Workplace Transport

advertisement

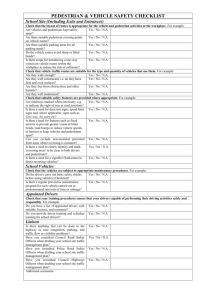

Workplace Transport – Code of Practice 3.47 Distribution: To be brought to the attention of all Directors, Heads of Service, Premises Managers, Supervisors, Employees and Trade Union Representatives. Introduction Every year, a significant number of people are killed by accidents involving vehicles in the workplace, and many more are injured. A lot of damage is also done to property. Better planning, training, awareness, and the appropriate use of vehicles, can avoid most of these accidents. The Council has a wide variety of workplaces including schools, depots and transport workshops this guidance is applicable to all workplaces, including employee and public car parks under the Council’s control. This Code of Practice has been produced to provide managers with practical information on how to eliminate or reduce workplace transport risks and prevent vehicle accidents at work. The most common accidents are caused by: • • • • people being hit by vehicles people falling from vehicles objects falling from vehicles on to people vehicles toppling over Definition Workplace transport relates to any vehicle that is used in a work setting, such as fork lift truck, compact dumpers, tractors or mobile cranes. It can also include cars vans and large goods vehicles when these are operating off the public highway. Contents Responsibilities - Designer & Client - Manager Risk Assessment Process Workplace Transport Risk Control Indicators Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 Page 2 Page 3 Page 3 - Safe Site - Safe Driver - Safe Vehicles Falls from vehicle Workplace Transport Hazard Checklist Page 5 Page 14 Page 16 Page 20 Page 21 RESPONSIBILITIES Designers and Clients This Code of Practice must be used by Designers and Clients to inform best practice around design decisions for the alteration of existing and construction of new premises. Sites must be designed and arranged so that vehicle movements are eliminated, or kept to a minimum. Sites must be constructed and set out in such a way to make it safe for the people and vehicles using it. Advice can be sought from the Traffic Management, Car Parks and Road Safety Section, however in general the following points should be considered: • traffic routes, preferably one-way, should be planned, signposted and, where possible, kept separate from doors, gates and routes for pedestrians; • where vehicles and pedestrians use the same routes they should be separated, with appropriate crossing points clearly marked, and signposted where necessary; • traffic routes must avoid sharp bends and passing close to vulnerable items, e.g. fuel pipes; • road and route junctions must be kept to a minimum with well signposted warnings of any potential obstructions/hazards being given, e.g. limited headroom; • traffic entrances must be wide enough, ideally to allow 2 vehicles to pass each other; • speed limits appropriate to the site must be set and clearly signposted; • sufficient and safe parking areas must be provided for all vehicles using the site; • clearly marked loading bays must, as far as possible, be situated in safe locations; • wherever possible, roads etc. must be constructed of tarmacadam, concrete, or other suitable material and provide a stable surface for vehicle movements and operations; • all roads and areas (including temporary worksites) where traffic movements take place should be adequately lit; Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 2 • where signposts etc. are used they should be constructed to Highway Code standards. Management Responsibilities The Premises Manager is ultimately responsible for management of workplace transport on existing sites. Where there is no one person in control of a particular site, senior managers must agree between themselves who will lead and co-ordinate workplace transport risk assessments and enforce relevant site rules. This should be documented in local Health & Safety arrangements. Responsibilities include: • Encouraging everyone to improve health and safety; . • Refusing to accept unsafe practices; • Introducing and actively monitoring workplace transport rules; • Any contract should spell out the need for workers to act safely. It should also clearly spell out the penalties for those who do not act safely; • Health and safety requirements are identified at the contract stage. These should be communicated to all those involved, including agency and contract drivers; • Checks should be made to make sure that agency, contract workers and delivery drivers all meet safety requirements; • Duty holders should know what action to take when workers fail to work safely; • Health and safety should always be thought about before any changes are made in the workplace. The changes may be because there are new vehicles or a change in how the work is done. RISK ASSESSMENT PROCESS Managers should apply the Council’s general procedures for risk assessment. The generic risk assessment form HSRA2 should be used to record findings. Managers first need to identify the work activities involving workplace transport. They then need to look at each activity and ask what are the possible dangers and what is causing those dangers. For example: • • • • Is there a danger of people being struck or run over by moving vehicles and what is the cause Is there a danger of people falling from vehicles Is there a danger of being struck by an object falling from a vehicle Is there a danger of the vehicle overturning Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 3 As with all risk assessments the first thing to identify are the hazards, areas to consider should include: • • • • The vehicles themselves. Are they safe and suitable for their use, are they properly maintained. The actions of the drivers and others who are near to vehicles. Are there pressures on operators that might encourage them to work less safely. For example do they have to rush to complete their work on schedule. Is there a risk of drivers becoming over tired. Are they working safely e.g. when getting into or out of vehicles during loading or unloading and are they observing routes and speed limits. Look for ‘short cuts’ that drivers may be tempted to use in both routes and safety procedures. The routes or roadways used by the vehicles. Are they safe and suitable for the types and number of vehicles using them. Are they properly maintained. Have you considered nearby obstructions, curbs or edges. What other people are doing. Are other workers, customers or members of the public kept clear of workplace vehicles wherever