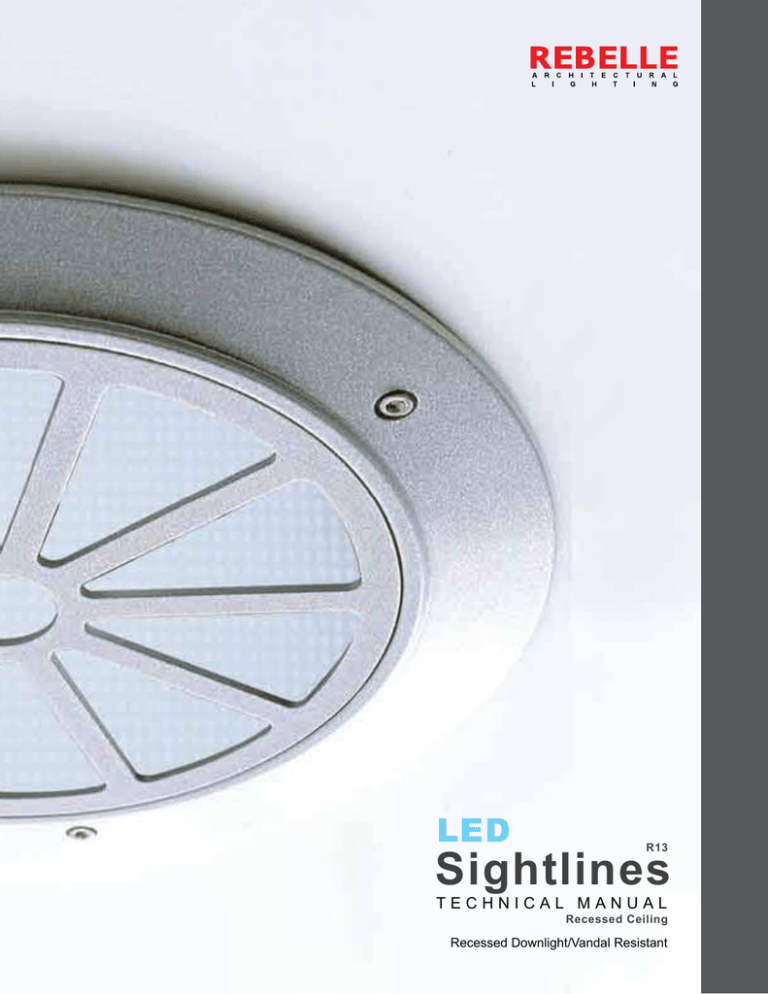

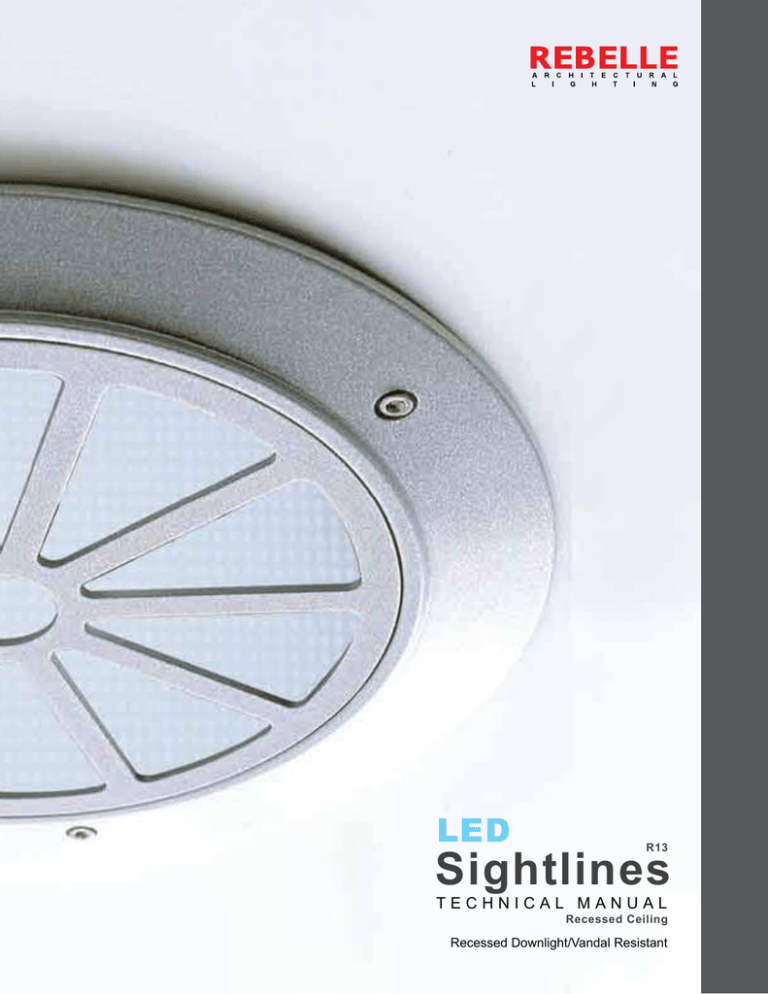

LED

Sightlines

R13

TECHNICAL MANUAL

Recessed Ceiling

Recessed Downlight/Vandal Resistant

CONCEPT

VANDAL RESISTANT RECESSED DowNLIGHT - LED

The Sightlines 8000LED Recessed Downlight Series is a premium

quality, vandal resistant recessed downlight designed for exterior

canopies and soffits. The luminaire design matches indoor open

reflector downlights in appearance to provide visual uniformity

between the building exterior and interior. Available in a standard

non insulated ceiling version for inverted T-bar, drywall, wet ceiling

and metal ceiling constructions. All units are “wet location” labeled

with an ingress protection level equivalent to IP 55. The Sightlines

8000LED Series provide the maximum vandal resistance to protect

recessed lighting installations in exposed public areas.

S I GH T L I NES - LED

RECESSED CEILING

-2-

The Sightlines Family

Recessed Ceiling - LED

The Sightlines 8000 Recessed Downlight Series comes in a standard non

insulated ceiling version for inverted T-bar, drywall, wet ceiling and metal ceiling

constructions. The 8000 Series design attributes are carried through into the

LED version. Pressure die cast aluminium trim, three point lock up using captive,

stainless steel allen drive bolts and double gasket seals - lens and ceiling, are

