NedCard Contactless modules Open Tool Specification

advertisement

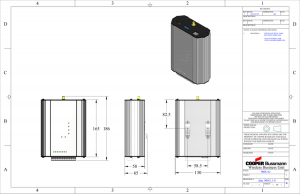

Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 NedCard Product specification Contactless Modules Open Tool July 2, 2012 Rev: F Status: Released Doc: OTN-01 ProductDoc_contactless OTN-01 rev F.doc Page 1 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 Contents: Document history 1 GENERAL INFORMATION 1.1 Purpose 1.2 Scope 1.3 Reference documents 2 NEDCARD PACKAGING PROCESS 2.1 Production flow 2.2 Process conditions 2.3 New chip qualification 2.4 Standard electrical test flow 2.5 Traceability 3 RECEIVING WAFER QUALITY 3.1 Wafer saw/grind and frame/foil requirements 3.2 Die lay-out requirements 3.3 Wafermap/inkdot requirements 3.4 Wafer handling information 4 DATASHEETS 4.1 Product types descriptions 4.2 Product NOA3 4.3 Product NOA3T 4.4 Product NOA3TL 4.5 Product NOA3S 4.6 Product NOA3ST 4.7 Product NOA6XT 5 GENERAL SPECIFICATIONS 5.1 Lead frame properties 5.2 Splices 5.3 Leader and trailer tape 5.4 Reject holes 6 PACKING SPECIFICATION 6.1 Shipping reels 6.2 Winding direction 6.3 Labeling finished goods 6.4 Packing method 6.5 Shipping box 7 STORAGE AND HANDLING FINAL PRODUCT 7.1 Storage recommendations 7.2 Reel handling recommendations 8 PRODUCT QUALITY 8.1 Reliability standards 8.2 General control plan 8.3 Yield data 8.4 Good/bad criteria 9 AQL TESTING 9.1 AQL sampling by NedCard 9.2 Acceptance testing by customer 10 MISCELLANEOUS 10.1 Major change procedure ProductDoc_contactless OTN-01 rev F.doc Page 2 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 Document History Version Date Rev A Oct 08 Rev B May, 09 Rev C Rev D Rev E Rev F Description Complete new specification Add cap dimensions and height tolerances; adding stripe plating NOA5 July 10 Drawing NOA3T error corrected (§4.3), Updated storage max. RH (60% -> 70%), updated AQL-sampling (§ 9.1) June, 11 NOA4 deleted, NOA5 deleted; Transparent leader tape deleted (§5.3); Dimensions/tolerances shipping reel added (§6.1) Feb, 12 Change minimum yield from test yield 80% to total yield 80% Test flow ISO 15693 changed, splice drawing updated July 12 NOA3S, NOA3ST and NOA6XT added. Several small corrections ProductDoc_contactless OTN-01 rev F.doc Checked by J. Smeets J. Smeets J. Smeets J. Smeets j. Smeets/ E. Wit E. Wit Page 3 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 1 General information 1.1 Purpose OTN-01 F July 2, 2012 This document defines NedCard’s Open Tool Smartcard Module packages for non_contact cards based on Super 35mm Film. It describes the general requirements with respect to the receiving wafers and it describes the manufacturing of the packaging process by NedCard including the product specific specifications of the final product. NedCard follows this specification unless otherwise agreed with the customer. 1.2 Scope This document describes in detail all relevant specifications of the assembly and testing process of open-tool non_contact modules for SmartCards. 1.3 Reference documents External references ISO/IEC 7810 Identification cards- Physical characteristics ISO/IEC 7816-1 Identification cards – Integrated circuit(s) cards with contacts: Part 1: Physical characteristics ISO/IEC 10373-1 Identification cards- Test methods = Part 1: General characteristics tests ISO/IEC 10373-3-Annex A Identification cards- Test methods Part 3: Integrated circuit(s) cards with contacts and related interfaces device: Annex A: 3 wheel test. ISO 2859-1974 Sampling procedures and tables for inspection by attributes. MIL-STD-883E, method 2019.5 Die shear strength MIL-STD-883E, method 2011.7 Bond strength (destructive bond pull strength) JEDEC STD-22-B116 Wire bond shear test method Mastercard CQM, 1.9 Card Quality Management, Infrastructure Quality requirements JESD 46B Customer notification of product/process changes NedCard references(1): CP-00 NedCard standard Control plan SF030 Wafer saw/grind and frame/foil requirements SF041 NedCard wafermap specification GBC-NC-01 Good Bad visual Criteria for Contactless products, NedCard (1) : Available on request ProductDoc_contactless OTN-01 rev F.doc Page 4 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 2 NEDCARD Packaging