possible. Managers should ask drivers, supervisors and any other employees at the site for their views on any problems and what could be done to make the work safer. The checklists attached as Appendix 1 and Appendix 2 will assist you with this process. Deciding who might be harmed and how The people that are likely to be harmed is anyone employed at the workplace or anyone who comes on site. This is likely to include drivers, all other employees, contractors, subcontractors, visiting drivers and members of the public. Evaluating the risks There are not many examples of hazards involving workplace transport that are low risk, because transport accidents are usually quite serious, or at least have the potential to be serious. However unlikely it is, if a hazard could cause serious harm, the risk is higher. For example, although it may be unlikely that a person may be struck by a load falling from a vehicle, if it did happen, someone could be killed or suffer serious injury, so the risk is high. If you have already taken measures to reduce particular risks, you will need to ask whether the other risks are acceptably low. For example; you might decide that as well as setting speed limits on vehicle routes, other measures such as road humps may be needed to make sure that vehicles do not drive too fast. If you decide that something more needs to be done, you should first try to remove the problem altogether (for example, by restricting vehicle movements to certain parts of the workplace). If you cannot remove the problem, try to reduce the risks to as low as reasonably practicable. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 4 WORKPLACE TRANSPORT RISK CONTROL INDICATORS To effectively control the risks associated with Workplace Transport Managers need to consider four aspects of work these are: • • • • Safe Sites Safe Vehicle Safe Driver Safe Working Procedures The information detailed below looks at each of these in turn and provides managers, supervisors and employees with examples of good practice. Safe Sites Every site is different so it is not possible to be prescriptive with guidance. However, there are common principles which if followed will significantly reduce the risk of serious incidents occurring. Remember that drivers, vehicles and pedestrians rarely behave perfectly, so allow adequate safety margins whenever possible. Entrances Entrances must be signed and provide clear guidance to visitors about where they need to go to report to Reception. Pedestrian/Vehicle Segregation Wherever possible, there must be a separate entrance for pedestrians to ensure segregation from vehicles. Wherever possible, pedestrians and vehicles must be physically separated throughout the site. This can be designed into new sites, but may be more difficult with existing premises, due to the layout and physical constraints. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 5 Traffic Routes Pedestrians and vehicles must be able to circulate safely and where they share a route, they must be separated. The route must be wide enough for the largest permitted vehicle to use. Traffic routes must also keep vehicle routes away from doors or gates that pedestrians use, or pedestrian routes that lead onto them, so that the safety of pedestrians is not threatened. There must be enough time for a driver, or pedestrian, to react successfully if they encounter one another (for example where there is limited visibility, or where other noise might mask the approach of a vehicle). Pedestrians should be kept away from areas where vehicles are working, unless they need to be there. Where possible, pedestrian routes should represent the paths people would naturally follow to encourage people to stay on them. Where needed, you should provide suitable barriers or guardrails for example: • • • At the entrances and exits to buildings At the corners of buildings, and; To prevent pedestrians from walking straight onto roads. Where vehicle and pedestrian routes cross, a marked, signed, and preferably raised crossing must be provided. Signage must warn of the crossing and that drivers must give way to pedestrians. Routes should avoid sharp or blind bends. There should be enough visibility at junctions and bends to allow drivers and pedestrians to see anything that might be dangerous. Where you cannot avoid them, consider measures such as traffic mirrors to help drivers see what is around the corner. Landscaping can reduce visibility at junctions and bends. Grass banks, hedges and planters should not interfere with driver/pedestrian visibility. Stop signs and signals will be required where visibility cannot be improved. The height of the vehicle must be taken into account, e.g. when the body of a vehicle is raised. Potentially dangerous overhead obstructions must be identified and access to these areas by these vehicles prohibited. It is important to plan where certain types of vehicle operation will take place, including; loading, unloading, sheeting, tipping etc. It is also important to plan where waste or recycling bins, skips or other containers are placed. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 6 Temporary Traffic Routes Temporary workplaces such as construction sites often have routes for vehicles and pedestrians which change as work progresses, or unprepared routes such as unsurfaced roads or open ground. Managers need to consider: • • • • Driver Competence, particularly in dealing with the sorts of hazards encountered on unprepared sites Providing information and instruction to drivers, especially if they are not familiar with temporary roadways Safe System of Work and traffic management for example the use of temporary road signs and traffic lights Supervision of drivers, vehicle activities and other employees Reversing Nearly a quarter of all deaths involving vehicles at work occur during reversing. Many other reversing accidents do not result in injury but cause costly damage to vehicles, equipment and premises. Most of these accidents can be avoided by taking simple precautions, such as those below. Remove the need for reversing altogether, by setting up one-way systems, for example drive-through loading and unloading positions. Where reversing is unavoidable, routes should be organised to minimise the need for reversing. Ensure visiting drivers are familiar with the layout of the workplace, and with any site rules. Do drivers have to report to reception on arrival? When designing a new site, avoiding the need to reverse should be addressed and eliminated during the design phase. In this example parking is banned from the whole courtyard area with replacement parking arranged offsite. Pedestrian walkways are now clearly marked, pedestrian barriers and bollards have been added. Waste management is controlled. Access is efficient for delivery vehicles. People are now able to reach their place of work safely by using the walkways provided. Good housekeeping makes pedestrians easier to see as they use the courtyard. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 7 There will be locations where reversing cannot be avoided and it is important to minimise the distance vehicles have to reverse. 'Reversing areas' should be planned out and clearly marked and provide sufficient space. People who do not need to be in reversing areas should be excluded and kept well clear. Ensure that the system of work prevents unauthorized people from entering the areas. Use barriers and clear demarcation lines which can be seen by drivers and pedestrians. When high visibility clothing is worn it will considerably improve the safety of people on site, so consider your policy and where it applies. • Identify all the people who are involved with the reversing of vehicles and take into account their capabilities when allocating tasks and deciding what training should be given. Consider identifying and training banksmen, both to keep the reversing area free of pedestrians and to ensure a safe vehicle maneuver. • Will need to use a clear, agreed system of signaling; • Will need to be visible to drivers at all times; • Will need to stand in a safe position, from which to guide the reversing vehicle without being in its way; • Should wear very visible clothing, such as reflective vests, and ensure that any signals are clearly seen; • If drivers lose sight of the signalers they should know to stop immediately; • Consider whether portable radios or similar communication systems would be helpful; Site layouts can be designed (or modified) to increase visibility for drivers and pedestrians, for example by: • increasing the area allowed for reversing; Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 8 • installing fixed mirrors in smaller areas; • reducing the dangers caused by 'blind-spots'; Most vehicles already have external side-mounted and rear-view mirrors fitted. These need to be kept clean and in good repair; Refractive lenses fitted to rear windows or closed-circuit television systems can be used to help drivers to see behind the vehicle; If drivers cannot see behind the vehicle, they should leave their cab and check behind the vehicle before reversing; Reversing alarms can be fitted: These should be kept in working order; • Audible alarms should be loud and distinct enough that they do not become part of the background noise; • where an audible alarm might not stand out from the background noise, flashing warning lights can be used; Other safety devices can be fitted to vehicles: • For example, a number of 'sensing' and 'trip' systems are available, which either warn the driver or stop the vehicle when an obstruction is detected close to, or comes in contact with, the reversing vehicle. • Stops such as barriers, or buffers at loading bays can be used. They should be highly visible, and sensibly positioned. • Where vehicles reverse up to structures or edges, barriers or wheel stops can be used to warn drivers that they need to stop. • White lines on the floor can help the driver position the vehicle accurately. Parking Provide marked parking areas for vehicles and where possible, separate vehicles. For example; avoid the need for car drivers to park in the same area as HGVs. Drivers leaving parked vehicles should not have to cross potentially dangerous areas. When drivers enter a workplace where parking is controlled you should clearly tell them (by signage if necessary) that they may only park in certain areas and how to recognise these areas. Wherever possible parking areas should be designed so that only simple manoeuvres are needed for vehicles to park and leave. Try to avoid the need for reversing. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 9 If a driver needs to move the load area of their vehicle close to a structure, reversing will often be unavoidable. However, parking arrangements can often be made in drive through patterns. If you can’t implement drive through parking, arrangements should encourage reverse parking (bays angled backwards to the flow of traffic). This will reduce the number of vehicles reversing out into the flow of traffic and improve visibility for reversing vehicles. Vehicles should be parked on firm and level ground, in a designated parking area if one is available. Parking areas should be: • • • • Level Firm Well lit Clearly marked, with safe walking areas Where vehicles have to be parked on a slope, they should: • • • • be parked facing up or down the slope, never sideways on. have their brakes applied be left in gear (when it is safe to do so). wheel-chocks must be used when necessary. Drivers must NEVER leave their vehicles without making sure that the vehicle and its trailer are securely braked. • People in control of workplaces where trailers are parked must make sure that drivers know trailer brakes MUST be used. Vehicle brakes are NOT designed to make trailers safe. Warning signs and instructions to drivers are some ways to help make sure that trailer breaks are used. A vehicle should not be left unless the brakes have been firmly applied, the engine stopped, the starter key removed, and any mounted equipment lowered to the ground. Remember: • • • • Brakes ON Engine OFF Key OUT Equipment SAFE Always secure the keys of vehicles left parked in workplaces overnight, at weekends, or when they are being left for long periods. Speed Limiting the speed that vehicles move around the workplace is a very important part of controlling traffic. Relying on the behaviour of drivers to observe speed limits cannot be relied on. The best way to restrict speed is to use physical features that mean drivers can’t move too quickly. Speed humps, raised humps, chicanes should be considered. