Powder Coating - IBA CHEMOLAK, sro

advertisement

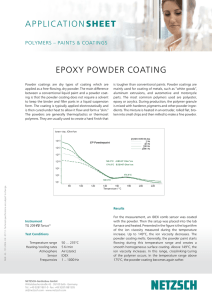

Powder coatings Company Presentation Special Products Contents • ĐBA Kimya Company Profile • Special Products ĐBA Kimya San. ve Tic. A.Ş. Group Companies Electrostatic Powder Coatings 100% ĐBA Kimya Electrostatic Powder Coatings 100% ĐBA Kimya Powder Coatings 50% ĐBA Kimya 50% Chemolak (SK) Wood&Industrial Coatings 50% ĐBA Kimya 50 % Valresa (SP) Sponsorship ĐBA Kimya TED Ankara College Ladies Volleyball team was qualified to 1st TR LEAGUE April 11th 2010/ ĐZMĐR • • • • • • • • Total Employment: 250 Closed area: 20,000 m2 Two production facility in Turkey + one in Slovakia Total capacity: 27000 tonnes/year Electrostatic Powder Coating 2000 different product 6 Regional Sales Office Domestic market Leader since 2002 In top ten european powder coating producers Atico Kayseri ĐBA Kimya Ankara New Wet Paint Facility Powder Coating Facility PC Production PC R&D Department Special Products Outdoor Products (Polyester) Architectural Paint Specifications Florida Test duration Powder Coating Product ĐBA Kimya Products GSB/Qualicoat Class1/BS6496/A AMA 2603-98 Qualicoat Class 2 AAMA 2604-98 AAMA-2605-98 Qualicoat Class 3 1 year 3 years 5 years 10 years yes limited limited limited PE28/PE58/ PE55 PSD70/ PSD77 - PHD80 1 year Florida test = 5-10 years • PE28-PE58-PE55 series are qualicoat approved powder coatings designed specifically for architectural applications. Color stability and gloss retention are within the specification up to 10 years. 3 year Florida test = 15-30 years • PSD70-PSD77 series are qualicoat approved superdurable polyester tgic free powder coatings. They are highly recommended to meet gloss retention and color stability requirements. Application areas are architectural aluminium extrusions. Hyper Durable Powder Coatings Floropolymer Durable-Super Durable-Hyper Durable • UV resistance is must for architectural applications • Standard polyester products, in some cases even with super-durable product should not be enough for UV resistance. • The duration of resistance, such as PVDF powder coating products are becoming necessary. • The 50-year warranty period products Bond Energy KJ/Mole UV Radiation 400 Carbon-Carbon (C-C) 350 Carbon-Fluorine (C-F) 485 Silicone-Oxygen (Si-O) 460 Polyester-Hyper- Durable PHD80 In contrast to the solvent-based liquid varnishes of the PVDF generation (which have to be applied as two- or four-coat systems and need baking at an object temperature of around 240 ºC), ĐBA Kimya’s new FC technology offers a number of attractive benefits. •%100 advanced fluoropolymer resin technology (C-F) •Minimum 30 years guaranteed performance on correctly pre-treated aluminium •Economical single-layer system •Solvent-free •Excellent chemical and solvent resistance •Metallic products (decorative pearl glimmer effects) •Curing at 200 °C Cost Calculation 1 m² açılır pencere profil maliyeti: 255 TL POLĐESTER boyalı maliyeti: 4 €/kg SUPER DAYANIKLI boyalı maliyeti: 10 €/kg HĐPER DAYANIKLI boyalı maliyeti: 50 €/kg Toz boya 0,25 kg/m² 1 €/m² 2,2 TL/m² 2 €/m² 4,4 TL/m² 12,5 €/m² 27,5 TL/m² QUV-B 313 Test Sonuçları “Anodized Look” Powder Coating PE10 series -Deep-matt powder coating system for elegant and stylish design in architectural and design applications - Innovative binding technology that enables a deep-matt gloss level of approx. 5 (60°) - Besides the reproduction of classical eloxal colours, with ĐBA Kimya PE10, it is possible to realise a multitude of fashionable and designer colours as well as to implement brilliant effects - Highly weather-resistant colours - Environmentally friendly Chameleon Powder Coatings Color change with angle • two different color tones onto surface • Outdoor durable • Especially aluminum-car-bike manufacturers would prefer a product like • Dry blend and bonding process is possible. Sublimation Technique • PU44 series is an exterior durable polyurethane besed powder coatings designed as a base coat for sublimation decoration techniques. Wooden patterns are created by applying a top coat through a sublimation decoration technique. • Antibacterial Powder Coating prevent the spread of dangerous micro-organism and suppress the growth of mold amd bacteria. – Significantly reduce microbial activity – Protects against the spread of microorganism – Provides protection over an extended period of time – Available ina wide range of colors Metallic Bonded