Process 2.1 Production flow OTN-01 F July 2, 2012 Wafer receipt Optional SLA CP-03 CP DA backlapping/ wafersaw by subcontractors Die attach and curing process DA Tape Adhesive CP WB CP-05 CP GT CP-07 CP VI CP-04 Wire bond process Encapsulation process CP-08 CP ET Gold-Wire GT UV or thermal molded Visual inspection & Good Bad Catalog NedCard = Process = Inspection step 100% Electrical test CP= control plan, SLA = Service Level Agreement CP-09 CP-10 CP CP QA QA-Gate inspection P&S Packing and Shipment Optional dropshipment =Materials CP CP-11 Reliability testing Every process step is controlled by an internal control Plan (CP-xx). A generic control plan can be found in document CP-00 NedCard standard control plan. ProductDoc_contactless OTN-01 rev F.doc Page 5 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 2.2 OTN-01 F July 2, 2012 Process conditions Cleanroom specification: The saw and thinning of wafers is performed in a clean room of class ISO 7 (10.000 class). The assembly of dies into modules is performed in a clean room of class ISO 8 (100.000 class). Humidity specification during assembly: 50 ± 20%. ESD specification: Precautions are taken to assure that any IC shall not be exposed to electrostatic charges more than 2 kV (ESD human body model). Reference: MasterCard CQM. 2.3 New chip qualification Each new chip device has to pass a qualification process as follows: Step 1 to 3 has to be performed before assembly process is started. 1. An incoming wafer inspection is performed on the first batch of wafers (see also wafer quality for the specifications). 2. A bonding diagram has to be supplied by the customer. 3. The electrical test will be done according to the NedCard standard test flow, unless a deviating test flow has been agreed between the customer and NedCard. 4. Start assembly process under special supervision. 5. Verification of the results and, if OK, product release by engineering. 2.4 Standard electrical test flow Standard test flow for 13.56 MHz devices: - Standard test flow for other frequencies: - open/shorts - leakage - functional test, if possible needs to be verified. 2.5 open/shorts leakage capacitance measurement (on request) REQ A/B – ATQ A/B (ISO14443 A/B) ATTRIB (ISO14443 A) SELECT (ISO 1444 A) IINVENTORY (ISO15693) Traceability and customer property At all times, there is a one-to-one relation between the customer’s wafer batch and NedCard batch number. Starting with the NedCard batch number and NedCard reel number, all Q-records are traceable. The traceability is guaranteed for a period of 5 years. The standard procedure concerning rest-wafers and rest chips is that these will be destroyed under supervision. On special request, all materials can be sent back to the customer. ProductDoc_contactless OTN-01 rev F.doc Page 6 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 3 Receiving wafer quality 3.1 Wafer saw/grind and frame/foil requirements OTN-01 F July 2, 2012 Wafer ring and wafer foil requirements: See document SF030 “wafer saw/grind and frame/foil requirements”. Changes in the received wafer characteristics must be communicated with NedCard. 3.2 Die lay-out requirements Die dimensions: see datasheets Bond-pad size: min. 75 x 75 microns (smaller possible, on request) Bond-pad pitch: min. 150 microns (smaller possible, on request) 3.3 Wafer map/inkdot requirements Bad devices can be marked either by inkdots or by using wafermaps. The specification for the standard wafermap is documented in SF041 NedCard wafermap specification. Any change in the wafer map design is considered as a major change and must be communicated with NedCard prior to shipment. 3.4 Wafer handling information All receiving wafers remain in their original packing/container (unopened) at normal room conditions until production starts under controlled clean room conditions. The original packing should provide for protection against mechanical shock, ESD charges and environmental degradation. The temperature and humidity in the storage facility for packed wafers is monitored. 