all incorporated. The Philips Fortimo LED Modules ensure a minimum rated

life of 50,000 hours with 70% lumen maintenance based on LM79 & LM80 test

procedures. The modules, drivers and wire harnesses provide 0 - 10 volt dimming

control and ensure the design temperature of the LEDs is never exceeded by virtue

Featuring:

Philips Fortimo Downlight Module

of a foldback circuit that reduces power if ever required. The 8000 Series design

ensures a high performance, low maintenance LED vandal resisting product.

'CTG'Trim

7.4"

1.75"

Ø9.8"

'PR' Trim

11.0"

'PR' Trim w/

'CG' Cast Guard

(Optional)

1.8"

14.5"

SI G HTLI NES - L E D

RECESSED CEILING

-3-

Dimensions

T-Bar / Plaster / Drywall / Metal Soffit Construction

7.4"

1.75"

CLEARANCE

RECESSED

DEPTH

7.1"

LIGHT OPENING

9.0"

CEILING CUT OUT

9.8"

OVERALL TRIM

2.09"

11"

5.25"

2.88"

2.09"

1.8"

14.5"

S I GH T L I NES - LED

RECESSED CEILING

-4-

Construction Details

T-Bar / Plaster / Drywall / Metal Soffit Construction

HOUSING ASSEMBLY

Cut Out for

Heat Sink

J-Box

(See Detail)

Bar Hangers

(Order Separately)

Adjustable Butterfly

Hangers

ELECTRICAL / THERMAL ASSEMBLY

Wiring Harness

Module to Driver

Fortimo Module

and Heat Sink

Supply and Control

Wiring to J-Box

VANDAL RESISTANT TRIM ASSEMBLY

Trim / Reflector

Assembly

Trim Detail

SI G HTLI NES - L E D

RECESSED CEILING

-5-

Construction(J-BoxDetail)(#1232)

