ISSN 2319-8885

Vol.02,Issue.12,

September-2013,

Pages:1281-1289

www.semargroups.org,

www.ijsetr.com

Simulation of Field Oriented Control of Sensor less Induction Motor

Drives using MRAS-Based Speed Estimator

A. NARENDER CHARY1

T. RAVICHANDRA 2

Asst. Prof, Dept of EEE, AVN Institute of Technology,

Hyderabad, AP-India, E-mail:naresh34@gmail.com.

Asst. Prof, Dept of EEE, AVN Institute of Technology,

Hyderabad, AP-India, E-mail: ravichandra34@gmail.com.

Abstract: MRAS based techniques have been proven to

be one of the best methods to estimate the rotor speed due

to its good high performance ability and straight-forward

stability approach .The proposed techniques use two

different models (the reference model and the adjustable

model) which have made the speed estimation a reliable

scheme especially when the motor parameters are poorly

known or having large variations. The proposed scheme

uses the error vector from the comparison of both models

as the feedback for speed estimation. In this scheme, the

performance of the rotor flux based MRAS (RF-MRAS)

and back EMF based MRAS (BEMF-MRAS) for

estimating the rotor speed is studied. Both schemes use the

stator equation and rotor equation as the reference model

and the adjustable model respectively. The output error

from both models is tuned using a PI controller yielding

the estimated rotor speed. The dynamic response of the

RF-MRAS and BEMF-MRAS sensor less speed

estimation is examined in order to evaluate the

performance of each scheme. The results obtained justify

the dynamic performance of the RF-MRAS and BEMFMRAS estimators.

Keywords: EMF, MRAS, RF-MRAS, BEMF-NRAS.

I. INTRODUCTION

In order to implement the vector control technique, the

motor speed information is required. Tacho generators,

resolvers or incremental encoders are used to detect the

rotor speed.However; these sensors impair the ruggedness,

reliability and simplicity of the IM. Moreover, they

require careful mounting and alignment and special

attention is required with electrical noises. Speed sensor

needs additional space for mounting and maintenance and

hence increases the cost and the size of the drive system.

However, in one aspect, the speed sensor elimination

reduces the total cost of the drive system. On the other

hand the sensor less drive system is more versatile due to

the absence of the numerous problems associated with the

speed sensor as discussed previously. Therefore it is

encouraged to use the sensor less system where the speed

is estimated by means of a control algorithm instead of

measuring. However eliminating the speed sensor without

degrading the performance is still a challenge.

In this dissertation, the speed sensor less estimation

concept via implementation of Model Reference Adaptive

System (MRAS) schemes was studied. It is well known

fact that the performance of MRAS based speed estimators

is beyond par from other speed estimators with regards to

its stability approach and design complexity. Although this

thesis is all about MRAS based speed estimators, but it is

also the aim of this project to investigate several speed

sensor less estimation strategies for IMs. Explanations on

the type of control strategies also were briefly discussed.

As far as simulation works concerned, the MRAS based

speed sensor less estimation schemes in this thesis has

been implemented in the field oriented structure (FOC) to

evaluate the estimator’ performance.

Significance of study: With the maturing technology of

the vector-controlled drives, the need for speed

information is crucial for control purposes and

traditionally, this information can be extracted using

mechanical sensor mounted on the motor shaft. However,

the presence of such sensor has reduced the system

reliability and increases the drives system’s size and the

overall cost. These problems have attracted the interest of

many researchers to develop techniques that can eliminate

the use of shaft sensor. This effort has led to growth of

various speeds sensor less estimation schemes based on

the simplified motor models. Therefore, the intention of

this work is to share the motivation of the previous

researchers to study the speed sensor less estimation

strategies. The reason behind adopting the MRAS based

speed sensor less estimation strategies in this research is

so obvious because it has been proclaimed as one of the

best methods available, especially when the motor

parameters are poorly known or have large variations.

Though the performance of MRAS based estimators is

Copyright @ 2013 SEMAR GROUPS TECHNICAL SOCIETY. All rights reserved.

