AB SCIEX Turbo V Ion Source Operator Guide

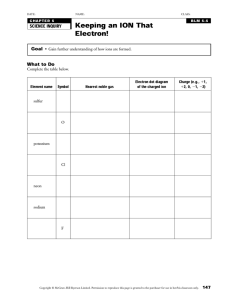

advertisement