1

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

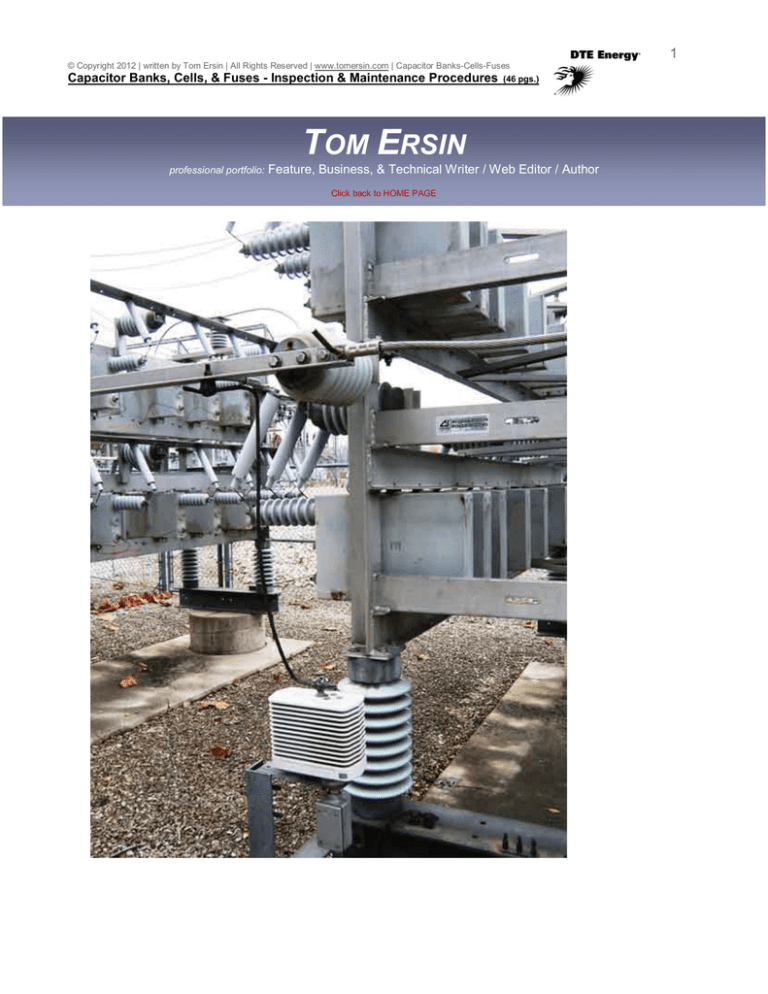

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

TOM ERSIN

professional portfolio:

Feature, Business, & Technical Writer / Web Editor / Author

Click back to HOME PAGE

2

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

CLICK HERE to suggest technical corrections

or clarity improvements from the field view.

CONTENTS

(press-and-hold “Ctrl” while clicking link)

DANGER

PRIOR TO ENERGIZING A PREVIOUSLY-FAILED CAPACITOR BANK, THE “CAPACITOR

BANK TROUBLESHOOTING SEQUENCE GUIDE” (Section V) MUST BE COMPLETED!

-) SAFETY

-) SCOPE & RESPONSIBILITY

-) QUICK REFERENCE (Equipment/Special Tools, Materials, Documentation)

I)

CAPACITOR CELLS – FAILURES & BLOWN FUSES

II) CAPACITOR-CELL FUSES – MAINTENANCE

-) SCOPE

A) CAPACITOR CELL INSPECTIONS

1) CAPACITOR BANK PROBLEMS

2) CAPACITOR-CELL FUSE

3) VISUAL INSPECTIONS

B) CAPACITOR CELL TESTING

C) FUSE REPLACEMENT

III) CAPACITOR-CELL FUSES – PRODUCT INFO

1) FUSE SPRINGS – GE: OLD (DISCONTINUED) & NEW

2) PRODUCT INFO

A) Capacitor Bank – 13.2-kV; 6-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

B) Capacitor Bank – 24-kV; 18-mVAR Max.; 100-kVAR Capacitor Cells; Expulsion

Fuses

3

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

C) Capacitor Bank – 24-kV; 18-mVAR Max.; 200-kVAR Capacitor Cells; Expulsion

Fuses

D) Capacitor Bank – 24-kV; 36-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

E) Capacitor Bank – 40-kV; 18-mVAR Max.; 100-kVAR Capacitor Cells; Expulsion

Fuses

F) Capacitor Bank – 40-kV; 18-mVAR Max.; 200-kVAR Capacitor Cells; Expulsion

Fuses

G) Capacitor Bank – 40-kV; 36-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

H) Capacitor Bank – 40-kVAR; 500-kVAR; 550-kVAR Capacitor Cells; Fuseless

IV) BANKGUARD CAPACITOR RELAYING – 59-N (aka 59-N BCR)

-) SCOPE

1) OPERATIONS

2) ALARMS

3) PROTECTION

V) CAPACITOR BANK TROUBLESHOOTING SEQUENCE GUIDE

1) FUSED 24-kV & 40-kV

2) FUSELESS 24-kV & 40-kV

VI) CAPACITOR BANK BALANCING

-) SCOPE

1) BALANCING

A) 13.2-kV BANKS

B) 24-kV & 40-kV BANKS

1) WYE-UNGROUNDED

2) WYE-GROUNDED

C) GENERAL

4

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

VII) CAPACITOR (aka “SHUNT CAPACITOR”) THEORY & OPERATION

1) PURPOSE

2) CONSTRUCTION & CONNECTIONS

A) CAPACITOR CELLS

B) CAPACITOR BANK INSTALLATIONS

C) CAPACITOR DISCHARGE

3) OPERATING INFORMATION

FIGURES

Capacitance Value Ranges for Power-Shunt Caps

Table 01

Capacitor Bank Group & Fuses

Figure 08

Capacitor Bank Installations

Figure 09

Current Flow

Figure 10

Fluke Multi-Meter

Figure 11

Fluke Multi-Meter

Figure 12

Fuse Element Components

Figure 13

Fuse Element – Horizontal Bushing Assembly

Figure 14

Fuse Element – Vertical Bushing Assembly

Figure 15

Fuses, Construction, & Connections

Figure 07

Lockout Relay (LOR)

Figure 06

Springs – Old and New Style

Figure 16

Strings & Measurement Points

Figure 17

Voltage-Sensing Potential Device

Figure 05

Wye-Grounded Capacitor Bank – Left-Side Rack In-Series with Right-Side Rack

Figure 04

Wye-Grounded Capacitor Bank – Upper Rack In-Series with Lower Rack

Figure 03

5

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Wye-Ungrounded Capacitor Bank – Left-Side Rack In-Series with Right-Side Rack

Figure 02

Wye-Ungrounded Capacitor Bank – Upper Rack In-Series with Lower Rack

Figure 01

-) SAFETY

[top]

This is a safe-use guide for the described equipment. Only qualified personnel should

proceed. Keep these instructions available to all Substation personnel. Read these

instructions carefully before proceeding. Otherwise, serious injury or equipment

damage could occur. FOLLOW ALL DTE & MIOSHA SAFETY REGULATIONS.