A. NARENDER CHARY, T. RAVICHANDRA

considerably good at high speed but operation at low and

zero speed is still a problem to overcome.

II.SPEED SENSORLESS ESTIMATION TECHNIQES

The speed estimation schemes based on the direct

synthesize of the IM equations can be broadly group into

two groups. The first one is the open loop observer which

does not have the feedback correction and the other one is

the closed loop observer which make use of the feedback

correction to improve the estimation accuracy. The open

loop calculation method is simple to implement but prone

to error because of high dependency on the machine

parameters. The closed loop group observers for speed

estimation are much more versatile in terms of

performance such as the Luenberger observers, Kalman

Filter observers, MRAS estimators and rotor slot

harmonics estimator. Each of these speed estimation

schemes differs from each other in terms of equations and

structure used but they share the same objective to provide

the speed information and to improve the performance of

the IM drive system.

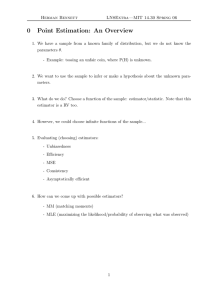

Model reference adaptive system estimators: The MRAS

approach uses two models. The model that does not

involve the quantity to be estimated (the rotor speed, r ) is

considered as the reference model. The model that has the

quantity to be estimated involved is considered as the

adaptive model (or adjustable model). The output of the

adaptive model is compared with that of the reference

model, and the difference is used to drive a suitable

adaptive mechanism whose output is the quantity to be

estimated (the rotor speed). The adaptive mechanism

should be designed to assure the stability of the control

system. A successful MRAS design can yield the desired

values with less computational error (especially the rotor

flux based MRAS) that an open loop calculation and often

simpler to implement. Figure below illustrates the basic

structure of MRAS. Different approaches have been

developed using MRAS, such as rotor flux based MRAS

(RF-MRAS), back e.m.f based MRAS (BEMF-MRAS),

and reactive power based MRAS (RP-MRAS) and

artificial intelligence based MRAS (ANN-MRAS). In the

following a basic description of these schemes will be

discussed.

(b)

Fig1. General Structure of MRAS based estimator

scheme. (a) Basic scheme using space vector notation.

(b) Basic scheme using space vector components

III. RF-MRAS VS BEMF-MRAS SPEED

ESTIMATORS

This research decided to use the RF-MRAS and BEMFMRAS based estimators to perform the simulation and

evaluation on the performance of the estimators as

mentioned earlier in the objectives of the study. These two

estimators have been chosen intentionally since they

uniquely differ in terms of the quantity used in the

reference model and the adjustable model but they share

almost the same realization in terms of structure. Both

structures also have been widely referred in the literature.

Hence, a fair comparison of the estimators can be

performed and the results from this study will enrich the

materials available for references in future. Therefore, this

chapter will discussed in detail the realization of the two

estimators from the IM dynamic equations up to the

construction of the estimators in the MATLAB/

SIMULINK.

A. RF-MRAS

The RF-MRAS estimator was initially proposed by

Schauder as an improvement to the drawbacks incurred in

the open loop estimator. It is possible to estimate the rotor

speed by using two models (the reference model and

adjustable model) which independently estimate the rotor

flux linkage components in the stationary reference frame

and by using the difference between these flux linkages

estimates to drive the speed of the adjustable to that of the

actual speed. The expressions for the rotor flux linkages in

the stationary reference frame can be obtained from the

stator voltage and rotor voltage equations of the IM as

described in chapter 2. Stator voltage and flux equations of

(2.11)-(2.12) and (2.5)-(2.6) have been manipulated and

simplified to obtain the rotor flux linkages as given by the

following equations:

(a)

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

Simulation of Field Oriented Control of Sensor less Induction Motor Drives using MRAS-Based Speed Estimator

s

qr

Lr

Lm

drs

(v

Lr

Lm

qs

(v

(1)

