Three Dimensional Modeling of the DC Potential Drop Method

advertisement

THREE DIMENSIONAL MODELING OF THE DC POTENTIAL DROP METHOD USING

FINITE ELEMENT ANDBOUNDARYELEMENT ANALYSIS

S. Nath, T. J. Rudolphi and W. Lord

College ofEngineering

Iowa State University

Ames, Iowa 50011

INTRODUCTION

Finite element (FE) and boundary element (BE) methods ofnumerical analysis have been

utilized in the solution ofnumerous electromagnetic nondestructive evaluation (NDE) phenomena.

Investigations using these methods have been undertaken by Lord [1,2,3], Palanisamy [4],

Atherton [5], Beissner [6], Burais [7] and others.

The finite element method (FEM) is a domain technique of solving the underlying governing

equation in the region. The solution obtained in the total region is ideal to study energy/defect

interactions, but the extensive discretization demands vast computer resources. On the other hand,

the potential savings in computation resources, due to a limited surface or boundary discretization,

is the primary motivation in using the boundary element method (BEM). The numerical solution

of the boundary integral representation of the governing equation is the BEM. This is based on the

two point kernel function (or fundamental solution) which is a distinctive feature ofthe BEM. The

kernel exists only for linear operators, which poses a limitation.

This research is part of an endeavor [8, 9] to compare and contrast FE and BE methods as

applied to electromagnetic NDE. In particular, this paper presents a three dimensional FE and BE

model ofthe DC Potential drop method to characterize fatigue cracks. The next few sections

describe the principle ofthe DC Potential drop (DCPD) method and its applications, the FE and

BE formulations, data obtained from modeling a compact tension specimen, and finally, some

conclusions.

DC POTENTIAL DROP METHOD

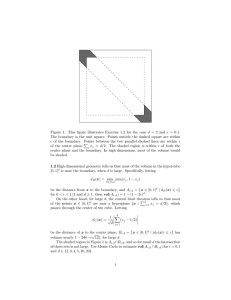

The operating principle of the potential drop method is that any surface defect or crack in a

conducting specimen will perturb the ftow of electric current around it, causing a measurable

potential difference across the crack. In the DCPD method, a constant current is passed through a

specimen and a probe straddles the crack with a fixed spacing. As the crack increases in length,

the uncracked cross-sectional area ofthe specimen decreases with an increase in the current path

resistance and potential. In practice, for a particular geometry, calibration curves are presented in

the form of JL as a function of A, where Uo is the reference potential drop, U is the potential

Uo

W

drop as the crack length increases and

~

is the crack length to specimen width ratio (Fig. 1).

Review 01 Progress in Quantitative Nondestructive Evaluation, Vol. 11

Edited by D.O. Thompson and D.E. Chimenti, Plenum Press, New York, 1992

553

DC Source

r------®---

-,,

Probe Leads

q

\

I

'---__t

r

/

-----

~

........

Figure 1

~w

1

_-.-

DC potential drop experimental setup

Applications for the DCPD method include monitoring fatigue, stress corrosion and creep

cracks. Additionally, the technique has been used to evaluate the extent of crack closure in fatigue

crack propagation studies and others [10, 11]. To date, calibration curves have been determined

experimentally [12, 13], analytically (Johnson's formula) [14] and numerically [10, 11]. These

have been accepted for use by the fracture mechanics community. Recently, Iwamura and Miya

[15], and Kubo and others [16], have used the measurement ofpotential in the specimen to predict

the shape and size of cracks in planar and tubular geometries.

The goveming partial differential equation (pde) for the DCPD method is Laplace's equation

V2V = 0

(1)

where V is the steady state potential in the geometry with a constant current in the plane of the

geometry. The next section briefly describes the FE and BE procedures used to solve Laplace's

equation with specific boundary conditions.

FORMULATION

Finite Element

The three dimensional FEM uses variational principles to solve Laplace's equation. The

problem can be stated as

F(V) =

JJ J[( dV

)2 + (dV )2 + (dV )2] dv

dX

dy

dZ

v

(2)

with boundary conditions given as,

V = 0 over surface SI

V = V I at point E

where F(V) is the functional for Laplace's equation, which is minimized over the entire domain.

The known potential at point E and at surface SI gives the desired uniform field around the crack

(Fig.2). By varying the surface SI, the crack length is changed. Eight node isoparametric

elements are used to discretize the geometry over which the potential V varies linearly.

