Novel methodology for broken-rotor-bar and bearing faults detection

advertisement

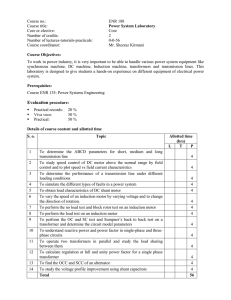

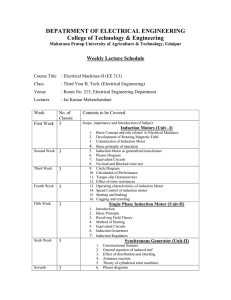

589 JournalHERNANDEZ-VARGAS of Scientific & Industrial et Research al: NOVEL METHODOLOGY FOR BROKEN-ROTOR-BAR AND BEARING FAULTS DETECTION Vol. 71, September 2012, pp. 589-593 Novel methodology for broken-rotor-bar and bearing faults detection through SVD and information entropy M Hernandez-Vargas, E Cabal-Yepez*, A Garcia-Perez and R J Romero-Troncoso HSPdigital Research Group, C A Telematica/Procesamiento Digital de Señales, Division de Ingenierias, Campus IrapuatoSalamanca, Universidad de Guanajuato, Carretera Salamanca – Valle de Santiago km 6.5 + 1.8 km, Comunidad de Palo Blanco, 36700 – Salamanca, Guanajuato, Mexico Received 23 April 2012; revised 07 August 2012; accepted 08 August 2012 This study introduces a novel methodology for early detection of broken-rotor-bars and bearing faults on induction motors by using singular value decomposition and information entropy estimation to detect motor operational condition. Proposed technique could detect these faults with a certainty greater than 99.7%. A field programmable gate array implementation is developed for online application of proposed approach in real-time. Keywords: Broken-rotor-bars (BRB), Faulty bearings (FBR), Field programmable gate arrays (FPGA), Induction motor, Information entropy, Singular value decomposition (SVD) Introduction Squirrel-cage induction motors are the most popular motors in industry1-2 . Studies3-5 are available on induction motor failure that produces unexpected interruptions on production lines. At least, 50% of faults in rotating machines are bearing related, and 10% are rotor faults6 . Fault identification of induction motors still represents a big challenge for condition monitoring (CM)7-10. Common signal processing techniques for CM are fast Fourier transform (FFT)11-13, and discrete wavelet transform (DWT)14-16. Singular value decomposition (SVD) and information entropy are techniques for extracting significant information from different datasets, but rarely used for induction motor CM17-19. This study presents a CM technique for induction motor that combines SVD with information entropy to detect broken-rotor-bars (BRB) and faulty bearings (FBR). Proposed Methodology Proposed methodology (Fig. 1) consists of a data acquisition system (DAS), matrix generation with acquired data in onboard memory, and a hardware processing unit implemented into an FPGA device for SVD and information entropy estimation to determine *Author for correspondence E-mail: ecabal@hspdigital.org quantitatively the operational condition of induction motor as healthy (HLT), BRB and FBR. Singular Value Decomposition (SVD) SVD of an m × n matrix A is defined as A = U ΣV T , where U and V are m×m and n×n orthogonal matrices, respectively. UUT=Im , and VVT=In , where I is identity matrix. Σ is a diagonal matrix such that Σ = diag (σ1 , σ2 , …, σn ), where σ1 , σ2 , …, σn are singular values of A20 . For m>n, at least m-n singular values are zero. If r=rank(A) and r<n, r of singular values are non-zero. U contains m left singular vectors, and V contains n right singular vectors. Most SVD algorithms are based on diagonalizing rotations to form orthogonal transformations that preserve angles and lengths. Jacoby Rotations Usually Jacobi rotation matrix J is used for diagonalization through rotations 21 . For instance, when applying J in Eq. (1) to 2×2 symmetric matrix AS in Eq. (2), rotation angle θ is chosen such that off-diagonal elements a ij =a ji of AS become zero, thus obtaining diagonal matrix AD in Eq. (3) as cos θ J = − sin θ sin θ cos θ …(1) 590 J SCI IND RES VOL 71 SEPTEMBER 2012 Fig. 1–Block diagram of proposed methodology aii AS = a ji aij a jj a ii AD = J T AS J = 0 Fig. 2–Artificially generated faults: a) One broken-bar; and b) Bearing defect …(2) 0 a jj …(3) If total number of outcomes in random event X is N, r probability p(xi ) is given as p ( xi ) = i , where r i N represents incidence rate of each possible outcome xi , n and total