(2)

s

s

Rs iqs

)dt Ls iqs

ds

s

s

Rs ids

)dt Ls ids

2

Where 1 Lm

Ls Lr

Whereas, the rotor voltage and flux equations have

been rearranged and simplified to give the derivatives of

rotor flux linkages in the stationary reference frame as

given by the following equations:

d qrs

dt

L

1 s

qr r drs m iqss

Tr

Tr

(3)

d drs

L

1

(4)

drs r qrs m idss

dt

Tr

Tr

Equations (1) and (2) were implemented as the

reference model since it is independent of rotor speed and

the equations (3) and (4) were implemented as the

adjustable model as it is speed dependent. The tuning

signal driving the adaption mechanism of this structure is

the error output due to comparison of both models. It

varies the rotor speed in order to force to zero the error

vector. The block diagram of the RF-MRAS structure is

shown in figure2. The adaption mechanism used in the

speed estimator structure is either P-I controller or fuzzy

based controller or artificial neural network based

algorithms. Here the P-I controller is used as the adaption

mechanism. In the next section the stability of RF-MRAS

will be discussed.

the actual value can be assured with suitable dynamic

characteristics. When designed according to these rules,

the stator error equations of the MRAS are guaranteed to

be globally asymptotically stable. The adaption

mechanism can be derived from the following state error

equations which is obtained by subtracting equations (3)

and (4) from the corresponding reference model equations

(1) and (2).

d d

1

(5)

d r q ˆ q ( r ˆ r )

dt

Tr

d q

1

(6)

q r d d ( r ˆ r )

dt

Tr

or in matrix form, d A W Since ̂ r is a

dt

.

function of the state error, these equations describing a

nonlinear feedback system as illustrated in Figure 3.

Fig3. MRAS equivalent nonlinear feedback system

To ensure the hyper stability of the system can be

achieved, two criterions must be established. Firstly, the

linear time-invariant forward path transfer matrix

(sI A) 1 must be strictly positive real and secondly, the

nonlinear feedback (which includes the adaption

mechanism) must satisfy Popov’s criterion for stability.

Popov’s criterion for stability requires a finite negative

limit on the input or output inner product of the nonlinear

feedback system. A candidate adaption mechanism which

satisfies the criterion can be obtained as given in the

following explanation. Let

t

ˆ r 2 1 d

(7)

0

Popov’s criterion requires that:

t1

W dt

T

Fig2. Speed estimation using RF-MRAS.

B. RF-MRAS stability

It is important to design the adaption mechanism of the

MRAS based estimators according to the hyper stability

concept. This will results in a stable and quick response

system where the convergence of the estimated value to

02

For all t1 0

(8)

0

Here, 02 is a positive and constant. Substituting for ,

W and ̂ r in this inequality, Popov’s criterion for the

present system becomes;

ˆ

t

0

d

q

t

qˆ d r 2 ( ) 1 ( )d dt 02

0

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

(9)

A. NARENDER CHARY, T. RAVICHANDRA

The following relation can be used to solve this inequality:

t1

1

k ( p. f (t )) f (t )dt 2 k. f (0)

2

,k 0

(10)

0

Using this expression, it can be shown that Popov’s

inequality is satisfied by the following functions:

1 K1 ( qˆ d dˆ q ) K1 ( qˆ d dˆ q )

(11)

2 K P ( qˆ d dˆ q ) K P ( qˆ d dˆ q )

(12)

Substituting equations (11) and (12) into equations (7)

yields the estimated rotor speed as follows:

K

(13)

ˆ r ( K P I )( qˆ d dˆ q )

p

The MRAS speed identification based on this adaption

mechanism is illustrated in figure 4 as being implemented

in the MATLAB/SIMULINK. This simulink blocks will be

used in the simulation to examine the performance of the

estimator. The factors Lr in (3.1)-(3.2) and Lm in (3)Lm

Tr

(4) have conveniently been incorporated into the

adaptation mechanism gains constants KP and KI. Although

the structure is quite simple in construction, the

performance of this system is poor at close to zero speed,

due to the presence of pure integration and the stator

resistance effect. In order to solve the problems with initial

conditions and drift, modification of the pure integration in

the voltage model by a low pass filter is used. Another way

is by inserting a linear transfer function in form of high

pass filter in both the reference and the adjustable model.