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 10 Speed limits must be clearly signed, appropriate to the nature of the site, and actively monitored and enforced by management. They need to be appropriate for; • • • • • • The vehicles using the route; The types of load and how they carry them; The driving surface; The layout of the route, including how tight bends are and visibility at junctions; Hazards along the way; and Work that takes place on or near the route. The limit should be a safe speed, but if it is unreasonably slow, drivers will be tempted to ignore it completely. Signs, Signals and Markings Signs are necessary to tell drivers and pedestrians about the routes they should use, and also to instruct people how to behave safely. These clear signs help arriving drivers know what to expect. You should use route markings to show traffic lanes, route edges, priority at junctions, stop lines, no-parking areas, pedestrian crossings and so on, and to instruct drivers (for example, ‘SLOW’). By law, road signs used to warn or give information to traffic in workplaces must be the same as those used on public roads, wherever a suitable sign exists. Where sign posts are used they should be constructed to Highway Code Standard. Drivers and pedestrians should be able to expect that the layout, signs, road furniture and markings on site will be similar to those on public roads. These signs can be used to show no vehicles over the height or width shown can continue You should use warning signs to show hazards along the way. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 11 A sign like this should be used to show that no vehicles over a certain maximum gross weight shown can continue, and why. You can use traffic lights to control the flow of traffic at busy junctions, at narrow places and at site entrances. You can also use speed sensors and flashing warning signs to help control the speed of traffic. You should provide signposting so that drivers do not go the wrong way. This should help prevent vehicles from moving around areas where pedestrians or other drivers might not expect them. You should place signs so that people have time to see and understand them, and take any action to reduce risks before they reach the hazard. All signs should: • • • be clear and easy to understand; stand out enough to be noticed; and be kept clean and well maintained so that they are visible at all times. If signs have to be visible in darkness, they will need to be reflective and, ideally, illuminated. Sign lighting needs be kept clean and working. You can find detailed information about reflective and lit road signs in BS 873-1: 1983 Road traffic signs and internally illuminated bollards. When deciding on signage within the workplace reference should also be made to Council’s Code of Practice – Safety Signs and Signals. Protecting Vulnerable Structures Fuel tanks or stores, CCTV columns or other vulnerable areas must be physically protected if there is a risk of a collision. When deciding how much protection is needed you need to know how likely it is that a vehicle will hit a feature, how it would hit (at what speed, from what angle, and how heavy it might be) and what the consequences would be. Protective barriers should be built to the standards set out in BS7669-3: 1994 Vehicle Restraint Systems Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 12 Normal site features that might need protection include tanks, cylinders, buildings, columns, masts, gantries and pipes. Loading Areas Wide loading areas should have two exit points, one at either end. All should have a refuge to prevent people becoming trapped and struck by vehicles. Designers should allow enough space around bays for vehicles to move safely into and out of the bay and for people to move around the vehicle without being trapped. The height of vehicle load platforms can vary quite a lot, even between when a vehicle is empty, or loaded. Dock levellers (adjustable ramps that cover the height difference between the vehicle and platform) should be specified where necessary. Loading and unloading areas should be: • • • • Clear of other traffic, pedestrians or other dangerous obstruction Level to maintain stability ,trailers should be parked on firm level ground Fenced or provide with other edge protection where there is a danger of people falling If necessary, protected against bad weather, e.g. strong winds can be very dangerous during loading The edges of loading bays must be clearly marked and fenced to prevent people falling off them. Temporary fencing should be incorporated into designs for exposed edges (the loading area) when they are not in use. Pedestrian segregation from area Lighting Every workplace must have suitable and sufficient lighting. All roads, manoeuvring areas and yards should be adequately lit. Areas near junctions, buildings, plant, pedestrian routes and areas where vehicles or mobile plant move regularly, all need particular attention. Where lights are placed is very important. Tall vehicles can block light, even when it comes from windows or lamps that are placed high on posts, or on walls, ceilings or canopies. Lights should be placed over the space between vehicle bays, rather than over the centre of the bay where they will be blocked by a tall vehicle. If drivers have to reverse towards strong lights you should make sure that the lights are not placed or angled so that they dazzle the driver, either directly, or in their mirrors. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 13 SAFE DRIVER Driver Training /Assessment Managers and Supervisors should arrange for employee’s ability to be assessed before they are allowed to drive. Training relevant to the type of vehicle must be offered where appropriate. Managers and Supervisors must ensure that employees have the skills to do their job safely. • • • • Employees need to be trained ,preferably to recognised standards Employee ability to drive safely needs to be assessed regularly Refresher training should be given if it is considered appropriate The level of supervision will depend on ability. It is mandatory that employees or volunteers, who are employed to drive Council insured vehicles undergo driver training which incorporates a practical assessment in order to ensure that they are capable of driving the vehicle safely. A competent person must undertake the training and assessment. Driver training must be appropriate for the particular type of vehicle to be driven and must include the following elements: • • • • • Driving techniques Vehicle/passenger safety Vehicle checking procedure Relevant legislation and risk assessment Driving practice/assessment Retraining/assessment must be conducted periodically, or where work activities change, or where there is reason to believe the driver needs training/assessment. Training is currently delivered by the Council’s driver assessor who is based within Risk Management and Insurance Services. Your local risk assessment should say how often assessment and refresher raining is carried out. Training should always be thought about before any changes in the workplace are made. Training may be needed because there are new vehicles or a change in how the work is