Important - KLIK Systems

advertisement

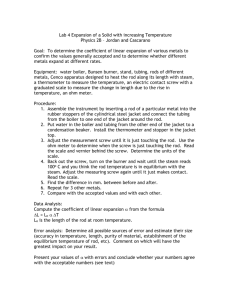

65B Surface Mounting Instruction 66 Fixing screw (not supplied) 66 Reflector Lamp Diffuser Important - Using appropriate fasteners to suit the mounting surface is the responsibility of the installer. - Fixings should be evenly spaced to avoid the over-loading of fasteners wires. Note: Extrusion body drilled in nominal suspension locations. Max Span 3.0m Timber Gyprock Metal plug Plastic plug These may need to be relocated onsite by installer to suit onsite requirements. Where possible advise Klik at time of order of fixing location requirments. Within 0.5m Join or bend www.kliksystems.com - info@kliksystems.com.au 10558-24-A 65B LED+50 Surface Mounting Instruction 1 2 3 Release lanyards Disconnect power cables Apply masking tape to the edge of the 150 Beam. Carefully pry loose the LED+50 module taking care not to scratch the system in the process. 5 4 Screw in lanyards, followed by power leads ensuring correct labelled plugs connect to each other Fasteners by others Feed in power and wire to terminals, after suspending the luminaire. Remove any masking tape before carefully snapping in the luminaire. 66 66 Important - Using appropriate fasteners to suit the mounting surface is the responsibility of the installer. - Fixings should be evenly spaced to avoid the over-loading of fasteners wires. Note: Extrusion body drilled in nominal suspension locations. Max Span 3.0m Timber Gyprock Metal plug Plastic plug These may need to be relocated onsite by installer to suit onsite requirements. Where possible advise Klik at time of order of fixing location requirments. Within 0.5m Join or bend 10558-21-A www.kliksystems.com - info@kliksystems.com.au 65 Beam Suspension Wire Instruction Item Number 1, 2, 3 or 4mtrs Title 1 Suspension Ceiling Barrel 2 8G x 38mm C/S self-tapping screw 3 Suspension Ceiling Barrel Cap 4 Suspension Wire (1,2,3,4 & 5mtr) 5 Gripper Wire Lug 6 65B 2mm End Plate 7 8G x 5/8" 6G Phil head screw 8 65 Beam Body 110 1 66 66 2 3 4 5 6 7 8 Important Using appropriate fasteners to suit the mounting surface is the responsibility of the installer. Units should be evenly supended to avoid the over-loading of suspension wires. A maximum loading of 50kg is recommended on a single wire at any one time. Type of protection: Class 1 Luminaire | Nominal Voltage 230-240V 50/60Hz 10 43 Max Span 3.0m 50kg Max. Loading 10 Max 29 Tool Less Adjustment Timber Gyprock Metal plug Plastic plug Max Tilt Lug Gripper Within 0.5m Join or bend 10337-27-C www.kliksystems.com - info@kliksystems.com.au 65B - 16mm Suspension Rod Instruction Calculating Rod Length Cutting and drilling Rod 4mm Assembling Rod & Pivot 2 Pivot used as drilling jig for Rod 57 Installing Rod in Bracket 6 Hook in slot 2 O/A Height Rod Length = O/A Height - 136mm 10 2 2 Holes drilled with Pivot Use screws to hold rod in pivot when drilling 4mm Screws must lock into holes drilled in rod 1 O4mm 1 2 Drill both sides 2 79 Screws used to lock pivot in position Earth strap for Pivot & rod (supplied) 9 14 9 15 4 3 17 4 9 5 20 2 6 1 8 18 19 1 12 2 11 10 13 Earth Connection (supplied) 16 7 Rod to system assembly Rod to mounting surface assembly Item Part Name Item Part Name Item Part Name Item Part Name 1 M4 x 8mm Pan head 6 Ceiling Mounting Bracket 11 65 Beam Body 16 16mm SuspRod Adaptor Base 2 M4 Pan head 12mm 7 Bracket Canopy 12 65B 2mm End Plate 17 M4 x 4mm Grub Screw 8 16mm Cast Ball Pivot Clamp 13 8Gx5/8" Csk 6G Phil Head 18 16mm Susp groove adaptor 3 M4 x 12mm Zinc Grub Screw 4 M4 internal star washer 9 M4 x 10mm Pan Head Screw 14 16mm SuspRod Flared End 19 M4 x 10mm Hex Head Screw 5 M4 Nut 10 16mm Suspension Rod 15 16mm SuspRod Adaptor Top 20 M4 Nylock Nut Important Choosing an appropriate fixing to suit the mounting surface is the responsibility of the installer. 58 Max Max Span 3.0 3.0m 73 11 44 38 45° O 26 PE Hole Mount Block Base Timber Gyprock Metal plug Plastic plug Maximum Pivot www.kliksystems.com.au - info@kliksystems.com.au Within 0.5m Join or bend 10347-08-D 110 65B - Concealed fixing end plate suspension instruction 66 Ceiling Barrel Suitable fixing 66 Ceiling barrel cap Suspension wire M4 Grub Screw Gripper Lug Lug Slid into suspension groove M4 Nut Concealed fixing end plate fitted Blind coupling pin R 5 Suspension groove entry hole Nut and grub screw slid along and tightened to prevent lug from slipping out. 20 Multi Section Unit Important Single Unit Choosing an appropriate fixing to suit the mounting surface is the responsibility of the installer. Note: Remove all labeling masking tape and clean unit as you go. 10° 43 10 10 Max Max Span 3.0m 29 Tool Less Adjustment Timber Gyprock M6 Stud Non Metal plug Max 10deg www.kliksystems.com.au - info@kliksystems.com.au Lug Gripper Within 0.5m Join or bend 10579-1-A 65 Beam Direct Fix Fix Wall al l Mounti unt ing Instruction 1 Remove components as shown to access inner wall of extrusion the fitting level, fasten the unit to 3 With designated surface, assuring the fasteners appropriate sized 2 Drill pilot holes at the location all components after the 4 Install luminaire is securely installed. securely penetrate supporting structures shown in Detail A, to suit selected fasteners Diffuser A Lamp B Power entry holes should exist and line up with power access to the luminaire before installation Reflector Fastener DETAIL B DETAIL A Reflector Angle to suit screw head size 66 Pilot hole to suit fastener 66 2m ‰ Max. Span Important Choosing an appropriate fixing to suit the mounting surface is the responsibility of the installer. The installer, shall be held accountable for the proper drilling of holes to match the onsite support structures. Timber/Concrete Plaster board www.kliksystems.com - info@kliksystems.com.au Max. span or with in 500mm of a join 10559-06-A