FRC/PPE

— WEAR ALL NECESSARY FLAME RESISTANT CLOTHING (FRC) & PERSONAL

PROTECTIVE EQUIPMENT (PPE) WHILE PERFORMING ANY PROCEDURES IN

THIS ARTICLE.

— ALL JOBS ON POWER EQUIPMENT REQUIRE MINIMUM OF CATEGORY 2 FRC.

— EQUIPMENT ENERGIZED TO ≥ 600-V MIGHT REQUIRE HIGHER FRC CATEGORY.

REFER TO DTE ENERGY ELECTRICAL SAFETY STANDARDS.

— THIS WORK REQUIRES SAFETY GLASSES WITH SIDE SHIELDS OR GOGGLES.

-) SCOPE & RESPONSIBILITY

[top]

A) This article provides instructions unique to this class of circuit breaker.

B) Qualified maintenance personnel must perform these procedures (adjustment, testing,

and inspection) as scheduled. Additionally, they will perform any other necessary

maintenance – with prior approval, if required, from the equipment engineer.

C) Circuit breaker testing results must fall within all established testing values. Any

deviations must be resolved with equipment engineer and/or manufacturer.

DANGER

1) BEFORE TESTING OR WORKING ON CIRCUIT BREAKER OR MECHANISM,

EQUIPMENT MUST BE PROTECTED AGAINST ALL SOURCES OF POTENTIAL &

STORED ENERGY BY ENSURING THE FOLLOWING:

6

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

— ALL DISCONNECTS ARE OPEN, OR OUTSIDE PROTECTION IS PROVIDED IF

NEEDED

— BREAKER IS COMPLETELY DE-ENERGIZED

[IF APPLICABLE]

ON SPRING-TYPE MECHANISMS, SPRINGS MUST BE DISCHARGED, &

CIRCUIT BREAKER MUST BE OPEN & RACKED OUT

[IF APPLICABLE]

ON PNEUMATIC & HYDRAULIC MECHANISMS, PRESSURE SUPPLY

VALVE IS CLOSED & PRESSURE DRAIN VALVE IS OPEN

— REQUIRED BARRIERS & TAGS ARE IN PLACE

2) IF A FAULTY CONDITION ARISES DURING ANY INSPECTIONS / PROCEDURES, THE

NECESSARY REPAIRS OR ADJUSTMENTS MUST BE PERFORMED BEFORE

PROCEEDING.

3) REVIEW ALL MANUFACTURER’S WARNINGS AND CAUTIONS.

4) PRIOR TO APPLYING TEST POTENTIAL, ENSURE ALL PERSONNEL ARE CLEAR

OF EQUIPMENT BEING TESTED.

5) DO NOT HI-POT OR INSULATION-RESISTANCE TEST (MEGGER) ANY SOLID STATE

DEVICES.

6) PRIOR TO ANY FUNCTIONAL TESTS, VERIFY THAT OPERATION OF AUXILIARY

SWITCHES — CONNECTED IN CONTROL CIRCUITS OF OTHER SYSTEMS — WILL

NOT ENDANGER PERSONNEL AND EQUIPMENT OUTSIDE BREAKER OR

EQUIPMENT BEING TESTED.

DANGER

PRIOR TO ENERGIZING A PREVIOUSLY-FAILED CAPACITOR BANK, THE “CAPACITOR

BANK TROUBLESHOOTING SEQUENCE GUIDE” (Section V) MUST BE COMPLETED!

-) QUICK REFERENCE (Equipment/Special Tools, Documentation)

[top]

•

Equipment/Special Tools

1) conductivity tester

7

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

2) insulation resistance tester (Megger) (500-2500-V)

3) multi-meter

4) scale (6-inch)

5) step-transformer

6) test leads – various

7) timing device

8) variac rectifier set

I)

CAPACITOR CELLS – FAILURES & BLOWN FUSES

[top]

WARNING

DIELECTRIC LIQUIDS & CAPACITOR CELLS:

— PERSONNEL MUST WEAR OIL-IMPERVIOUS GLOVES (STOCK NO. 981-0014) &

COVER-ALL GOGGLES (STOCK NO. 981-0190) WHEN WORKING WITH LEAKING

CAPACITOR CELLS, DIELECTRIC-SPLASH CLEANUP, OR ANY OTHER

POSSIBLE DIELECTRIC-LIQUID CONTACT.

— CHECK GLOVE INTEGRITY BEFORE EVERY JOB.

— AFTER COMPLETING JOB, WASH HANDS & FACE WITH WARM WATER & SOAP.

— ANYTHING THAT COMES IN CONTACT WITH DIELECTRIC SPLASH MUST BE

SEALED IN A CLAMP-TOP DRUM CONTAINER & SENT TO SALVAGE-WSC.

- THIS INCLUDES RAGS, CLOTHES, STONES, DIRT, & LEAKING,

RUPTURED, OR PUNCTURED CAPACITOR CELLS.

- DEFECTIVE CAPACITOR CELLS SENT TO SALVAGE-WSC MUST BE

PROMPTLY FOLLOWED BY A MEMO TO THE “INSULATION

COORDINATOR” STATING LOCATION, CAPACITOR CELL MAKE, CATALOG

NO., SERIAL NO., kVAR RATING, VOLTAGE LEVEL, REASON FOR

SCRAPPING, & REMOVAL DATE.

