Introduction to LED Lighting

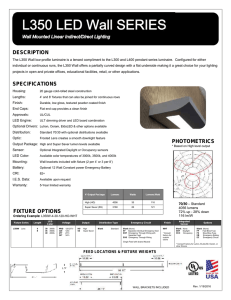

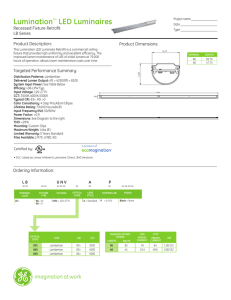

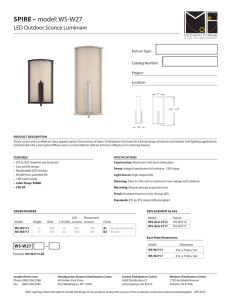

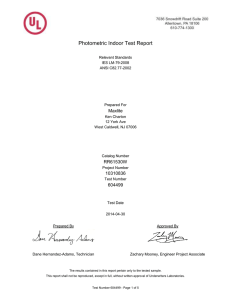

advertisement

Introduction to LED Lighting Presented by: Darrell Huffman Mercer-Zimmerman Learning Objectives LO1: What is an LED? LO2: LED Terminology LO3: Why LED? LO4: LED Equivalency LO5: LED Control LO1: What is an LED? Lighting Emitting Diode An LED is a type of solid-state diode that emits light when voltage is applied. The light output of an LED is a function of its physical construction material used, and amount of current passing through the device. LED can also radiate infrared (heat) energy or UV energy. Generated Light from Direct Electronic Transitions in a Semiconductor Device No Filament Failures Ongoing Technological Advancement AC/DC Conversion Thermal Management Optical Efficiency LED luminaires use light emitting diodes to produce light very efficiently. The movement of electrons through a semiconductor material illuminates the tiny light sources we call LEDs. A small amount of heat is released backwards, into a heat sink, in a well-designed product; LEDs are basically cool to the touch. LO1: What is an LED? White Light: There are two primary ways of producing white light-emitting diodes (WLEDs), LEDs that generate highintensity white light. • One is to use individual LEDs that emit three primary colors— red, green, and blue —and then mix all the colors to form white light. • The other is to use a phosphor material to convert monochromatic light from a blue or UV LED to broadspectrum white light, much in the same way a fluorescent light bulb works. • Phosphor: A coating of phosphorescent material which photons from a royal blue LED pass through causing those photons to exit with a different color property. • Remote Phosphor: A phosphor conversion technique in which photons from a royal blue LED pass through a phosphor material that is not attached to the LED chip. white light y red green w m phosphor Blue c LED blue RGB SYSTEM PHOSPHOR SYSTEM LO1: What is an LED? LED Die (Chip) • Light emitting semiconductor. LED Package • LED Chip integrated with electrical, thermal, optical, and mechanical interfaces. LED Array • An assembly of LED packages on a printed circuit board that are intended to connect an LED driver. LO1: What is an LED? LED Module • A component part of an LED light source that includes one or more LED arrays connected to the LED driver. Electrical, thermal, optical, and mechanical components may also be part of an LED module. LED Driver • A power source with integral LED control circuitry designed to meet the specific requirements of a LED array. Heat Sink • A part of the thermal system that conducts or convects heat away from sensitive components, such as LEDs and electronics. LED Luminaire • A complete LED lighting unit consisting of a light source and driver together with parts to distribute light, to position and protect the light source, and to connect the light source to a branch circuit. LO1: What is an LED? Component Selection, Luminaire Design, Final Assembly, Testing Thermal Management Power Input Dimmer or Control System Power Supply & Driver Power Management LED Package Heat Sink Secondary Diffuser Optics Optical Management Luminaire Assembly Integrity Light Output LO2: LED Terminology Lumen Output • The total lumens emitted of a light source, system or solution. Color Rendering Index (CRI) • A measure of the degree of color shift objects undergo when illuminated by the light source as compared with the same objects when illuminated by a reference source of comparable color temperature. The reference source has a CRI of 100. Correlated Color Temperature (CCT) • The absolute temperature of a blackbody whose chromacticity most nearly resembles that of the light source. Usually specified in Kelvin (K). The lower the Kelvin temperature, the warmer the light feels, or appears. Efficacy • The light output of a light source divided by the total electrical power input to that source, expressed in lumens per watt (lm/W). LO2: LED Terminology LM-79 Test • LM-79: Measures an LED luminaire or integral lamp as a whole system Total Luminous Flux (Lumens) Luminous Intensity Distribution (Photometrics) Luminous Efficacy (LPW – Lumens Per Watt) Color Characteristics (CRI, CCT, etc.) • LM-79 requires that solid state lighting products be tested to “Absolute Photometry.” Conventional HID/Fluorescent uses “Relative Photometry.” • Absolute Photometry - lumen output of LED based luminaires that is dependent on the chip, thermal management, drive current and optical system. LO2: LED Terminology LM-80 Lumen Maintenance Information • LM-80: Measures lumen maintenance of light source to the array or module but not as a complete system. 