Cover Spring Clip

Integral Ground Wire

Anti Vibration

Tabs (2 per side)

1 1/8"Ø Knockout (2)

7/8"Ø Knockout (3)

Locator Press Outs

Mounting Foot

5 1/4"

Covers (2)

4 15/32"

1 3/4"

4 7/8"

4 5/32"

3 7/32"

S I GH T L I NES - LED

RECESSED CEILING

-6-

Construction - Butterfly Bracket (#1254)

1/2" X 1-1/2"

CHANNEL

FURRING STRIP

CHANNEL

1/2" DIA. EMT (X2)

LOCK FOR 3/4"

BAR HANGERS

2-3/32"

POSITION 5/8" - 3/4"

BAR HANGERS

2 POSITIONS FOR

1/2" BAR HANGERS

ACCEPTS #10 CARRIAGE BOLT

TO SECURE BRACKET

LOCK FOR 1/2" BAR

HANGERS

3"

6-1/4"

2-3/32"

SI G HTLI NES - L E D

RECESSED CEILING

-7-

Construction - Bar Hangers (#1287) (order Separately)

1 3/8"

Female

15/32"

13 1/2"

13/32"

1 3/8"

Male

13 1/2"

Features Include:

1. Mechanical interface to prevent them from slipping apart, yet if necessary, this can be overcome with

a solid tug

2. Formed cross sections offer superior rigidity

3. Contains small outward extending tabs for positioning flush with underside joists.

4. Contains integral nails, which are

- located as far away as possible from main bar to permit easy nailing.

- oriented panel to joist wood grain for easier installation.

- toothed to resist pullout

- the sharpest available achieved through a proprietary process.

- retracted and surrounded for added safety prior to installation.

5. Contains auxiliary nailing hole for added retention, also located far from the main bar to permit easy

nailing.

6. Contains slots for engagement with suspended ceiling T-bar, whose depth lets the plaster frame sit

flush with the underside of ceiling panels.

7. Contains hole for locking hangers to T-bar using #8 self tapping screw.

8. Contains second auxiliary face nailing hole for transverse or other unusual mounting orientations.

9. Extendable from 14" to 24" centers.

S I GH T L I NES - LED

RECESSED CEILING

-8-

Fixed mounting

slotted bracket

Mounting bar

hangers #1207 - optional

horizontal adjustment

Electrical tray

assembly

Housing assembly

Adjustable butterfly

brackets

Trim assembly

(includes

reflector)

Approx.

Clearance

8.0"

J-Box with

coverplates

Ceiling

thickness

1 3/4" max

7.75"

9.00"

14" MIN

24 MAX"

#1287 Mounting

bars (optional)

IMPORTANT

Disconnect power before installing fixtures. Read instructions before

starting work. This product must be installed in accordance with the

applicable installation code by a person familiar with the construction

and operation of the product and the hazards involved.

Sightlines 8000 Series

HOUSING INSTALLATION - NON IC

ELECTRICAL TRAY INSTALLATION

1

Remove housing assembly from shipping container.

Make sure parts bag containing mounting bracket and

hardware is available.

1

2

The mounting bracket accepts a variety of mounting

rails. The #1287 adjustable bar hangers are useful for

many installations but must be ordered separately.

The electrical tray comes in two components, the heat

sink with the Fortimo module and the driver plate with

the driver. A dedicated cable connects the module to the

driver and preconnected set of wires in a sleeve connects

the driver to the J-Box.

2

Housing must be positioned in the required location and

adjusted to position with the underside of the housing

level with the underside of the finished ceiling.

Install the heat sink / module by inserting it through the

housing opening and attaching the heat sink with the

screws provided.

3

The driver plate and driver need to mount to the housing

angle with the module to driver cable connected and wire

tied in place with the driver to J-Box cable routed and

tied in place as well. The driver plate has keyhole slots to

mate with screws in the housing angle.

4

Connect fixture leads to appropriate supply leads and insert into J-Box. Attach cover plate. Test.

3

4

The mounting bracket carriage bolts and wing nuts

should be installed to allow vertical adjustment of the

housing after the ceiling is in place.