Tajima and Hori improved Schauder’s work by proposing

a robust flux observer of which poles are designed in

function of rotor speed and rotor time constant. As a result,

the system is completely robust to the rotor resistance

variation.

C. BEMF-MRAS

The problem at low speed region can be somehow

resolved by replacing the pure integration of the stator

voltage with a filter. However, the natural delay related to

a filter is still present. To avoid completely the integration,

the back e.m.f quantity is used instead of the rotor flux

linkage. This MRAS technique was originally proposed by

Peng and Fukao to provide an improvement to the RFMRAS technique. The BEMF-MRAS based technique as

depicted in figure 5 does not require any pure integration in

its reference model. The estimator uses the induced back

e.m.f in its reference and adjustable models instead of rotor

flux linkages as applied in the RF-MRAS. The equations

for the direct and quadrature-axis back e.m.f in the

reference and adjustable models follow from equations (1)(4), as given by these equations:

(1) Reference model

emd vds ( Rs ids Ls

dids

)

dt

(14)

emq vqs ( Rs iqs Ls

diqs

(15)

dt

)

(2) Adjustable model

eˆmd

L2m

1

1

(ˆ r imq imd idss )

Lr

Tr

Tr

eˆmq

L2m

1

1

(ˆ r imd imq iqss )

Lr

Tr

Tr

dim

1

1

r im im i s

dt

Tr

Tr

(16)

(17)

(18)

D. BEMF-MRAS stability

As far as the design of the adaptation mechanism is

concerned, hyper stability approach is important to ensure

the stability of the system and the estimated quantity will

converge to the actual value. Referring to figure 3, instead

of using the rotor flux, the design considers the back e.m.f

as it input. The design of BEMF-MRAS adaptation

mechanism is almost the same as carried out for RFMRAS.

Differentiating both sides of equations (16) and (17),

the following equations can be obtained.

dem

L2 dis

1

(19)

r em em m

dt

Tr

Lr Tr dt

Letting em eˆm and subtracting (19) for the adjustable

model and from (19) for the reference model giving the

appropriate state error equation:

d

1

r (ˆ r r ) eˆm

dt

Tr

(20)

Or in matrix form, d A W . Since ̂ r

is

dt

Fig4. Block diagram of RF-MRAS estimator.

produced by the adaptation mechanism, these equations

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

Simulation of Field Oriented Control of Sensor less Induction Motor Drives using MRAS-Based Speed Estimator

describe a nonlinear feedback system as shown in figure 3.

To ensure stability of system, Popov’s criterion for hyper

stability as given in equation (21) must be satisfies.

t1 0

t1

Wdt

2

0

(21)

0

comparative assessment of the estimator’ performance can

be evaluated and conclusion made applied to both

estimators.

IV.SIMULATION RESULTS

A. BEMF-MRAS SPEED ESTIMATION

Letting

ˆ r ( K P

KI

)(eˆm )

p

(22)

Speed Response Dynamics:

And substituting for W in equality (3.21) gives the

following simplified equation.

t1

( eˆ

0

m

)( r ( K P

KI

)(eˆm ))dt 02

p

(23)

Using the same quantity equation as in (10), inequality

in (23) has been satisfied. Rewriting equation (22) yields

the estimated rotor speed of the estimator.

K

(24)

ˆ r ( K P I )(eˆm em )

p

The MRAS speed estimation system based on this

adaptation mechanism can be obtained as depicted in

figure5. The factor Lr

has been conveniently

L2m

Fig6. RF-MRAS speed estimator

incorporated into the adaptation mechanism gain constants

K P and K I . The structure is constructed in the MATAB/

SIMULINK for simulation and evaluation purposes.