done. Please refer to Council’s Code of Practice – Managing Occupational Road Risk for further advice regarding driver training and assessment. Fitness to Drive All drivers of Council insured vehicles must undergo routine health screening which will include eyesight and hearing test with the Occupational Health Service on a three yearly basis, or undergo a comparable health screening with an outside agency, to the standard laid down by the Occupational Health Service Guidelines on medical fitness for drivers. A comparable medical must comprise of a full medical history and examination (height, Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 14 weight, blood pressure, pulse and urine analysis) to include mobility, hearing test (audiometry or equipment, vision testing (snellen and colour vision or keystone) and consideration of neurological and system disorder. Managers and Supervisors are responsible for ensuring that relevant Health Assessments are established and appropriate fitness testing carried out, relevant to the type of driving undertaken by employee group. Managers must ensure that an assessment is made of all new employees before starting work to ensure that these standards are met initially. Drivers who develop or have medical conditions which may affect their entitlement to drive certain vehicles must inform their manager and be withdrawn from driving duties on full pay until medical approval to resume driving is approved by the Occupational Health Service. Alcohol &Drugs Drivers must not be under the influence of substances taken for recreation or therapeutic reasons whilst they are at work, Drivers must not drink alcohol during working hours or be over the legal limit (as prescribed by the Road Traffic Act 1988, Section 5 (80mg of alcohol per 100ml of blood) due to the after effects of alcohol consumed prior to undertaking driving duties. Drivers must be taken off driving duties when they are taking medication that may affect their ability to drive safely, unless they have written evidence from their doctor or the Occupational Health Service declaring that their ability to drive safely is not affected whilst taking medication. Further information can be found in the Council’s Health and Safety Code of PracticeManaging Occupational Road Risk. Visiting and Agency Drivers/Operators The responsibilities for Agency drivers are determined by who pays their wage and issues their contract of employment. If this is the Agency, then the majority of health and safety responsibilities fall to the Agency, including health and safety awareness training and provision of personal protective equipment. Managers must liaise with the Agency and inform them of any special, significant risks which drivers may encounter on site. The Council still has a legal duty to make reasonable checks to ensure that visiting and agency drivers are trained and qualified to do their jobs and to make sure that they are fit to drive through assessment. They must also have a basic understanding of their responsibilities under health and safety law and be able to understand the safety signs and signals used on sites. Managers and Supervisors should develop documented local arrangements with Agencies that they use. This should include liaison with them to obtain evidence of qualifications and training. You should also clarify arrangements for induction training and any specific training that is needed to raise awareness of risks faced on particular Council sites. This may include including Agency Drivers on specific health and safety training provided for your employees. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 15 VEHICLE SELECTION & MAINTENANCE Procurement Managers must make sure that work equipment, including vehicles, is suitable for its purpose. When choosing work equipment you must take account of the working conditions and the risks to the health and safety of employees using the work equipment. You must also take account of any further risk posed by the use of chosen work equipment, for example, maintenance personnel. When selecting new vehicles, managers should consider significant and foreseeable health and safety risks that may arise from everyday use and maintenance, such as work at height. Procurement of refuse vehicles with low level hydraulic systems will avoid or significantly reduce the need for maintenance personnel to work at height. Where this is not possible, use of appropriate equipment for work at height and training for maintenance personnel should be considered at procurement stage. Maintenance Each vehicle should come with a handbook giving Manufacturer’s Guidance on regular maintenance. This could range from drivers carrying out start-up safety checks before using the vehicle, to regular preventative maintenance based on time and mileage. To help identify faults while the vehicle is being used, the driver will need instruction, or training, on carrying out appropriate checks and reporting any problems. Managers may find it helpful to give drivers a list of daily checks to sign off their vehicles. The design of vehicles used on public roads has to meet specific legal standards, set out in the Road Vehicles (Construction and Use) Regulations. The overall standard of vehicles used in workplaces should be at least as good as for public roads. In some cases, there are specific supply standards dealing with mobile plant in the workplace (for example, some lift trucks). Workplace vehicles should be stable under working conditions and provide a safe way to get into and out of the cab, and any other parts of the vehicle that need to be accessed regularly. Access features on vehicles, such as ladders, steps or walkways, should have the same basic features as site-based access systems. Planned maintenance should be thorough, regular and frequent enough to meet both the manufacturer’s guidelines and common sense. Managers should arrange servicing and maintenance through the Council’s Vehicle Workshops at South Hylton Depot Wherever relevant, the following precautions should be taken when maintaining vehicles: • brakes should be applied and, where necessary, wheels should be chocked; • engines should always be started and run with brakes on and in neutral gear; • raised parts should be suitably propped or supported; Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 16 • a way of restraining wheels, such as a tyre cage, should be used when inflating tyres on split-rim wheels; • tyres should be removed from wheels before welding, cutting or heating work begins on a wheel or wheel rim fitted with a tyre, even if the tyre is deflated. • beware