripple current causes its internal temperature to rise, drying the electrolyte. A drop in capacitance and increased power losses due to high ESR occur when: • a reverse voltage is continuously applied • the capacitor is subjected to a very high number of charge/discharge cycles • applied current exceeds the maximum rated ripple current How to optimise for the application’s conditions Standard load life test limits applied to aluminium capacitors, at their rated voltage and maximum rated temperature, typically measure: the elapsed time until the capacitor suffers a 20% or 30% decrease in capacitance from its initial value; a 200% or 300% increase in loss tangent which is a measure of the power losses attributable to the dielectric; or a 200% increase in leakage current, whichever occurs first. These standard limits provide a quick but rough means of comparing the performance of competing devices. But they do not necessarily reflect the requirements of any given application. So to optimise the lifetime/cost trade-off and to find the best possible capacitor for a specific power supply, the designer must calculate the expected life of capacitors under evaluation in the expected operating conditions of the application. Before doing so, it is worthwhile considering how the operating conditions of the power supply might be modified so as to minimise the hazard to any aluminium capacitors on the board. The electrical characteristics of aluminium electrolytic capacitors are more sensitive to temperature than those of other types of capacitors. This is because of the liquid electrolyte in aluminium capacitors, the properties of which, such as conductivity and viscosity, are strongly affected by temperature. In order to reduce the device’s exposure to high temperatures, the designer needs to understand the flow of thermal energy through it. This is shown in Figure 1. Inside the dotted line, all the materials are at the device’s junction temperature, Tj; outside the dotted line is the ambient temperature, Ta. The heat generated inside the dotted line is carried outside it by convection, radiation and conduction. If the designer can implement a means to improve the heat flow out of the capacitor, its expected operating lifetime will be extended. Indeed, according to the Arrhenius theory, the life of an aluminium capacitor doubles with every 10°C drop in ambient temperature. Such a drop has a direct effect on the designer’s lifetime calculation when the heat generated by resistive losses, such as in timing circuits, is negligible. Fig. 1: The three ways in which heat escapes from a power supply’s capacitor [Source: Vishay, Engineering Solutions document ‘Aluminum capacitors in power supplies’, page 9.] 26 EMAIL INFO@My-FTM.COM FOR SAMPLES AND DATASHEETS TECHNICAL VIEW to calculate the effect of operating conditions Here, the relationship between lifetime and ambient temperature is: L = L0 2 n Table 1 shows an example calculation for a part from the NRZJ series of aluminium capacitors from NIC Components, the NRZJ182M35V12.5X35. The information available from the datasheet is: Tmax = 105°C L0 = 1000 hours I0 = 4.12A Tmax – Ta 10 where: L = estimated life [hours] L0 = life at rated temperature [hours] Lmax = rated temperature [°C] La = ambient temperature [°C] The calculation was applied to estimate the device’s operating lifetime at an ambient temperature of 95°C. NIC Components specifies the value of ∆Tj0 at 7°C. An example of an expected life calculation according to this equation is shown in Figure 2. I100kHz [A] Life Expectancy at 95°C ∆Tj [°C] Hours years 2.5 2.6 29,752 3.4 3.0 3.7 27,120 3.1 3.5 5.1 24,121 2.8 4.0 4.12 6.6 7.0 20,825 20,000 2.4 2.3 4.5 8.4 17,327 2.0 Table 1: Lifetime calculation for the NRZJ182M35V12.5X35 capacitor from NIC Components Fig. 2: Calculation of various capacitors’ expected life over a broad range of ambient temperatures This equation needs to be modified in the case of aluminium capacitors in power supplies, however, since resistive losses are an important factor. The effect of ripple current on lifetime estimates can be calculated as follows: L = L0 2 n Tmax – Ta 10 ∆T ∆T – ( 10 – (0.25 ∆T ) 10 – (0.25 ∆T ) ) 2 j0 n n j0 j where: ∆Tj0 = temperature rise caused by rated ripple current [°C]. This is the maximum differential temperature from the core to the external capacitor case. This value will vary depending on the materials used in the device’s construction. There is no easy way for the user to calculate this value, so manufacturers provide this information on request. Every series of capacitors, and sometimes even different case sizes within a series, will have a different value for ∆Tj0 . ∆Tj = temperature rise caused by the actual ripple current [°C], expressed as: ∆Tj = ∆Tj0 (II ) 100kHz where: I100kHz = actual ripple current at 100kHz I0 = rated ripple current at 100kHz PW NRE-JL (Nichicon) (NIC Components) (Vishay) Temperature Range [°C] -55 to 105 -40 to 105 -55 to 105 Ripple rated at 105°C 100kHz [mArms] 3680 3450 3000 Useful Life at 105°C [Hours] 8000 10000 10000 0.019 j n n Superior performance of specialist power-supply capacitors A comparison of the lifetime of an aluminium electrolytic capacitor such as the NRZJ series, specially designed for use in power supplies, with that of a general purpose capacitor will show a dramatic difference in lifetime when used in an AC-DC or DC-DC converter. Specialised powersupply capacitors can be obtained from leading manufacturers such as Nichicon and Vishay as well as NIC Components, shown in Table 2. These manufacturers offer miniature capacitors with a wide temperature range, very long useful life, high ripple-current capability and low impedance. Some of them are AEC-Q200 qualified for use in automotive applications. Nichicon offers the PS, CS, PH, PX, PW and PA series, NIC Components the NRZJ and NRE-JL series, and Vishay the 150 RMI and 136 RVI series. 2 0 Note that, if ∆Tj >20, the designer should contact the manufacturer’s representative for further guidance. A lifetime estimation calculated using the equation above includes a margin of error; it is not a value guaranteed by the manufacturer. Therefore manufacturers of aluminium capacitors recommend that designers should allow a wide safety margin between the calculated value and the intended service life. Also, even if the calculation indicates an expected lifetime of more than 15 years, manufacturers recommend limiting the service life expectation to 15 years. 150 RMI Impedance at 20°C 100kHz [Ω] 0.015 0.019 Impedance at -10°C 100kHz [Ω] 0.03 0.056 0.044 Case Size [mm] 18 x 35.5 16 x 31.5 18 x 31 Table 2: Comparison of 3,300µF aluminium capacitors rated for 35V Clearly then, a lifetime performance comparison will help the designer to find the best device for the application. If, however, a device cannot be found which offers the required combination of performance and price, the designer can consider the option of cooling, in order to extend the life of a cheaper capacitor with inferior performance. The basic method of cooling a capacitor is to mount it in free space. The natural circulation of air around the capacitor will provide sufficient cooling for most applications. If this is not sufficient, a heatsink will increase the flow of heat from the device. The most common type of heatsink is an aluminium extrusion attached to the closed end of the capacitor. As shown above, whichever capacitor is used in a power supply, the designer can ensure that the device survives for its average rated lifetime by regulating the temperature, ripple current and applied voltage to within the manufacturer’s specified limits. The above information is specific to NRE‐JL series from NIC Components For information on ‘ΔTj0’ (temperature rise caused by rated ripple current) for other For more information e-mail NIC product series, please contact NIC Technical Support at tpmg@niccomp.com info@my-ftm.com 150542 VISIT THE ONLINE FTM MAGAZINE AT: WWW.My-FTM.COM 27