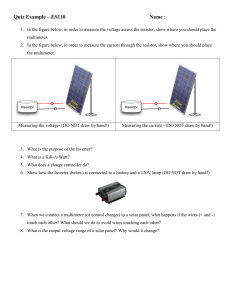

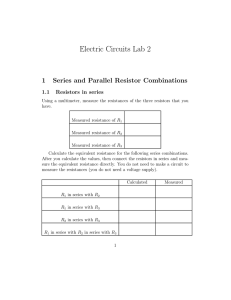

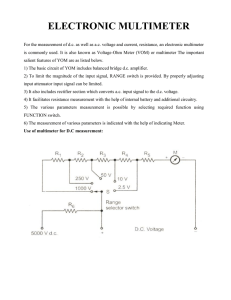

Untitled - Introni.it

advertisement