of the risk of explosion when draining and repairing fuel tanks, and from battery gases. Fuel tanks should never be drained or filled when the equipment is hot or in a confined space, nor should they be drained over a pit; • take care to avoid short-circuiting batteries. Batteries should be charged in wellventilated areas. Suitable personal protective equipment should be provided and used for handling battery acid; • measures should be taken to prevent maintenance staff from breathing asbestos dust from brake and clutch lining pads; • only people who have received the relevant information, instruction and training should be allowed to carry out maintenance work. Fitting further features to existing vehicles (‘retrofitting’) needs careful planning: • retrofitting must not significantly weaken the chassis or body structure; • in particular, you should not consider drilling holes in the chassis and welding to it without the approval of the original manufacturer; • retrofitting should also take account of the structure of the vehicle. Sensitive points such as fuel tanks will need to be avoided. Visibility and warning devices Drivers should be able to see clearly around their vehicle, to allow them to spot hazards and avoid them. It is important that vehicles are readily visible to people around them. As part of their risk assessment, Managers should specify additional vehicle lights, reflectors, reversing lights and possibly other warning devices (for example, rotating beacons or reversing alarms). Painting and markings can also help to make the vehicle stand out. Vehicles should have large enough windscreens (with wipers where necessary) and external mirrors to provide adequate all-round visibility. Road-going vehicles are fitted with conventional side mirrors, and it is often worthwhile adding extra mirrors to reduce blind spots for drivers. Side mirrors angled to allow drivers of larger vehicles to see cyclists and pedestrians alongside their vehicles are also available, and can be effective in improving visibility around the vehicle from the driving position. These mirrors are fitted to larger road-going vehicles as standard. Managers and supervisors should ask employees for their views. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 17 Items should not be placed in the windscreen area or in the way of mirrors or monitors, where they might get in the way of visibility from the driving position. A good guide can be that the area of the windscreen that is kept clear by the wipers should not be obscured, and nor should the side windows. Windows and mirrors will also normally need to be kept clean and in good repair. Dirt or cracks can make windows or mirrors less effective. Vehicles should have seats and seat belts (or other restraints where necessary) that are safe and comfortable. There must be one seat for each person carried. People must never be carried in a vehicle which does not specifically have a seat. CCTV Closed-circuit television (CCTV) can cover most blind spots and is appropriate for some vehicles (e.g. refuse collection) where the driver can’t see clearly behind or around the vehicle. Both black-and-white and colour systems are available. Colour systems can provide a clearer image where there is little contrast (for example, outside on an overcast day). However, black-and-white systems normally provide a better image in lower light or darkness, and usually come with infrared systems, which can be more effective than standard cameras during the hours of darkness. Monitor images should be adjustable to make them useful in the different light conditions in which they are likely to be used. It may be necessary to shield screens from glare by using a hood. The most effective position for the CCTV camera is high in the middle of the vehicle’s rear where one camera is being used, or in the upper corners where two cameras are used. However, CCTV systems do have some limitations: • if vehicles are leaving a darker area to a more strongly lit area (for example, driving out of a building), the change in the level of brightness can mean that CCTV systems do not work for a moment as they adjust; • a dirty lens will make a camera much less effective; • it can be difficult for drivers to judge heights and distances on CCTV monitors. It is important that using CCTV systems does not lead to drivers being complacent about safety. Managers should ensure that all drivers know how to use the equipment properly, and should be trained in using CCTV systems. Reversing alarms should be fitted to all commercial and site based vehicles and should be loud and distinct enough to make sure that they do not become part of the background noise. They are not always useful as they may be drowned out by other noise, or may be so common on a busy site that pedestrians do not take any notice. It can also be hard to know exactly where an alarm is coming from. Reversing alarms may be appropriate, but might be most effective used with further measures to reduce reversing risks, such as warning lights. Guarding Appropriate guards must be fitted to dangerous parts of the vehicle (for example, power take-offs, chain drives, exposed hot exhaust pipes). Advice should be sought from the Manufacturer or supplier as necessary. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 18 Vehicles should be suitable for any loads carried on them. When selecting vehicles, managers should consider; • • • • The nature of the loads How loads are to be put on to and taken off the vehicle Risks arising from this, such as manual handling Where necessary, how employees will access the load areas safely Roll over protection Where appropriate, vehicles should have driver protection to prevent injury if the vehicle overturns, and to prevent the driver from being hit by falling objects. This could include roll protection, operator restraints and falling object protection. ROPS on some kinds of vehicles can reduce the risk of injury if it overturns, but are not fully effective unless the driver is also wearing an appropriate restraint. Lift trucks and ‘thorough examination By law, lifting equipment must be ‘thoroughly examined’ at appropriate intervals to make sure it is safe to use. This includes the lifting gear on lift trucks. The intervals between thorough examinations should be either: • in line with an examination scheme drawn up by a ‘competent person’ who must be independent from line managers. The competent person can be in-house or from an outside organisation such as an insurance company; or • at least every 12 months, unless the truck operates for more than 40 hours a week, is