TM

The model JP jockey pump controllers are specifically

designed to control jockey pumps in order to maintain the

desired water pressure in fire pump serviced systems. A

jockey pump installation prevents unnecessary starting of

the fire pump due to small leaks.

Jockey Pump Controller

Full voltage across the line starter

(Patent Pending)

Micro Processor Based

Individual models are specific to the voltage available on

site:

x JP1: 120 V / single phase / 60Hz

x JP2: 220–240 V / single phase / 50/60Hz

x JP3: 208 to 600 V / three phase / 50/60Hz

N.Y.C.

APPROVED

OPTIONAL

TM

The standard power circuit consists of a horsepower rated

disconnect switch, a thermo-magnetic motor protector and

a motor contactor for across the line full voltage starting.

Consult factory for other types of motor protection or

starting methods available.

The automatic operation of the jockey pump is achieved

with an electronic pressure monitoring module which

utilizes a pressure transducer as a pressure sensing

device. It allows the user to digitally set the start and stop

pressure values and on or off delay timers (timers are

optional) if required. The module continuously displays the

system pressure and, when required, the start and stop

pressure settings. The system pressure reading can be

viewed without opening the door of the controller.

The module also allows the user to choose the units of

measure of the pressure reading in psi, bar, kPA, feet of

head and meter of head.

The model JP jockey pump controllers are built in

accrodance to the latest Underwriters Laboratories

UL508A and C.S.A C22.2 No.14 standards.

STANDARD FEATURES

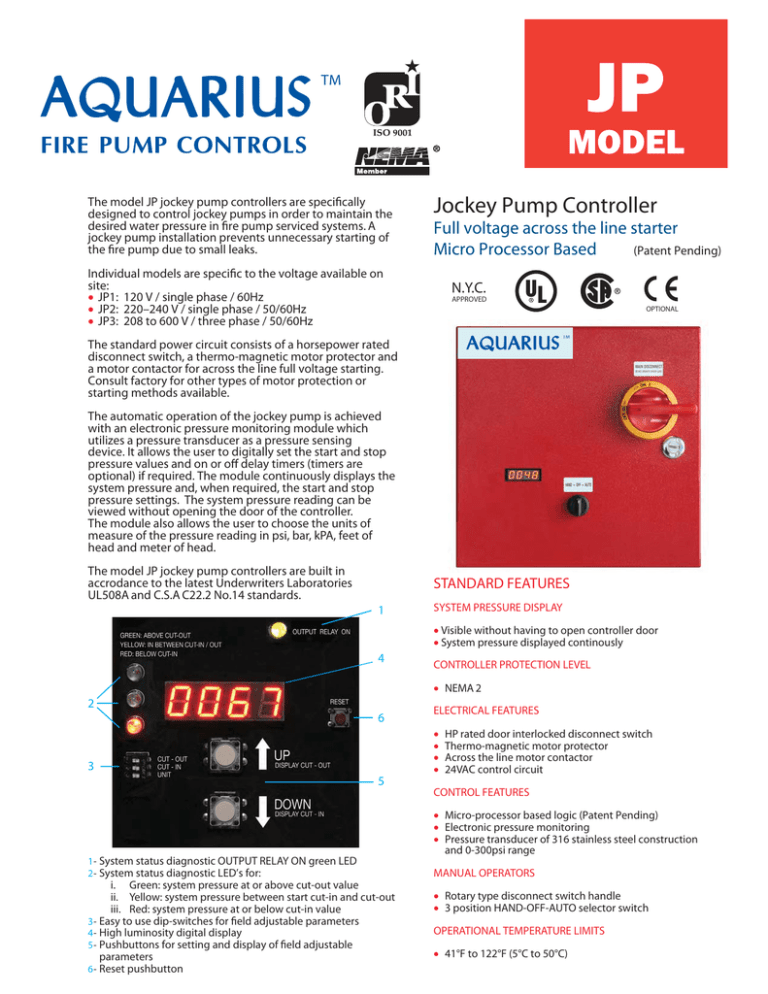

1

SYSTEM PRESSURE DISPLAY

x Visible without having to open controller door

x System pressure displayed continously

4

CONTROLLER PROTECTION LEVEL

x NEMA 2

2

6

ELECTRICAL FEATURES

x

x

x

x

3

5

HP rated door interlocked disconnect switch

Thermo-magnetic motor protector

Across the line motor contactor

24VAC control circuit

CONTROL FEATURES

x Micro-processor based logic (Patent Pending)