4 Data sheets 4.1 Product types descriptions The open tool contact modules are divided into several types, depending on the tape lay-out and the Glob tope type. The different product types are listed in the table below: Product type Tape type NOA3 NOA3T NOA3TL NOA3S NOA3ST NOA6XT Pitch (mm) 9.5 9.5 9.5 9.5 9.5 9.5 Preferred die thickness (μm) 150 100 100 150 100 50 Maximum die size (X x Y) (mm) 3.0 x 3.1 3.0 x 3.1 3.2 x 3.4 2.8 x 3.1 2.8 x 3.1 2.8 x 3.1 Maximum module height (µm) 380 330 330 380 330 250 nominal encapsulation X/Y size (mm) 4.80 x 5.10 4.80 x 5.10 4.80 x 5.10 4.80 x 5.10 4.80 x 5.10 4.80 x 5.10 Further details are listed in the data-sheets per product type. ProductDoc_contactless OTN-01 rev F.doc Page 7 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.2 OTN-01 F July 2, 2012 Data sheet NOA3 (only available until Q1 2013) Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Nedcard NOA3, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.3 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 150 μm x = 3.0 mm y = 3.1 mm x = 0.8 mm y = 0.8 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23-25μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ±0.05) mm x (5.10 ±0.05) mm (380 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 160 μm z = 90 µm Specs on request Specs on request NOA3 Module (All dimensions are in mm.) ProductDoc_contactless OTN-01 rev F.doc Page 8 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 Drawing NOA3 package Module Dimensions: NOA3 Package (All dimensions are in mm.) Back Side ProductDoc_contactless OTN-01 rev F.doc Chip Side Crossection Page 9 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.3 OTN-01 F July 2, 2012 Data sheet NOA3T (only available until Q1 2013) Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Nedcard NOA3, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.4 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 100 μm x = 3.0 mm y = 3.1 mm x = 0.8 mm y = 0.8 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23-25μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ± 0.05) mm x (5.10 ± 0.05) mm ( 330 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 130 μm z = 90 µm Specs on request Specs on request NOA3T Module (All dimensions are in mm.) ProductDoc_contactless OTN-01 rev F.doc Page 10 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 Drawing NOA3T package Module Dimensions: NOA3T Package (All dimensions are in mm.) Back Side ProductDoc_contactless OTN-01 rev F.doc Chip Side Crossection Page 11 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.4 OTN-01 F July 2, 2012 Data sheet NOA3TL (limited availability) Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Nedcard NOA3, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.4 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 100 μm x = 3.2 mm y = 3.4 mm x = 2.0 mm y = 2.0 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23-25μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ± 0.05) mm x (5.10 ± 0.05) mm ( 330 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 130 μm z = 90 µm Specs on request Specs on request NOA3TL Module (All dimensions are in mm.) ProductDoc_contactless OTN-01 rev F.doc Page 12 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: OTN-01 F July 2, 2012 Drawing NOA3TL package Module Dimensions: NOA-3TL Tape (All dimensions are in mm.) Contact Side ProductDoc_contactless OTN-01 rev F.doc Globtop Side Crossection Page 13 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.5 OTN-01 F June 20, 2012 Data sheet NOA3S Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Heraeus XOA2, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.4 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 150 μm x = 2.8 mm y = 3.1 mm x = 0.8 mm y = 0.8 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23 μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ±0.05) mm x (5.10 ±0.05) mm (380 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 160 μm z = 90 µm Specs on request Specs on request NOA3S Module (all dimensions in mm) ProductDoc_contactless OTN-01 rev F.doc Page 14 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: Module dimensions: NOA3S package (all dimensions in mm) LF Side ProductDoc_contactless OTN-01 rev F.doc OTN-01 F June 20, 2012 Drawing NOA3S package Chip Side Crossection Page 15 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.6 