5

Pull supply wiring into J-Box as per applicable electrical

code requirements (90ºC). J-Box box is suitable for

branch circuit conductors (4 IN and 4 oUT).

6

If mounting is suspended T-Bar ceiling construction, the

#1287 Bar Hangers can hook over the vertical leg of

T-Bar and can be supported independently of the T-Bar

ceiling.

Notes:

These units are listed/certified as non-ic recessed units. They are meant to

be installed with 1/2" space around the recessed housing, except at point of

mounting contact. Insulation must be kept away from housing by a minimum

of 3".

SI G HTLI NES - L E D

REV. 03/18/13

www.rebellelighting.com

© 2013 REBELLE All rights reserved.

REBELLE ARCHITECTURAL LIGHTING 11475 - 201A Street, Maple Ridge, B.C. Canada V2X 0Y3

P 604.465.5739 F 604.465.9801 E info@rebellelighting.com W rebellelighting.com RECESSED

-9-

CEILING

VANDAL RESISTANT TRIM ASSEMBLY

Trim / Reflector

Assembly

Trim Detail

IMPORTANT

Disconnect power before installing fixtures. Read instructions before

starting work. This product must be installed in accordance with the

applicable installation code by a person familiar with the construction

and operation of the product and the hazards involved.

Sightlines 8000 Series

TRIM INSTALLATION

1 Trim assembly is separately packaged ready for installation once the finished ceiling is complete (finished opening should be 9”ø.)

2 Trim is fully gasketed at lens and ceiling surface. Top of

reflector mates with bottom of Fortimo module.

3 Trim has three #8 - 32 stainless cap screws (9/64" hex

key) that are captivated to trim with Nylon washers.

Screws thread into spring nuts on housing plaster ring.

S I GH T L I NES - LED

RECESSED CEILING

www.rebellelighting.com

© 2013 REBELLE All rights reserved.

REV. 04/11/13

REBELLE ARCHITECTURAL LIGHTING 11475 - 201A Street, Maple Ridge, B.C. Canada V2X 0Y3

P 604.465.5739 F 604.465.9801

- 1 0 - E info@rebellelighting.com W rebellelighting.com

Fortimo LED DLM Module

Module

Rated

Power

(W)

Module

Efficacy

(Lm/W)

System

Input

Power

(W)

System

Efficacy

(Lm/W)

Input

Voltage

(V)

Module B50L70

(Hours)

T case max 65°C

T

ambient

(°C)

5/6

5/6

15

14

73.5

78.5

19

18

58

61

120to277

120to277

50K

50K

-20

-20

4000

3000

5/6

5/6

13

31

84.5

64.5

17

36

65

56

120to277

120to277

50K

50K

-20

-20

3500

4000

5/6

5/6

29

28

69.0

71.5

34

33

59

61

120to277

120to277

50K

50K

-20

-20

Fortimo LED DLM System

(module and driver)

Approxinitial

Lumens

CRI

Fortimo LED DLM1100 19W/830 UL

Fortimo LED DLM1100 18W/835 UL

1100

1100

80

80

3000

3500

Fortimo LED DLM1100 17W/840 UL

Fortimo LED DLM2000 36W/830 UL

1100

2000

80

80

Fortimo LED DLM2000 34W/835 UL

Fortimo LED DLM2000 33W/840 UL

2000

2000

80

80

Fortimo LED DLM System

(module and driver)

CCT

Color

(K) Consistency

(SDCM)

Module Part Number

Driver Part Number

Cable Part Number**

Fortimo LED DLM1100 19W/830 UL

Fortimo LED DLM1100 18W/835 UL

Fortimo LED DLM1100 17W/840 UL

Fortimo LED DLM2000 36W/830 UL

929000498303

929000499603

929000498403

929000498503

913701213402

913701213402

913701213402

913701213402

442240069731

442240069731

442240069731

442240069731

Fortimo LED DLM2000 34W/835 UL

Fortimo LED DLM2000 33W/840 UL

929000499703

92900049860

913701213402

913701213402

442240069731

442240069731

* Current specifications, subject to change, for latest specifications please contact your local Philips sales representative.