[top]

8

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

A) See Section II: CAPACITOR-CELL FUSES-MAINTENANCE to if cell, fuse, or both need

replacement.

B) Refer to “Maintenance Letter 346” for proper reporting of failed capacitor cells.

C) If replacement capacitor cells or fuses are unavailable, capacitor banks MUST be

balanced to avoid overvoltage on remaining banks. See Section VI: CAPACITOR BANK

BALANCING.

II)

CAPACITOR-CELL FUSES – MAINTENANCE

(back)

[top]

-) SCOPE

A) Defective or Blown Fuse Element

Substation Operator will change a defective or blown fuse element in a capacitor cell, as

soon as conditions permit, to restore service.

B) Defective Capacitor Cell

Substation Operator will submit an OFW to Substation Maintenance to replace a

defective capacitor cell and its fuse element.

1) CAPACITOR CELL INSPECTIONS

[top]

A) Capacitor Bank Problems

•

Capacitor-bank problems usually occur in one of its individual capacitor cells.

B) Capacitor-Cell Fuse

[top]

•

Each capacitor cell within a capacitor bank is typically fused (fuse-protected). If a

capacitor-cell disturbance occurs, the fuse should blow, which disconnects capacitor

cell from capacitor bank.

[NOTE]

Some capacitor-bank installations are non-fused.

C) Visual Inspections

[top]

Other common problems are caused by corroded or fatigued fuse elements. Therefore,

Substation Operator will visually inspect all components of a capacitor bank that is shut

down for maintenance. This includes the following:

1) Fuses and Fuse Connections

9

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

Replace fuse if any of the following are found:

i)

loose, frayed, corroded, or otherwise deteriorated components

ii)

melted or broken-open links

iii)

deteriorated horn fiber (from moisture entering open end of fuse tube)

iv)

swollen horn-fiber insert (impedes ejection of tail from fuse tube)

v)

horn fiber used as insect nest

vi)

swollen fuse tubes (in some McGraw-Edison cells) (compromises integrity

of outside Bakelite tube)

2) Capacitor Cells

a) Remove any wildlife nesting (e.g., bird or wasp nests) during shutdown.

b) Submit an OFW for Substation Maintenance to replace a capacitor cell if any of

the following are found:

i)

broken, cracked, or chipped cell bushings

ii)

leaking, bulging, ruptured, punctured, charred, or otherwise damaged cells

3) Electrical Connections

•

Submit an OFW for Substation Maintenance to inspect/repair connections if any

of the following are found:

o

loose or corroded connections

4) Capacitor Rack and Support Insulators

•

Submit an OFW for Substation Maintenance to make repairs if any of the

following are found:

o

tracking, arcing, cracked, chipped, or broken rack components or insulators

2) CAPACITOR CELL TESTING (see Figures 11 & 12)

[top]

A) After capacitor bank is shut down and properly protected (see Article 405), Substation

Operator will test capacitor cell for proper capacitance before replacing its fuse element.

10

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

B) This testing is done with a hand-held, battery-operated Fluke Multi-Meter – set to

“Capacitance Tester” – as follows:

1) Insert test leads into Fluke Multi-Meter. (see Figure 11).

•

RED TEST LEAD goes into the “Volts, Ohms, Diode Test” receptacle.

•

BLACK LEAD goes into the “Common Terminal.”

2) Turn rotary switch to capacitance setting: “Ω /

“

3) Press and hold down YELLOW KEY for two (2) full seconds. “µF” will appear on

LCD screen.

4) Connect multi-meter lead probes across terminals of capacitor cell with blown fuse.

LCD screen will display “OL” momentarily, then, will automatically switch back to

“µF.”

5) Record capacitance reading, and compare it with the acceptable capacitance value,

listed in TABLE 01: CAPACITANCE VALUE RANGES FOR POWER SHUNT

CAPACITORS.

6) If capacitance value is WITHIN acceptable range (from Table 01), install new fuse in

capacitor cell.

7) If capacitance value is OUTSIDE of acceptable range, do NOT install new fuse in

capacitor cell. Submit OFW to Substation Maintenance for defective capacitor cell

replacement.

3) FUSE REPLACEMENT (see Figures 13, 14, & 15)

[top]

A) If performing a blanket replacement of all fuse tubes, old tubes will be sent to, and

inspected at, Maintenance Headquarters to salvage any that are re-usable.

•

•

Salvageable fuse tubes are characterized by the following:

o

fuse link must freely slip out of tube when held vertically with the ferrule down

o

fuse-tube’s insides must be perfectly smooth

Fuse LEADERS (LINKS) are NOT salvageable – their tails were custom-cut for each

location and likely will not fit other locations

B) Wherever a capacitor cell has caused its fuse element to blow, replace BOTH

components.

C) When a capacitor cell blows its fuse – and the cell appears normal – Substation

Operator will test cell for defect.

11

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

NOTICE

SUBSTATION OPERATOR WILL SUBMIT AN OFW TO SUBSTATION MAINTENANCE FOR

DEFECTIVE CELL REPLACEMENT.

[top]

D) After determining that a capacitor cell is NOT defective, Substation Operator will replace

defective fuse unit as follows:

1) Perform required switching and protective procedures to shut down capacitor bank.

2) Unscrew fuse tube, and remove defective unit.

3) Check for fuse tube obstruction from mud daubers, dirt, moisture swelling, etc. Clear

any obstruction.

4) Ensure replacement fuse tube and leader (link) are proper size

(see Section III, 2, D).

5) Do NOT cut fuse tube to shorten it. They are sized according to capacitor-cell

voltage rating.

6) Feed new fuse leader (link) through fuse tube.

•

Check for, and reject, any leader (link) damaged by crimps, bends, or frayed

leader wire.

7) Ensure that fuse’s knurled bolt is tight and its washer is in place (see Figure 15).

8) Screw fuse tube back onto its rack.

9) Remove jamb nut from bushing terminal.

10) Remove fuse clamp.

11) Remove defective fuse leader (link), if it is still present.

12) Bend flipper spring up toward fuse-tube end so that it is ≤ one (1) inch from tube.

•

Visually inspect flipper-spring integrity (see Section III, 1 regarding discontinued

old-style GE flipper spring – with bracket – which must be replaced).

o

When a fuse blows, an improperly installed or poorly designed flipper spring

can cause “leader whipping” (a swinging faulted leader, which could contact –

12

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

or arc with – neighboring fuse leaders (links) or capacitor cells, possibly

causing a “domino” effect of multiple capacitor-cell failures and fires).