used to lift people, or has a side shift or attachments fitted. By law, these must be thoroughly examined at least every six months. ‘Competent person’ means a person chosen by the employer to carry out thorough examinations based on his or her level of knowledge of the equipment, problems and their causes, methods of testing and diagnosing faults. A national scheme of accredited, quality-assured examiners is run by Consolidated Fork Truck Services, and endorsed by the HSE. Privately owned vehicles Managers, foremen and site operators do not usually have much control over the condition of private vehicles (such as employees’ cars) brought into the workplace. However, private vehicles can be regulated by: • restricting the type of vehicle allowed onto the site; • restricting their routes; • providing clearly signposted parking areas wherever possible, away from main routes and dangerous areas; • enforcing speed limits; and Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 19 • making sure visiting drivers report to the site office. You should make it clear to everyone that driving in the workplace calls for the same standard of care as on public roads, and often needs even more skill and care. Falls from Vehicles. Falling from vehicles is a significant cause of workplace transport injuries. Employers have a legal duty to prevent falls. As with all work at height, there are basic steps that should be taken to reduce the chances of people falling and being injured: • • • If you can avoid the need for work at height then do so. When you can’t avoid working at height you must take steps to prevent falls If there are any remaining risks of falls you should take steps to minimise them. If Managers and Supervisors consider the checklist detailed below it will assist reducing falls from vehicles. • • • • • • • • • • Always use all equipment provided to avoid work at height. If work at height is unavoidable then use fall arrest system if possible especially when roping and sheeting Don’t jump from the lorry or load Report damaged, loose or inadequate steps and hand holds – ensure the steps are safe to use Report damaged or broken sheeting devices Report slippery surfaces, for example those that are oily or greasy Avoid tripping hazards Wear suitable footwear for the job Ensure steps and work areas are well lit Use edge protection on tail lifts Do not walk backwards near the rear or side of the vehicle bed Communication Good communication is essential for maintaining a safe workplace and helps to ensure that safety information can be spread through the organisation and be put into use as effectively as possible. Managers should listen to the safety concerns of their employees and take appropriate actions. Further Information and Advice Is available from the Corporate Health and Safety Team, Corporate Personnel Services, telephone number 0191 5531735. Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 20 Appendix 1 WORKPLACE TRANSPORT - MANAGERS HAZARD CHECKLIST Large goods vehicles (including articulated and draw bar combination vehicles) □ transporting raw materials □ transporting other manufacturing materials □ transporting machined or finished products □ delivering of business supplies (stationary, couriers, canteen) □ moving products or stock between buildings □ waste removal Light goods vehicles □ transporting raw materials □ transporting other manufacturing materials □ transporting machined or finished products □ deliveries of business supplies (stationary, couriers, canteen) □ cash collection or delivery □ moving products or stock between buildings □ waste removal □ contractors and others (maintenance, cleaners, building work) Motorised or other handling equipment □ movement of raw materials around the site □ movement of components, supplies, stock etc. around the site □ movement of waste materials around the site Cars □ entering or leaving the premises. Consider employees, clients, other visitors, taxis □ touring security vehicles Vehicles carrying passengers □ consider coaches and minibuses Motor Cycles and Cycles □ entering and leaving the premises □ around storage areas □ couriers Other work machinery and plant including contractors vehicles □ tractors □ all-terrain vehicles □ backhoes and other earth-moving machinery □ dumpers □ mobile cranes in transit (although lifting operations should not be thought of as WP Trsp Pedestrians □ entering or leaving the premises □ moving from building to building, or from one work area to another □ moving within storage areas □ moving across vehicle traffic routes □ moving through vehicle manoeuvring areas □ moving from vehicles to buildings, or back (e.g. drivers reporting to site office) Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 21 Appendix 2 Workplace Transport – Site Inspection Checklist The following checklist is intended as a guide to indicate the areas that employers should look at when doing a risk assessment. The checklist will not necessarily be comprehensive or relevant for all work situations. 1. Management and supervision of workplace transport Check, in consultation with your employees, that your level of management control/supervision is adequate. Check in consultation with your employees, that your level of management control/supervision is adequate Are site rules documented and distributed Yes No Are your supervisors, drivers and others, including contractors and visiting drivers aware of site rules. Are they aware of their responsibilities in terms of helping to maintain a safe workplace and environment. Has a risk assessment been completed for all workplace hazards Is the level of supervision sufficient to ensure that safe standards are maintained Are sanctions applied when employees, contractors, etc fail to maintain these standards Are adequate steps taken to detect unsafe behaviour of drivers of both site and visiting vehicles as well as pedestrians. Are the underlying reasons investigated to correct safe behaviours Is there good co-cooperation and liaison on health and safety matters between your staff and those who collect or deliver goods Check what your drivers and other employees actually do when undertaking their work activities Do drivers drive with care, e.g. use the correct routes, drive within speed limit and follow any other safety rules Do your drivers and other employees have enough time to complete their work without rushing or working excessive hours. Do you monitor job and finish work to ensure drivers are not rushing to cut corners Are employees using safe work practices, e.g. when un(coupling), un(loading),securing loads, carrying out maintenance