**Other cable options are available. Please contact your local Philips sales representative for more information.

SI G HTLI NES - L E D

RECESSED CEILING

- 11 -

a significant improvement over traditional technology, but they fall short of the LED’s potential.

Code Compliance

As with other types of lighting, LED lighting must meet life safety code requirements for

emergency illumination. LED fixtures serving as emergency units must therefore provide

at least 90 minutes of emergency lighting and fulfill foot-candle mandates. Philips

Bodine emergency LED drivers allow these fixtures to meet or exceed code.

When normal power fails, the Philips Bodine emergency drivers immediately switch

Integral Emergency

LED Driver - Bodine

into emergency mode and support fixtures at reduced lumen output for a minimum of

90 minutes. When AC power is restored, the drivers return to their charging mode.

Philips Bodine BSL17C / BSL17C-C2

Emergency LED Driver

Highlights

●

90-minute code-compliant runtime

●

Dual input (120/277, 60 Hz)

●

Non-conduit version available, BSL17

●

Suitable for indoor and damp. BSL17 is also suitable for

sealed & gasketed fixtures.

●

Flexible output voltage range of 30 to 80 VDC

●

Multiple mounting configurations

●

Dimensions: 12” x 2.4” x 1.5”

●

Five-year warranty (not pro-rata)

●

Compatible with Philips Lightolier Calculite

●

For Philips Fortimo, use BSL17C-C2 (Class 2)

PHILIPS BODINE BSL17C EMERGENCY LED DRIVER

2

Ideal for

LED downlight applications

Watts

Operates an emergency lighting load up to 7 W @ 200 mA max

Certification

UL Component Recognized for factory installation only; CSA Certification pending

WARNING: TO PREVENT HIGH VOLTAGE FROM BEING PRESENT ON YELLOW & YELLOW/

BLACK OUTPUT LEADS PRIOR TO INSTALLATION, CONVERTER CONNECTOR MUST BE OPEN.

DO NOT JOIN CONVERTER CONNECTOR UNTIL INSTALLATION IS COMPLETE AND AC POWER IS

SUPPLIED TO THE EMERGENCY DRIVER.

LED brochure

./4%

-AKESURETHENECESSARYBRANCHCIRCUITWIRINGISAVAILABLE!NUNSWITCHEDSOURCEOF

POWERISREQUIRED4HEEMERGENCYDRIVERMUSTBEFEDFROMTHESAMEBRANCHCIRCUITAS

the AC driver.

EMERGENCY DRIVER AND AC DRIVER MUST BE FED FROM THE SAME BRANCH CIRCUIT

490)#!,3#(%-!4)#3/.,9-!9"%53%$7)4(/4(%2$2)6%23#/.35,44(%&!#4/29&/2/4(%27)2).'$)!'2!-3

WIRING DIAGRAMS

S I GH T L I NES - LED

WALL

SWITCH

UNSWITCHED HOT

WHT/RED

RECESSED CEILING

COMMON

WHITE

WHITE

WHT/BLK

BLACK

AC LED

DRIVER

ORANGE/BLACK

OUTPUT

OUTPUT

BLUE

YEL/BLK

YELLOW

F

L

E

X

A

L

E

E

M

D

E

R

D

G

R

E

I

N

V

C

E

Y

R

WALL

SWITCH

BLACK 120V

OR

ORANGE 277V

BLACK

ORANGE/BLACK

BLACK

UNSWITCHED HOT

WHT/RED

(CAP UNUSED LEAD)

F

L

E

X

ORANGE/BLACK

ITS

VIOLET

VIOLET

BROWN

BROWN

B

WHITE

RED

CONVERTER

CONNECTOR

WHITE

COMMON

-12-

WHITE

BLUE

BLACK

WHITE

WHT/BLK

BLACK

AC LED

DRIVER

THERMAL

PROTECTOR

OUTPUT

OUTPUT

BLUE

YEL/BLK

YELLOW

F

L

E

X

A

E

M

E

R

G

E

N

C

Y

L

E

D

D

R

I

V

E

R

BLACK 120V

OR

ORANGE 277V

BLACK

ORANGE/BLACK

BLACK

(CAP UNUSED LEAD)