Minimizing the functionalleads to a matrix equation

554

A

Typical

62 .5 mm

four node

boundary

elemen,

w =50mm

Typical

eigh' node

finite element

SI

I

l __ _ _ _

~30mm~

Figure 2

Compaet tension speeimen with boundary eonditions

[S] {P} = {Q}

(3)

where [S] is banded, symmetrie and sparse, {Q} is a veetor due to the boundary eonditions and {P}

is a veetor ofunknowns V to be determined at every node point in the domain.

Boundary Element

The boundary integral equation (BIE) for Laplaee's equation is

e(S)V(s) =

JI [G(t,S) ~~ ctJ - ~~ (t,S)vctJ] dS

(4)

where S is the entire surfaee sUITounding the domain, G is the two point kernel funetion or the

fundamental solution given by

G(t,S)

=--s

41tr

where ris the veetor from Sto X. e(s) is the free term determined from the loeal geometry at point

Sand eorresponds to the prineipal part of the SIE as extraeted from a limit analysis as S

approaehes the boundary. The fundamental solution has a weak singularity

normal derivative has a strong singularity O(

~).

?

O(~), while its

r

This strong singularity is regularized before it is

integrated. Applying the homogenous Neumann boundary eondition over the total surfaee, exeept

over surface SI and point E, the boundary value problem is solved by diseretizing the surfaee into

four node isoparametrie elements, varying the potential over eaeh element linearly, and then

forming a matrix equation:

[T]{P} - [H] {

~~ } = {O}

The eoeffieient matriees [T] and [H] are non-symmetrie and fully populated, while {P} and

(5)

{~Pn}

0

are veetors ofthe unknown potential and its normal derivative at the nodes on the surfaee.

555

RESULTS

A quarter of the compact tension specimen is modeled for the simulations (Fig. 2). The

discretization for the FE model has 1548 nodes as compared to 260 nodes for the BE model. These

meshes are optimized by trial and error. The FE algorithm exploits the symmetric and sparsity

pattern of the global matrix and stores only its lower tri angular portion. A preconditioned

Incomplete Cholesky Conjugate Gradient (ICCG) technique is used to solve the set oflinear

equations, making it quick and efficient. The essence of the BEM technique is the regular and

singular integration ofthe kernel and its normal derivative. The bulk ofthe processing time is

devoted to the integration, and assembly ofthe stiffuess matrix. The cpu time forthe FE and BE

model for predicting each point on the calibration curve is 225.5 and 501 seconds respectively .

2.20

-

2. 10

-

2.00

-

I

./

111

0

w_

o

0

0

1.90 1.80

-

Y. 1.70

J-

Y\I

0

1

--

0

4 ___ __

- JO.,._

f

i

UD

I

1/: ,',

j..•• ".,, ,

I"

J//

1.40

1.30

I.

2.

3.

4.

" li

;~"

1.20

I~'

FEM (t=25 .4mm)

BEM (t=25.4m m)

FEM (t=6.25mm)

BEM (t=6.25mm)

/

0.40

Figure 3

"

, ,

.,','

1.50

1.00

I

l/~2,~.3, /'4

1

1.60

1.10

/

0.60

A

W

0. 0

1.00

FE and BE simulated calibration curves

Figure 3 compares the calibration curves for two different thicknesses for the two models. The

results indicate less than three percent error. Compared to the data obtained from 10hnson's

formula (analytical) and experimental data [101, results from the three dimensional numerical

models for a 25.4 mm specimen (Fig. 4) confirms the validity ofthese codes. Figure 5 is the

calibration curves using FE for varying specimen thickness. In the next two plots one can

visualize the effect ofthe excitation and the boundary conditions in the compact tension specimen.

Figure 6 compares the potential distribution on the top layer for the FE and BE models, which are

nearly identical. Aseries ofpotential distributions in the different layers is plotted in Fig. 7 from

the solution obtained by the FEM.

556

3.40

3.20

3.00

2.80

2.60

-

I

I

3.60

I G

- llIIl

--

-- ---

J--

=,u_~

-,

.1'

..

l.....

1

--

1

:

- ; 0 ...-

~

uo

2

,

,

,)

/ :. .' - .,'

" ,'

, ~/'~ 4

, .,'

2.20

,~:...

2.00

""

~

--

V

~.

1.80

1. lohn on' formu la

..... .? ~ 2. 2 dimensional

./

1.60

1.40

.S

1.00

,,

,,

, "... ,'

.Y. 2.40

1.20

J

.J~

P V

3. Experimental (25.4 mm)

4. 3 dimensional (25.4 mm)

?

400.00

500.00

600.00

0.25. 1 x 10. 3

&-

800.00

700.00

30,20, experimental and Johnson's forrnula comparison

Figure4

UNO

2. 0 I-- ~

2.60 I - f-

-Gil

I

:

<w_

2.00 I - I1.80

I 1

I1

I

11

,

,

2.40 I - I2.20 I - I-

J-

./

3.00 I - ~

i

I

l,.