13) Feed fuse leader (link) through eye-end of fuse spring.

14) Wrap fuse leader (link) – clockwise – around terminal bushing.

•

Ensure that leader (link) is not binding with flipper.

15) Replace fuse clamp.

16) Replace jamb nut, and tighten it.

17) Cut off any excess fuse leader (link).

III)

CAPACITOR-CELL FUSES – PRODUCT INFO

[top]

1) FUSE SPRINGS – GE: OLD (DISCONTINUED) & NEW

(back)

A) OLD GE capacitor-cell fuse spring – identified by a bracket supporting the flipper

spring (see Figure 16)

•

Old GE capacitor-cell fuse springs must be replaced.

B) NEW GE capacitor-cell fuse spring (used since 1984) – has NO bracket supporting

the spring (see Figure 16)

2) PRODUCT INFO

[top]

A) Capacitor Bank – 13.2-kV; 6-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

1) Capacitor Cells – 200-kVAR; 7.62-kV (2-bushings)

•

Edison Stock # 666-9174

•

Approved Manufacturers: GE (Cat. # 58L107WC70); Cooper Power Systems

(Cat. # CUM00011Y1 – includes capacitor cell and current-limiting fuse)

2) Current-Limiting Fuses

•

Edison Stock # 666-9106

•

Approved Manufacturer: Cooper Power Systems (8.3-kV; 40-A); Type NXC (Cat.

# FA5J40)

13

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

B) Capacitor Bank – 24-kV; 18-mVAR Max.; 100-kVAR Capacitor Cells; Expulsion

Fuses

[top]

1) Capacitor Cells – 100-kVAR; 6.9-kV

•

Edison Stock # 666-9016

•

Approved Manufacturers: GE (Cat. # 54L316WC70); Cooper Power Systems

(Cat. # CUM00011Y2 – includes capacitor cell and current-limiting fuse)

2) Fuse Tubes

•

Edison Stock # 666-9020

•

Approved Manufacturers: GE (Cat. # 115A1615G41); Cooper Power Systems

(Cat. # CCM149B1)

3) Fuse Flipper Springs

•

Edison Stock # 666-9019

•

Approved Manufacturer: GE (Cat. # 248A6954G1)

4) Fuse Links – 25-kV

•

Edison Stock # 703-0123

C) Capacitor Bank – 24-kV; 18-mVAR Max.; 200-kVAR Capacitor Cells; Expulsion

Fuses

[top]

1) Capacitor Cells – 200-kVAR; 6.9-kV

(back)

•

Edison Stock # 666-9040

•

Approved Manufacturers: Cooper Power Systems (Cat. # CUM00011Y3 –

includes capacitor cell and fuse link)

Recommendation

Try to stock only the above-listed brands, for the following reasons:

o

tight clearances between fuse and top of capacitor-cell bushing

o

all capacitor cell sizes vary between manufacturers

Failed 200-kVAR capacitor cells – while still under warranty – are returned to,

and replaced by, the manufacturer. When manufacturer replacements arrive,

14

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

send them back to the Maintenance Headquarters that originally handled the

failed cells. That Maintenance Department should then place these replacement

cells in same-make capacitor banks.

2) Fuse Tubes

•

Edison Stock # 666-9020

•

Approved Manufacturers: GE (Cat. # 115A1615G41); Cooper Power Systems

(Cat. # CCM149B1)

3) Fuse-Flipper Springs

a) Horizontal Mounting

•

Edison Stock # 666-9053

•

Approved Manufacturer: GE (Cat. # 248A6954G1)

b) Vertical Mounting

•

Edison Stock # 666-9019

•

Approved Manufacturer: GE (Cat. # 248A6954G1)

4) Fuse Links – 40-kV

•

Edison Stock # 703-0124

D) Capacitor Bank – 24-kV; 36-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

(back)

[top]

1) Capacitor Cells – 200-kVAR; 6.9-kV

•

Edison Stock # 666-9995

•

Approved Manufacturers: Cooper Power Systems (Cat. # CUM00011Y4 –

includes capacitor cell and current-limiting fuse) (see Section III, 2, C, 1 for

replacement policy)

2) Current-Limiting Fuses

•

Edison Stock # 666-9106

15

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

Approved Manufacturer: Cooper Power Systems (8.3-kV; 40-A); Type NXC (Cat.

# FA5J40)

3) All capacitor banks rated at 24-kV; up to 36 mVAR – except McGraw-Edison

capacitor banks – may be equipped with either Westinghouse CLXP or COL fuses.

These cells have a current-limiting fuse and expulsion link, in-series. Whenever

these fuses are blown or damaged, replace entire unit with an NXC current-limiting

fuse.

E) Capacitor Bank – 40-kV; 18-mVAR Max.; 100-kVAR Capacitor Cells; Expulsion

Fuses

[top]

1) Capacitor Cells – 100-kVAR; 12-kV

•

Edison Stock # 666-9014

•

Approved Manufacturers: GE (Cat. # 54L301WC70); Cooper Power Systems

(Cat. # CUM00011Y6 – includes capacitor cell and fuse link)

2) Fuse Tubes

•

Edison Stock # 709-0096

•

Approved Manufacturers: GE (Cat. # 31F2807G1); Cooper Power Systems (Cat.

# FN3Y2C)

3) Fuse-Flipper Springs

•

Edison Stock # 666-9019

•

Approved Manufacturer: GE (Cat. # 248A6954G1)

4) Fuse Links – 15-kV

•

Edison Stock # 703-0127

F) Capacitor Bank – 40-kV; 18-mVAR Max.; 200-kVAR Capacitor Cells; Expulsion

Fuses

[top]

1) Capacitor Cells – 200-kVAR; 12-kV

•

Edison Stock # 666-9039

•

Approved Manufacturers: Cooper Power Systems (Cat. # CUM00011Y7 –

includes capacitor cell and fuse link) (see Section III, 2, C, 1 for replacement

policy)

16

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

2) Fuse Tubes

•

Edison Stock # 709-0096

•

Approved Manufacturers: GE (Cat. # 31F2807G1); Cooper Power Systems (Cat.