number of outcomes N is given as N = ∑ ri . If A is not symmetric, off-diagonal elements can still be annihilated by applying a symmetrizing rotation as AS = J T A and a diagonalization rotation as AD = J T AS J . i =1 For entropy calculation, Mitchell algorithm24 is considered in this study because of its advantages during hardware implementation. Experimental Setup and Instrumentation System Hestenes-Jacobi Method Hestenes 22 observed equivalence between annihilation of a matrix element and orthogonalization of two vectors applying Jacobi rotations. If an m×n nonsymmetric matrix A is multiplied by an orthogonal matrix U, a matrix B whose rows are orthogonal is obtained. B is normalized by calculating squares of row norms, then B=SS -1B=SV, where S is a diagonal matrix containing square norm of each row in B, and V is an orthonormal matrix obtained by dividing each row in B by its corresponding square norm. From this, and because U is an orthogonal matrix, B=UA =SV and A=UTSV, where S = diag(s1 , s2 , …, sn ) are squares of singular values (σ1 , σ2 , …, σn ) of A. Information Entropy Shannon23 defined entropy as a measure of average information contents associated with a random outcome. Considering a random event X with n possible outcomes x1 , x2 , x3 ,…, xn , and every xi (i=1, ..., n) with a probability p(xi ), then information entropy H(X) of a random event X is given as n H ( X ) = − ∑ p ( xi ) log 2 [ p ( xi )] i =1 …(4) Proposed methodology based on SVD computation and information entropy estimation for BRB and FBR identification in real-time is used to classify induction motor condition online. Under experiment setup, different 1-hp three-phase induction motors (model WEG 00136APE48T) are used. Tested motors have 2 poles, 28 bars, and receive a power supply of 220 V AC, at 60 Hz. Applied mechanical load is that of an ordinary alternator. One phase of startup transient current is acquired using an AC current clamp (model Fluke i200s). A 16-bit serial-output analog-to-digital converter (ADC) (ADS7809) 25 is used in data acquisition system (DAS). A sampling frequency f 0 = 1.5 kHz is used to obtain 4096 samples during induction motor startup transient, acquiring up to the tenth harmonic of fundamental frequency, and beyond. Start of motor is controlled by a relay in order to synchronize the data acquisition with the motor switch on. Sampled data are arranged into a 32×128 matrix. Obtained matrix is processed by SVD computation algorithm implemented in FPGA device along with information entropy unit, which provides induction motor condition based on the information contents from obtained singular values. HERNANDEZ-VARGAS et al: NOVEL METHODOLOGY FOR BROKEN-ROTOR-BAR AND BEARING FAULTS DETECTION 591 Fig. 3–Power-supply-current to induction motors under different operational conditions: a) Healthy; b) Motor with a broken bar; and c) Motor with faulty bearing Fig. 4–Density functions defining detectability zones obtained by proposed methodology to identify a healthy motor (HLT), a motor with a broken-rotor-bar (BRB), and a motor with a faulty bearing (FBR) Case Study 1: Broken Rotor Bars (BRB) BRB condition is produced artificially by drilling one hole (diam 7.938 mm) without harming rotor shaft (Fig. 3a). Case Study 2: Faulty Bearing (FBR) FBR is produced artificially by drilling a hole (diam 1.191 mm) on its outer race using a tungsten drill bit (Fig. 3b). Hardware Implementation Proposed methodology was implemented in a low cost FPGA device Cyclone- II EP2C35F672C6 from Altera, embedded on DE2 development board from Terasic 26 with maximum operational frequency of 65.928 MHz. FPGA implementation figures (used and available, respectively) in Altera device for various resources were as follows: MULT 18×18, 21 of 35; logic elements, 7632 of 33216; and RAM bits, 434,643 of 483,840. Results and Discussion Utilizing FPGA implementation of proposed methodology, startup transient current supply to a healthy motor (Fig. 3a), a motor with one BRB (Fig. 3b), and a motor with a FBR (Fig. 3c) is processed by computing SVD of generated matrix. Then, information entropy from obtained