-- lO_~-----

1.60

:;.

" .'

,~. .,:>#

,/:"

;((:' .

, " ...:.'

-p:L

V'

;-' "

" ."

1.20

___tE

1.00

)

,', J..:'" .

- -, " . ' -. ,,'- ' -

1.40

2

1. Expl (25.4mm)

2. t=25.4mm (FE)

3. t= 12.5mm (FE)

4. t=6 .2Smm (FE)

0.80

0.60

0.40

0.20

0.00

0.00

Figure 5

0.20

0.40

0.60

0.80

1.00

AfW

Calibration curves for varying thickness

557

o

c '"

o

,>

,

..J

.D

.J

l ~

J ~

~

.J

1l

...J

o

.:!~

c ...

~

J

o

Q.

o

0 ,,,___

30~

,

\

"\ '\

I

,

,

,

I

,

62..5 mm

0

c '"

\

"

!

,

w

\

'\

'\

~J.

\

____

0

.>

,

J

--;Omm---

JJ

.J

1l

...J

0

J

o

Q.

.018 02

X-GRIO '

1.0 21. 0 27.0

Figure 6

558

.

.\

"-

1.0 60

. 9.0 12.0 15

I

,

/\

,

I

Potential distribution

I

Figure 7

Potential distribution at different layers

CONCLUSIONS

According to the authors' knowledge, this is the first time a finite thickness compact tension

specimen is modeled for predicting fatigue crack depth. Plots indicate that the potential

distribution is constant throughout the thickness except elose to the excitation. This confirms that

calibration curves are independent of thickness, leading one to conelude that a two dimensional

model is sufficient to predict fatigue crack lengths by the DCPD method. Computing times show

the FE algorithm is faster which can be attributed to the efficient preconditioning and iterative

solver; ICCG. In general, for problems involving infinite boundaries, or problems with more

degrees of freedom, BEM will be faster. For smaller problems, the FEM is efficient and attractive

if one exploits the properties of the global matrix. The BEM needs only surface discretization,

which reduces the problem dimension and, correspondingly, the number of unknowns.

REFERENCES

1.

W. Lord, IEEE Transactions on Magnetics, Vol. MAG-19, No. 6, p. 2437 (1983).

2.

W. Lord and R. Palanisamy, Materials Evaluation, Vol. 38, No. 5, p. 38 (1980).

3.

W. Lord, Y. S. Sun, S. S. Udpa and S. Nalh, IEEE Transactions on Magnetics, Vol. MAG-24,

p. 435 (1988).

4.

R. Palanisamy, PhD dissertation, Colorado State University, (1983).

5.

D. L. Atherton, W. Czura, T. R. Schmidt, S. Sullivan and C. Toal, Journal ofNondestructive

Evaluation, Vol. 8, p. 37 (1989).

6. R. Beissner, IEEE Transactions on Magnctics, Vol. MAG-26, No. 5, p. 2076 (1990).

559

7.

N. Burais and A. Nicolas, IEEE Transactions on Magnetics, Vol. MAG-25, p. 3010 (1989).

8.

S. Nath, Y. K. Shin, W. Lord and T. J. Rudolphi, in Review ofProgress in Quantitative NDE

edited by D. O. Thornpson and D. E. Chimenti (plenum Press, New York, 1989), Vol. 9A, p.

303.

9.

S. Nath, W. Lord and T. J. Rudolphi, in Review ofProgress in Quntitative NDE, opsit , Vol.

WA, p. 317 (1990).

10.

R. O. Ritchie and K. J. Bathe, International Journal ofFracture, Vol. 15, No. I, p. 45 (1979).

11.

G. H. Aronson and R. O. Ritchie, Journal ofTesting and Evaluation, Vol. 7, No. 4, p. 208

(1979).

12.

K. H. Schwalbe and D. HelIrnan, Journal ofTesting and Evaluation, Vol. 9, No. 3, p. 218

(1981).

13.

R. O. Ritchie et al., International Journal ofFratcture Mechanics, Vol. 7, No. 4,p. 462,

(1971).

14.

H. H. Johnson, Materials Reserach and Standards, Vol. 5, No. 9, p. 442 (1965).

15.

Y. Iwamura and K. Miya, IEEE Transactions on Magnetics, Vol. MAG-26, No. 2, p. 618

(1990).

16.

S. Kubo, K. Ohji and T. Sakagami, International Journal of Applied Electrornagnetics in

Materials, Vol. 2, p. 81 (1991).

560