# FN3Y2C)

3) Fuse-Flipper Springs

•

•

Horizontal Mounting

o

Edison Stock # 666-9053

o

Approved Manufacturer: GE (Cat. # 248A6954G2)

Vertical Mounting

o

Edison Stock # 666-9019

o

Approved Manufacturer: GE (Cat. # 248A6954G1)

4) Fuse Links (25-kV)

•

Edison Stock # 703-0123

G) Capacitor Bank – 40-kV; 36-mVAR Max.; 200-kVAR Capacitor Cells; CurrentLimiting Fuses

[top]

1) Capacitor Cells – 200-kVAR; 12-kV

•

Edison Stock # 666-9996

•

Approved Manufacturers: Cooper Power Systems (Cat. # CUM00011Y8 –

includes capacitor cell and current-limiting fuse) (see Section III, 2, C, 1 for

replacement policy)

2) Current-Limiting Fuses

•

Edison Stock # 666-9122

•

Approved Manufacturer: Cooper Power Systems (15-kV; 25-A); Type NXC (Cat.

# FA6J25)

4) All 40-kV capacitor banks rated up to 36mVARS — except Cooper Power Systems

banks — may be equipped with either Westinghouse CLXP or COL fuses. Whenever

these fuses are blown or damaged, replace entire unit with an NXC current-limiting

fuse.

17

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

H) Capacitor Bank – 40-kV Fuseless

[top]

1) Capacitor Cells – 400-kVAR; 12-kV

•

Edison Stock # 666-9992

•

Approved Manufacturers: Cooper Power Systems (Cat. # CEP99205A1)

2) Capacitor Cells — 500-kVAR; 12-kV

•

Edison Stock # 666-9991

•

Approved Manufacturers: Cooper Power Systems (Cat. # CEP99169A1)

3) Capacitor Cells — 550-kVAR; 12-kV

•

Approved Manufacturers: Cooper Power Systems (Cat. # CEP06095A1)

IV) BANKGUARD CAPACITOR RELAYING – 59-N

(aka 59-N BCR)

[top]

-) SCOPE (see Figures 05 & 06)

A) 59-N bankguard capacitor relaying (59-N BCR) is designed to reduce voltage

disturbances on the DTE Energy sub-transmission system, with the goal of preventing

catastrophic equipment failure.

B) The most common 59-N bankguard capacitor relaying (59-N BCR) scheme consists of a

voltage-sensing potential device installed between the 40-kV capacitor-bank neutral

bus and the substation ground mat.

C) When the potential device (see Figures 05 & 06) senses a trouble-indicating neutral-bus

voltage, it energizes a lockout relay (LOR), which isolates the capacitor bank and locks

out the capacitor switcher.

1) OPERATIONS

[top]

This bankguard relaying scheme engages when neutral-bus voltage reaches a certain

value: the equivalent of four (4) capacitor cells failing on one (1) phase.

A) In most substations, when this value is detected, the 59-N BCR energizes its 1_ _94

LOR, which trips and locks out the capacitor switcher.

18

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

In these installations, a diode is installed within the 40-kV circuit breaker. This

prevents breaker from tripping if the problematic neutral-bus voltage value is caused

by a capacitor failure.

B) In substations where fault capacity exceeds 30-kA, the 1_ _94 LOR will do the

following:

1) Trip the 40-kV trunk or tie-line circuit breaker.

2) Lockout the capacitor switcher.

3) Allow trunk or tie-line circuit breaker to reclose.

C) Two other possible substation events could generate a voltage difference between

ground and capacitor neutral bus:

1) A fault could occur within substation ground mat, elevating the potential of that

ground.

•

This is rare, and sufficient relay protection would be cost-prohibitive.

The protection provided by such a scheme yields the same results as the 59-N

bankguard relaying scheme; every protected capacitor in the affected area would

be isolated.

2) Trouble could arise on equipment connected to capacitor bank, creating voltage

spikes that could rupture capacitor cells.

a) When capacitor-bank-connected equipment fails, the capacitors should

automatically drain through faulted equipment. But this is NOT guaranteed, and

subsequent reclosures can prompt capacitor-cell failures to cascade.

b) Therefore, whenever any capacitor-bank-connected equipment energizes its own

protective relay to trip the circuit breaker, it also energizes the 59-N BCR LOR to

isolate capacitor bank. The affected circuit breaker then completes its normal

reclosing cycle.

2) ALARMS

[top]

A) The 59-N BCR scheme and the 1_ _94 LOR are alarmed separately. Whenever the 59N BCR picks up and isolates the capacitor switcher, there should be TWO (2) alarms to

acknowledge.

1) A 59-N operation is indicated by the RED LAMP mounted to face of bankguard relay

panel. Reset it by pushing button also mounted on panel.

2) Alarm switch for 1_ _94 LOR is located on switchboard panel. Acknowledge by

engaging the toggle-switch.

19

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

B) If protective relays on trunk or tie-line initiate a capacitor-switcher lockout, a circuitbreaker alarm AND a 1_ _94 alarm will be generated. However, the trunk or tie-line

circuit breaker may remain closed upon capacitor-switcher’s reclosure. This would

cancel one of the alarms.

3) PROTECTION

[top]

Since the 59-N BCR system contains a potential device, a secondary switch is installed on

the device. This secondary switch is located within the capacitor-switcher control

compartment – OR – within a weatherproof box mounted (below) the potential device, inside

the capacitor fenced enclosure. This secondary switch is considered a protective

tagging point.

NOTICE

— THE RED INDICATING LAMPS LOCATED ON THE 59-N BCR PANEL ARE SELFCONTAINED UNITS.

— SUBSTATION OPERATOR WILL SUBMIT A “FIVE (5)-DAY URGENT OFW” IF THIS

LAMP NEEDS REPLACEMENT.

V)

CAPACITOR BANK TROUBLESHOOTING SEQUENCE

GUIDE

(back)

[top]

DANGER

PRIOR TO ENERGIZING A PREVIOUSLY-FAILED CAPACITOR BANK, THIS “CAPACITOR

BANK TROUBLESHOOTING SEQUENCE GUIDE” (Section V) MUST BE COMPLETED!

1) FUSED 24-kV & 40-kV

[top]

A) Inspect for, and note, capacitor-cell blown fuses and capacitor-cell bulges.