OTN-01 F June 20, 2012 Data sheet NOA3ST Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Heraeus XOA2, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.4 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 100 μm x = 2.8 mm y = 3.1 mm x = 0.8 mm y = 0.8 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23 μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ±0.05) mm x (5.10 ±0.05) mm (330 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 110 μm z = 90 µm Specs on request Specs on request NOA3ST Module (all dimensions in mm) ProductDoc_contactless OTN-01 rev F.doc Page 16 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: Module dimensions: NOA3ST package (all dimensions in mm) LF Side ProductDoc_contactless OTN-01 rev F.doc OTN-01 F June 20, 2012 Drawing NOA3ST package Chip Side Crossection Page 17 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 4.7 OTN-01 F June 20, 2012 Data sheet NOA6XT Data Table and module drawing Lead frame format Lead frame material Size of antenna area X-pitch Heraeus XOA2, super 35 mm film, modules in 3-row matrix 80 μm CuSn6 tape, Ag plated Approx. 5.0 mm x 1.4 mm 9.5 mm Die Attach Epoxy Preferred die thickness Maximum die size Minimum die size Non conductive, Thermoset 50 μm x = 2.8 mm y = 3.1 mm x = 0.8 mm y = 0.8 mm Wire bonding process Wire material Ultrasonic Ball Wedge Bonding Gold, >99.9% Au; diameter 23 μm Encapsulation material Encapsulation dimensions Total product height Epoxy based filled mold compound, black (4.80 ±0.05) mm x (5.10 ±0.05) mm (250 + 0/ - 35) μm Products per reel Rejecthole positions Reject hole size Typical 20’000 units Type “E” (see also § Rejectholes --> Type “E”) 2.0 mm Disconnect punch: max. 50 μm Reject punch: max. 100 μm At begin of reel typically 10 modules At end of reel typically 4 modules Metal punching burrs # defect punched modules at begin/end of reel Specs on request z = 55 μm z = 45 µm Specs on request Specs on request NOA6XT Module (all dimensions in mm) ProductDoc_contactless OTN-01 rev F.doc Page 18 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: Module dimensions: NOA6XT package (all dimensions in mm) LF Side ProductDoc_contactless OTN-01 rev F.doc OTN-01 F June 20, 2012 Drawing NOA6XT package Chip Side Crossection Page 19 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 5 General specifications 5.1 Lead frame properties Length: Type X-pitch OTN-01 F June 20, 2012 Endless Super 35 mm film, three row modules 9.5 mm Picture: Thickness dimensions Material CuSn6 Basic material Ag Plating material Thickness 80 ± 5 μm Overall plating: min. 1 μm Optional spot plating (die-pad + inner antennas): min. 3 μm Total thickness (incl. overall plating) X/Y dimensions Film width Sprocket hole pitch Sprocket hole size Film edge to sprocket hole center Sprocket hole center distance Cumulative pitch 24 x 9.5 mm 82 ± 5 μm Value 35.000 mm 4.750 mm 1.42 x 1.42 mm 1.585 mm 31.830 mm 228.000 mm Tolerance ± 30 μm ±20 μm + 40/ -0 μm +30/ -0 μm ± 20 μm ± 30 μm The Ag spot-plating is on the die-pad and the two antennas. ProductDoc_contactless OTN-01 rev F.doc Page 20 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 5.2 OTN-01 F June 20, 2012 Splices Number of splices Distance between 2 slices Splicer tape Dimension splicer tape Gap in X distance without tape Overlap in Y at both tape sides Sprocket hole pitch across splice Max. 10 per 10 meter Min. 0.5 meter Polymide (Kapton) width: (15 ± 1) mm Min. 0 (no overlap)–Max. 0.2 mm Max. 0.2 mm 9.5 ± 0.1 mm On both sides Thickness: (60 ± 10) μm See drawing Splice tape remains See drawing Drawing of the NedCard splice: Splices XOA2 tapes (all dimensions in mm) Chip Side The position of the rejecthole type “E” is shown in this drawing (see also chapter reject holes) ProductDoc_contactless OTN-01 rev F.doc Page 21 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 5.3 Leader and trailer tape Type of leader/trailer tape FCI 199-01 opaque white PET tape 5.4 OTN-01 F June 20, 2012 length Min. 2.1 m; thickness 125 ±10 micron Reject holes All rejected modules (including splices) are identified by a rejecthole. Dependent on the tape type, the position of the rejecthole is different. Position code tape type