F

L

E

X

ITS

VIOLET

VIOLET

BROWN

BROWN

B

WHITE

RED

CONVERTER

CONNECTOR

./4%

-AKESURETHENECESSARYBRANCHCIRCUITWIRINGISAVAILABLE!NUNSWITCHEDSOURCEOF

POWERISREQUIRED4HEEMERGENCYDRIVERMUSTBEFEDFROMTHESAMEBRANCHCIRCUITAS

the AC driver.

EMERGENCY DRIVER AND AC DRIVER MUST BE FED FROM THE SAME BRANCH CIRCUIT

490)#!,3#(%-!4)#3/.,9-!9"%53%$7)4(/4(%2$2)6%23#/.35,44(%&!#4/29&/2/4(%27)2).'$)!'2!-3

WIRING DIAGRAMS

wiring Diagram for Fixtures with Fortimo DLM and Driver

WALL

SWITCH

UNSWITCHED HOT

WHT/RED

ORANGE/BLACK

COMMON

WHITE

WHITE

WHT/BLK

BLACK

BLUE

OUTPUT

OUTPUT

AC LED

DRIVER

YEL/BLK

YELLOW

F

L

E

X

A

E

M

E

R

G

E

N

C

Y

L

E

D

D

R

I

V

E

R

WALL

SWITCH

BLACK 120V

OR

ORANGE 277V

BLACK

UNSWITCHED HOT

WHT/RED

(CAP UNUSED LEAD)

ORANGE/BLACK

BLACK

ORANGE/BLACK

F

L

E

X

ITS

WHITE

COMMON

VIOLET

VIOLET

BROWN

BROWN

B

WHITE

BLUE

BLACK

WHITE

WHITE

CONVERTER

CONNECTOR

WHT/BLK

BLACK

AC LED

DRIVER

RED

THERMAL

PROTECTOR

LED LOAD

LED LOAD

LED LOAD

LED LOAD

BLUE

OUTPUT

OUTPUT

YEL/BLK

YELLOW

F

L

E

X

A

E

M

E

R

G

E

N

C

Y

L

E

D

D

R

I

V

E

R

BLACK 120V

OR

ORANGE 277V

BLACK

ORANGE/BLACK

BLACK

(CAP UNUSED LEAD)

F

L

E

X

ITS

VIOLET

VIOLET

BROWN

BROWN

B

WHITE

CONVERTER

CONNECTOR

RED

WITH THERMAL PROTECTOR

WIRING DIAGRAMS FOR FIXTURES WITH THE FORTIMO DLM & DRIVER

TABLE 1. UL CLASSIFIED LOADS

WALL

SWITCH

UNSWITCHED HOT

Fortimo DLM and

SLM Series,

Load Reference

Fortimo LED DLM1100

19W/830UL

Fortimo LED DLM1100

18W/835UL

RATED

WATTAGE (W)

19

18

QTY OF LEDS

IN ARRAY

10 or 14

10

LED PART NO.

OR TYPE OF

LED

10 or 14

LXML-PRO1,

Color bin 5

average

Fortimo LED DLM2000

36W/830UL

36

14

LXML-PRO1,

Color bin 5

average

Fortimo LED DLM2000

34W/835UL

34

14

LXML-PRO1,

Color bin 5

average

Fortimo LED DLM2000

33W/840UL

33

14

LXML-PRO1,

Color bin 5

average

18

9

LUXEON Rebel

LXM3-PW71

WHITE

WHT/BLK

WHITE

(NEUTRAL)

BLUE

BLACK

(LINE)