x Electronic pressure monitoring

x Pressure transducer of 316 stainless steel construction

and 0-300psi range

1- System status diagnostic OUTPUT RELAY ON green LED

2- System status diagnostic LED’s for:

i. Green: system pressure at or above cut-out value

ii. Yellow: system pressure between start cut-in and cut-out

iii. Red: system pressure at or below cut-in value

3- Easy to use dip-switches for field adjustable parameters

4- High luminosity digital display

5- Pushbuttons for setting and display of field adjustable

parameters

6- Reset pushbutton

MANUAL OPERATORS

x Rotary type disconnect switch handle

x 3 position HAND-OFF-AUTO selector switch

OPERATIONAL TEMPERATURE LIMITS

x 41°F to 122°F (5°C to 50°C)

JP

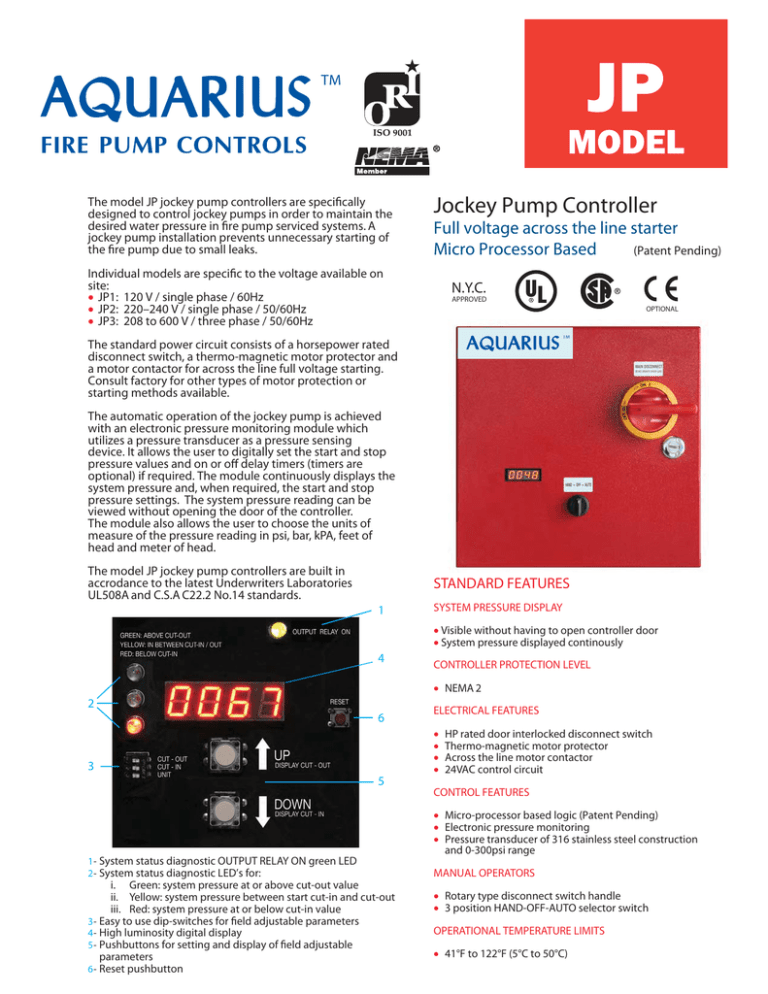

WIRING SCHEMATIC

MODEL

BUILT TO UL 508A & CSA C22.2 No. 14 STANDARDS

Jockey Pump Controller

LEGEND

DS: DISCONNECT SWITCH

OL1: THERMOMAGNETIC MOTOR PROTECTOR

C1: MOTOR CONTRACTOR

XTR: CONTROL TRANSFORMER

FU1: FUSE

PT1: PRESSURE TRANSDUCER

SS1: SELECTOR SWITCH

Full voltage across the line starter

Micro Processor Based

(Patent Pending)