Fig7. BEMF-MRAS speed estimator

Tracking capability:

Fig5. Block diagram of BEMF-MRAS estimator.

As being mentioned earlier, these two estimators were

chosen as candidates for comparison because of its

similarity (almost similar) in terms of structure realization

(refer Figure 4 and 6). Whereas the parts that differentiate

them are only quantities used in the models, and the

presence of pure integrator in the RF-MRAS. Those

criteria should give the clear stand on the reason for

choosing these two estimators. Therefore a fair

Fig8. Reference speed of 100 rad/sec.

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

A. NARENDER CHARY, T. RAVICHANDRA

BEMF-MRAS:

Fig9. RF-MRAS speed estimation

Fig12. P=0.009 and I=0.1

B. TUNING THE ADAPTIVE GAIN CONSTANTS RFMRAS

Fig13. P=0.009 and I=1.7

Fig10. P=1 and I=1

C. SENSITIVITY TO PARAMETER VARIATION

(a) Stator resistance (Rs) variation:

RF-MRAS incorrect Rs setting

Fig11. P=1 and I=100

(a) 1.0 Rs

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

Simulation of Field Oriented Control of Sensor less Induction Motor Drives using MRAS-Based Speed Estimator

(b) Rotor resistance (Rr) variation

RF-MRAS incorrect Rr setting

(b)

1.2 Rs

Fig14.

(a) 1.0 Rr

BEMF-MRAS incorrect Rs setting:

(b)1.2 Rr

(a)1.0 Rs

BEMF-MRAS incorrect Rr setting:

1.2 Rs

Fig15.

(a)1.0 Rr

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

A. NARENDER CHARY, T. RAVICHANDRA

BEMF-MRAS, estimation of rotor speed is not

feasible for both estimators.

RF-MRAS estimator has significant effect from

the parameters variation (especially stator resistance)

but the BEMF-MRAS is robust to parameter

variation.

Therefore, as a whole, considering all the key criteria

for comparison, it can be concluded that the BEMFMRAS embrace the requirement as a versatile estimators.

It is good in tracking capability and superb in insensitivity

to parameter variation.

VI. REFERENCES

(b) 1.2 Rr

V.CONCLUSIONS

This thesis has been devoted to provide a complete

comparison of the MRAS based speed estimators of the

induction machine and that objectives have been achieved.

RF-MRAS and BEMF-MRAS are two estimators which

are uniquely differ in terms of quantity used but almost

similar in the structure realization. The estimator’s

performance has been investigated using three key criteria

of comparison; tuning the adaptation gain constants, the

speed tracking capability and sensitivity to parameters

uncertainty. From the simulation and literature study, the

works in this project has arrived at the following

conclusion:

RF-MRAS based speed estimator is simple and

straightforward in implementation but BEMF-MRAS

based speed estimator is quite complex.

In case of RF-MRAS based speed estimator, low

values of adaptation gains do not yield in convergence

of the speeds, increasing the gains yield in better

convergence of the estimations. So the adaptation

gains must be taken as large as possible and limited

only by noise consideration. In case of BEMF-MRAS

based speed estimator, the relationship between the

adaptive gain constants and the tracking performance

is not as simple as in the case of RF-MRAS based

speed estimator. The non-linearity in tuning the

adaptation gain constants has made the process of

tuning the BEMF-MRAS speed estimators a difficult

one.

RF-MRAS

estimator

has

good

tracking

performances at high speed and even at low speed

operation but the BEMF-MRAS estimator show better

and superior performance overall. At low speed close

to zero operation, due to effect of stator value in RFMRAS and instability of back e.m.f quantity in

[1] Schauder, C. (1992). “Adaptive speed identification for

vector control of induction motor without rotational

transducers”.

IEEE

Transactions

on

Industrial

Applications. vol. 28. No. 5: pp. 1054-1061.

[2] Peng, F. Z. and Fukao, T. (1994). “Robust speed

identification for speed sensor less vector control of

induction motors”. IEEE Transactions on Industrial

Applications. vol. 30. No. 5: pp. 1234-1240.