B) Inspect for, and note, YELLOW TARGETS and/or RED TARGETS on capacitor

switcher.

20

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

C) Then, follow this troubleshooting sequence:

1) If Step 1 issues (blown fuses, bulged cells) are found, follow Step 4: Capacitor Banks

Diagnosis Sequence (below).

2) If Step 2 issues (targets on switcher) are found, follow Step 5: Switcher Diagnosis

Sequence (below).

3) If Step 1 AND Step 2 issues are found, follow Step 4: Capacitor Banks Diagnosis

Sequence AND Step 5: Switcher Diagnosis Sequence, in-parallel (below).

D) Capacitor Banks Diagnosis Sequence

[top]

1) Verify that “Red Tag Protection” has been applied.

2) Do the following:

a) Determine and record capacitor-cell voltage rating: _____________

b) Determine and record capacitor-cell kVAR rating: ______________

c) Count capacitor cells on lower rack and upper rack of each phase, and record

results, (below).

[NOTE]

Most capacitor banks are balanced top-to-bottom; some are balanced leftto-right.

X⏀

Y⏀

Z⏀

No. of upper cells

______________

______________

______________

No. of lower cells

______________

______________

______________

Total per phase

______________

______________

______________

d) From Table 01 (below) determine and record capacitor-cell capacitance range.

Min. ________ µf

Max. ________ µf

e) Determine (and record) the phase-capacitance range by multiplying total number

of cells per phase by the min. and max. capacitance-cell values.

(back)

f)

21

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Total cells per phase

_____________ x

Min. ________ µf

= __________ µf

Total cells per phase

_____________ x

Max. ________ µf

= __________ µf

[top]

3) Measure and record capacitance on each phase.

X⏀ ____________ µf

Y⏀ ____________ µf

Z⏀ ____________ µf

4) Compare individual values obtained in Step C.

a) Value variations should be < half (1/2) of an individual cell’s capacitance.

b) Each phase measurement must fall within the min./max. range established in

Step V, 1, 4, B, v. (phase-capacitance ranges).

i)

If these criteria are met, skip to Step 5: Switcher Diagnostic Sequence.

ii)

If these criteria are NOT met, continue with Step E.

5) Measure and record the capacitance of each rack (which will total six (6)

measurements). The protective grounds by the switcher must be temporarily

removed.

X1⏀ ______________ µf

X2⏀ ______________ µf

Y1⏀ ______________ µf

Y2⏀ ______________ µf

Z1⏀ ______________ µf

Z2⏀ ______________ µf

6) Compare individual values obtained in Step E.

[top]

a) Value variations should be < half (1/2) of an individual cell’s capacitance.

b) Each rack measurement must fall within 50% of the min./max. range established

in Step V, 1, 4, B, v. (phase-capacitance ranges).

i)

If these criteria are NOT met, verify continuity of each capacitor-cell fuse.

•

If a blown fuse is found, measure the cell capacitance.

o

If cell capacitance is within range, replace fuse.

o

If cell capacitance is NOT within range, replace cell AND fuse.

22

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

ii)

(46 pgs.)

Re-check Step F bulleted requirements. If these criteria still are NOT met

after replacing any blown fuses/bad cells, measure capacitance of each

individual capacitor cell for acceptance.

E) Switcher Diagnosis Sequence

•

Refer to Job procedures:

o

350-015: S&C Circuit Switchers, Vertical & Center Break Models 34.5-kV

through 345-kV

— OR —

o

350-017: Southern States Cap Switcher 72

2) FUSELESS 24-kV & 40-kV

[top]

A) Inspect for, and note, capacitor-cell bulges.

B) Inspect for, and note, YELLOW TARGETS and/or RED TARGETS on capacitor

switcher.

C) Then, follow this troubleshooting sequence:

1) If Step 1 issues (bulged cells) are found, follow Step 4: Capacitor Banks Diagnosis

Sequence (below).

2) If Step 2 issues (targets on switcher) are found, follow Step 5: Switcher Diagnosis

Sequence (below).

3) If Step 1 AND Step 2 issues are found, follow Step 4: Capacitor Banks Diagnosis

Sequence AND Step 5: Switcher Diagnosis Sequence, in-parallel (below).

D) Capacitor Banks Diagnosis Sequence

[top]

1) Verify that “Red Tag Protection” has been applied.

2) Do the following:

a) Determine and record capacitor-cell voltage rating: _____________

b) Determine and record capacitor-cell kVAR rating: ______________

c) From Table 01 (below) determine and record capacitor-cell capacitance range.

23

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

Min. ________ µf

(46 pgs.)

Max. ________ µf

d) Determine (and record) the phase-capacitance range by dividing total number of

cells per phase by four (4), then multiplying the result by the min. and max.

capacitance-cell values.

Total cells per phase

_____________ x

Min. ________ µf

= __________ µf

Total cells per phase

_____________ x

Max. ________ µf

= __________ µf

[top]

3) Measure and record capacitance on each phase.

X⏀ ____________ µf

Y⏀ ____________ µf

Z⏀ ____________ µf

4) Compare individual values obtained in Step C.

a) Value variations should be < half (1/2) of an individual cell’s capacitance.

b) Each phase measurement must fall within the min./max. range established in

Step V, 2, 4, B, v. (phase-capacitance ranges).

i)

If these criteria are met, skip to Step 5: Switcher Diagnostic Sequence.

ii)

If these criteria are NOT met, continue with Step E.

5) Measure and record the capacitance of “strings” (i.e., groups of capacitor cells inseries). Number of strings could vary depending on capacitor bank size. See Figure

xx to identify strings and measurement points on a typical 24/40-kV - 18 mVAR

fuseless capacitor bank (18 strings, 6 strings per phase).

X1⏀ ______________ µf

X2⏀ ______________ µf

X3⏀ ______________ µf

X4⏀ ______________ µf

X5⏀ ______________ µf

X6⏀ ______________ µf

Y1⏀ ______________ µf

Y2⏀ ______________ µf

Y3⏀ ______________ µf

Y4⏀ ______________ µf

Y5⏀ ______________ µf

Y6⏀ ______________ µf

Z1⏀ ______________ µf

Z2⏀ ______________ µf

Z3⏀ ______________ µf

Z4⏀ ______________ µf

24

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

Z5⏀ ______________ µf

(46 pgs.)