YEL/BLK

YELLOW

LXML-PRO1,

Color bin 5

average

17

Fortimo LED SLM1100

18W/830

COMMON

LXML-PRO1,

Color bin 5

average

Fortimo LED DLM1100

17W/840UL

WHT/RED

ORANGE/BLACK

18

9

LUXEON Rebel

LXM3-PW61

17

9

16

LUXEON Rebel

LXM3-PW71

Fortimo LED SLM2000

33W/835

33

16

LUXEON Rebel

LXM3-PW61

BLACK

F

L

E

X

ORANGE/BLACK

BLACK

ITS

VIOLET

VIOLET

BROWN

BROWN

TYPE 1

B

WHITE

RED

CONVERTER

CONNECTOR

RED

BLUE

GREY

GREY

ORANGE

FORTIMO DLM

BLUE

RED

YELLOW (LED-)

BLACK (LED+)

WALL

SWITCH

UNSWITCHED HOT

WHT/RED

ORANGE/BLACK

ORANGE/BLACK

COMMON

WHITE

WHT/BLK

WHITE

(NEUTRAL)

BLACK 120V

OR

ORANGE 277V

BLACK

(LINE)

YEL/BLK

YELLOW

BLACK (LED+)

FORTIMO DLM

DRIVER

F

L

E

X

(CAP UNUSED LEAD)

YELLOW (LED-)

33

D

R

I

V

E

R

BLACK 120V

OR

ORANGE 277V

(CAP UNUSED LEAD)

ORANGE

LUXEON Rebel

LXM3-PW51

Fortimo LED SLM2000

33W/830

L

E

D

YELLOW (LED-)

FORTIMO DLM

DRIVER

BLUE

Fortimo LED SLM1100

17W/840

A

BLACK (LED+)

ORANGE/BLACK

Fortimo LED SLM1100

18W/835

F

L

E

X

E

M

E

R

G

E

N

C

Y

RED

CONVERTER

CONNECTOR

RED

A

L

E

E

M

D

E

R

D

G

R

E

I

N

V

C

E

Y

R

ORANGE/BLACK

ITS

F

L

E

X

VIOLET

OPTION 6

BROWN

B

WHITE

BLUE

ORANGE

GREY

GREY

ORANGE

Fortimo LED SLM2000

31W/840

31

16

LUXEON Rebel

LXM3-PW51

FORTIMO DLM

BLUE

RED

YELLOW (LED-)

BLACK (LED+)

NOTE:

For Type 2 units, Flex A is not provided. The wires exit through the opening near the studs on the bottom of the unit.

2

SI G HTLI NES - L E D

RECESSED CEILING

-13-

S I GHTLINES - LED

RECESSED CEILING

-14-

SIGHTLINES - LED

RECESSED CEILING

-15-

S I GHTLINES - LED

RECESSED CEILING

-16-

SIGHTLINES - LED

RECESSED CEILING

-17-

S I GHTLINES - LED

RECESSED CEILING

-18-

Pa i n t F i n i s h e s

Powder Coat Paint

Eight Standard Colors

The colors shown below are available for all Rebelle

products and are suitable for interior and exterior use.

other colors are available to match RAL standards, or

to match a specific color sample. Both RAL and color

match are premium priced color options.

WS

WT

AN

SM

GM

BT

BM

BZ

satin white

textured

white

natural

aluminium

metallic

silver

gunmetal

textured

black

black matte

textured

bronze

Surface Preparation and Application Process

Rebelle’s powder painting process utilizes only polyester powders

welded assemblies are shot blasted to near white specifications prior

to ensure durability and permanence in outdoor applications. The

to the five stage pre-treatment process. Following pre-treatment, all

process follows a documented quality assurance procedure to ensure

parts are coated using an electrostatic process to allow for a consistent,

the longevity of the finish in the most rigorous climates. All of Rebelle’s

even coating on parts. After coating, parts are then transferred to cure

luminaires go through a five-stage chemical pre-treatment prior to

in a high temperature oven. Paint production samples are continually

paint application in order to remove all surface impurities. To allow

checked to ensure they adhere to strictly controlled quality standards.

for a consistent, even coating on parts, all heavy cast aluminum and

SI G HTLI NES - L E D

RECESSED CEILING

-19-

REBELLE ARCHITECTURAL LIGHTING

11475 - 201A Street, Maple Ridge, BC, Canada V2X 0Y3

P 604.465.5739 F 604.465.9801

E info@rebellelighting.com W rebellelighting.com