Hole size Position (mm) see splice drawings X/Y Position tolerance (see *) Type “E” All 2.0 mm ± 0.3 mm 4.625 mm (X) 2.515; 12.165; 21.815 mm (Y) ⊕ ∅ 0.4 (M) (*): The X/Y position tolerance of the NedCard rejecthole is based on the Maximum Material Condition (MMC, indicated by symbol M in the drawings). This means that the tolerance increases with increasing hole diameter. When hole diameter = 1.7 mm (minimum), the position tolerance is ± 0.20 mm. When hole diameter = 2.0 mm (optimal), the position tolerance is ± 0.35 mm. Some rejected modules might be completely cut out from the lead frame (see also the splice drawing). ProductDoc_contactless OTN-01 rev F.doc Page 22 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 6 Packing specification 6.1 Shipping reels OTN-01 F June 20, 2012 The product is wounded on standard anti-static shipping reels, together with an anti-static interliner tape. Reels have an inner core diameter of 200 mm. The outer dimension is 330 mm. See figure below. Reel type: TX36-08-A2. ESD Surface resistivity: 108 - 1011 Ohms/SQ Outer diameter: 330 m +0.3/-0.4 mm Total thickness of reel: 45.2 max. ProductDoc_contactless OTN-01 rev F.doc Page 23 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 6.2 OTN-01 F June 20, 2012 Winding direction Winding description: Encapsulation-side: Outside; Triangles points towards leading side. ProductDoc_contactless OTN-01 rev F.doc Page 24 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 6.3 OTN-01 F June 20, 2012 Labeling finished goods Each finished reel contains a self adhesive label. Content of the finished good label contains information in text format as well as in bar-code format. The information on the label is as follows: Customer product name: xxxxxxxxxx <barcode customer product name> Finish date: xxxxxxxx Customer product no.: xxxxxxxxxx <barcode customer product no.> NedCard product no.: xxxxxxx <barcode Nedcard product no.> NedCard Reel lot no.: ABC081215.C5 ; see (*) below <barcode reel lot no.> Wafer Batch no.: xxxxxxxx <barcode wafer batch no.> Total units: xxxxxx <bar code total units> Total good units: xxxxxxxxx, <bar code total good units * Explanation of the code used for the NedCard lot no.: 12345AB/6 12345 Reference to the order AB Reference to the waferbatch in this order 6 Reel no. 6 in this waferbatch. ProductDoc_contactless OTN-01 rev F.doc Page 25 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 6.4 OTN-01 F June 20, 2012 Packing method ProductDoc_contactless OTN-01 rev F.doc Page 26 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 6.5 OTN-01 F June 20, 2012 Shipping Box ProductDoc_contactless OTN-01 rev F.doc Page 27 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 7 Storage and handling final products 7.1 Storage recommendations OTN-01 F June 20, 2012 Chip card modules on reels should be kept in their original packing when not in use. Breakage of the packing will result in faster degradation of the modules on the reels. Storage temperature: Relative humidity: Storage duration: 7.2 15 °C to 30 °C Max 70% and no condensation allowed. Max 1 year when kept in original unbroken packing. Reel handling recommendations The reel is (partly) open at the two sides (left/right sides). Be careful that part of the tape can be damaged when placing a reel on an (uneven) surface. The leader-and trailer tape are not anti-static and might attract dust. Special precautions are required for handling reels with molded encapsulation bodies: the stiff plastic guard band is essential for protection against cracks in the mold caps. See reel handling instruction below. ProductDoc_contactless OTN-01 rev F.doc Page 28 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 8 Product Quality 8.1 Reliability standards Item Method and condition OTN-01 F June 20, 2012 Specification Level: Modules 1 Die shear strength MIL–STD-883E, method 2019.5 For die–size < 4,1 mm2 Die shear: > 0,6 kg/mm2 For die–size > 4,1 mm2 Die shear: > 2,5 kg 2 Ball shear strength Jedec STD-22, method B116 Ball shear: Min. 21 g 3 Wire pull strength MIL-STD-883E, method 2011.7 Wire pull: Min. 3 g 4 Temperature cycling test Mastercard CQM Version 1.9, - 40 0C/ + 125 0C, transfer time < 1 min no fails at 100 