Z2⏀ ______________ µf

6) Determine the average for values obtained in Step E. All individual string values

should be within ± 0.2 µf of each average.

7) If the average values do not fall within ± 0.2 µf of each average, measure the

capacitance of each cell for acceptance.

E) Switcher Diagnosis Sequence

•

Refer to Job procedures:

o

350-015: S&C Circuit Switchers, Vertical & Center Break Models 34.5-kV

through 345-kV

— OR —

o

350-017: Southern States Cap Switcher 72

Table 01 – Capacitance Value Ranges for Power-Shunt Caps

[top]

UNIT VOLTAGE

RATING (kV)

6.9

6.9

6.9

7.62

12.0

12.0

12.0

12.0

12.0

UNIT POWER

RATING (kVAR)

100

200

500

200

100

200

400

500

550

CAPACITANCE VALUE RANGE

(MICROFARAD)*

MINIMUM

MAXIMUM

5.54

6.49

11.09

12.97

27.72

32.43

9.09

10.64

1.83

2.14

3.67

4.29

7.33

8.58

9.16

10.72

10.08

11.75

* Capacitance value ranges are based on -0% to +15% manufacturing tolerance,

with temperature compensation from -20 degrees Celsius to +40 degrees Celsius.

(back)

(see Figure 17 – Strings and Measurement Points)

25

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

VI) CAPACITOR BANK BALANCING

(back)

[top]

-) SCOPE

Follow these guidelines for balancing capacitor banks.

1) BALANCING

[top]

If more than one (1) capacitor-cell fuse is found blown on one (1) phase – resulting in an

imbalance – Substation Operator will de-energize capacitor bank and keep it out-of-service

until failed fuses are replaced.

However …

Under certain system conditions, the System Supervisor may require the capacitor bank to

remain in-service, for voltage support, before replacement parts are available. If so,

Substation Operator must balance the capacitor bank to avoid overvoltaging remaining

banks.

A) 13.2-kV BANKS

[top]

•

Wye-ungrounded connection

•

Ratings vary from 3-mVAR to 6-mVAR.

•

200-kVAR capacitor cells

•

Each bank contains three (3) phases.

o

Each phase contains one (1) group.

•

Each group contains capacitor cells connected in-parallel.

BALANCING REQUIRES EACH PHASE GROUP TO CONTAIN SAME NUMBER

OF FUNCTIONING CELLS CONNECTED IN-PARALLEL.

B) 24-kV & 40-kV BANKS

[top]

•

Outdoor rack-type construction

•

Wye-grounded – OR – wye-ungrounded connection

•

Ratings vary from 4.8-mVAR to 30-mMVAR.

26

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

o

4.8-mVAR banks use 100-kVAR capacitor cells.

o

30-mVAR banks use 200-kVAR capacitor cells.

Each bank contains three (3) phases.

o

Each phase contains two (2) racks (in an upper/lower OR right/left configuration)

connected in-series.

•

(46 pgs.)

Each rack contains capacitor cells connected in-parallel.

BALANCING REQUIRES EACH RACK – OF ALL THREE (3) RACK

CONFIGURATIONS (PAIRS) – TO HAVE SAME NUMBER OF FUNCTIONING

CAPACITOR CELLS CONNECTED IN-PARALLEL.

[NOTE]

A few small-size capacitor banks contain only one (1) rack per phase.

•

Each bank contains three (3) phases.

o

Each phase contains one (1) rack.

Each rack contains two (2) sides connected in-series.

o

•

Each side contains capacitor cells connected in-parallel.

BALANCING REQUIRES EACH SIDE – OF ALL THREE (3) RACKS – TO HAVE

SAME NUMBER OF FUNCTIONING CAPACITOR CELLS CONNECTED INPARALLEL.

1) WYE-UNGROUNDED (see Figures 01 & 02)

[top]

a) Upper Rack In-Series with Lower Rack (see Figure 01)

•

To balance 24-kV or 40-kV ungrounded capacitor banks, each rack (upper

and lower) of all three (3) phases must contain same number of capacitor

cells, connected in-parallel.

b) Left-Side Rack In-Series with Right-Side Rack (see Figure 02)

•

To balance 24-kV or 40-kV ungrounded capacitor banks, each rack (left-side

and right-side) of all three (3) phases must contain same number of capacitor

cells, connected in-parallel.

c) One Side of Small Bank In-Series with Other Side of Small Bank

27

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

To balance 24-kV or 40-kV ungrounded capacitor banks, each small bank

(both sides or groups) of all three (3) phases must contain same number of

capacitor cells, connected in-parallel.

2) WYE-GROUNDED (see Figures 03 & 04)

[top]

Since each phase of 24-kV or 40-kV grounded capacitor banks can be independently

balanced, the number of connected capacitor cells per phase can be unequal without

causing an overvoltage condition.

a) Upper Rack In-Series with Lower Rack (see Figure 03)

•

To balance 24-kV or 40-kV grounded capacitor banks within each phase, the

number of capacitor cells on lower rack must equal number of capacitor cells

on upper rack.

b) Left-Side Rack In-Series With Right-Side Rack (see Figure 04)

•

To balance 24-kV or 40-kV grounded capacitor banks within each phase, the

number of capacitor cells on left-side rack must equal number of capacitor

cells on right-side rack.

2) GENERAL

[top]

A) When balancing a capacitor bank, Substation Operator will completely remove

disconnected (blown) fuse element – or secure it – to prevent its contact (aka “leader

whipping”) with capacitor-bank frame, another fuse, or another capacitor cell.

B) On capacitor banks containing current-limiting fuses, Substation Operator will conduct a

continuity check of ALL limiters following a blown-fuse replacement or a capacitor-bank

balancing operation. Defective current limiters cause voltage imbalances on in-service

capacitor cells.

C) Fuseless capacitor banks cannot be balanced.

VII) CAPACITOR (aka “SHUNT CAPACITOR”) THEORY &

OPERATION

[top]

1) PURPOSE

Capacitors (aka “shunt capacitors”) are installed throughout the DECO electrical system.

When installed near an inductive load, capacitors improve voltage regulation and allow

additional equipment capacity. Therefore, system-load capacity is increased.