singular values is estimated. This process is applied on 20 different trials for each motor condition. Obtained entropy values on each condition are sent to a PC for presentation purposes. Mean µ(H) and standard deviation σ(H) are computed. A 3σ rule that ensures a 99.7% of certainty on detecting motor condition is used (Fig. 4). Detectability zones defined by proposed 592 J SCI IND RES VOL 71 SEPTEMBER 2012 Table 1Statistical study on obtained current signal and singular vales from generated 32×128 matrix Statistical parameter Current signal Generated-matrix Singular values Mean Standard deviation RMS Entropy Mean Standard deviation RMS Entropy Motor condition HLT BRB FBR -0.0233 10.7055 10.7042 9.3858 22.4587 120.1740 121.7812 1.6276 -0.0236 10.9270 10.9257 9.2949 23.7738 122.5029 124.3065 2.0094 -0.0233 7.3456 7.3443 9.0368 24.7252 127.7475 127.9070 2.7170 Table 2Comparison chart of advantages and disadvantages of proposed methodology against earlier studies for induction motor fault detection Method (ref) Detected faults Applied analyses Implementation On/Off-line [7] Faulty bearings, 3 broken bars Noise statistics, bias analysis, FFT, statistical reliability test, signature identification Qualitative analysis in software Off-line [8] Shaft defect, faulty bearings Analysis of a laser beam of reflection through installation a robust optical sensor Infrared thermography, 2D Qualitative analysis by voltage signal observation Off-line [9] Misalignment, faulty bearing, mass unbalance wavelet transform, mahalanobis distance, relief algorithm, support vector machine, linear discriminant Quantitative analysis in software Off-line [12] 1 Broken bar FFT, wavelet transform, peak measurement, and multivariate control charts Qualitative analysis in software Off-line [14] Voltage supply, broken bars, and locked rotor Motor model, wavelet multi resolution, artificial neural networks Qualitative analysis in software Off-line [15] Faulty bearings Wavelet transform, support vector machine, artificial neural networks, mean square error Qualitative analysis in software Off-line [16] Short circuit, 5 broken bars, and faulty bearings Wavelet packet, mean, variance, standard deviation, skewness, kurtosis Qualitative analysis in software Off-line [19] 1 broken bar Hilbert transform, symbol tree sliding window, information entropy Quantitative analysis in software Off-line Proposed 1 broken bar, faulty bearings SVD, information entropy Quantitative analysis in Hardware (FPGA) On-line methodology are shown as density functions. From results (Table 1) from distinct statistical analyses on obtained startup-transient current data and singular values of generated 32×128 matrix for each treated condition, it is HERNANDEZ-VARGAS et al: NOVEL METHODOLOGY FOR BROKEN-ROTOR-BAR AND BEARING FAULTS DETECTION clear that proposed methodology ensures 99.7% of effectiveness on BRB or FBR detection in a quantitative way, since corresponding detectability zones are clearly and completely separated. From comparison chart (Table 2), it is clear that proposed methodology offers a simple approach optimized for hardware implementation through SVD and information entropy estimation, different from earlier studies that usually require combination of standard, and non-standard techniques executed off-line for single or multiple fault detection. FPGA-based hardware implementation of proposed technique is used for online analysis in real-time applications. It employs 24.3152 ms to identify induction motor condition, whereas a 2.4GHz Intel Core Duo elapses 680.6819 ms to carry out this task. Conclusions This study introduced a novel methodology for early detection of BRB and FBR in induction motors. Proposed approach fuses singular value decomposition with information entropy. Results show high effectiveness of proposed technique utilizing a 3σ rule, which ensures 99.7% of certainty on estimating induction motor condition in a quantitative way. FPGA-based hardware implementation allows online analysis utilizing proposed methodology in real-time applications. 