AN/USM-223 TM 11-6625-654-14 MULTIMETER

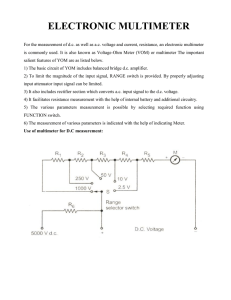

advertisement