Do managers and supervisors routinely challenge and investigate unsafe behaviours they may come across Do managers and supervisors set a good example, for instance by obeying vehicle/pedestrian segregation instructions, and by wearing high visibility garments where these are needed Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 22 2. Site layout and internal traffic routes Check that the layout of routes is appropriate Are the roads and footways suitable for the types and volume s of vehicular traffic and pedestrian traffic using them Are vehicles and pedestrians kept safely apart Where necessary are there suitable pedestrian crossing places on vehicle routes Is there a safe pedestrian route that allows visiting drivers to report for instruction before entering the site Are there adequate numbers of suitable parking places for all vehicles and are they used Is there a properly designed and signed one-way system used on vehicle routes within the workplace Is the level of lighting in each area sufficient for the pedestrian and vehicle activity Check that vehicle traffic routes are suitable for the type and quantity of vehicles which use them Are they wide enough Do they have firm and even surfaces Are they free from obstructions and hazards Are they well maintained Do vehicle routes avoid sharp bends Check that suitable safety features are provided where appropriate Are roadways marked where necessary, e.g. to indicate the right of way at road junctions Are road signs, as used in the Highway Code, installed where necessary Are features such as fixed mirrors (to provide greater vision at blind bends) road humps (to reduce vehicle speeds), or barriers (to keep vehicles and pedestrians apart) provided where necessary. 3. Vehicle selection and suitability Check that vehicles are safe and suitable for the work for which they are being used Have suitable vehicles and attachments been selected for the tasks which are actually undertaken Do vehicles have good direct visibility or devices for improving vision where reversing can’t be eliminated and where significant risk still remains e.g. external and side mirrors, vision aids such as CCTV, sensing device Are they provided with horns, lights, reflectors, reversing lights and other safety features as necessary Do they have effective service and parking brakes Do they have seats and seatbelts where necessary Are there guards to prevent access to dangerous parts of the vehicle ,e.g. power take-offs.chain drives, exposed exhaust pipes Do drivers have protection against bad weather conditions, or against an Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 23 unpleasant working environment, i.e. the cold,dirt,fumesand excessive noise and vibration Is there a safe means of access and egress to and from the cabs and other parts that need to be reached Are surfaces where people walk on vehicles slip resistant Is driver protection against injury in the event of an overturn and measures in place to prevent the driver being hit by falling objects, provided where necessary Are operators involved or consulted on vehicle selection 4. Vehicle maintenance Check the level of vehicle maintenance is adequate Is there a regular preventative maintenance programme for every vehicle, carried out at predetermined intervals of time or mileage Is there a system for reporting faults on the vehicle and associated equipment and carrying out remedial work Where vehicle attachments lift people or objects are thorough examinations undertaken by a competent person Do Drivers carry out basic safety checks before using the vehicle 5. Vehicle movement Check that the need for REVERSING is kept to a minimum, and where reversing is necessary that it is undertaken safely and in safe areas Have drive-through, one-way systems been used, wherever possible to reduce the need for reversing Where reversing areas are needed they marked to be clear to both drivers and pedestrians Are non-essential personnel excluded from areas where reversing occurs If risk assessment shows site controls cannot be improved further and you need a banksman to direct reversing vehicles, are they adequately trained and visible 6. Un(loading) Activities Check that there are safe systems for Loading and unloading operations Are loading/unloading operations carried out in an area away from passing traffic, pedestrians and others not involved in the loading/unloading operation Are the load(s), the deliver vehicle(s) and the handling vehicle(s) compatible with each other. Are the loading/unloading activities carried out on ground that is flat, firm and free from potholes Are parking brakes always used on trailers and tractive units to prevent unwanted movement, e.g. when coupling vehicles Are the vehicles braked and or stabilised as appropriate, to prevent unsafe Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 24 movements during loading and unloading operations Are systems in place to prevent trucks driving away while they are still being un(loaded) Are lorry drivers and others kept in a safe place away from the vehicle while un(loading) is being carried out Is there a safe area marked where drivers can observe (loading) if necessary Has the need for people to go on to the load area of the vehicle been eliminated where possible and if not is safe access provided and used Is appropriate lifting equipment available for un(loading)vehicles Is loading/unloading carried out so that, as far as possible the load is spread evenly to avoid the vehicle or trailer becoming unstable Are checks made to ensure the load is adequately secured in line with the Department for Transport Code of Practice and not loaded beyond their capacity before the vehicle leaves the site 7. Driver competence Check that you selection and training procedure ensure that your drivers and other employees are capable of performing their work activities safely and responsibly Do drivers possess the necessary licences or certificates for the vehicles they are authorised to drive e.g. FLT Do you check the previous experience of your drivers and assess them to ensure they are competent Do you provide site specific training on how to perform the job, and information about particular hazards, speed limits, the appropriate parking and loading areas Do you have a planned programme of refresher training for drivers and others to ensure their continued competence Do your drivers undergo a medical assessment prior to commencement of their employment and is this repeated on a three yearly basis Name: Position: Signature: Date: Procedural Arrangements (June 2008) Workplace Transport – Code of Practice 3.47 25