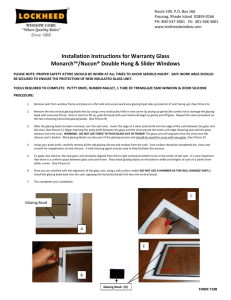

Traditional Windows

advertisement