Here’s how:

28

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

A) Induction motors, transformers, and other inductive equipment draw a line current

greater than the actual power they consume. This happens because the magnetizing

current in the circuit (produced as the magnetic fields build up and collapse within each

cycle) reaches its maximum value one quarter of a cycle LATER than the voltage wave

does (LAGGING the impressed voltage by 90°).

B) Capacitors draw a current that reaches their maximum value one quarter of a cycle

SOONER than the voltage wave does (LEADING the impressed voltage by 90°).

C) Therefore, capacitor current is 180° out-of-phase (exactly opposite) with the

magnetizing current supplied by inductive equipment (motors, transformers, etc.). So

when a load comprising inductive AND capacitive equipment is connected to a line, the

magnetizing current (between capacitor and generator) is reduced by the capacitorcurrent level.

D) (See Figure 10) As shown, if E is the direction of the voltage, Ip is the current supplying

the useful power, and Im is the magnetizing current, then Il is the line current (produced

by “graphic addition”). As a result, Il is greater than Ip by the current amount needed

to supply useful power.

E) Consider a capacitor drawing current Ic – and an equal but opposite current Im. If these

two were now connected in-parallel, Ic and Im would balance out, and the total line

current would coincide with Ip in magnitude and direction.

1) The power current Ip, multiplied by voltage, equals “true power” (kW).

2) The line current Il, multiplied by voltage, equals “apparent power” (kVA).

3) The ratio of true power to apparent power (kW : kVA) is the “power factor” of the

circuit.

Capacitors are connected to the system during heavy-load periods. This produces the

following effects:

A) Raises power factor of load and system as a whole.

•

Amount of power-factor improvement depends on amount of reactive load and

amount of connected capacitance.

B) Causes voltage to rise at the load.

•

Amount of voltage increase depends on amount of reactive drop and amount of

connected capacitance.

To obtain optimum voltage regulation, capacitors are connected to, AND

disconnected from, the DTE Energy electrical system by automatic switchgear.

29

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

This switchgear can be controlled automatically (by time clocks or VAR controllers), OR

can be controlled manually by Substation Operator.

Because amount of magnetizing current (identified as “Im” in Figure 10) is reduced,

more load-carrying capacity becomes available.

•

Indeed, if Ic should exceed Im, load would contain a leading power factor, causing

voltage to rise.

•

This can cause transformers, lines, etc., to have a greater load AFTER capacitor is

online than before it was connected.

On the DTE Energy system, capacitor use is frequently manipulated by System

Supervisor to maintain 24-kV and 40-kV buss voltage while incoming transmission

lines are out-of-service during light-load periods.

2) CONSTRUCTION & CONNECTIONS

[top]

A) Capacitor Cells

1) Each capacitor-bank cell contains two (2) bushings (13.2-kV metal-enclosed cap

banks and fuseless) or one (1) bushing (24-kV and 40-kV fused cap banks). In all

cases bushings are insulated from their case and connected to special thin-foil paper

layers.

•

The paper layers are infused with refined mineral oil – OR – synthetic chlorinated

biphenyl.

o

Neither is flammable or explosive.

2) With fused capacitor banks, each capacitor cell’s source side is fused with an

indicating-type high-voltage power fuse.

B) Capacitor Bank Installations

[top]

•

On Westinghouse, GE, and Cooper (McGraw-Edison) capacitor-bank installations,

individual capacitor cells are supported by an insulated rack. (see Figure 09)

o

This rack is energized from the parallel series combination’s midpoint.

C) Capacitor Discharge

[top]

3) Capacitors retain a dangerous charge even after their energy source has been

removed.

30

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

•

(46 pgs.)

Therefore, it is mandatory that capacitor-bank installations be discharged

before any work is performed on them.

4) As shown in Figure 08, upon removal of energy source, entire capacitor bank will

discharge down to a 50-volt level within five (5) minutes.

5) As a further safeguard, all three (3) capacitor-bank phases – and the insulated rack –

are grounded by ground switches – OR – a set of removable grounding leads, which

Substation Operator must install before any capacitor equipment work is performed.

3) OPERATING INFORMATION

[top]

A) A capacitor may retain above-normal operating voltages after disconnection from the

line.

•

These voltages are dependent upon the voltage-wave resting point when circuit

breaker was opened.

B) Therefore, whenever a capacitor is de-energized, wait at least five (5) minutes before

re-energizing it.

•

Otherwise, excessive capacitor voltage may damage equipment connected to the

bus.

C) Whenever a capacitor is connected to a bus, the current surges two (2) to three (3)

times normal during first 1/4 to 1/2 cycle.

[top]

31

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 01 — Wye-Ungrounded Capacitor Bank – Upper Rack In-Series with Lower Rack

(back)

[top]

32

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 02 — Wye-Ungrounded Capacitor Bank – Left-Side Rack In-Series with Right-Side Rack

(back)

[top]

33

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 03 — Wye-Grounded Capacitor Bank – Upper Rack In-Series with Lower Rack

(back)

[top]

34

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 04 — Wye-Grounded Capacitor Bank – Left-Side Rack In-Series with Right-Side Rack

(back)

[top]

35

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 05 — Voltage-Sensing Potential Device

(back)

[top]

36

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 06 — Lockout Relay (LOR)

(back)

[top]

37

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 07 — Fuses, Construction, & Connections

(back)

[top]

38

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 08 — Capacitor Bank Group & Fuses

(back)

[top]

Figure 09 — Capacitor Bank Installations

(back)

[top]

39

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 10 — Current Flow

(back)

[top]

Figure 11 — Fluke Multi-Meter

(back)

[top]

40

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 12 — Fluke Multi-Meter

(back)

[top]

41

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 13 — Fuse Element Components

(back)

[top]

42

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 14 — Fuse Element – Horizontal Bushing Assembly

(back)

[top]

43

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 15 — Fuse Element – Vertical Bushing Assembly

(back)

[top]

44

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 16 — Springs – Old and New Style

(back)

[top]

45

© Copyright 2012 | written by Tom Ersin | All Rights Reserved | www.tomersin.com | Capacitor Banks-Cells-Fuses

Capacitor Banks, Cells, & Fuses - Inspection & Maintenance Procedures

(46 pgs.)

Figure 17 — Strings & Measurement Points

(back)

[top]