Powder Coating • Possibility to use reclaims • No separation during application and transport • Consistent color uniformity and metallic appearance • Improved application characteristics • Possibility to use higher metallic pigment amounts (max 10%) • Less agglomeration on the guns, ejectors and nozzles • Minimum picture framing effect • PU40 Antigraffiti powder coating is an exterior durable thermosetting powder coating based on polyurethane resins designed for anti-graffiti applications • High crosslink density • Excellent solvent resistance • Less permeability • Good impact resistance IN-Mold Powder Coating for the inmold painting of SMC (sheet • • • • • • molding compound) Eliminates post+painting operation Seals pores and isolates fibers in the molding step Complete coverage of complex shapes Environmentally friendly Excellent hardness Outstanding chemical, scratch, stain and graffiti resistance Solar Reflectance PC – Used for cool indoor temperature – More reflect sun light than standart colors (UV-VisibleIR 295-2500 nm) – Different colors Soft touch Powder Coating – Soft touch feeling – Outdoor and indoor – Excellent chemical resistance – Different colors • Lotus effect Powder Coating – Similar phenomena like lotus leaves – Structure and matt surface – Angle of water droplet >150° – Cleaning with rain – Weather resistance – Not possible clearcoat and glossy product Lotus efect structure Classical structure Water droplet does not wet the surface White Board PC White Board Product Code: F29.9978.189GL BEYAZ 078 TB Easy Clean High crosslink density High chemical resistance Kolay silinebilir ve daha az iz bırakır MDF Powder Coatings on MDF General Codification F59.####.13#XX.MDF Structure effect is common in powder coatings on MDF Glossy look possible with te currently developed formulations Surface quality does not meet the expectations for all applications Needs sanding and polishing for perfect surfaces • FF22 series is a low curing thermosetting mat powder coating. The resulting powder coating can be 25 ±5 gloss 60° with curing 160 °C 15 min . • FF20 series is a thermosetting mat powder coating with very good yellowing resistance compared to conventional mat powder coatings • FF55 series is low curing thermosetting powder coatings. It provides to save energy, time and money (140°C/10 min). • TC (thin coating) Products provide up to 55% less consumption than conventional powder coatings. It is designed specifically for white good coaters to offer significant cost savings. Thin Coating 70 µm 30 µm METAL SUBSTRATE Thin Coating TC Standart Coating d: 1.65 gr/cm³ Consumption: 8.66 m²/kg For 866 m² we need 100 kg PC d: 1.70 gr/cm³ Consumption : 19.61 m²/kg For 866 m² we need 44.16 kg PC 55% less consumption Ultra Thin Coating UTC 70 µm 20 µm METAL SUBSTRATE Standart Coating d: 1.65 gr/cm³ Consumption: 8.66 m²/kg For 866 m² we need 100 kg PC Ultra Thin Coating UTC d: 1.75 gr/cm³ Consumption : 28,57 m²/kg For 866 m² we need 30,33 kg PC 70% less consumption Synergy of Low Bake + UTC • FF55.T9608.149UTC – Low curing temp. 140 °C 10’ • Less energy consumption • Less yellowing problems – Ultra Thin Coating • Less powder consumption • Less room for storage • Less transportaion costs • F56 series is based on special epoxy resins and hardeners providing a film with high thermal resistance up to 330 °C. Application areas are stoves, car exhausts and barbecues. LOW COST 100% Silicon base Powder Coating S54 series – Silicon resin + special pigment + special Filler – Resistant up to 500 °C – Black and aluminium color • Zincoprim is a zinc rich epoxy powder coatings designed to be used as a primer coat. It provides excellent protection against corrosion. Application areas are agricultural machinery, gas cylinders, marine environments. • FP series is based on fusion bond epoxy which provides excellent protection against corrosion. FP series coatings meet all pipeline specifications . • FP6102 Blue colour meets the requirements of BS 6920 for use with potable cold water and hot water up to 85 °C WRAS Test Report Summary Test Std: BS6920 • CorrShield (Corrosion Shield) – Utilization of an improved of PE resin technology for corrosion protection. – Removes or decreases the need for a chemical pretreatment. – 1-2 mm Corrosion on surfaces without chemical pretreatment in 504hours. – Replaces epoxy primer. – No TGIC or heavy metals. – Less waste due to lack of chemical pretreaments. THANK YOU !