3 Temperatures to be tested at: 55C, 85C and 3rd is selected by LED Manufacturer. 6K hours min testing period. 10K preferred. Testing on a component level approved method for measuring lumen depreciation of solid-state (LED) light sources, arrays & modules • LM-80 does not cover measurement of luminaires. • LM-80 does not define or provide methods for estimation of life. LO2: LED Terminology TM-21 • TM-21: provides a method for determining an LED luminaire or integral replacement lamp’s expected operating life, based on initial performance data collected per LM-80 testing. • For 6,000 hrs of data (LM-80 min) and up to 10,000 hrs, use data from the last 5,000 hrs. • For greater than 10,000 hrs of testing, use the last ½ of the collected data. • TM-21 can extrapolate up to 6 times the data. • IES has determined end-of-life of LED products to be when the lumen output is 70% of its initial output (30% depreciation). This is known as L70. • Conventional lamp life is rated when 50% of the lamps in an installation burn out. This is known as B50. LED Luminaires and lamps do not “fail” like conventional sources. LED luminaires and lamps gradually decrease in output over time. LO2: LED Terminology 50,000 Hours is…….? 137 Years 68.5 Years 34.2 Years 22.8 Years 17.1 Years 11.4 Years 5.7 Years 1 Hour/Day 2 Hours/Day 4 Hours/Day 6 Hours/Day 8 Hours/Day 12 Hours/Day 24 Hours/Day LO2: LED Terminology Efficacy (LPW) CCT (°K) CRI Lifetime (Hours) LED 100+ 2700 – 6500 70 – 95 30,000–100,000+ Incandescent 8 – 15 2500 – 2800 97+ 750 – 1500 Tungsten Halogen 10 – 15 2800 – 3200 97+ 3000 -- 5000 Compact Fluorescent 50 – 80 2700 – 5000 80 – 85 10,000 – 16,000 Linear Fluorescent 70 – 110 2700 – 8000 50 – 90 24,000 – 55,000+ Induction 48 – 75 2700 – 5000 80 – 85 100,000 Metal Halide 70 – 125 2700 – 10,000 60 – 95 10,000 – 20,000 High Pressure Sodium 70 – 145 1800 – 2550 20 – 25 16,000 – 55,000 Lamp Type LO2: LED Terminology Lighting Facts • Lighting Facts® is a program of the U.S. Department of Energy that showcases LED products for general illumination from manufacturers who commit to testing products and reporting performance results according to industry standards. Energy Star • ENERGY STAR is a joint program of the U.S. Environmental Protection Agency and the U.S. Department of Energy whose goal is to help consumers save money and protect the environment through energy efficient products and practices. LO3: Why LED? – Financial & Emotional Reduced Maintenance Long Life, No Lamp Controls Integration Replacement Financial Visual Comfort (safety) Energy Savings Instant on/off (safety) Reduced Carbon Footprint Mercury / Lead Free Emotional 15 LO3: Why LED? – Environmentally Friendly Most LED Fixtures Comply With RoHS, (Restriction of Hazardous Substances) • No mercury or lead • 4 mg of mercury (most commercial lamps have <5 mg) is enough to contaminate up to 7,000 gallons of freshwater. • The mercury from one fluorescent bulb can pollute 6,000 gallons of water beyond safe drinking levels. • Each year and estimated 600 million fluorescent lamps are disposed of in U.S. landfills amounting to 30k lbs of mercury waste. Sources: EPA.gov, NaturalNews.com, lamprecycle.org, energywiseepa.org/why/mercury LO3: Why LED? – Rugged Construction Solid State Construction • LED chips are completely embedded in an epoxy resin enclosure which is much more sturdy than traditional glass bulbs and fluorescent tubes. • With no loose or moving parts LEDs are virtually indestructible. LO3: Why LED? – Thermal Management Thermal Management • Every 10C° ↑ = ½ life of LED • Every 10C° ↑ = 5% loss in output • Every 10C° ↓ = 2x life of LED • Every 10C° ↓ = 5% gain in output LO3: Why LED? - Controllability HID: LED: 100 lm/W 100 lm/W 40% Utilization Efficiency Lighting Efficacy 40 LPW 80% Utilization Efficiency Lighting Efficacy 80 LPW Energy Savings, Higher min., Better uniformity LO4: LED Equivalency • Best way to compare Traditional Lamp Sources vs LED is by doing calculations via lighting calculation software. • Fixture selection is dependent on the following: • – – – – – • – – If replacing existing: What type of fixture are you replacing (troffer, parabolic, etc)? How many lamps are in the existing fixtures? Are you needing the same amount of light, more light, less light? Look at IES recommendations and run calcs. Are you trying to do a one-for-one replacement? What LED product are you trying to use? If new space: What type of space are you trying to light? Look at IES recommendations and run calcs. What LED product are you trying to use? LO4: LED Equivalency • In addition, as you have been learning, it is hard to do a direct comparison of LED lumens to traditional source lumens. With LED’s, the lumen output given is typically the DELIVERED lumens. With traditional sources, you are typically looking at the raw lumens of the lamps and then have to take into account the efficiency of the fixture. • However, you can do some quick comparisons to give you an idea. – Interior: 3 Lamp T8 Fluorescent Recessed Troffer • Bare Lamp Lumens = 2950 lumens x 3 = 8850 lumens • Fixture Efficiency (look at fixture cutsheet) = let’s assume 78% • 8850 lumens x 0.78 = 6903 lumens (need an LED fixture that has approximately 6903 DELIVERED lumens) – Exterior: Look at street side Downward Delivered Lumens. LO4: LED Equivalency TYPE III 250W MHPS TYPE III 107W LED LO4: LED Equivalency HID vs. 71% Luminaire Efficiency [15,620 Fixture lms] 55 LPW [Luminaire Efficacy] 283W PSMH LED 100% Luminaire Efficiency [10,680 fixture lms] 99.8 LPW - Luminaire Efficacy 22,000 lms 107W LED [Absolute] 10,680 lms 62% Energy Reduction Street Side = 45% 9,908 lms Street Side = 82.8% 8,845 lms 7,134 lms 0.912 LLF [Light Loss Factor] 8,067 lms [63.4% of Fixture Lumens] 0.72 LLF [Light Loss Factor] Comparible Task Lumens While Saving 30-75% Energy. LO4: LED Equivalency HID (Metal Halide) vs. LED LLF = BF * LDD * LLD Ballast Factor 1.0 Ballast Factor 1.0 DIRT (LDD) 0.90 DIRT (LDD) 0.95 Lumen Depr’n (LLD) 0.96 Lumen Depr’n (LLD) LLD = Mean Lumens 0.65-0.80 [40% Rated Life] ÷ Initial Lumens LLF = 0.9 * 0.80 = 0.72 LLD = Lumen depreciation per TM-21 50,000 Hrs @ 25°C Ambient LLF = 0.95 * 0.96 = 0.912 LO4: LED Lighting Case Study Aflac Support Center Headquarters – Columbus, GA Before After Project Description: (61) Existing 1000W MH fixtures Replaced with (53) Cooper Ventus LED (303W) 25 LO4: LED Lighting Case Study Aflac Support Center Headquarters – Columbus, GA Before After Benefits: Reduced load by 76% (49 kW) Average $17,500 in annual savings (166,000 kWh) 3.4 Year Payback Maintenance-free for over 10 years Reduction equivalent to 120 metric tons of CO2 emissions annually 26 LO5: LED Control Verify control system, LED Driver & method are compatible Fixture LED Driver Control Unit Switching control Bi-Level Switching Dimming Methods • • • • • • Option 1: Turn off 50% of the LEDs. • Option 2: Dim LED module to 50%. • Forward Phase (Leading Local wall station Schedule-based Occupant-based Lumen-based Panel-based Edge, Triac, SCR, Incandescent) • Reverse Phase (Electronic Low Voltage, Trailing Edge) • • • • Three-wire (Lutron Hi-Lume) 0 – 10V DMX 512 DALI LO5: LED Control Start by asking a few questions: • Will loads be switched or dimmed? • If dimmed, is the LED driver dimmable? • Which dimming method(s) does the LED driver support? (i.e. forward phase, 0-10V, etc.)? • Which dimming controls have been tested for compatibility with the LED driver? • Can the LED driver/control provide the desired minimum dim level? • Are there special requirements from the driver or controls manufacturer (ie inrush power)? • Is color changing control required? • Does the fixture need to work with existing controls? If so, what are the existing controls? QUESTIONS?