TYPICAL SPECIFICATION

The jockey pump controller shall be a model JP__

and rated for _______V. / _______HP / _______

Phase / _______ Hz and listed with UL (UL508A)

and CSA.

The minimum rating of the enclosure shall be

NEMA 2, drip proof. The power circuit of the

controller shall incorporate a door interlocked

horsepower rated disconnect switch, a

thermo-magnetic motor protector and a contactor

for across the line starting of the electric motor.

The control circuit of the controller shall incorporate

a control transformer for 24VAC control power and

a Hand-Off-Auto selector switch.

The controller shall be micro-processor logic based

(Patent Pending). Automatic operation of the

jockey pump shall be achieved with an electronic

pressure monitoring module in conjunction with

a pressure transducer. The module shall allow

the user to digitally set the jockey pump start

and stop pressure values. It shall display these

values when required and constantly display the

system pressure. The user shall be able to view

the system pressure without opening the door of

the controller. The user shall be able to choose the

units of measure of the pressure reading in psi,

bar, kPA, feet of head and meter of head.

The pressure transducer shall be of 316 stainless

steel construction and have a range of 0-300psi.

Both the module and the pressure transducer

shall be mounted inside the controller to prevent

unauthorized adjustments or tampering.

OPTIONS

1MIMIMUM RUN PERIOD TIMER

2RUN GREEN PILOT LIGHT

3POWER ON WHITE PILOT LIGHT

4ELAPSED TIMER METER

5MOTOR RUN ALARM CONTACT

6LOSS OF POWER ALARM CONTACT

7OVERLOAD, SHORT CIRCUIT ALARM CONTACTS

7A - OVERLOAD PILOT LIGHT

8NEMA 12 ENCLOSURE

8A - NEMA 3/3R ENCLOSURE

9NEMA 4 ENCLOSURE

10 - NEMA 4X - 304sst ENCLOSURE

10A - NEMA 4X - 316sst ENCLOSURE

12 - CE MARK WITH EXTERNALLY MOUNTED WETTED PARTS

13A - EXTERNALLY MOUNTED WETTED PARTS

18 - AUDIBLE ALARM

19 - ANTI-CONDENSATION HEATER AND THERMOSTAT

20 - ANTI-CONDENSATION HEATER AND HUMIDISTAT

22 - PHASE REVERSAL / FAILURE PILOT LIGHT AND ALARM CONTACT

23 - CONTROL POWER HEALTHY PILOT LIGHT AND ALARM CONTACT

24 - PUMP FAILURE VIA CURRENT SENSING RELAY

25 - LOW ZONE PUMP CONTROL FUNCTION

26 - HIGH ZONE PUMP CONTROL FUNCTION

28 - SELECTOR SWITCH IN AUTO ALARM CONTACTS

29 - SELECTOR SWITCH IN OFF OR MANUAL ALARM CONTACTS

30 - MOTOR HEATER CIRCUIT

31 - SERVICE ENTRANCE RATING

NOTES:

- Three (3) phase incoming power wiring schematic shown.

Also available in single phase incoming power

- Consult factory for other options

HOW TO ORDER:

Ex.:

JPx JP3 -

V/

208 /

HP /

2HP /

Ph / Hz

3Ph / 60

TM

JP-BRO-001/E Rev.4

Aquarius Fluid Products, Inc.

2585 Millennium Drive, Unit B . Elgin, IL 60124

T: 847.289.9090 . F: 847.289.9292

800.208.8181 . www.aquariusfp.com

Subject to modification without notice

All rights reserved.