8 9 10 11 12 13 14 15 16 17 References 1 2 3 4 5 6 7 Zhang P, Du Y, Habetler T G & Lu B, A survey of condition monitoring and protection methods for medium-voltage induction motors, IEEE Trans Ind Appl, 47 (2011) 34-46. Li Z. Application of new niche genetic algorithm on electromagnetic system optimization, J Sci Ind Res, 70 (2011) 506-512. Sakthivel V P, Bhuvaneswari R & Subramanian S, Artificial immune system for parameter estimation of induction motor, Expert Syst Appl, 37 (2010) 6109-6115. Gandhi A, Corrigan T & Parsa L, Recent advances in modeling and online detection of stator interturn faults in electrical motors, IEEE Trans Ind Electron, 58 (2011) 1564-1575. Tallam R M, Lee S B, Stone G C, Kliman G B, Yoo J, Habetler T G & Harley R G, A survey of methods for detection of stator-related faults in induction machines, IEEE Trans Ind Appl, 43 (2007) 920-933. El Hachemi Benbouzid M, A review of induction motors signature analysis as a medium for faults detection, IEEE Trans Ind Electron, 47 (2000) 984-993. Choi S, Akin B, Rahimian M M & Toliyat H A, Performanceoriented electric motors diagnostics in modern energy conversion systems, IEEE Trans Ind Electron, 59 (2012) 1266-1277. 18 19 20 21 22 23 24 25 26 593 Fulzele A G, Arajpure V G, Holay P P & Patil N M, Condition monitoring of shaft of single-phase induction motor using optical sensor, Mech Syst Signal Pr, 29 (2012) 428-435. Younus A M D & Yang B-S, Intelligent fault diagnosis of rotating machinery using infrared thermal image, Expert Syst Appl, 39 (2012) 2082-2091. Bellini A, Filippetti F, Tassoni C & Capolino G-A, Advances in diagnostic techniques for induction machines, IEEE Trans Ind Electron, 55 (2008) 4109-4126. Amezquita-Sanchez J P, Cabal-Yepez E, Romero-Troncoso R J, Osornio-Rios R A & Garcia-Perez A, Determination of system frequencies in mechanical systems during shutdown transient, J Sci Ind Res, 69 (2010) 415-421. Garcia-Escudero L A, Duque-Perez O, Morinigo-Sotelo D & Perez-Alonso M, Robust condition monitoring for early detection of broken bars in induction motors, Expert Syst Appl, 38 (2011) 2653-2660. Menacer A, Kechida R, Champenois G & Tnani S, Application of the Fourier and wavelet transform for fault detection in induction motors at the startup electromagnetic torque, in Proc IEEE Int Symp on Diagnostics for Electrical Machines, Power Electronics & Drives SDEMPED (Bologna, Italy) 2011, 664-668. Devi N R, Rao P V R & Gafoor S A, Wavelet – ANN based fault diagnosis in three phase induction motor, in Proc Annu IEEE Indian Conf INDICON (Hyderabad, India) 2011, 1-8. Konar P & Chattopadhyay P, Bearing fault detection of induction motor using wavelet and Support Vector Machines (SNMs), Appl Soft Comput, 11 (2011) 4203-4211. Ece D G & Basaran M, Condition monitoring of speed controlled induction motors using wavelet packets and discriminant analysis, Expert Syst Appl, 38 (2011) 8079-8086. Yang D-M, Induction motor bearing fault detection with non stationary signal analysis, in Proc 4th IEEE Int Conf on Mechatronics ICM (Kumamoto, Japan) 2007, 1-6. Cabal-Yepez E, Romero-Troncoso R J, Garcia-Perez A & Rodriguez-Donate C, Novel hardware processing unit for dynamic on-line entropy estimation of discrete time information, Digit Signal Process, 20 (2010) 337-346. Aydin I, Karakose M & Akin E, A new method for early fault detection and diagnosis of broken rotor bars, Energ Convers Manage, 52 (2011) 1790-1799. Olver P J & Shakiban C, Applied Linear Algebra, 1st edn (Upper Saddle River, NJ) 2006. Strumpen V, Hoffmann H & Agarwal A, A Stream Algorithm for the SVD, Technical Memo MIT-LCS-TM-641 (Massachusetts Institute of Technology, Cambridge, Massachusetts) 2003. Hestenes M R, Inversion of matrices by biorthogonalization and related results, J Soc Ind App Math, 6 (1958) 51-90. Shannon C E, A mathematical theory of communication, Bell Syst Tech J, 27 (1948) 379-423, 623-656. Mitchell J N, Computer multiplication and division using binary logarithms, IRE Trans Electron Comput, 11 (1962) 512-517. Burr-Brown products from texas instruments incorporated, ADS7809 Data Sheet, 2004. Altera Corporation, DE2 Development and Educational Board, User Manual, (San Jose CA, USA) 2008.