Standard Density Rectangular Catalog

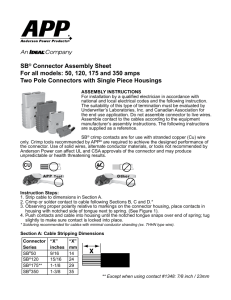

advertisement