cycles 5 Temperature/Humidity test Mastercard CQM Version 1.9, 850C/ 85%RH No fails after 500 h Level: Integrated circuit cards 6 Dynamic bending test ISO/IEC 10373-1 ISO 7816-1, no rejects at 2000 cycles 7 Dynamic torsion test ISO/IEC 10373-1 ISO 7816-1, no rejects at 1000 cycles 8 3 Wheel mechanical test ISO/IEC 10373-3, A-1, tested with a force of 8N no rejects at 100 cycles 9 Wrapping mechanical test Mastercard CQM Version 1.9 R=25 mm no rejects at 10 cycles ProductDoc_contactless OTN-01 rev F.doc Page 29 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 8.2 OTN-01 F June 20, 2012 General control plan An overview of the control plan during the assembly/test processes is given in document CP00 Nedcard standard Control plan. On special request, data is available. 8.3 Yield data (1) Test yield: The number of good modules divided by the number of devices in one reel. The test yield per reel is typically > 99.0 %. The minimum test yield per reel is 80%. Hence the maximum amount of all defect marked modules will not exceed 20 %. Reels with a yield lower than 80 % (either total yield or test yield) will not be released for shipping before approval of the customer. Total batch yield: The number of total pass modules divided by the total number of received good devices. The total yield per batch is typically > 98.5 %. (1) Assembly related yield 8.4 Good/bad criteria The definition of the visual good/bad criteria is outlined in details in the document GBC-NC-01 “Good Bad visual Criteria for Contactless products, NedCard”. 9 AQL testing 9.1 AQL sampling by NedCard As is shown in the production flow, the assembly/test flow is finalized by a QA-gate procedure. The QA-gate inspection is organized according to the AQL system, ISO 2859, single sampling, normal inspection. Batch size: 300.000 pcs AQL level II, code Q: sample size 1250 defect category AQL accept reject Critical defect 0.015 % 0 1 Major defect 0.065% 2 3 Minor defect 0.65 % 14 15 Critical defects: Critical defects are cracks in mold cap, delaminations, singulation punchings touches the cap, damaged splices, wrong winding direction. Major defects: Major defects are deep scratches (exposed metals), damaged leadframe/antennas, mold flash on antennas, exposed die/wire, partial fills, mechanically damaged mold cap. Minor defects: Minor defects are fingerprints, dents, pinmarks, stains, corrosion, metal burr, pinholes, strange particles. The sample is taken from one reel (selected at random in the batch). A reject at the QA-gate leads to two actions: - A correction of the assembly process. - The rejected reel is subject to a re-inspection and is resubmitted at the QA-gate. ProductDoc_contactless OTN-01 rev F.doc Page 30 of 31 Product Specification Contactless modules Open Tool Document number: Rev: Date: 9.2 OTN-01 F June 20, 2012 Acceptance testing by customer Acceptance testing by the customer can be organized in-line with the AQL sampling by NedCard. The inspection can be organized per shipping batch or per individual reel. Note: It is crucial that the sample is representative for the batch under evaluation. Hence the modules in the samples must be distributed at random in the batch. Alternatively, the customer may select an individual reel/batch and perform a 100 % inspection. The accept/reject criteria are then defined by the AQL-level. This leads to the following accept/reject criteria per reel (assuming 20.000 modules) in terms of number of defects per reel. Defect category Critical defects Major defects Minor defect Accept 3 defect 13 defects 130 defects reject 4 defects 14 defects 131 defects The accept/reject criteria per effect category (critical/major/minor) are valid for the sum of all fails in one category. 10 Miscellaneous 10.1 Major change procedure According to JEDEC 46-B. Customer will be notified a minimum 90 days before the scheduled shipment of the identified product. Shipment may occur upon approval by the customer. Customer should accept receipt of the change notification within 30 days of delivery of the change notification. Lack of acknowledgement of the change notification with 30 days constitutes acceptance of the change. ProductDoc_contactless OTN-01 rev F.doc Page 31 of 31