[3] Ta-Cao, M., Uchida, T. and Hori, Y. (2001). “MRAS

based speed sensor less control for induction motor drives

using instantaneous reactive power”. IECON IEEE/IES

Annual Conf. pp. 1417-1422.

[4] Cirrincione, M. and Pucci, M. (2005). “An MRASbased sensor less high-performance induction motor drive

with a predictive adaptive model”. IEEE Transactions on

Industrial Electronics. vol. 52. No. 5: pp. 532-551.

[5] Illas, C., Bettini, A., Griva, G. and Profumo, F. (1994).

“Comparison of different schemes without shaft sensors

for field oriented control drives”. IEEE/IES Annual

Meeting IECON, pp. 1579-1588.

[6] Bodson, M. and Chiasson, J. (2002). “A comparison of

sensor less speed estimation methods for induction motor

control”. Proc. American Control Conf. pp. 3076-3081.

[7] Viorel, I. A. and Hedesiu, H. (1999).”On the induction

motors speed estimator’s robustness against their

parameters”. IEEE Journal. pp. 931-934.

[8] Blasco-Gimenez, R., Asher, G.M., Sumner, M. and

Bradley, K.J. (1996). “Dynamic performance limitation

for MRAS based sensor less induction motor drives. Part

2: Online parameter tuning and dynamic performance

studies”. IEEE Proc. Electrical Power Application. vol.

143. No. 2: pp. 123-134.

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289

Simulation of Field Oriented Control of Sensor less Induction Motor Drives using MRAS-Based Speed Estimator

[9] Jin, S, Wei.Z. and Zhenyi, H. (2004). “One novel

Author’s Profiles:

th

scalar control scheme for induction machine”.30 Annual

Conf. Of the IEEE Ind. Electronics Society. pp. 347-352.

[10] Holtz, J. (2002). “Sensor less control of induction

machine”. Proc. Of the IEEE. vol. 90. No. 8: pp. 13591394.

[11] Martins, C. A. and Carvalho, A. S. (2001).

“Technological trends in induction motor electrical

drives”. IEEE Porto Power Tech Conf.

[12] Shi, K. L., Chan, T. F., Wong, Y. K. and Ho, S. L.

(2000). “Speed estimation of an induction motor drive

using extended kalman filter”. IEEE Journal. pp. 243-248.

[13] Krishnan, R. and Bharadwaj, A. S. (1990). “A review

of parameter sensitivity and adaptation in indirect vector

controlled induction motor drive systems”. IEEE Journal.

pp. 560-565.

[14] Chee-Mun Ong,” Dynamic simulation of Electrical

Machinery using Matlab/Simulink” Prentice Hall

Publishers PTR.1998.

Mr A.Narender chary,

Assistant Professor in Department of

EEE AVNIET –Hyderabad. Obtained

his B.Tech., from JNTU Hyderabad,

and M.Tech., from JNTU, Anantapur,

having

the

overall

teaching

experience of 5 Years and Industrial

experience in vishakapatnam steel

plant and guided good number of B.

Tech., and M. Tech., Projects.

Mr T.Ravichandra,

Assistant Professor in Department

of EEE, AVNIET–Hyderabad.

Obtained. B.Tech, from JNTU

Hyderabad, and M.Tech, from

JNTU, Anantapur, having the

overall teaching experience of 5

Years and guided good number of

B. Tech., and M. Tech., Projects.

[15] Bimal K.Bose,” Modern power Electronics and AC

drives”. Prentice Hall Publishers PTR.2001.

[16] R.Krishnan,” Electric Motor Drives Modeling,

Analysis, and Control”. Prentice Hall Publishers

PTR.2001.

[17] A.E.Fitzgerad, Charles Kingsley, Jr., Stephen

D.Umans,” Electric Machinery”. The McGraw-Hill

Company.2003.

International Journal of Scientific Engineering and Technology Research

Volume.02, IssueNo.12, September-2013, Pages:1281-1289